Bean grinder

A bean grinder and bean bin technology, applied in coffee mills, spice mills, household appliances, etc., can solve problems such as inaccurate powder output and inaccurate grinding thickness levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

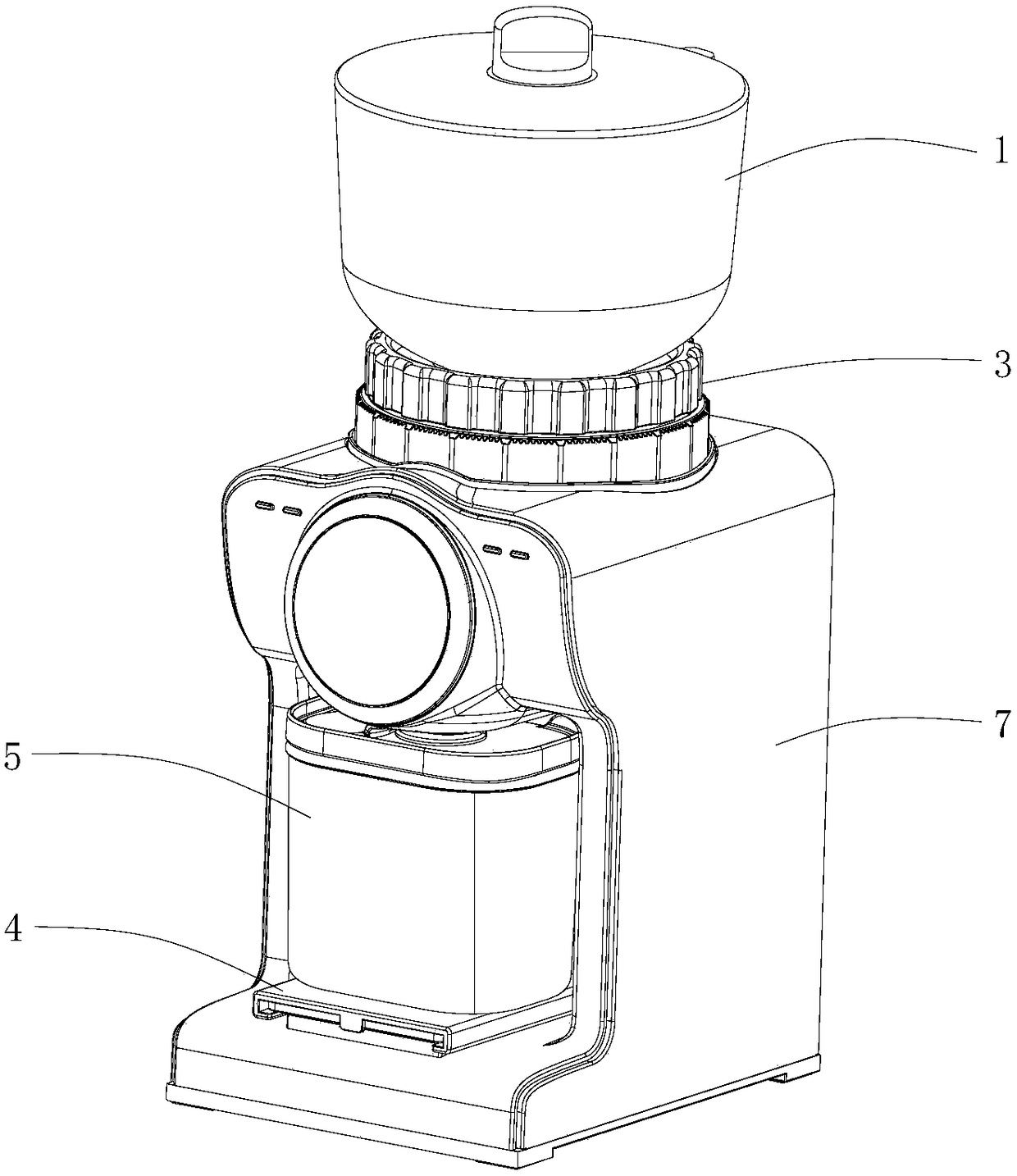

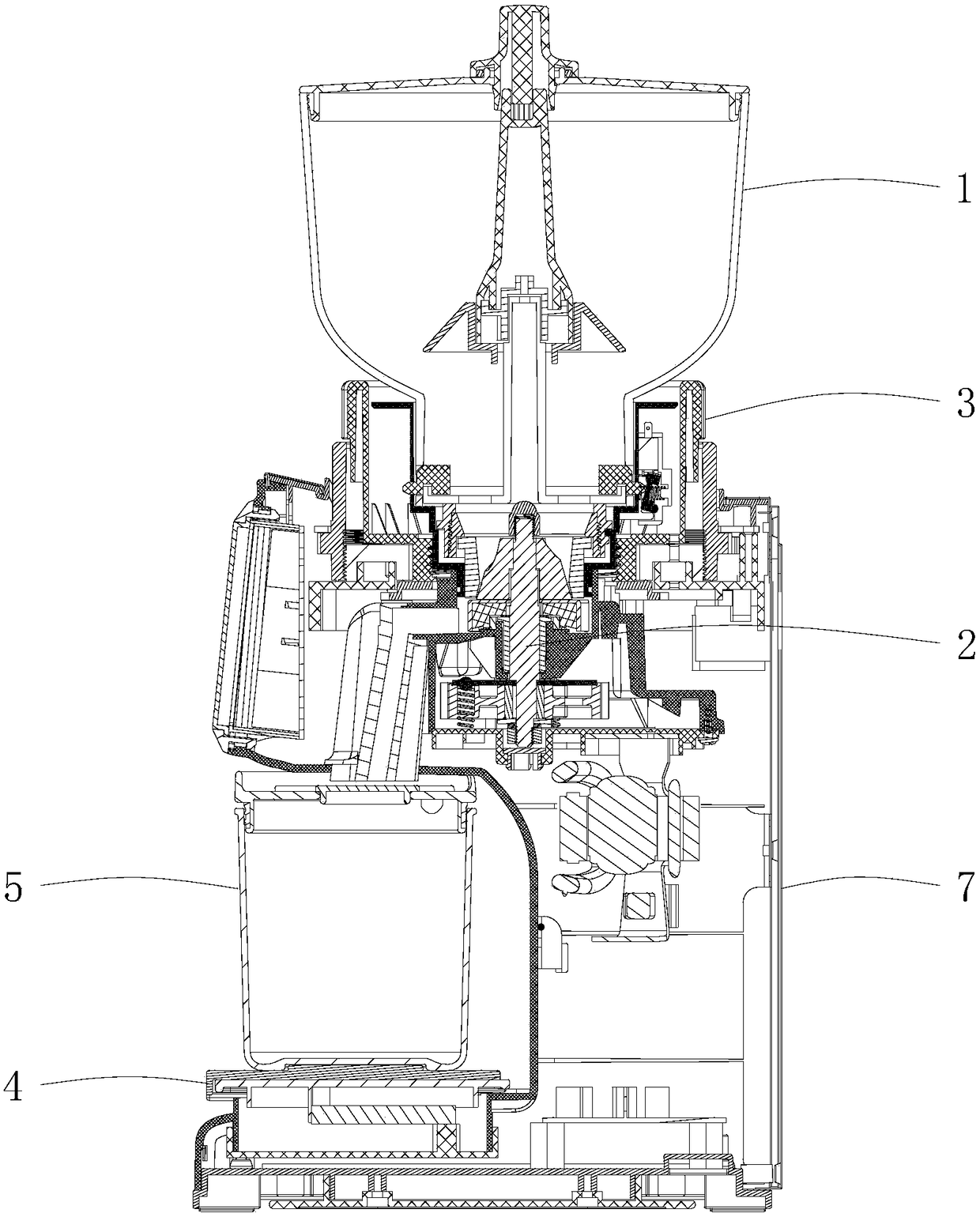

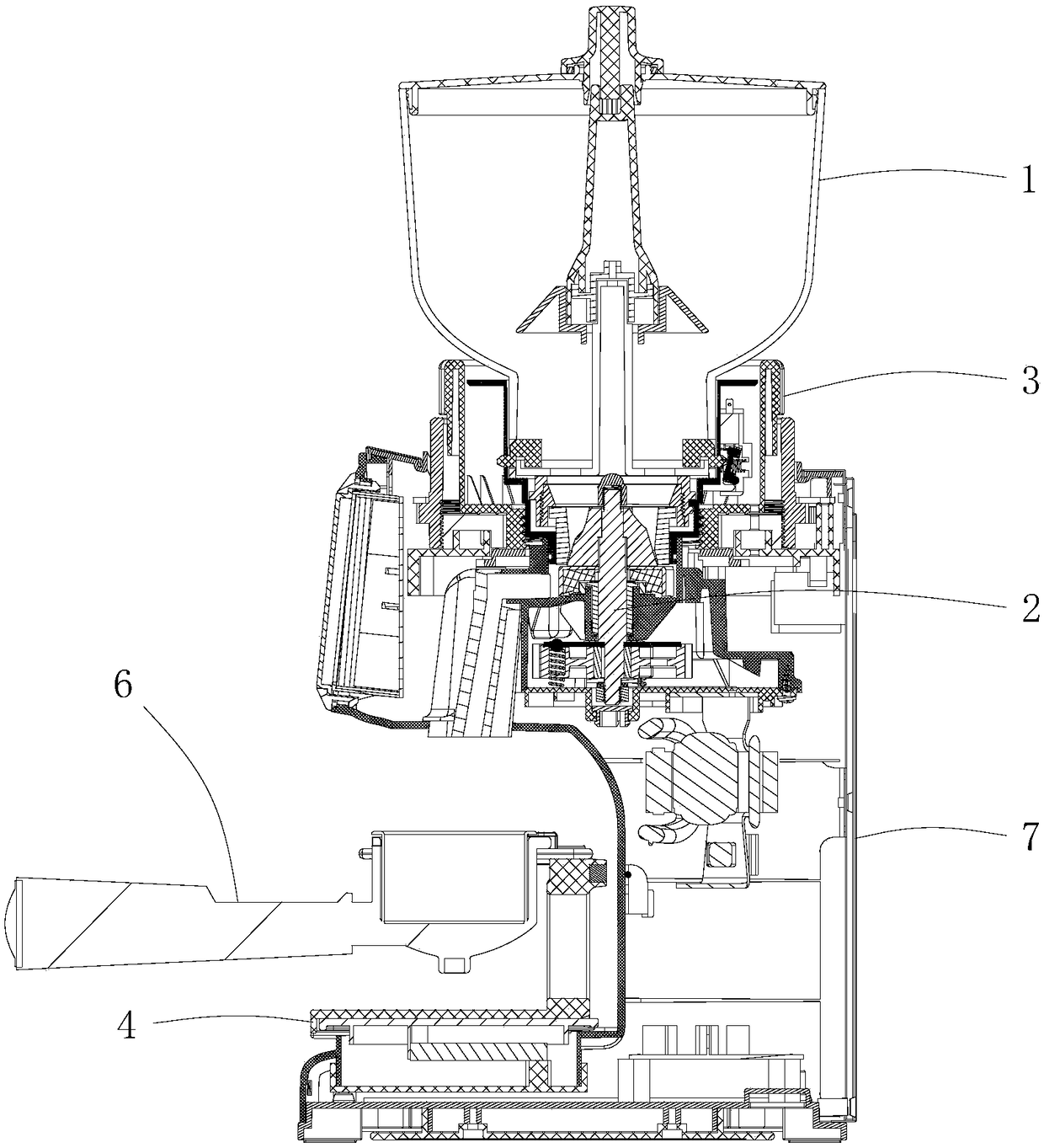

[0031] see Figure 1 to Figure 3 As shown, the grinder of the present invention includes a bean bin assembly 1, a grinding assembly 2, a double thickness adjustment assembly 3, a weighing assembly 4, a powder receiving container composed of a powder tank 5 or a powder scoop 6, a body 7 and a control system. The grinding assembly 2 is installed inside the fuselage 7 and is the main functional part of the machine, and is used to grind coffee beans or other beans into bean powder; the double-adjustable thickness assembly 3 is installed on the fuselage 7 above the grinding assembly 2 for Adjust the grinding thickness of the grinding assembly 2; the bean bin assembly 1 is detachably installed on the double thickness adjustment assembly 3 for storing and providing beans to the grinding assembly 2; the powder tank 5 or powder scoop 6 is placed in the weighing assembly 4, used to receive the ground soybean powder from the grinding assembly 2, the weighing assembly 4 is located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com