Patents

Literature

42results about How to "Keep it compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

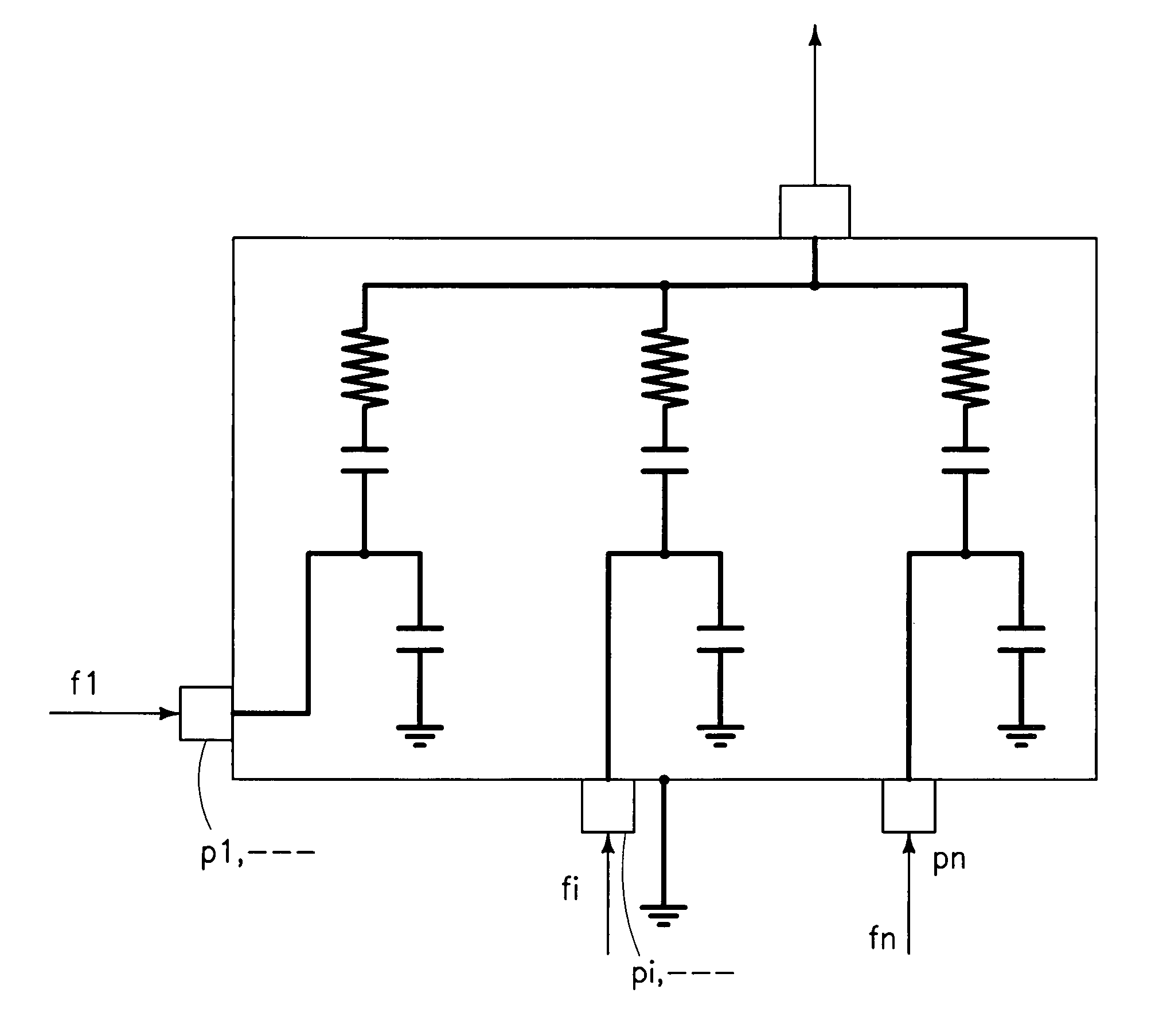

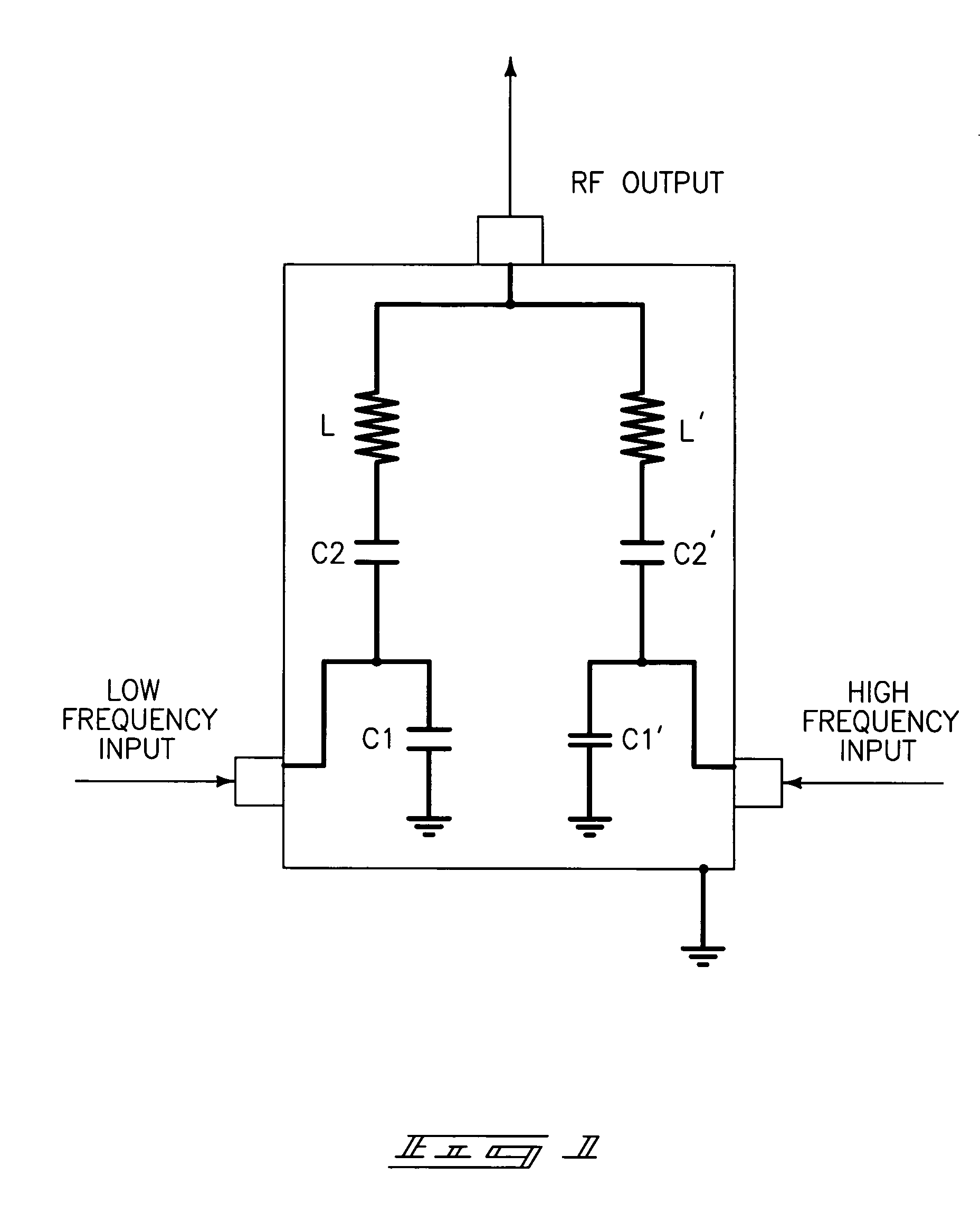

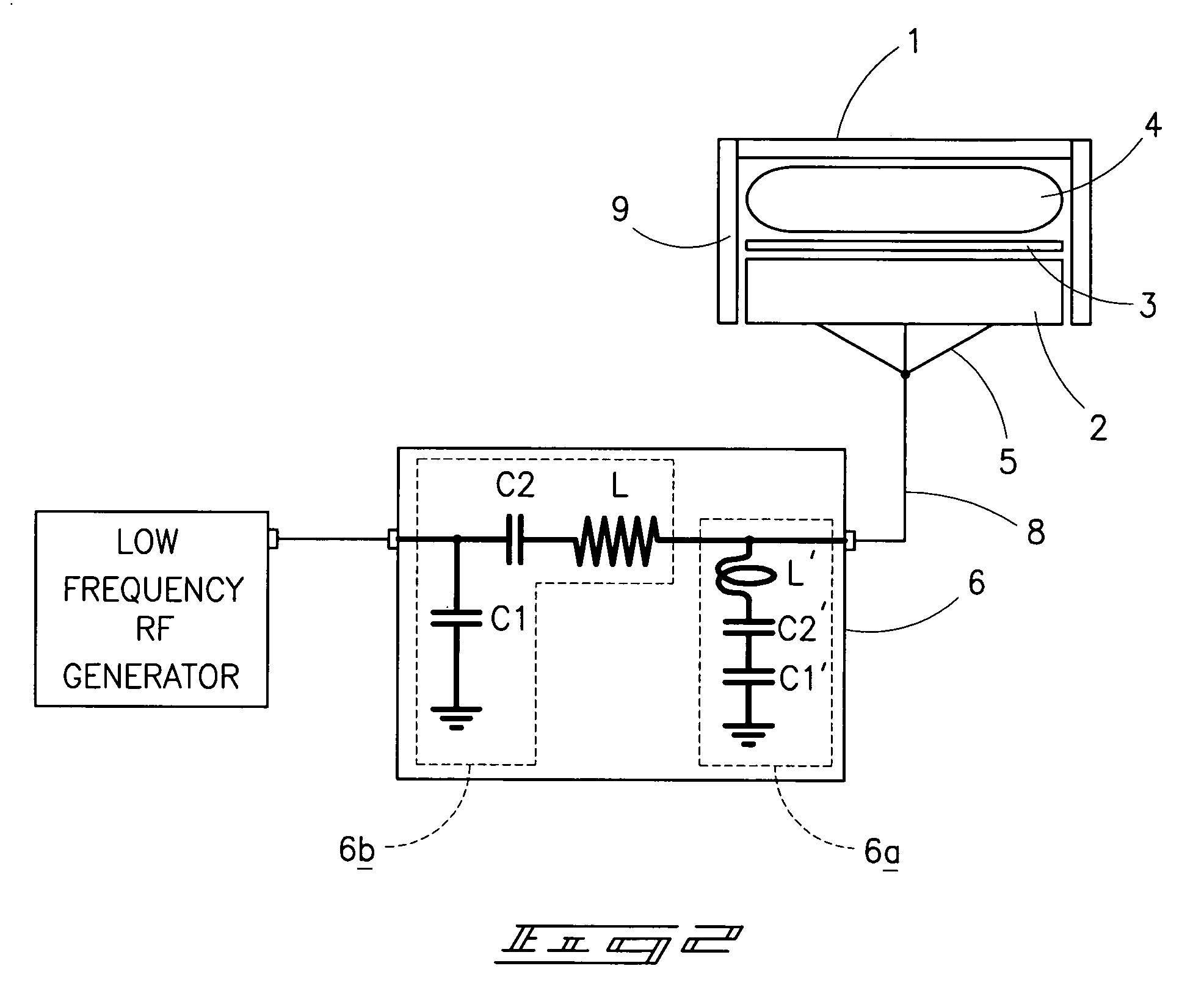

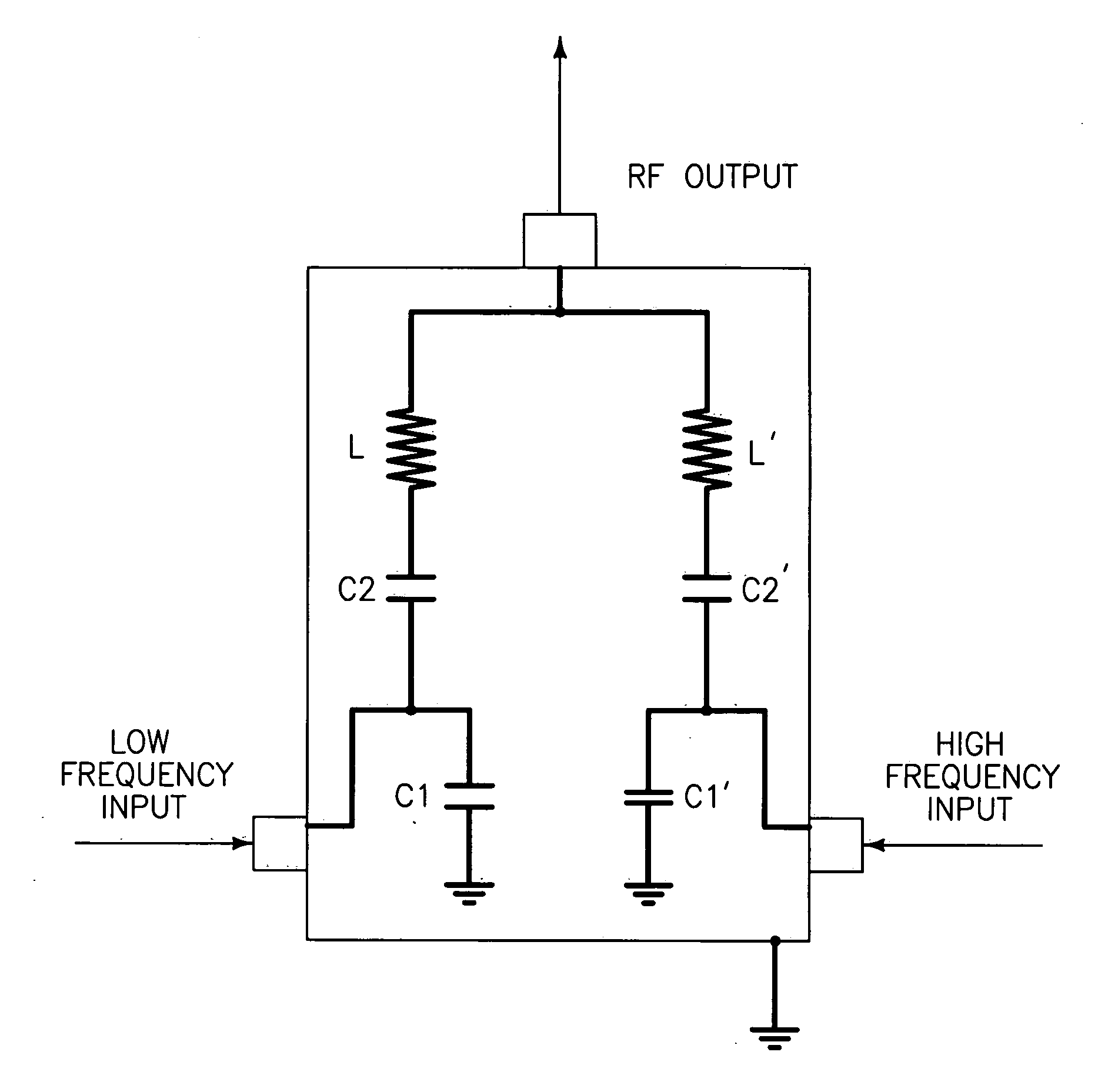

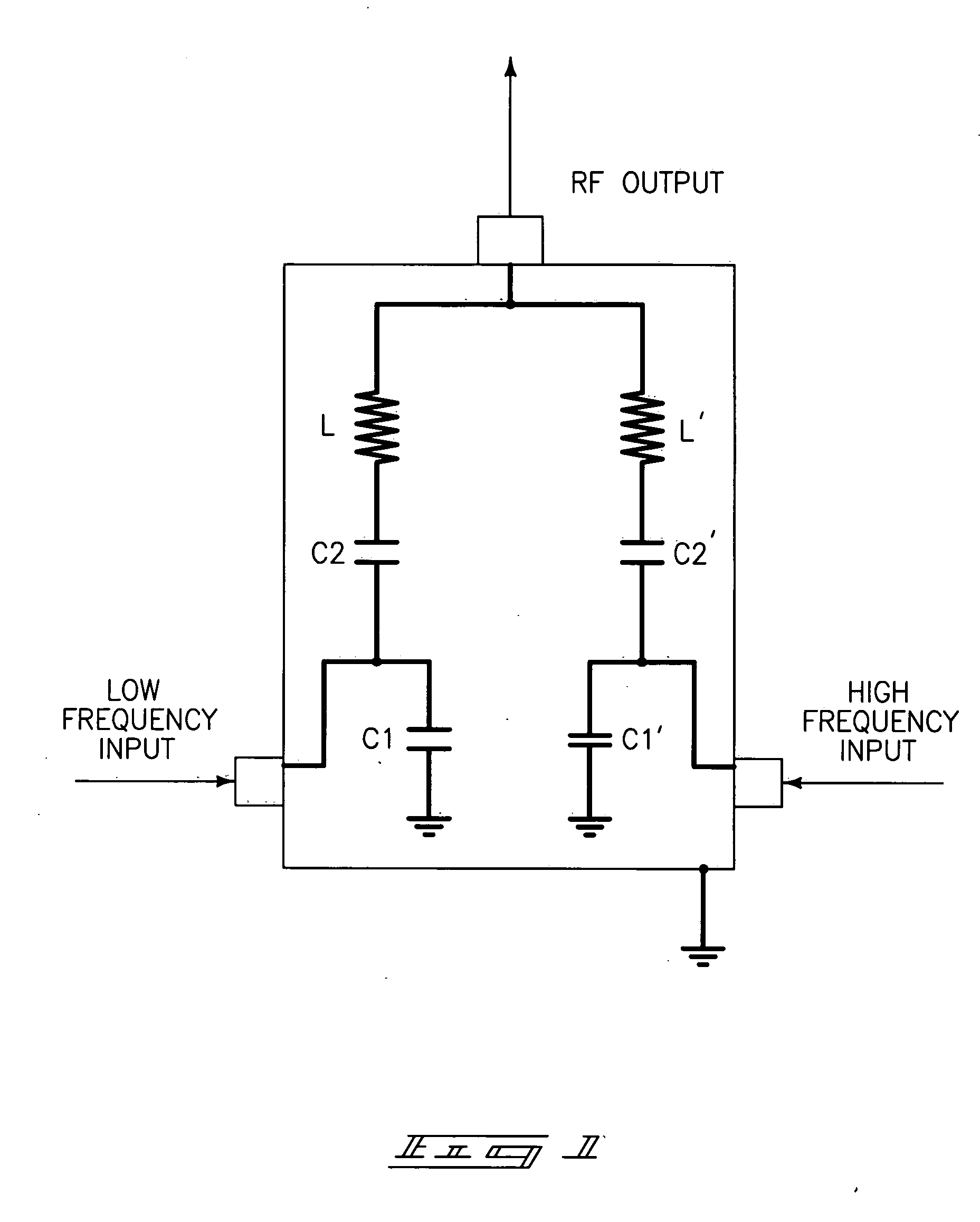

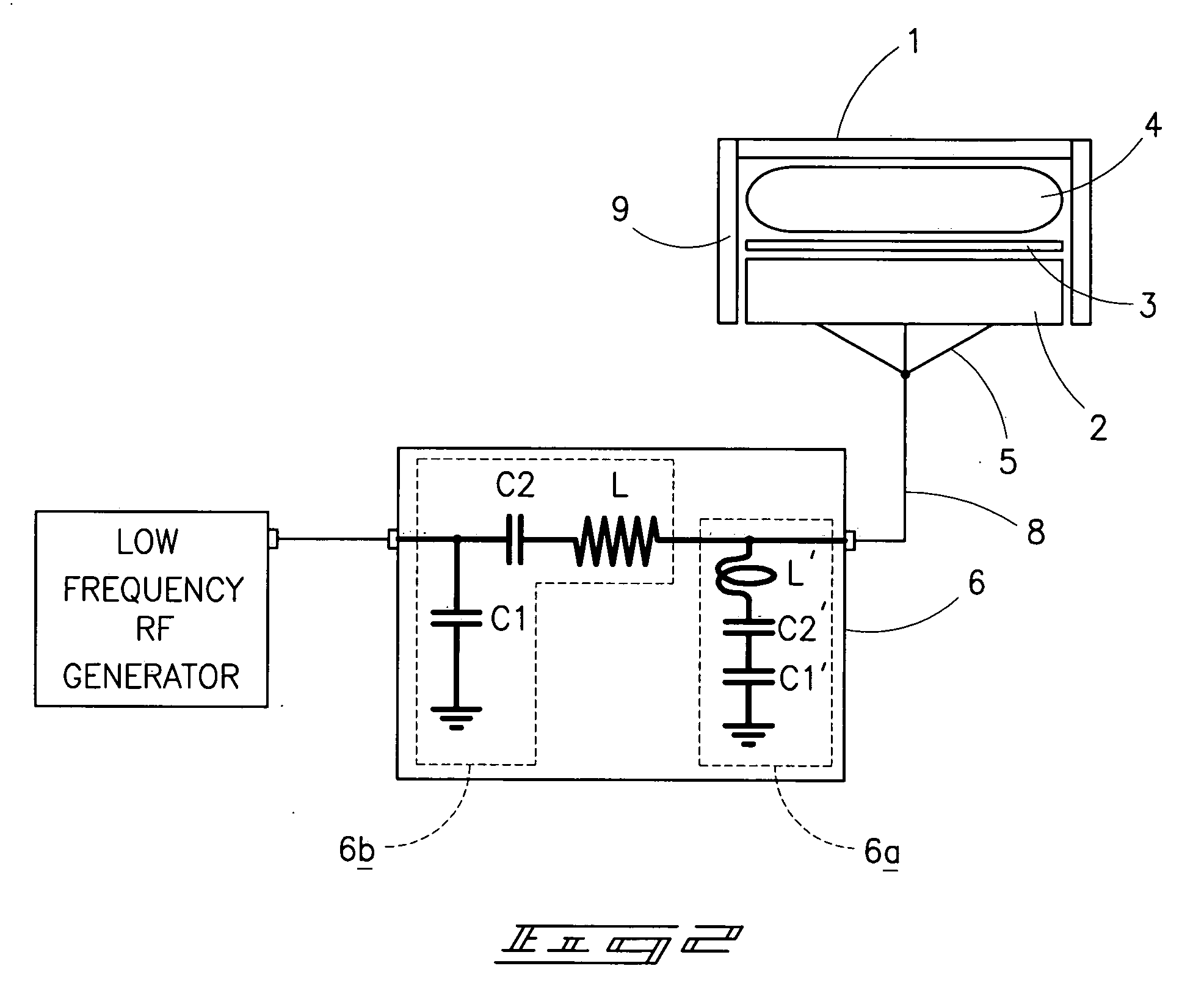

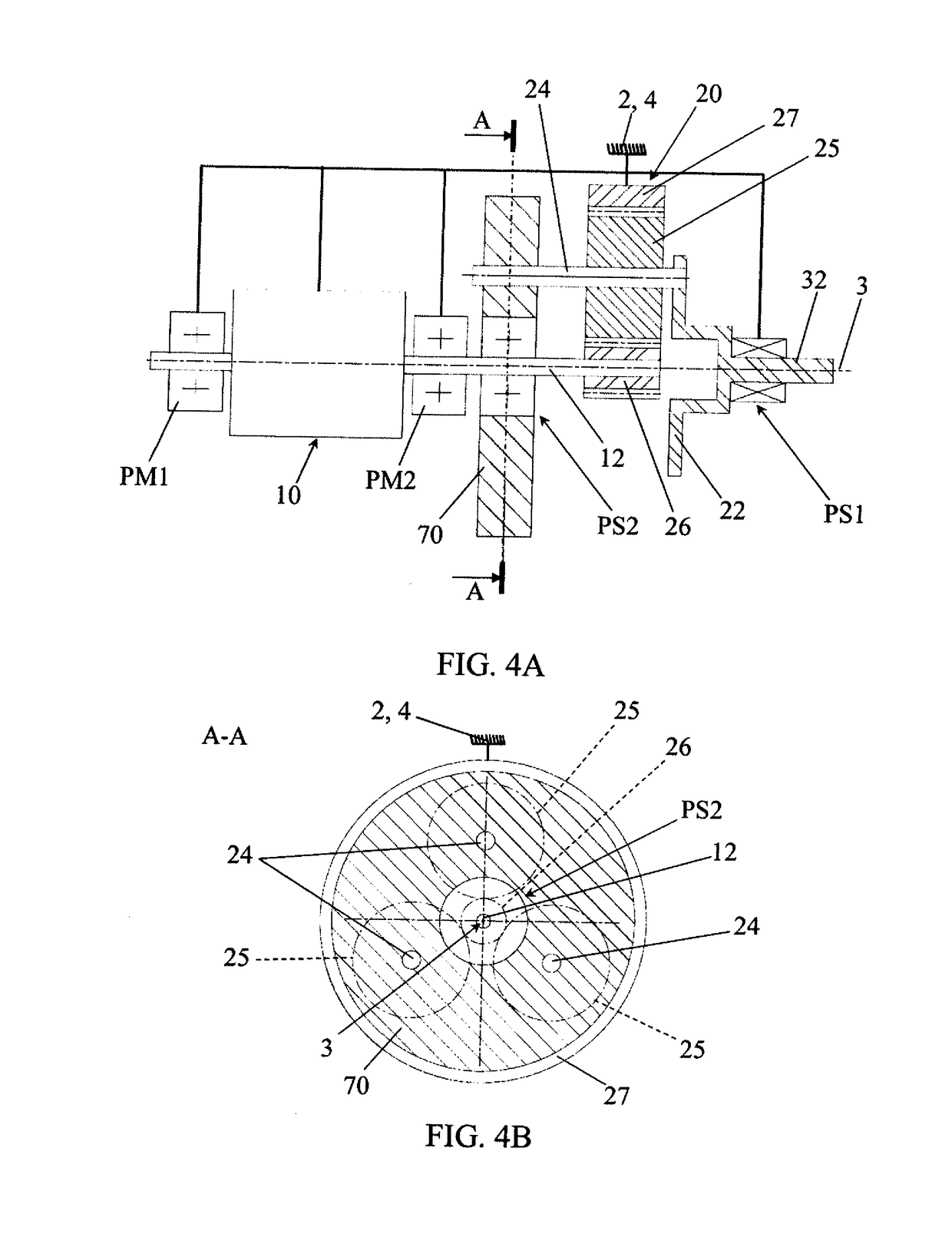

RF matching network of a vacuum processing chamber and corresponding configuration methods

ActiveUS7868556B2Overcome problemsHeatMultiple-port networksElectric discharge tubesEngineeringHigh impedance

A RF matching network is described, and which includes a 1st to nth RF generators, and wherein each RF generator has a different frequency, and wherein the frequencies of the 1st to the nth RF input ports decline in sequence, and wherein between the ith frequency RF input port, and the output port is a ith circuit, which has a high impedance at the output port to all RF generator frequencies other than the ith frequency; and wherein the ith circuit, when connected to a RF generator with the ith frequency, and wherein measuring from the output port to the ith circuit, the ith circuit has a first impedance at the ith frequency; and when measuring from the output port in the opposite direction to the ith circuit, the ith circuit has a second impedance at the ith frequency; and wherein the first impedance is a substantial conjugate match of the second impedance.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

