Coffee maker

A technology of coffee machines and branch pipes, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of increasing device costs and troublesome operation, and achieve the effect of improving hygienic and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

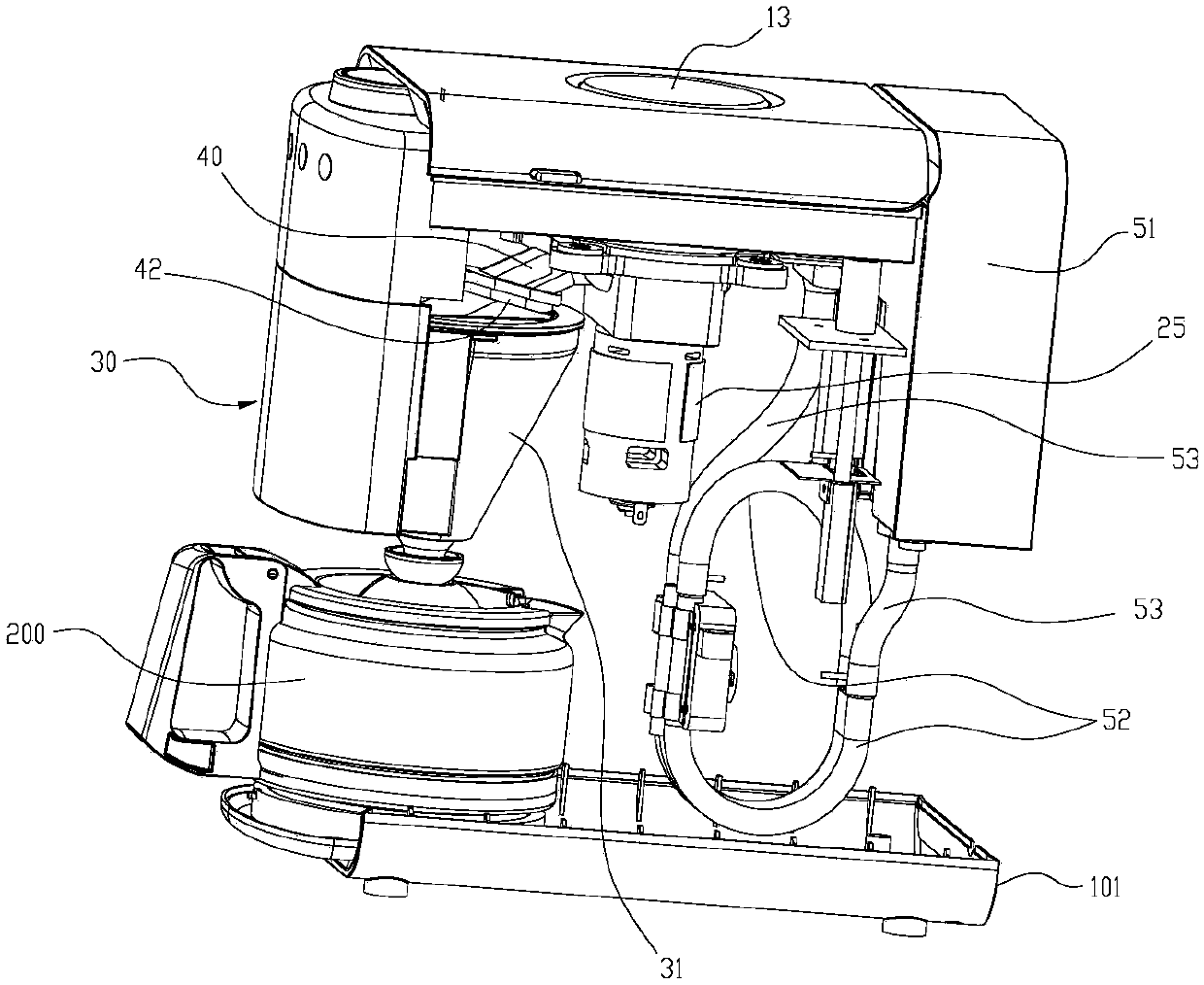

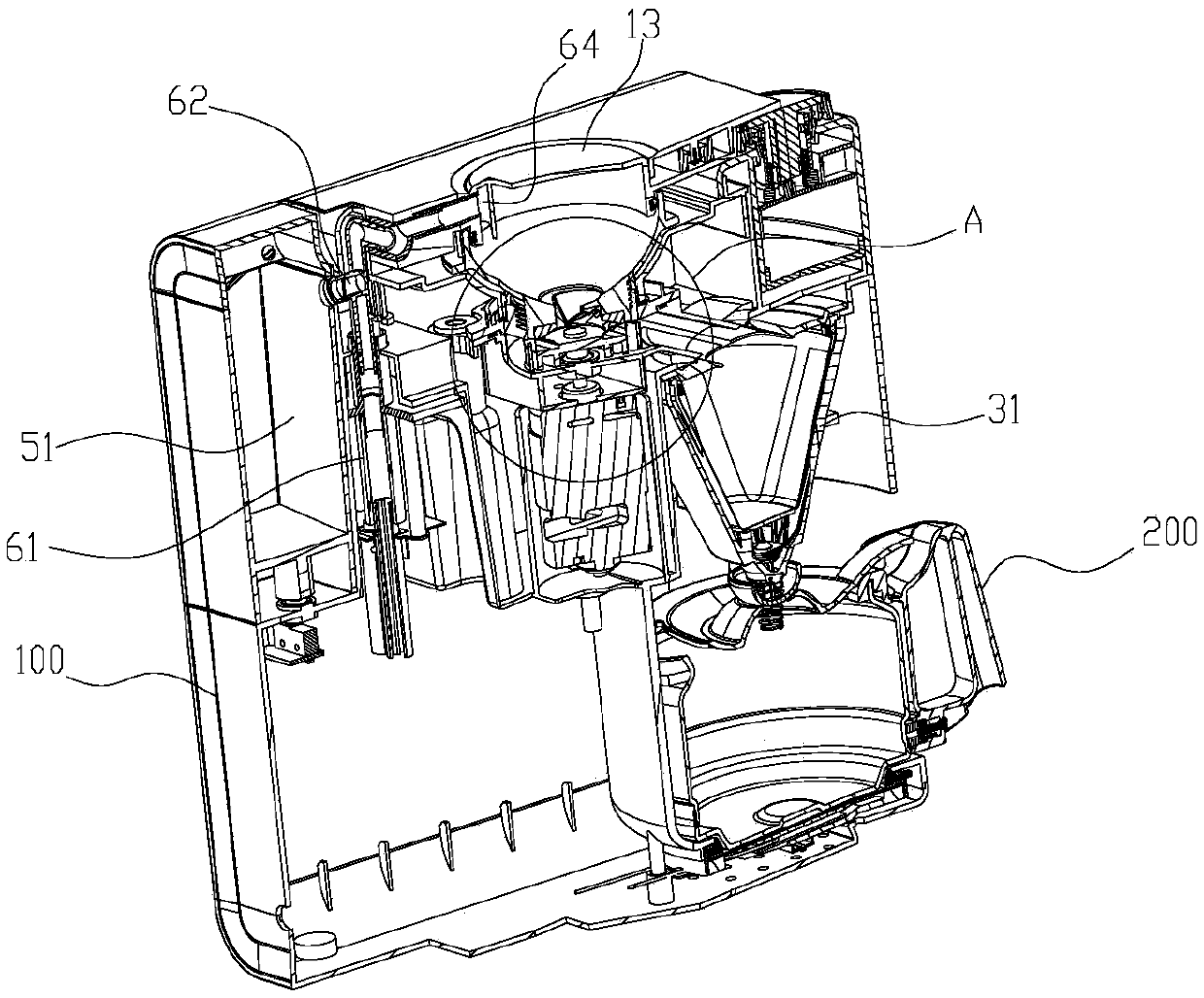

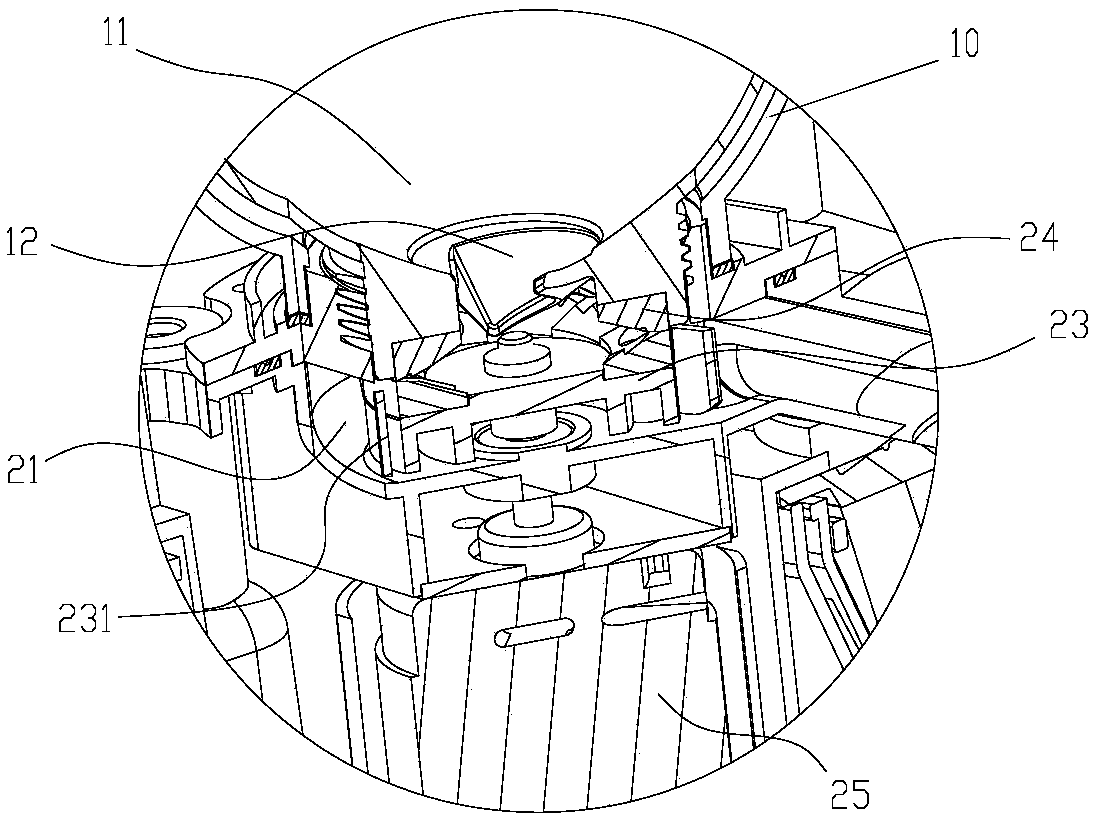

[0031] like Figure 1 to Figure 6 As shown, one embodiment of the present invention discloses a coffee machine for grinding coffee beans into powder and brewing the powder into coffee. The coffee machine includes a main body 100 , an upper grinder 24 , a lower grinder 23 , a powder channel 41 , a brewing assembly 30 , a power assembly, a water supply assembly, a heat source and an air pipe 60 . Wherein, a bean-holding chamber 11 and a bean-grinding chamber 21 are formed at the upper position inside the main body 100, and the bean-receiving chamber 21 is located below the bean-holding chamber 11 and communicates with the bean-holding chamber 11, and the bean-holding chamber 11 is used to accommodate coffee beans, and the coffee b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com