Rotational speed regulating system of bean grinding device

An adjustment system and bean grinding technology, which is applied to spice mills, coffee mills, kitchen utensils, etc. It can solve the problems of easy stalling of the milling device, low powder output, and easy damage to the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

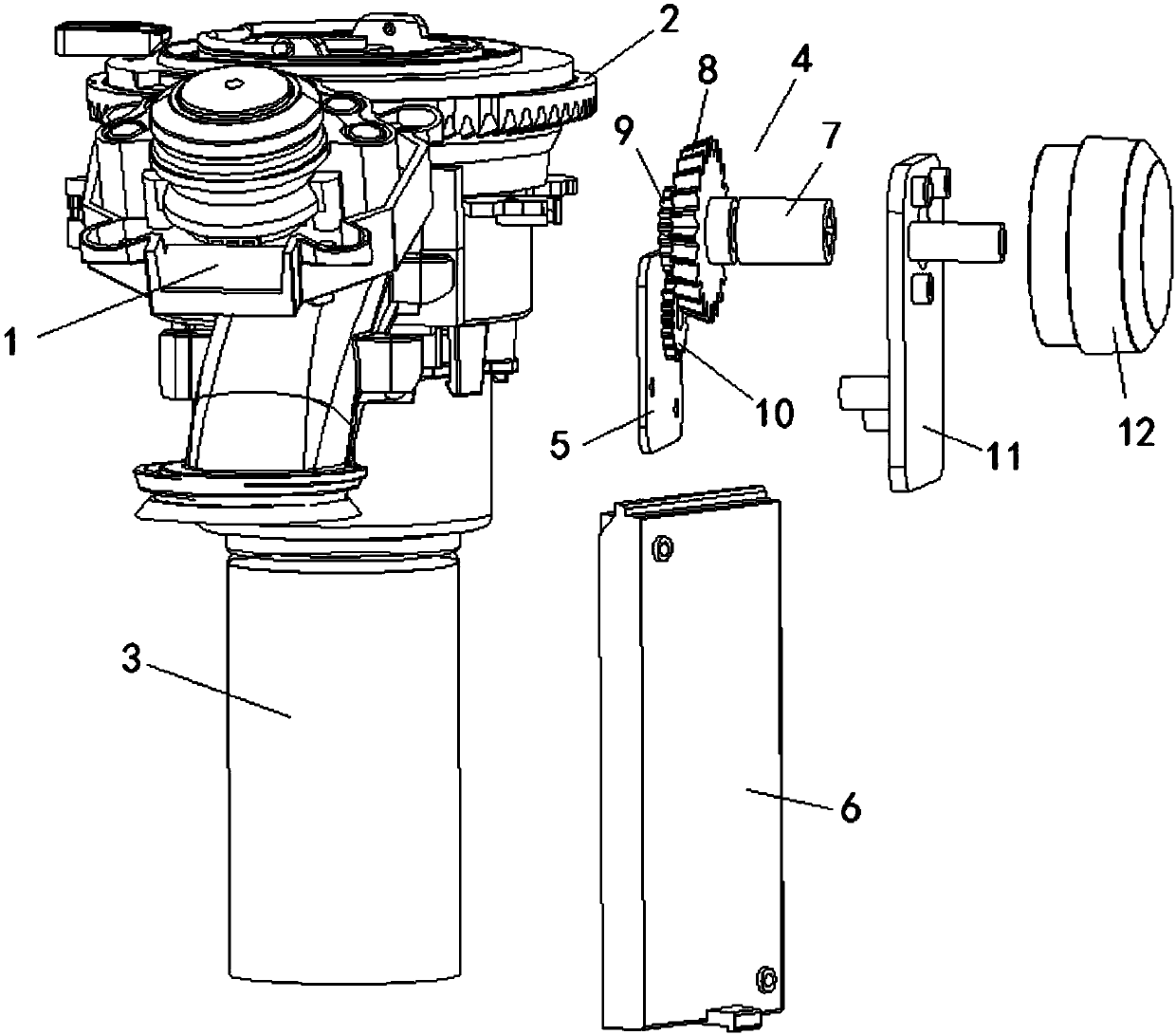

[0016] like figure 1 As shown, the rotational speed adjustment system of a bean grinding device according to the present invention, the bean grinding device includes a grinding wheel set 1, a gear plate 2 and a motor 3, the motor 3 drives the grinding wheel set 1 to rotate the grinder, and the gear The disc 2 is used to adjust the grinding wheel set 1 to switch between the coarse gear and the fine gear, and it is characterized in that the adjustment system includes an adjustment gear 4, a potentiometer 5 and a controller 6, and the adjustment gear 4 and the The gear plate 2 is meshed, and the adjustment gear 4 is in transmission cooperation with the potentiometer 5, the potentiometer 5 is connected to the input end of the controller 6, and the output end of the controller 6 is connected to the motor 3's control terminal. The rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com