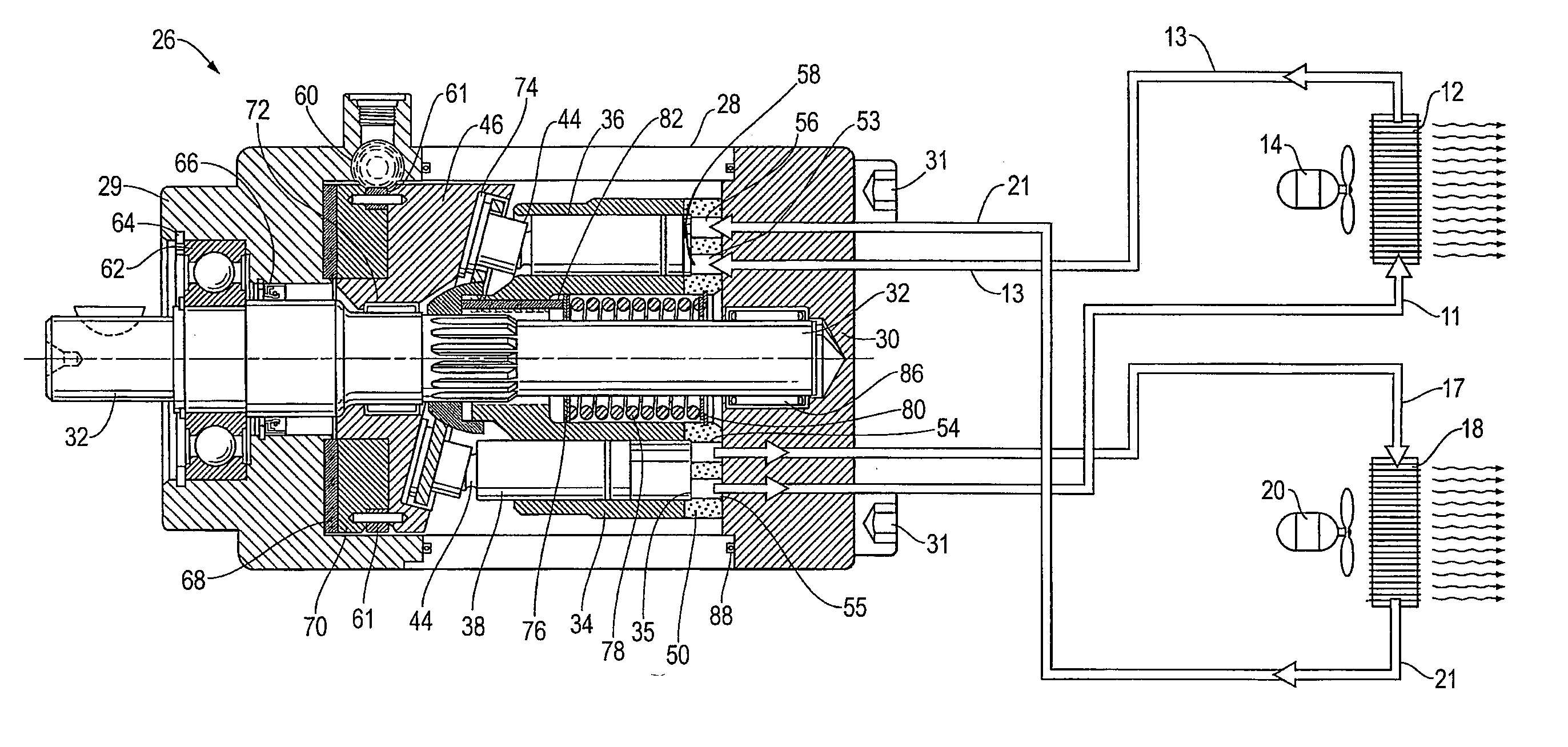

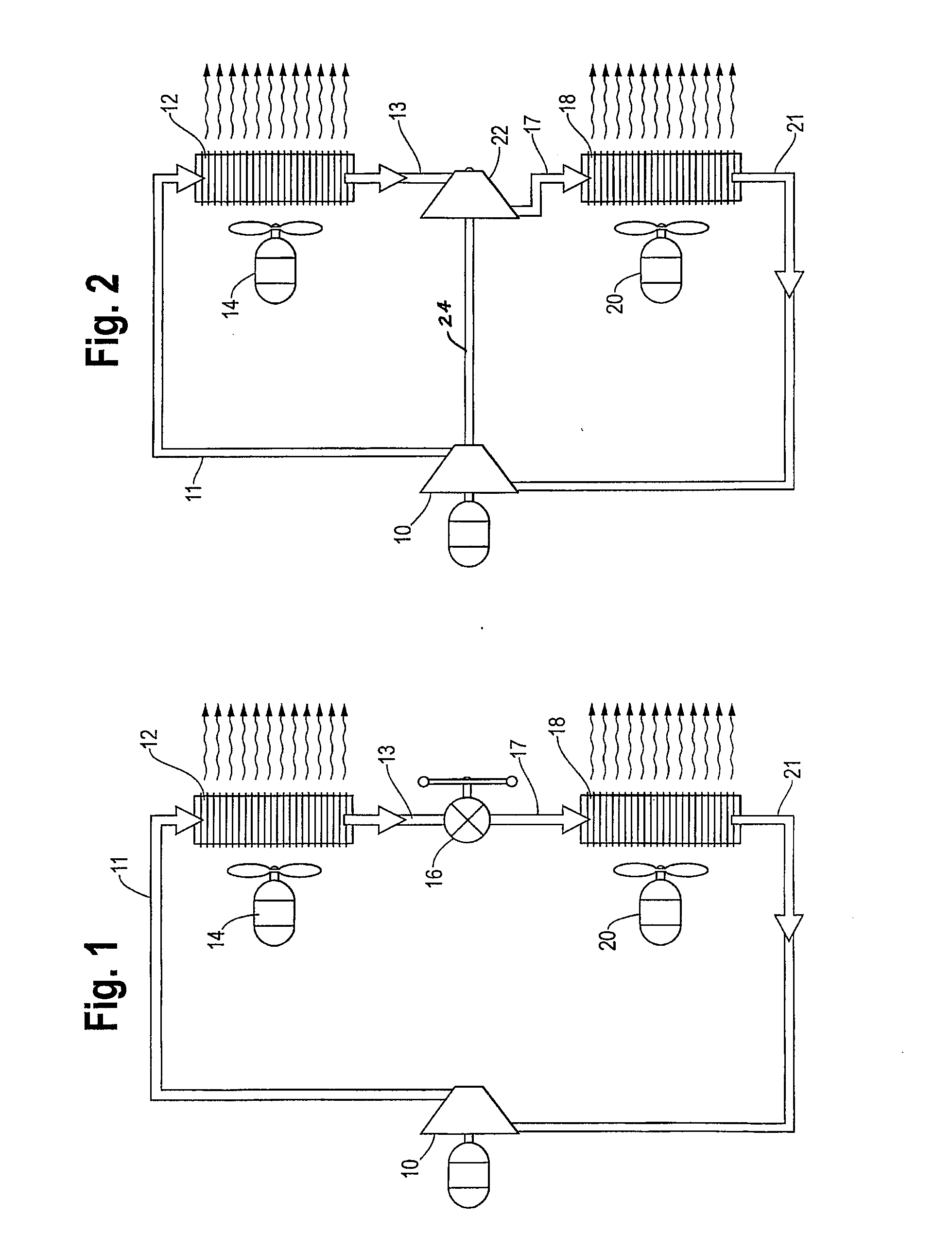

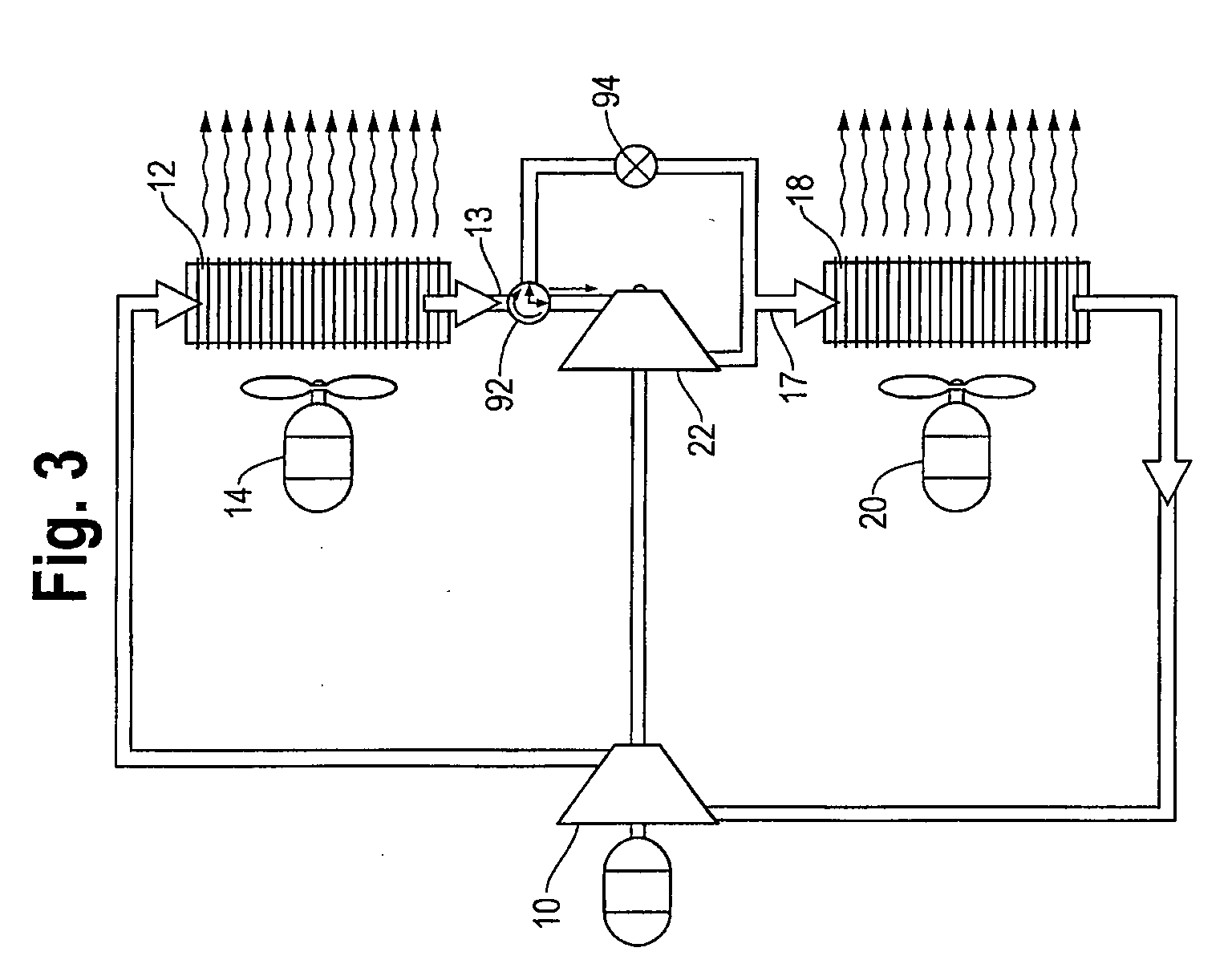

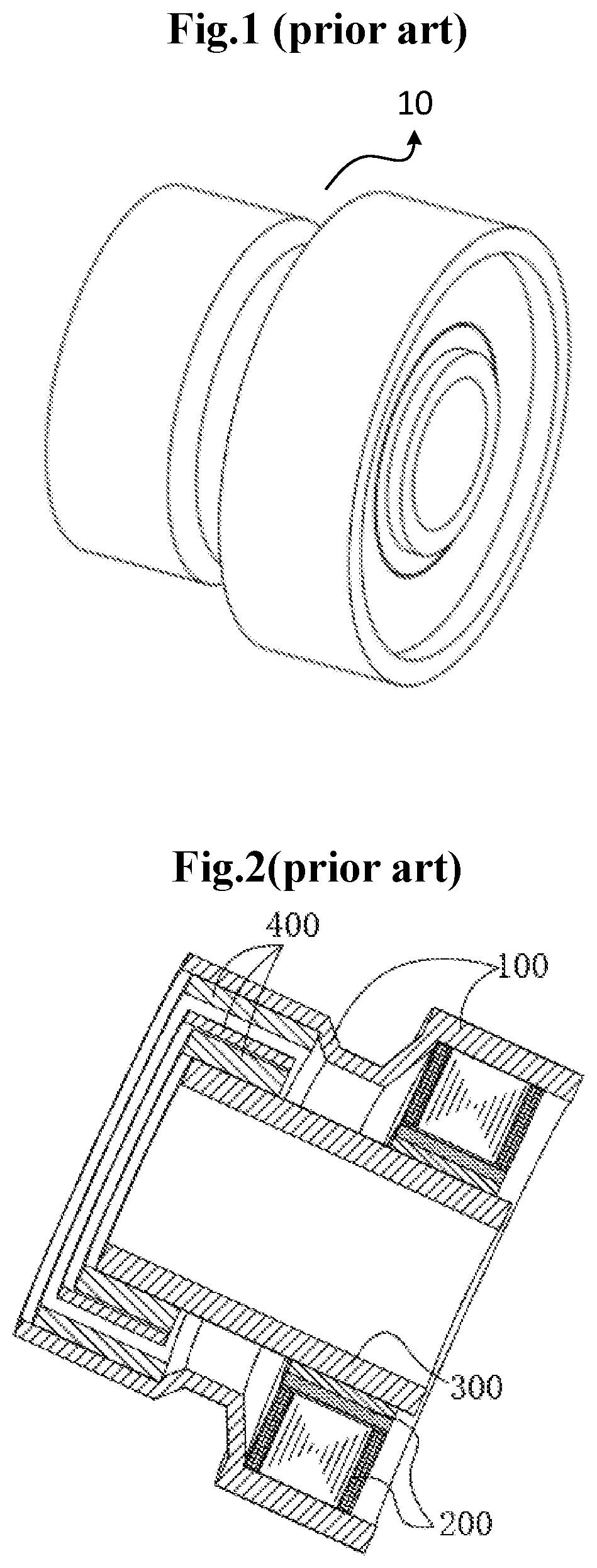

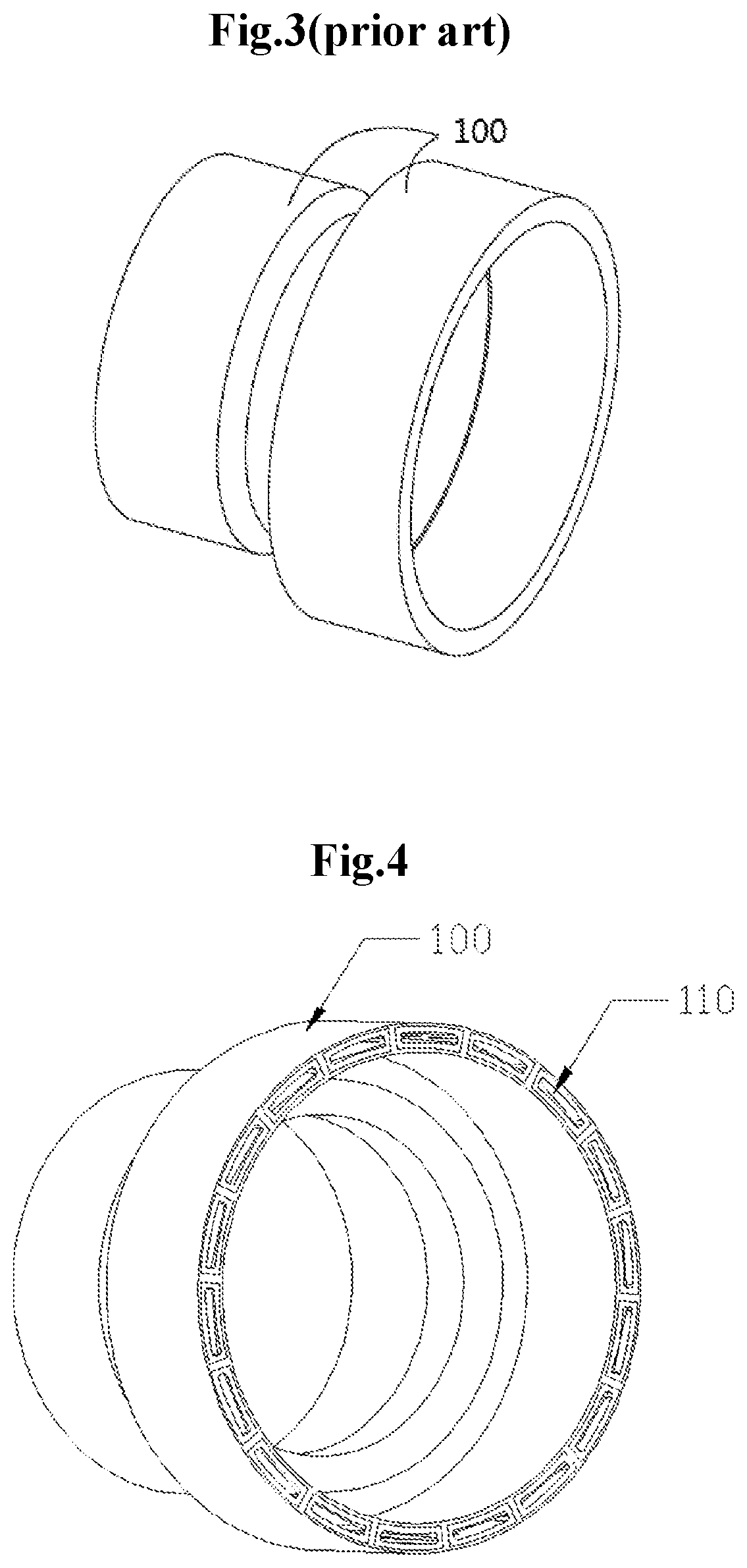

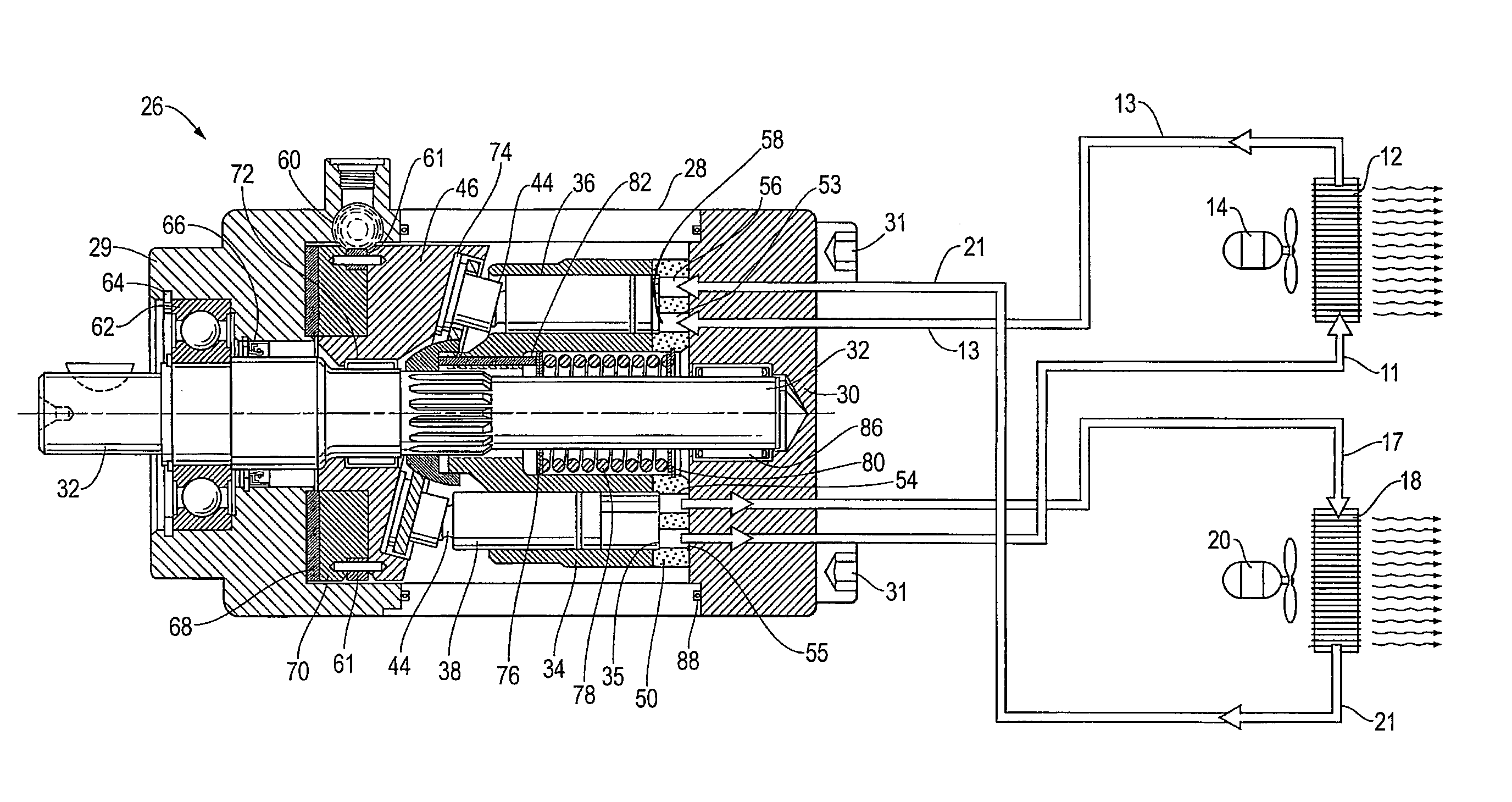

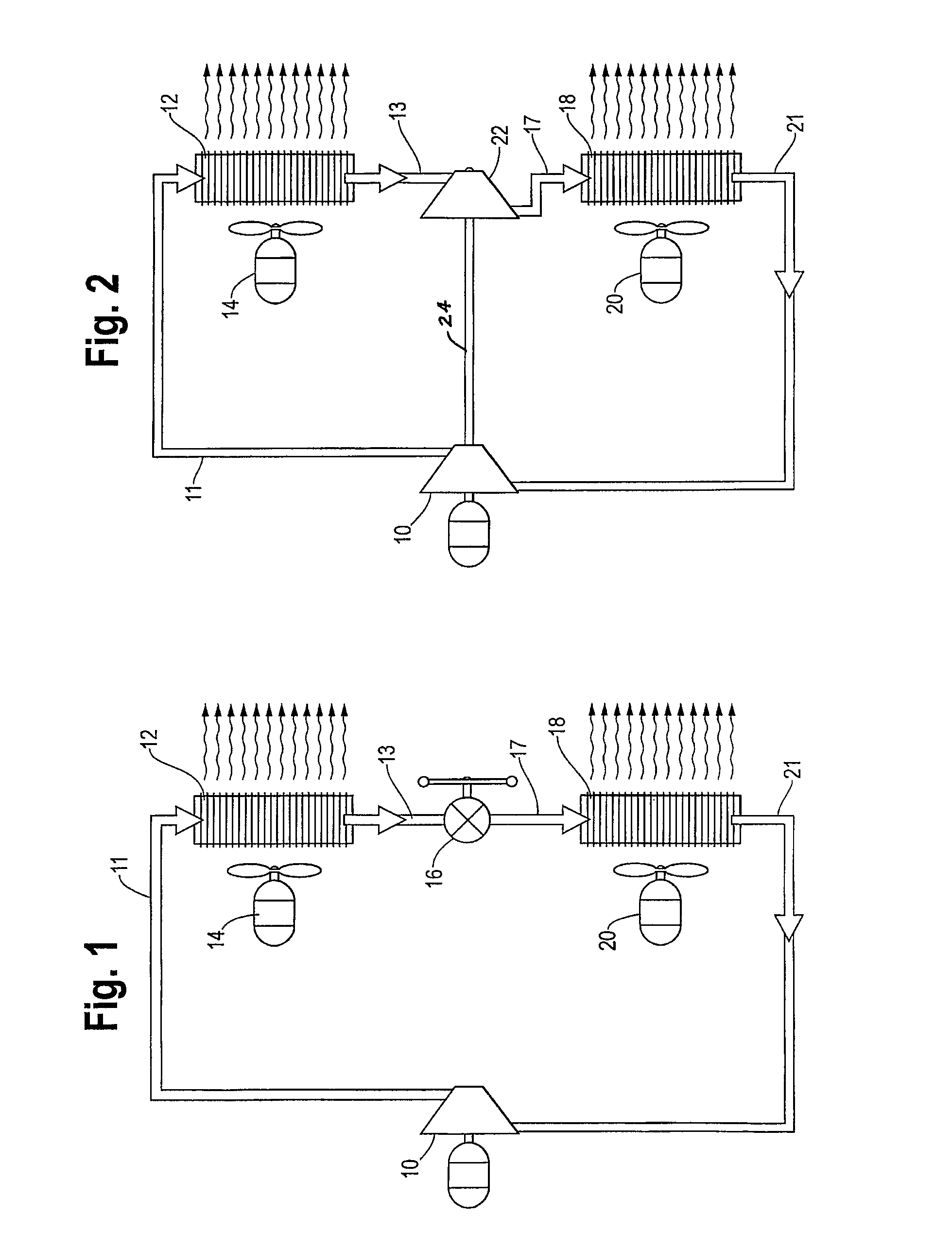

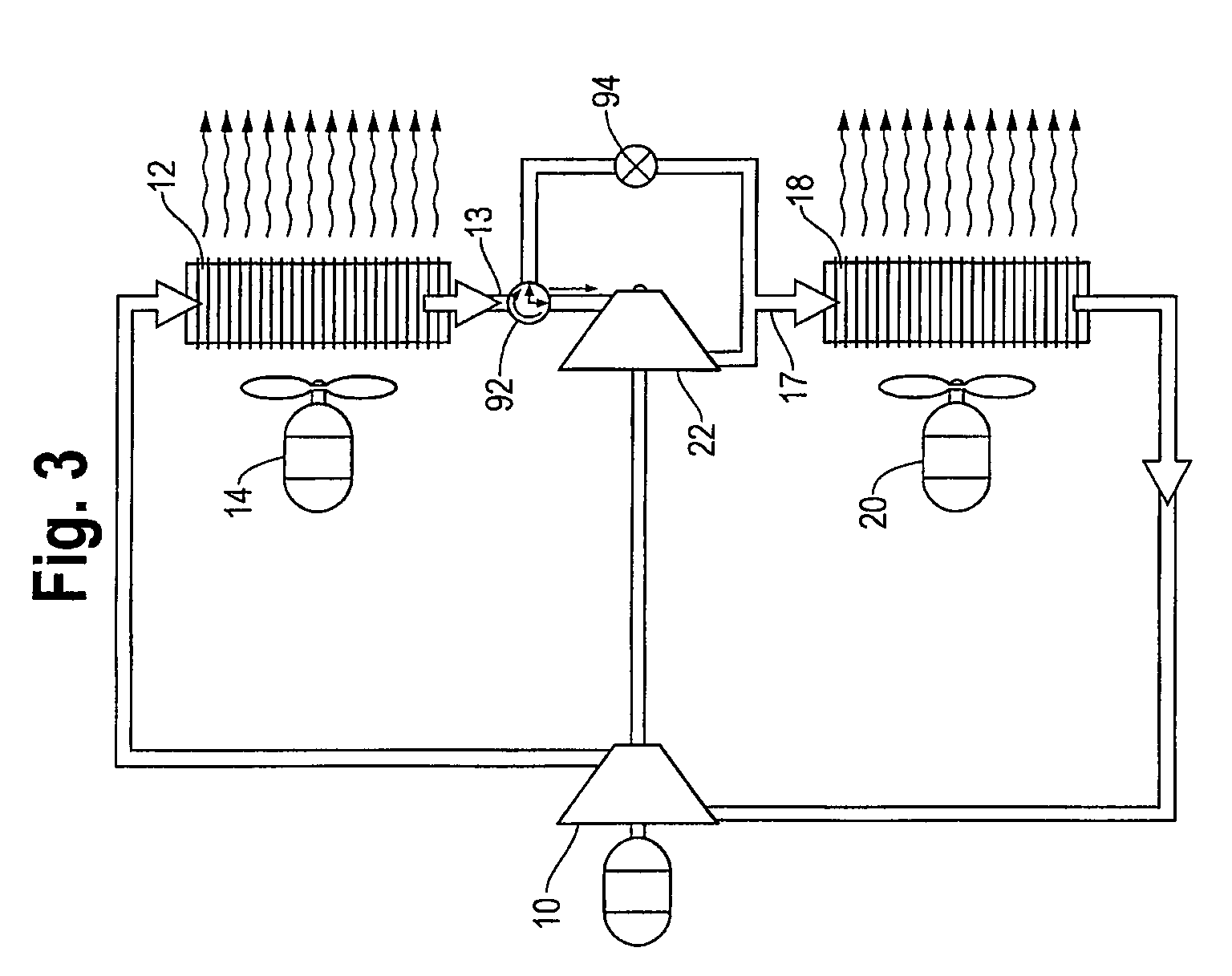

Integrated compressor/expansion engine

InactiveUS20090249826A1Retaining compressor compactnessRetaining configurationDomestic cooling apparatusCompression machines with non-reversible cycleDrive shaftHigh pressure

A multi cylinder compressor / expansion engine having a centrally mounted drive shaft. A cylinder barrel is mounted on the drive shaft and both the cylinder barrel and the drive shaft rotate about a common axis. There is a plurality of cylinders in the cylinder barrel with pistons disposed in each of the cylinders. Some of the cylinders are compression cylinders and some of the cylinders are expansion cylinders. The compression cylinders discharge a fluid at a first high pressure from the engine. The expansion cylinders receive fluid at a second pressure which provides energy to the engine thereby reducing the energy required for the engine to rotate the drive shaft.

Owner:WHITEMOSS

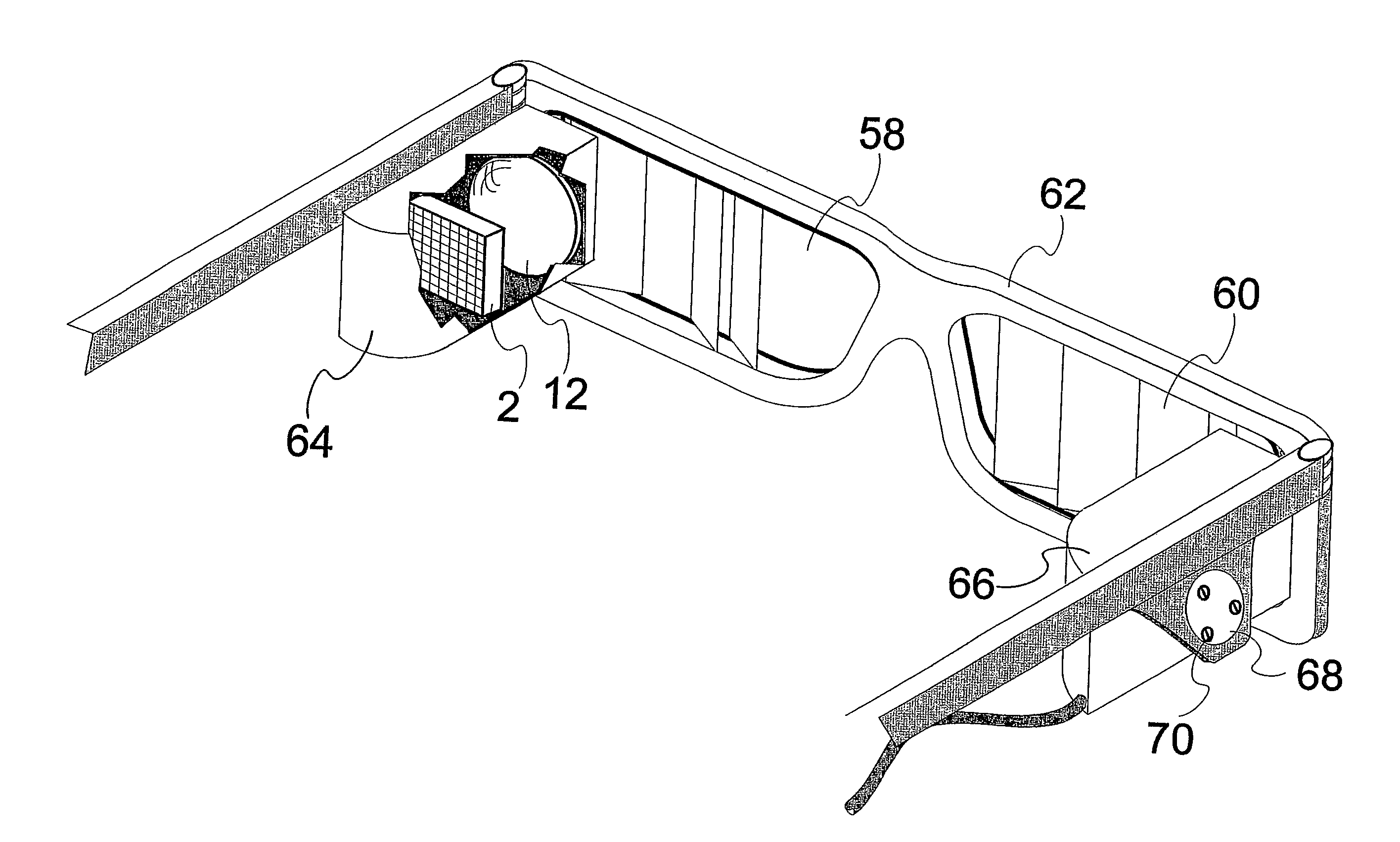

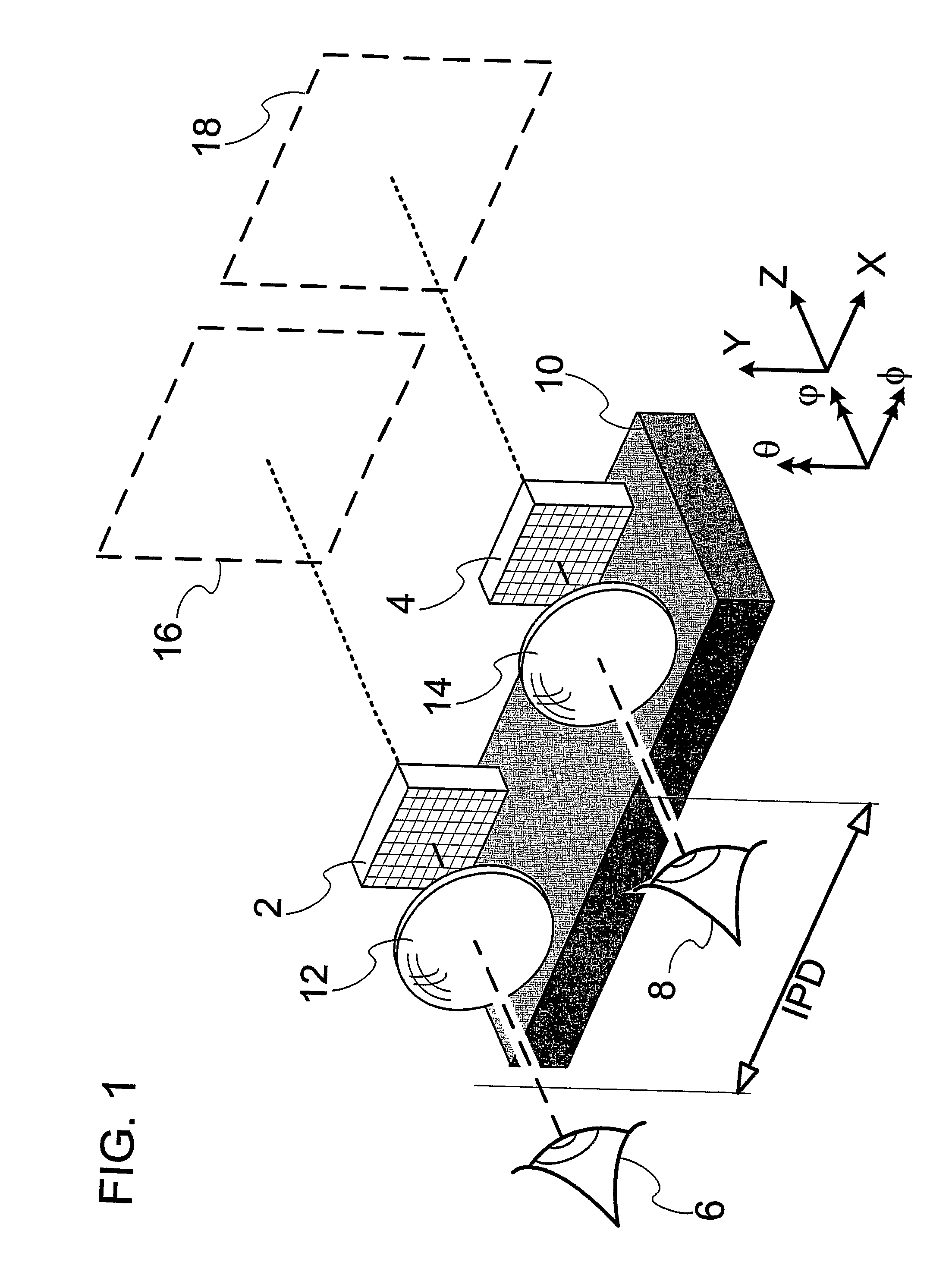

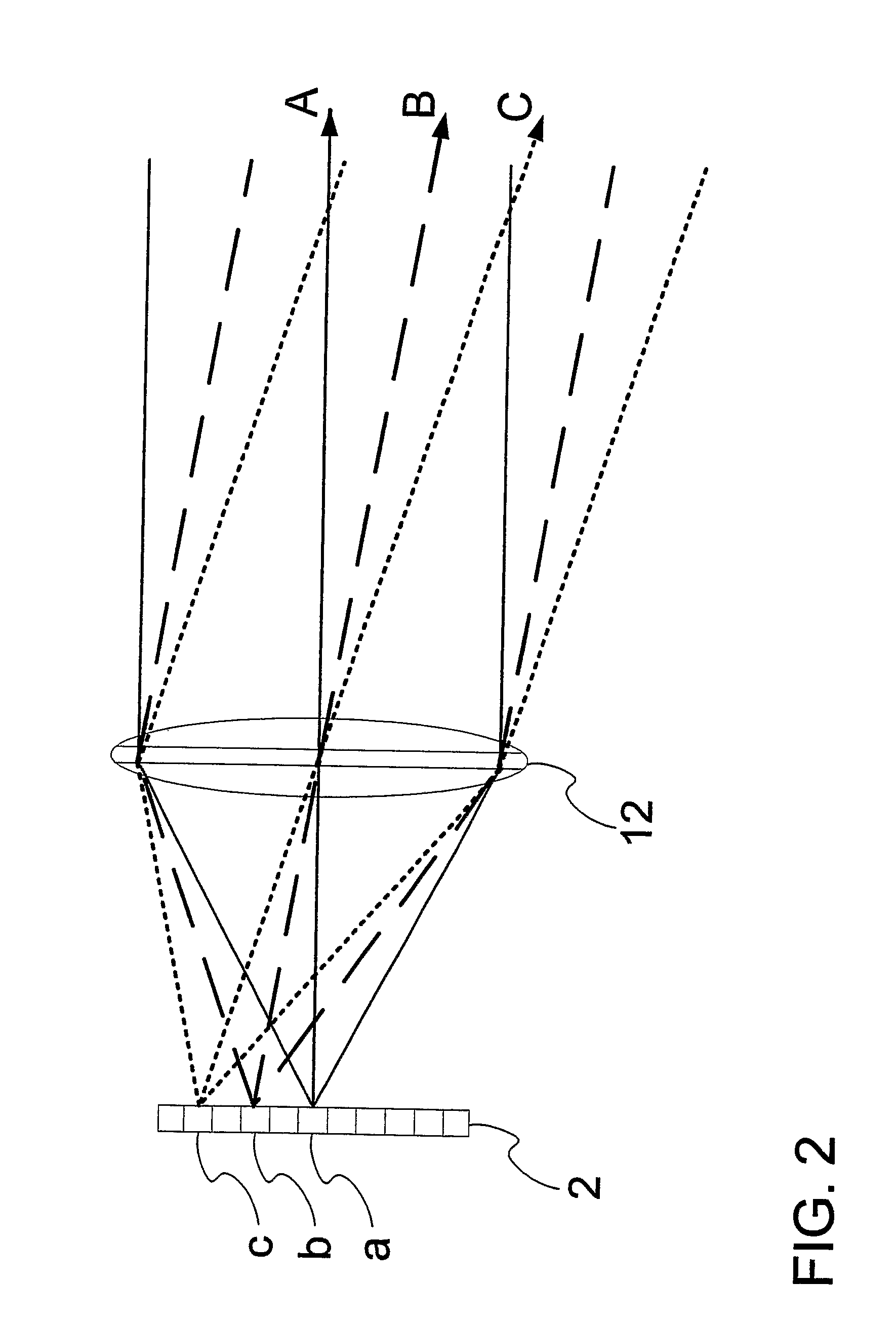

Device and method for alignment of binocular personal display

ActiveUS8446340B2Improve alignment accuracyKeep it compactProjectorsCathode-ray tube indicatorsDisplay deviceComputer science

Owner:LUMUS LTD

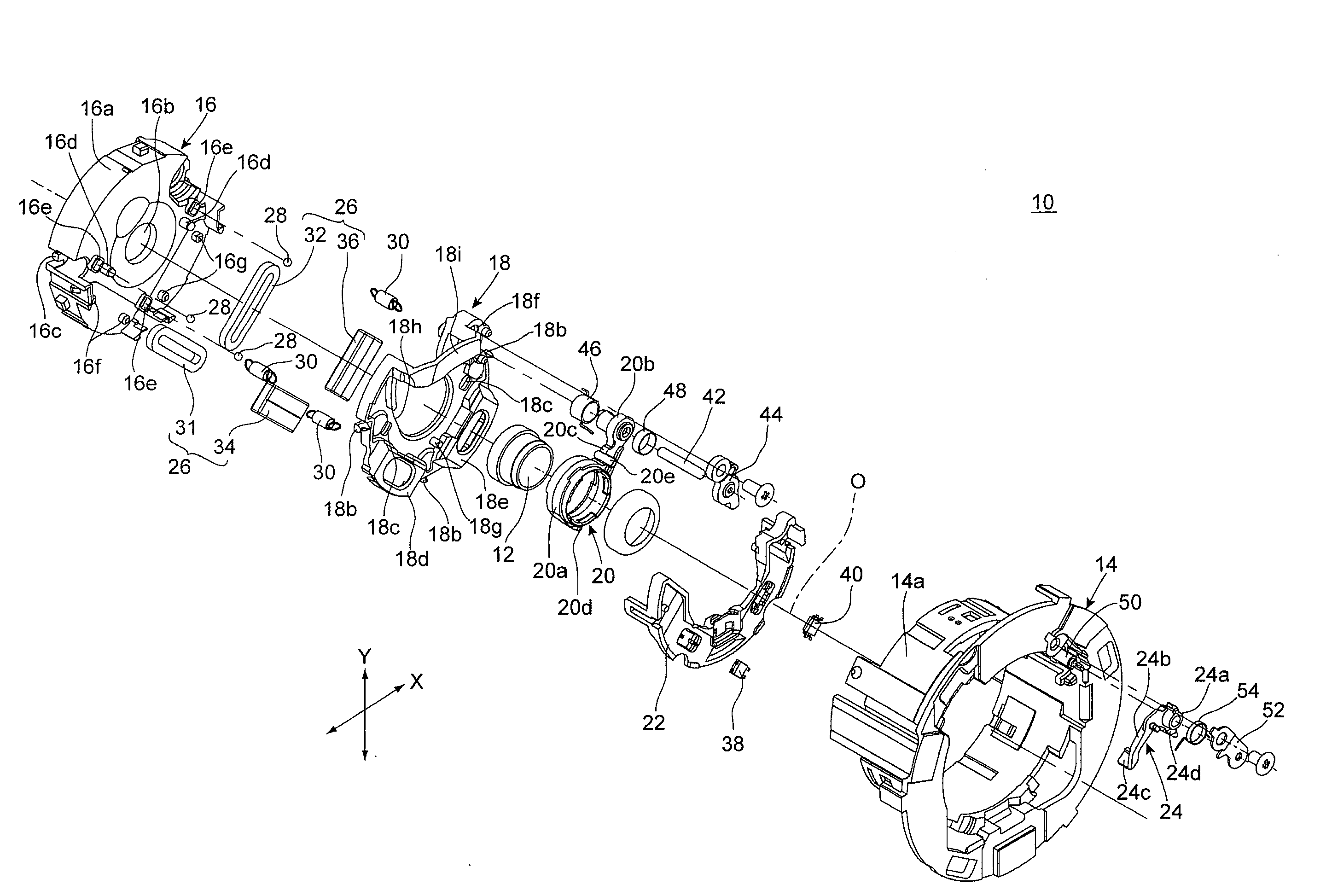

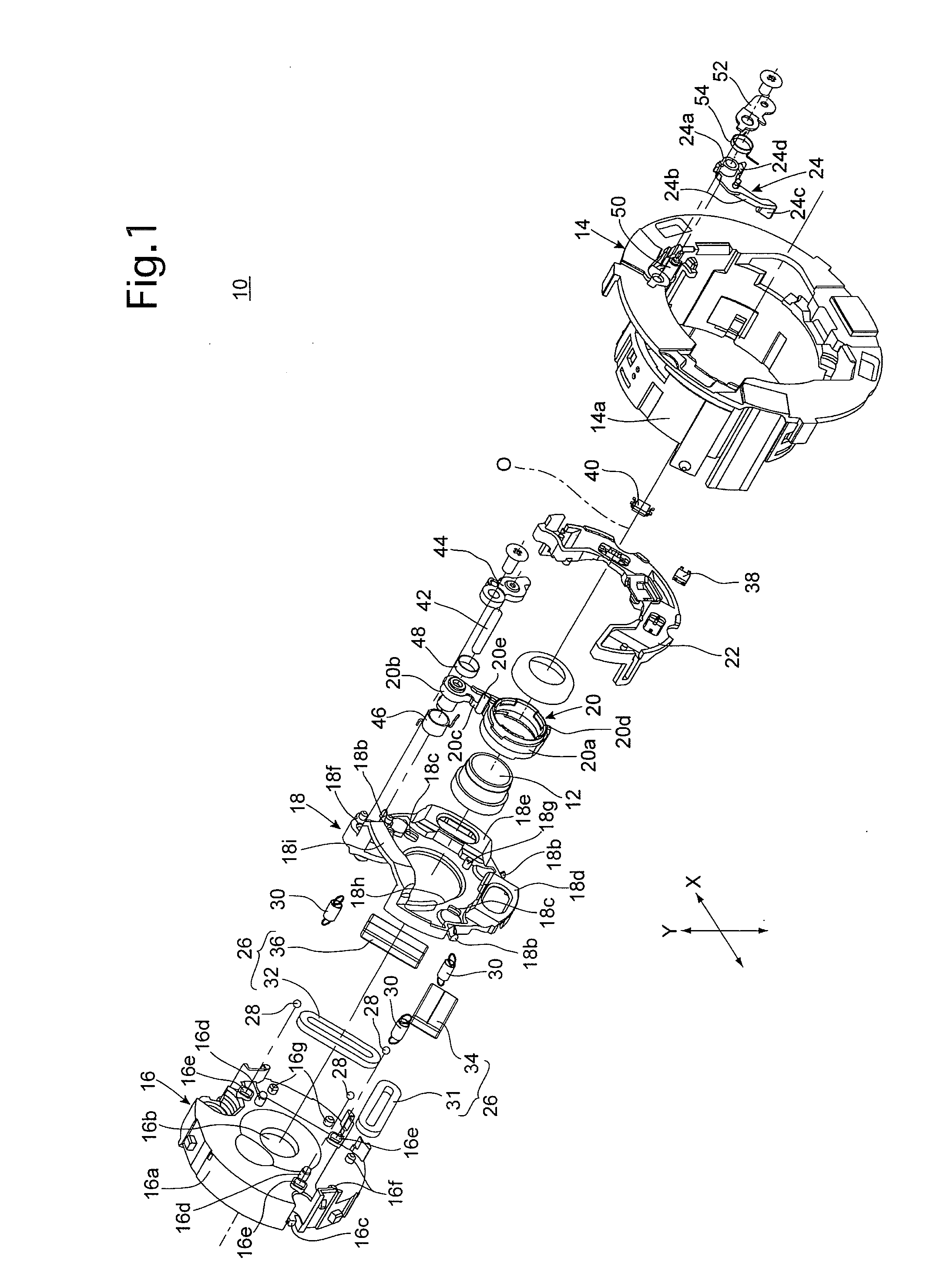

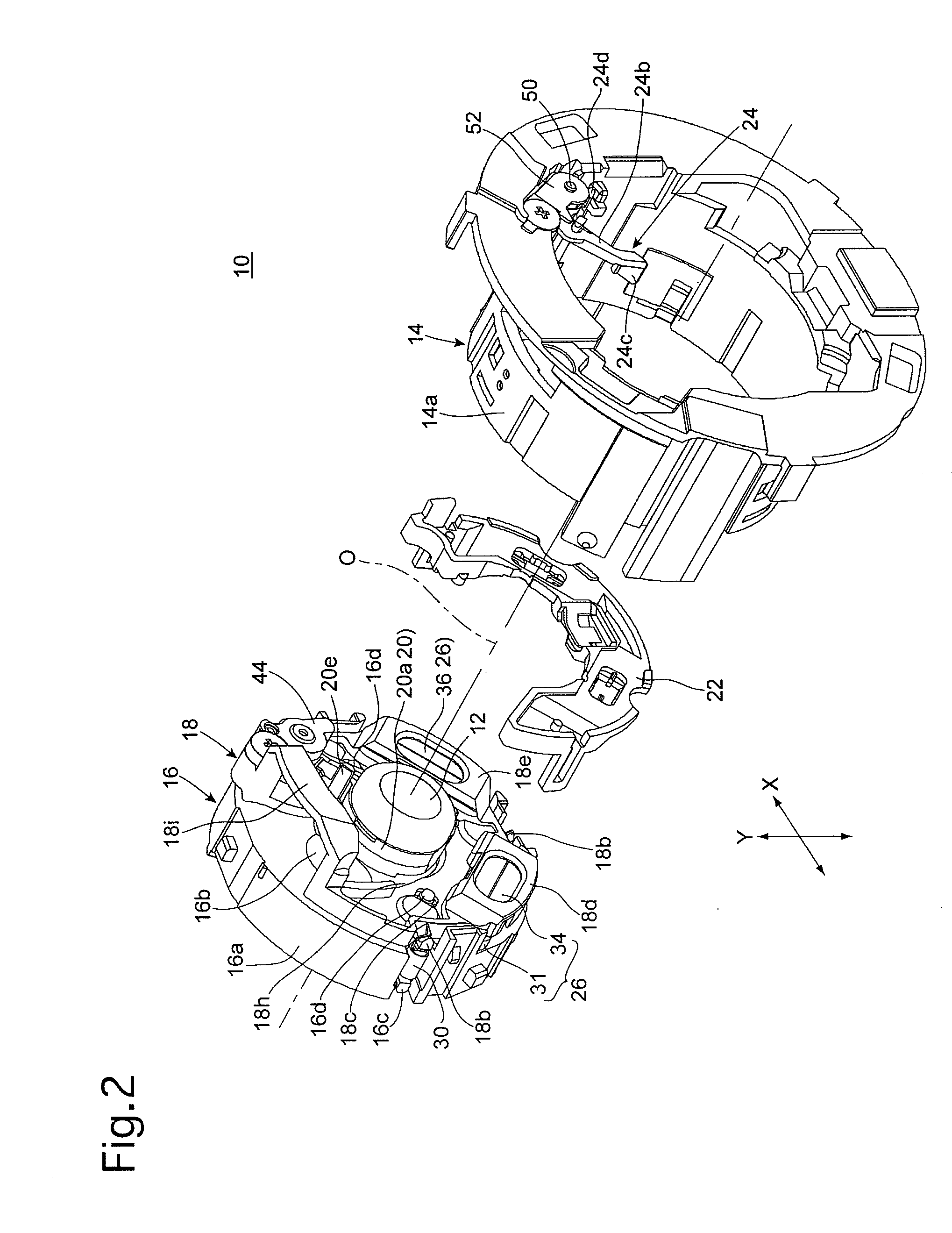

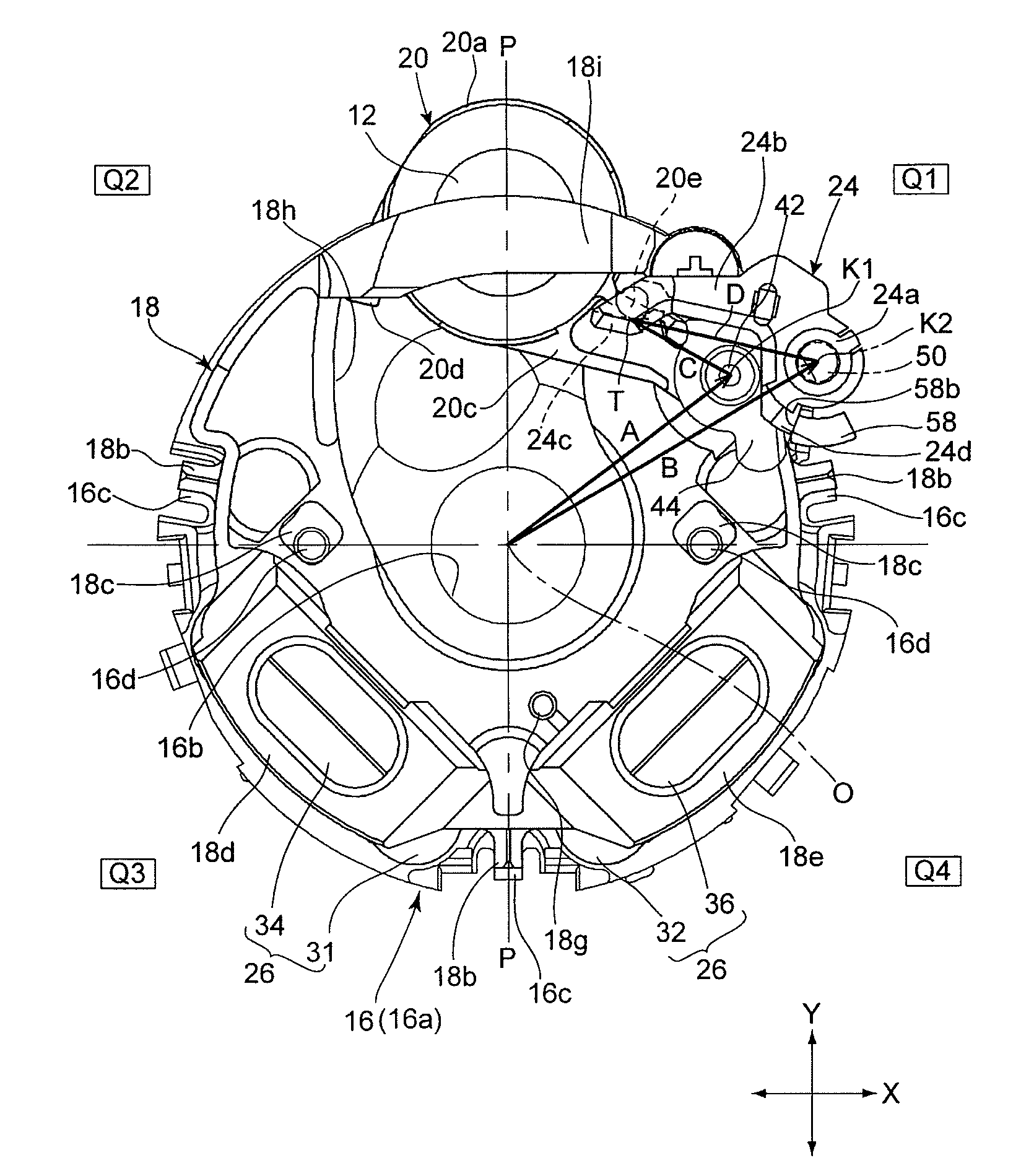

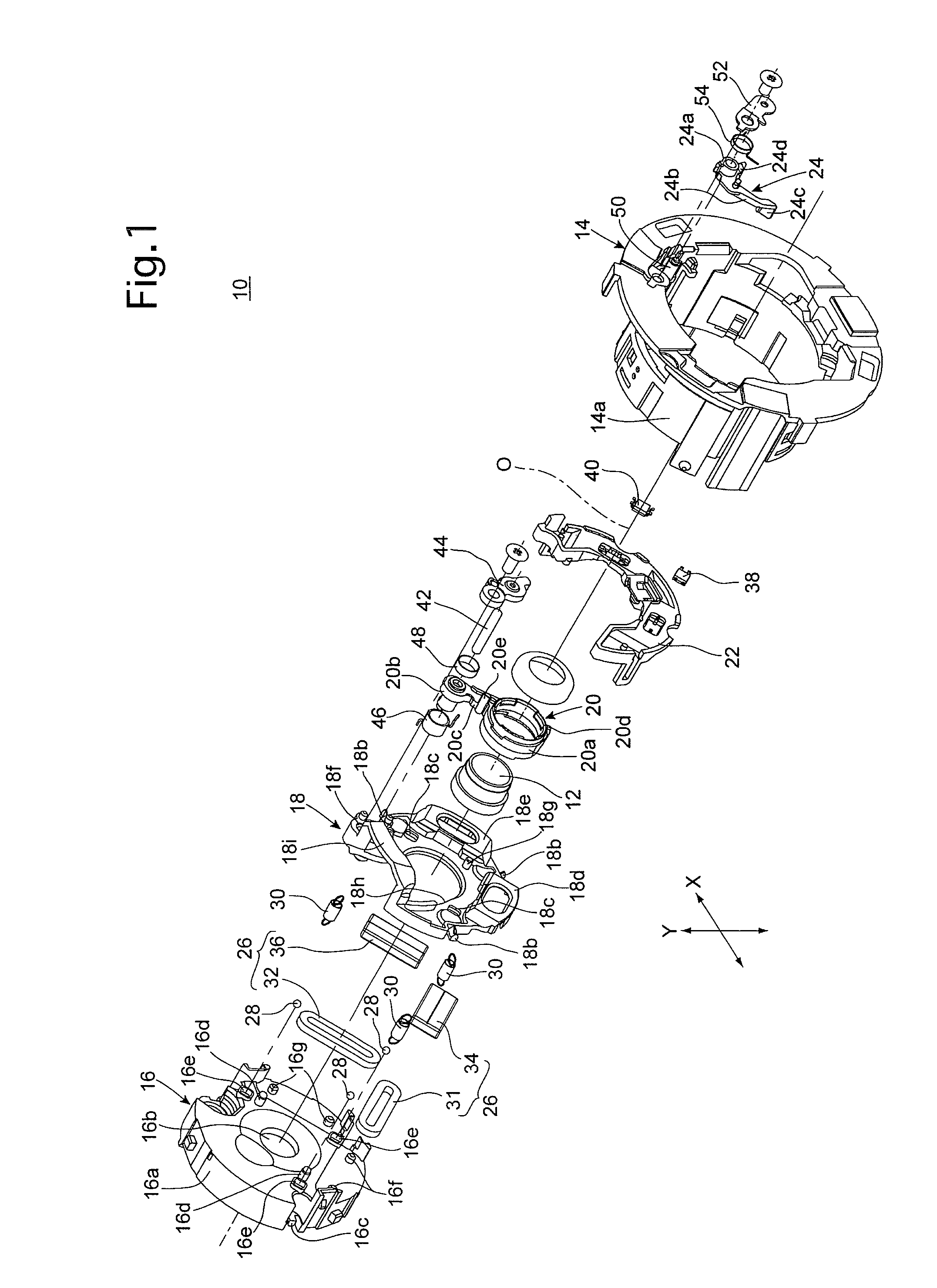

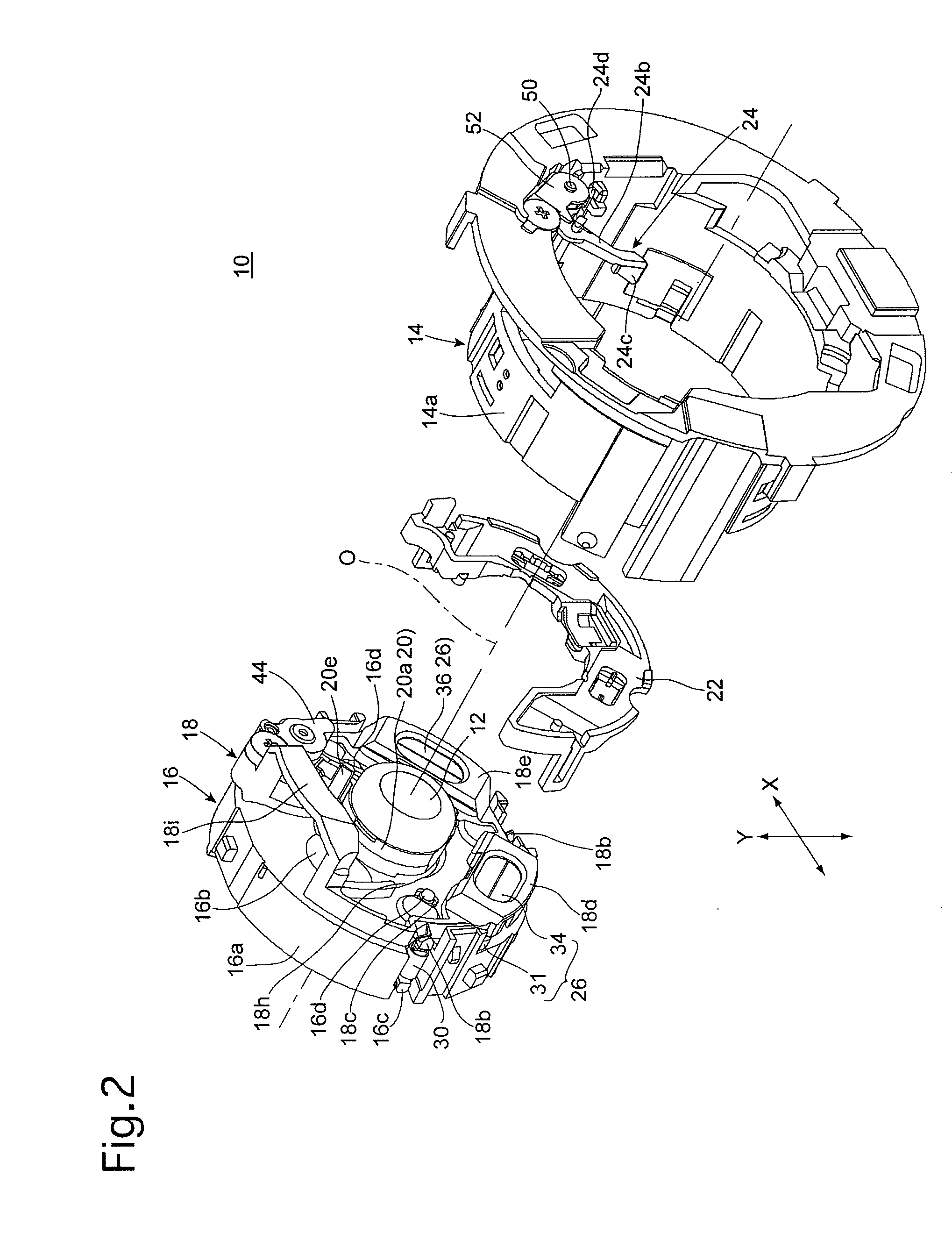

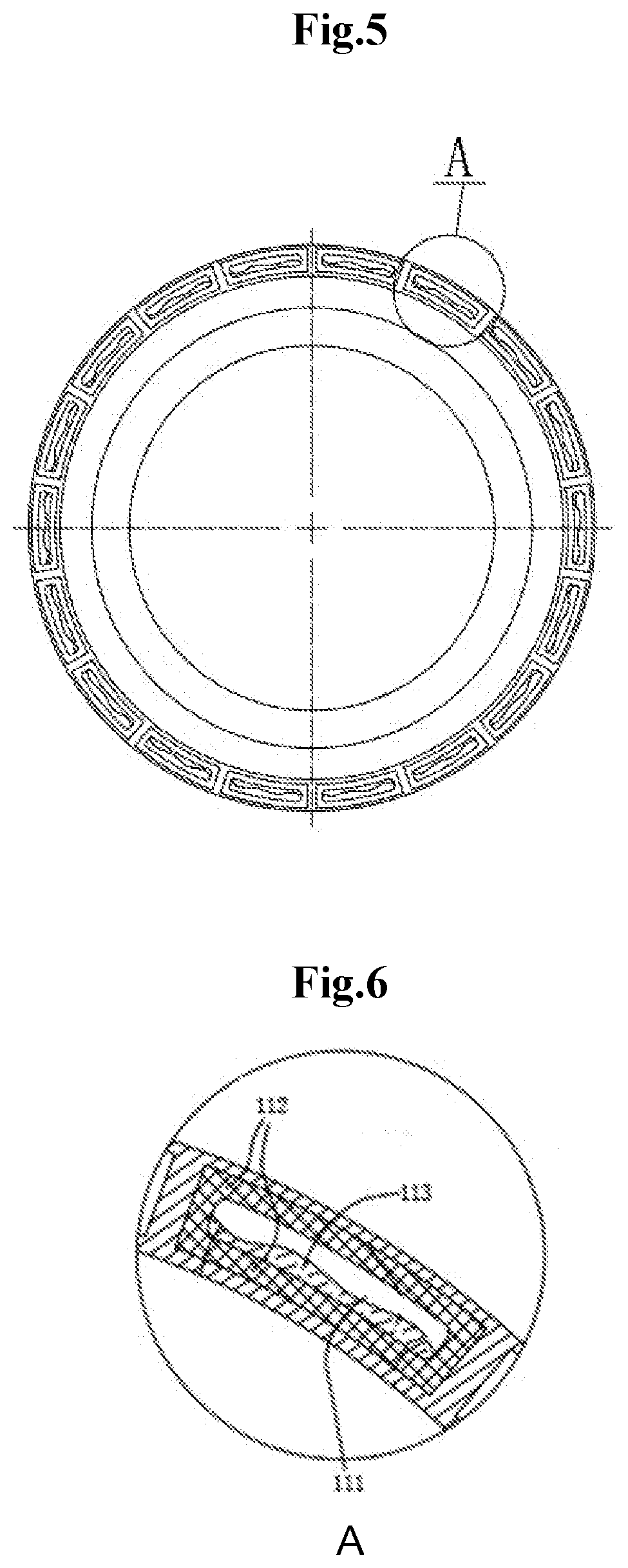

Position controller for removable optical element

InactiveUS20120218635A1Improve accuracyKeep it compactTelevision system detailsPrintersRotational axisOptical axis

A position controller for a removable optical element in an optical system includes an advancing / retracting ring; a removable optical element holding member supported by the advancing / retracting ring and rotatable about a first rotational axis between an insertion position on the optical axis and a removed position; an insertion holder which holds the removable optical element holding member at the insertion position; a removal drive member supported by the advancing / retracting ring and rotatable about a second rotational axis between an insertion allowance position and a forced removing position; and an insertion / removal controller. A rotational radius from the second rotational axis to a contact point between the removable optical element holding member and the removal drive member is greater than a rotational radius from the first rotational axis to the contact point.

Owner:HOYA CORP

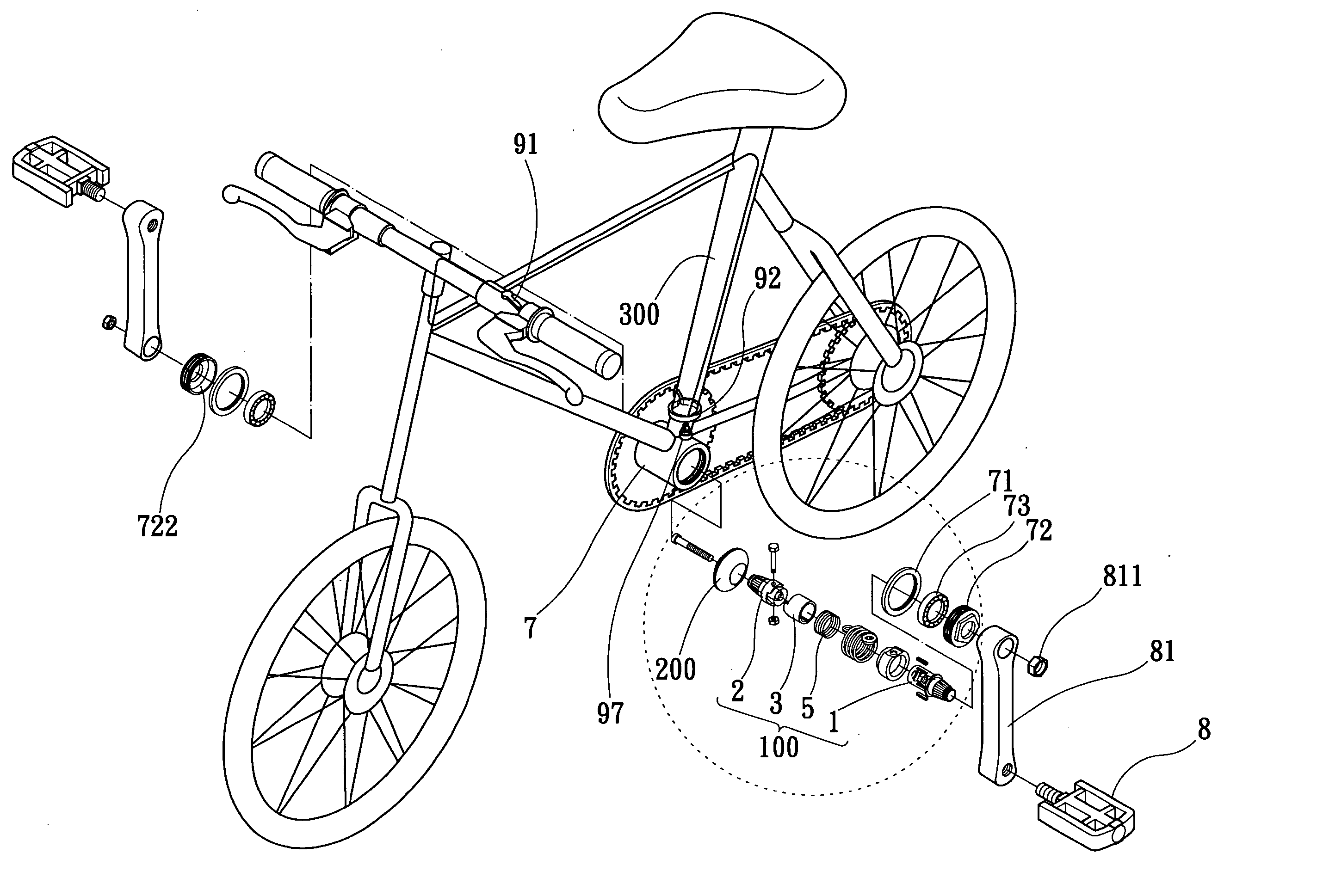

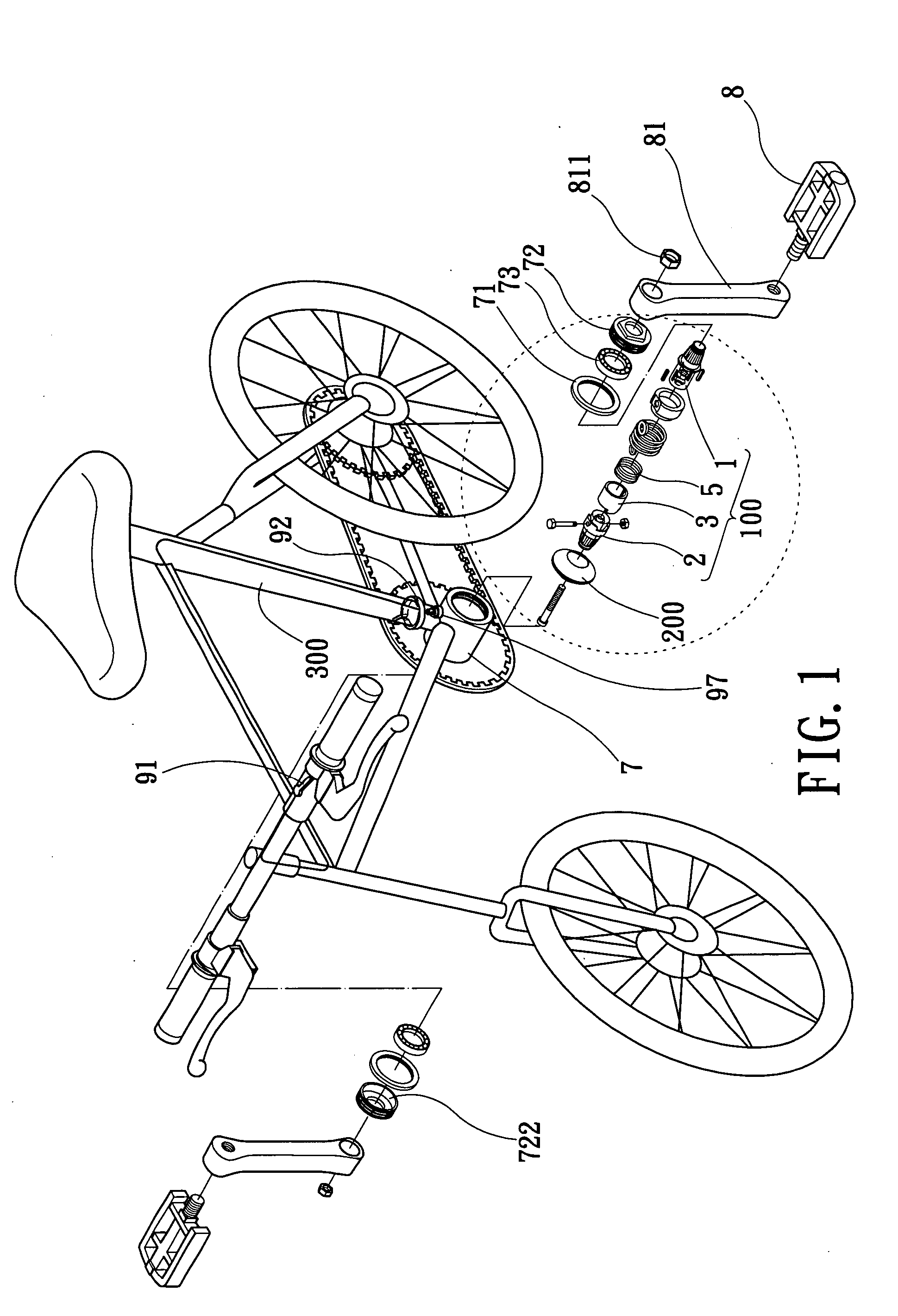

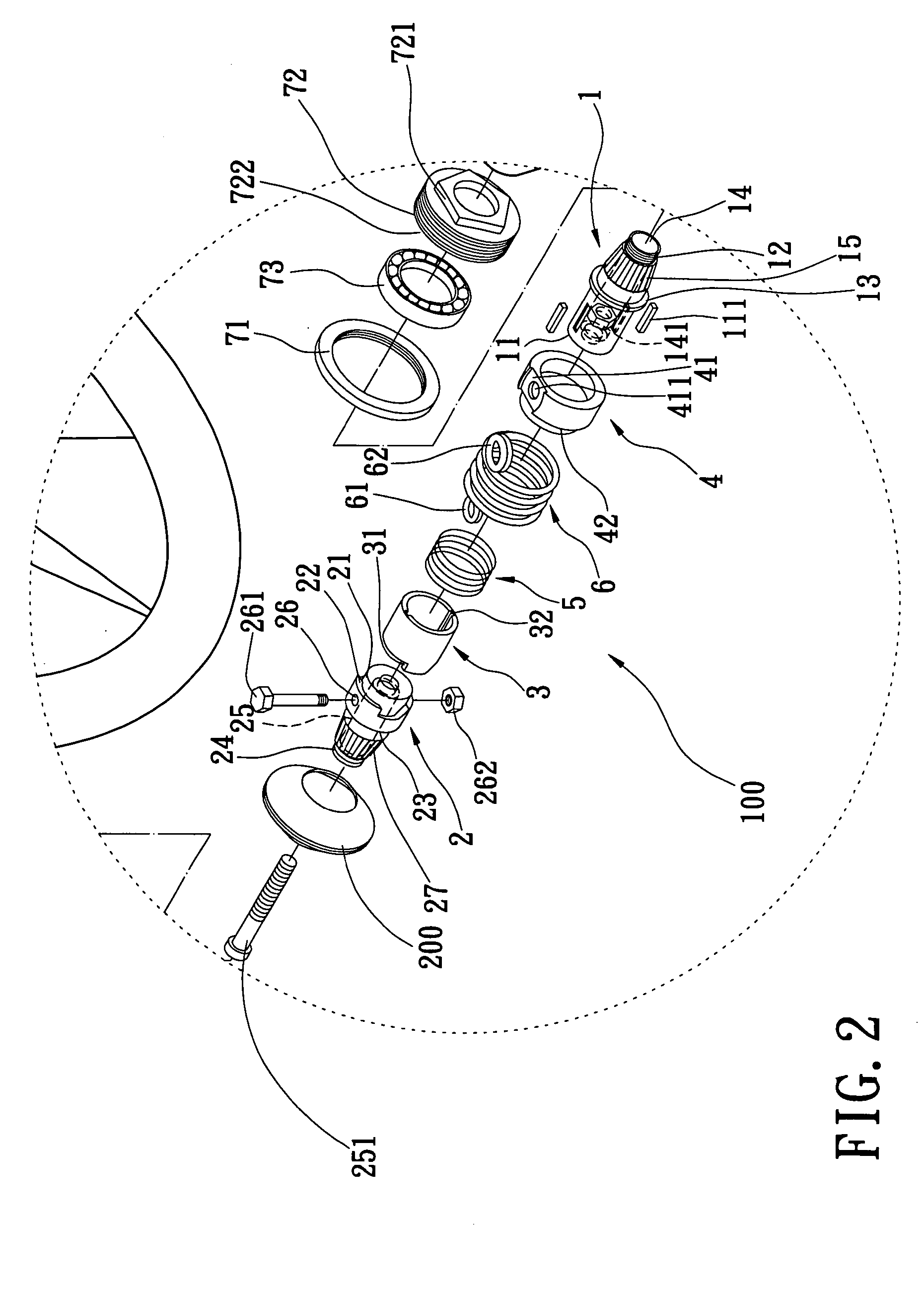

Pedal shaft structure of a bicycle having a second pedaling function

InactiveUS20050011302A1Enhance effectively entertainment abilityKeep it compactControlling membersVehicle cranksEngineeringWire rope

A pedal shaft structure of a bicycle having a second pedaling function is proposed. A shaft tube of the bicycle has a braking unit and a shaft. Pedals are arranged at two ends of the shaft through cranks. The shaft has a main shaft, a second spring and a pair of bearings. The main shaft has a first shaft, a second shaft, a first bushing and a first spring. The second spring is telescoped at the main shaft and one end thereof is fixed to the second shaft. The pair of bearings are arranged at two ends of the shaft tube and telescoped at two ends of the main shaft. The braking unit comprises an insertion hole formed at the shaft tube, an insertion rod inserted into the insertion hole, a steering component, a steel rope connected between the steering component and the insertion rod.

Owner:WANG CHIEN KUO +1

RF matching network of a vacuum processing chamber and corresponding configuration methods

ActiveUS20070030091A1Overcome problemsHeatMultiple-port networksElectric discharge tubesEngineeringRadio frequency

A RF matching network is described, and which includes a 1st to nth RF generators, and wherein each RF generator has a different frequency, and wherein the frequencies of the 1st to the nth RF input ports decline in sequence, and wherein between the ith frequency RF input port, and the output port is a ith circuit, which has a high impedance at the output port to all RF generator frequencies other than the ith frequency; and wherein the ith circuit, when connected to a RF generator with the ith frequency, and wherein measuring from the output port to the ith circuit, the ith circuit has a first impedance at the ith frequency; and when measuring from the output port in the opposite direction to the ith circuit, the ith circuit has a second impedance at the ith frequency; and wherein the first impedance is a substantial conjugate match of the second impedance.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

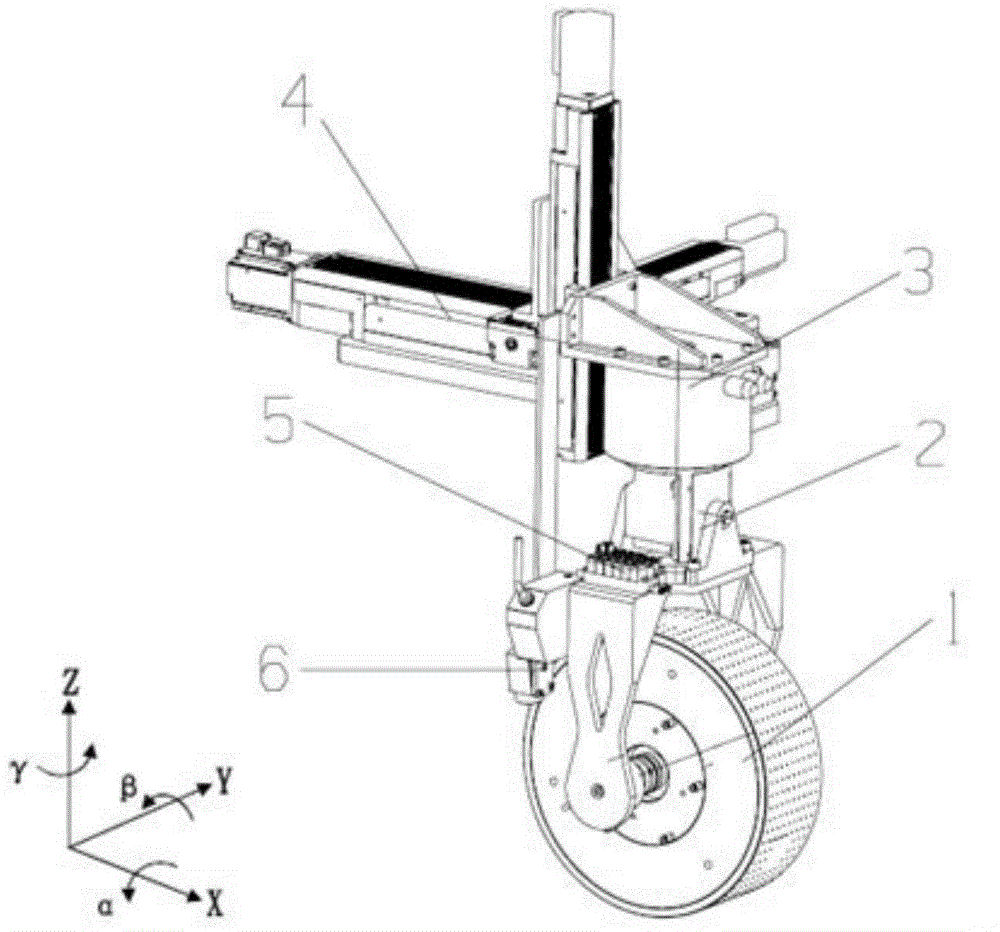

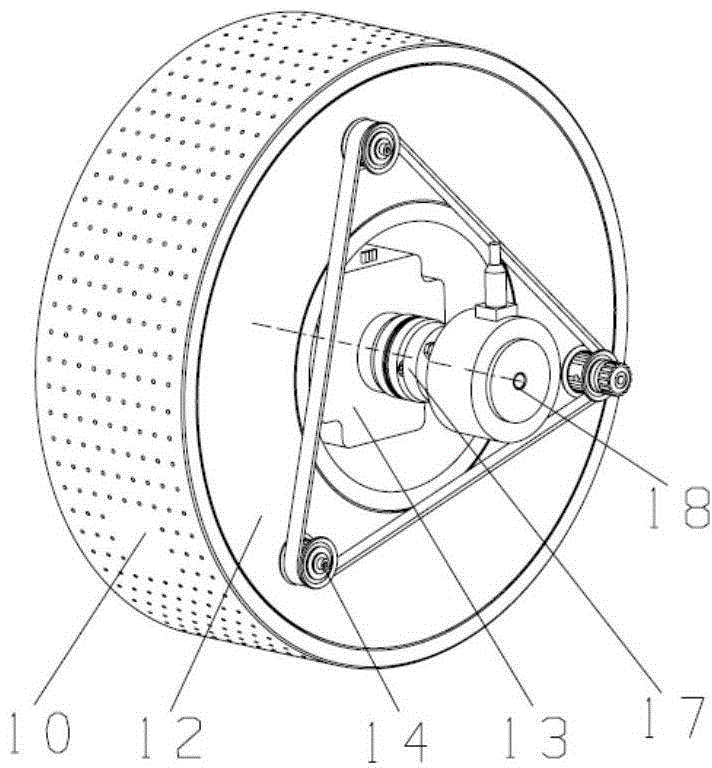

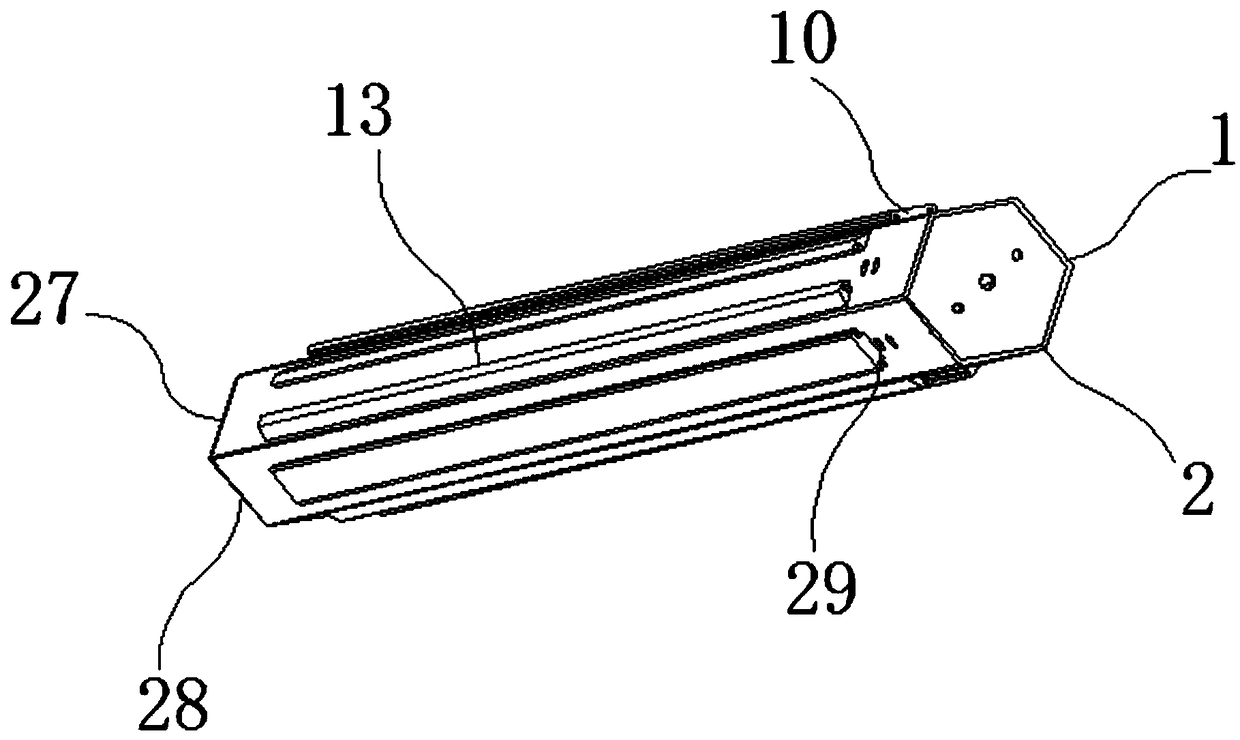

Multi-degree-of-freedom mechanical hand for transferring flexible film

ActiveCN104647374ACompact structureEasy to controlProgramme-controlled manipulatorGripping headsMulti degree of freedomEngineering

The invention discloses a multi-degree-of-freedom mechanical hand for transferring a flexible film. The mechanical hand comprises a pickup unit, an alpha rotating module, a gamma rotating module, an XYZ triaxial translation module, an air path distribution unit and a visual positioning unit, wherein the pickup unit has a beta rotating degree of freedom for rotation around the Y axis, and can be used for axially and circumferentially regulating a suction area; the alpha and gamma rotating modules and the XYZ triaxial translation module are used for achieving the alpha and gamma rotating degrees of freedom for the rotation of the mechanical hand around the X axis and the Z axis and a degree of freedom for translation in three directions X, Y and Z; the air path distribution unit is used for executing the switching control and the vacuum degree detection of each vacuum air path in the pickup unit; the visual positioning unit is used for the position and angle detection of the flexible film in an XY plane and the position detection of the flexible film in the Z axis. According to the mechanical hand, the space attitude, the transfer force and the suction interval of the mechanical hand can be automatically regulated to highly accurately suck and transfer the flexible film according to the characteristics, the size and the position of the flexible film.

Owner:HUAZHONG UNIV OF SCI & TECH

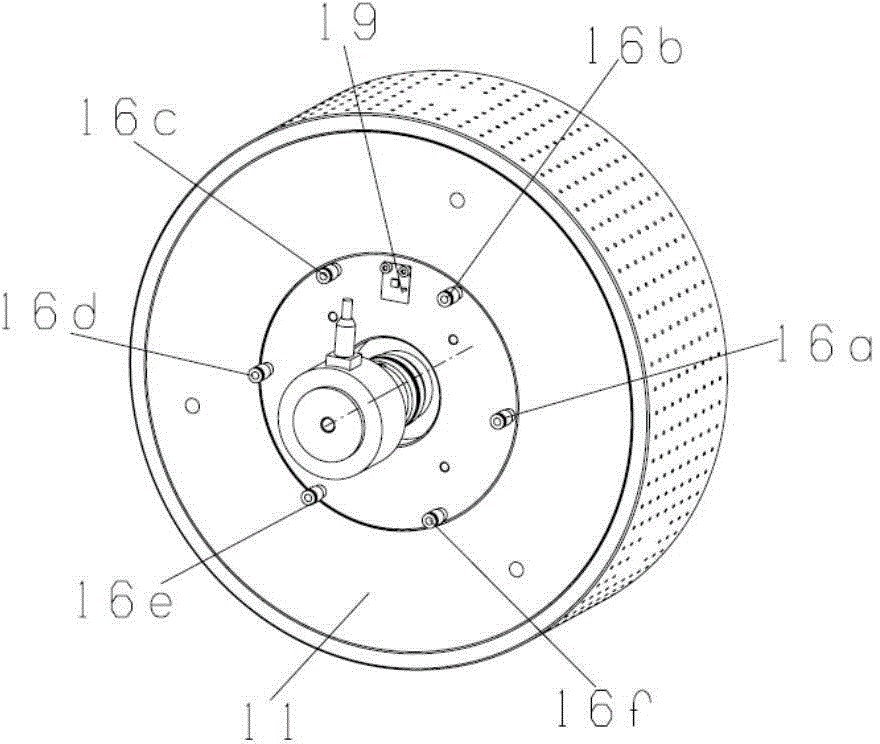

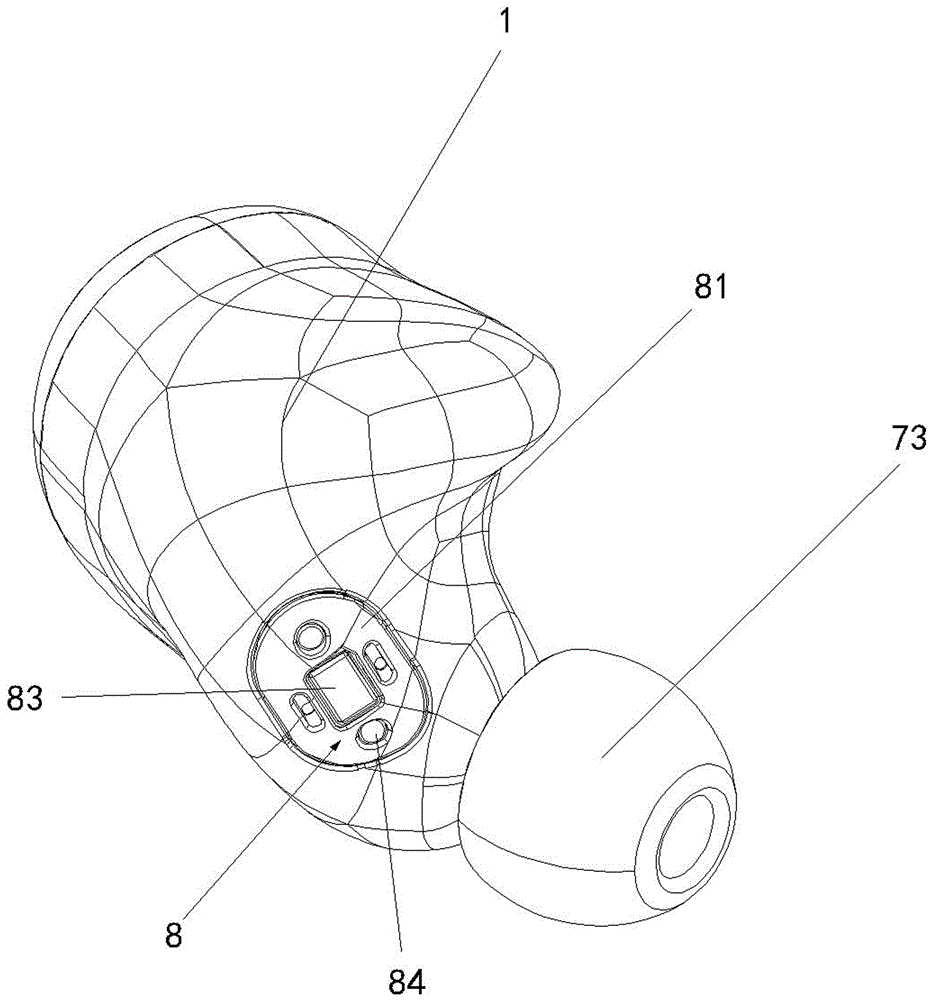

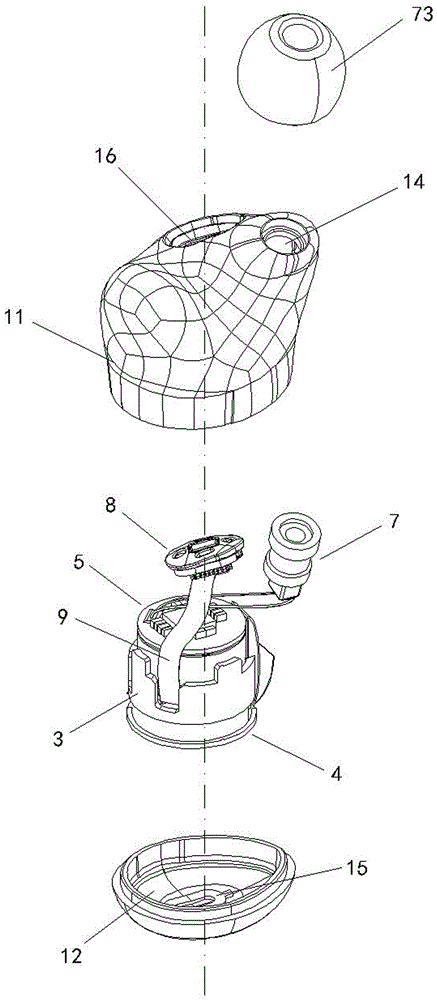

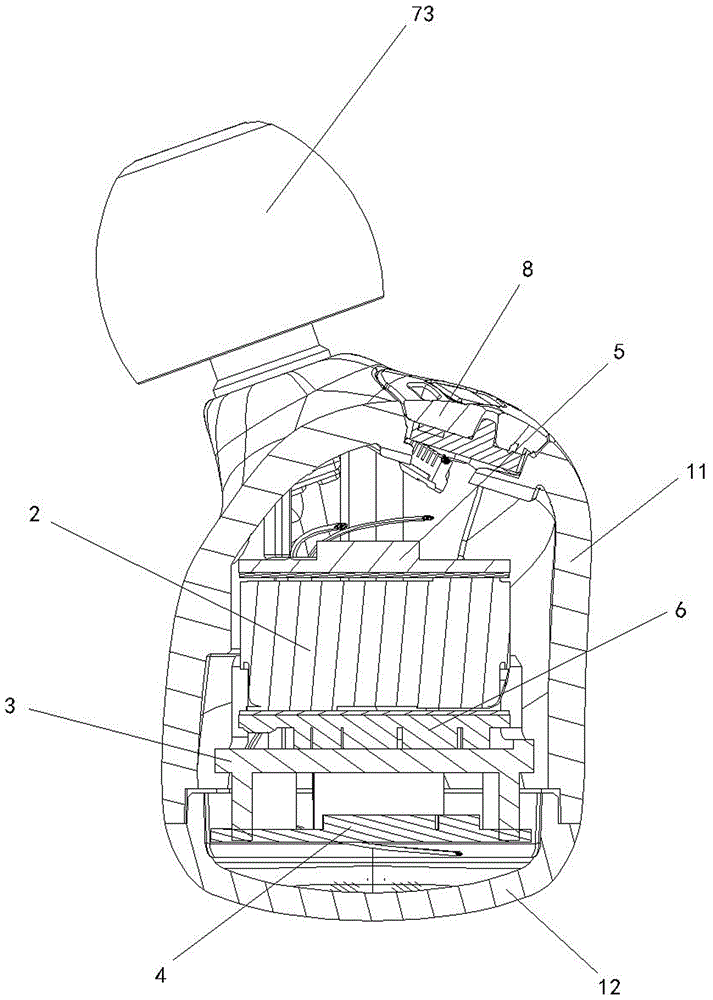

Wireless headset

ActiveCN105872887AKeep it compactMaintain reliabilityEarpiece/earphone attachmentsHuman bodyRadio frequency signal

The invention discloses a wireless headset, which comprises a case, a headset core and a battery, wherein the headset core is arranged in the case, and is electrically connected with the battery. The wireless headset is characterized by also comprising a connecting element; the headset core comprises a radio frequency module; the radio frequency module and the battery are arranged in the connecting element; after the connecting element is arranged in the case, clearance environments are formed at two sides of the radio frequency module, so that good radio frequency signals can be ensured; the electromagnetic interference can be effectively reduced; the compactedness and the reliability of the inside structure of the whole headset are maintained through the connecting element. The wireless headset has the advantages that the casing is designed into a human engineering casing identical to the human body auricle shape; after put into an ear, the wireless headset is perfectly matched with the ear; the wearing is comfortable; the wireless headset can be worn and used for a long time.

Owner:GUANGZHOU HEYGEARS INTELLIGENT TECH CO LTD

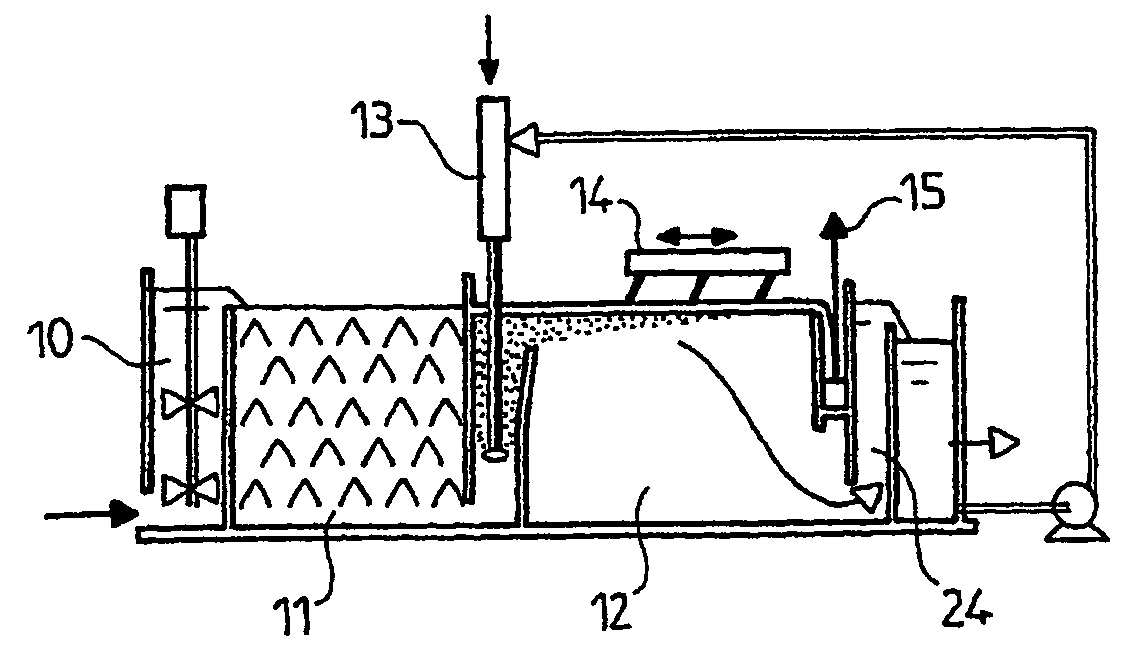

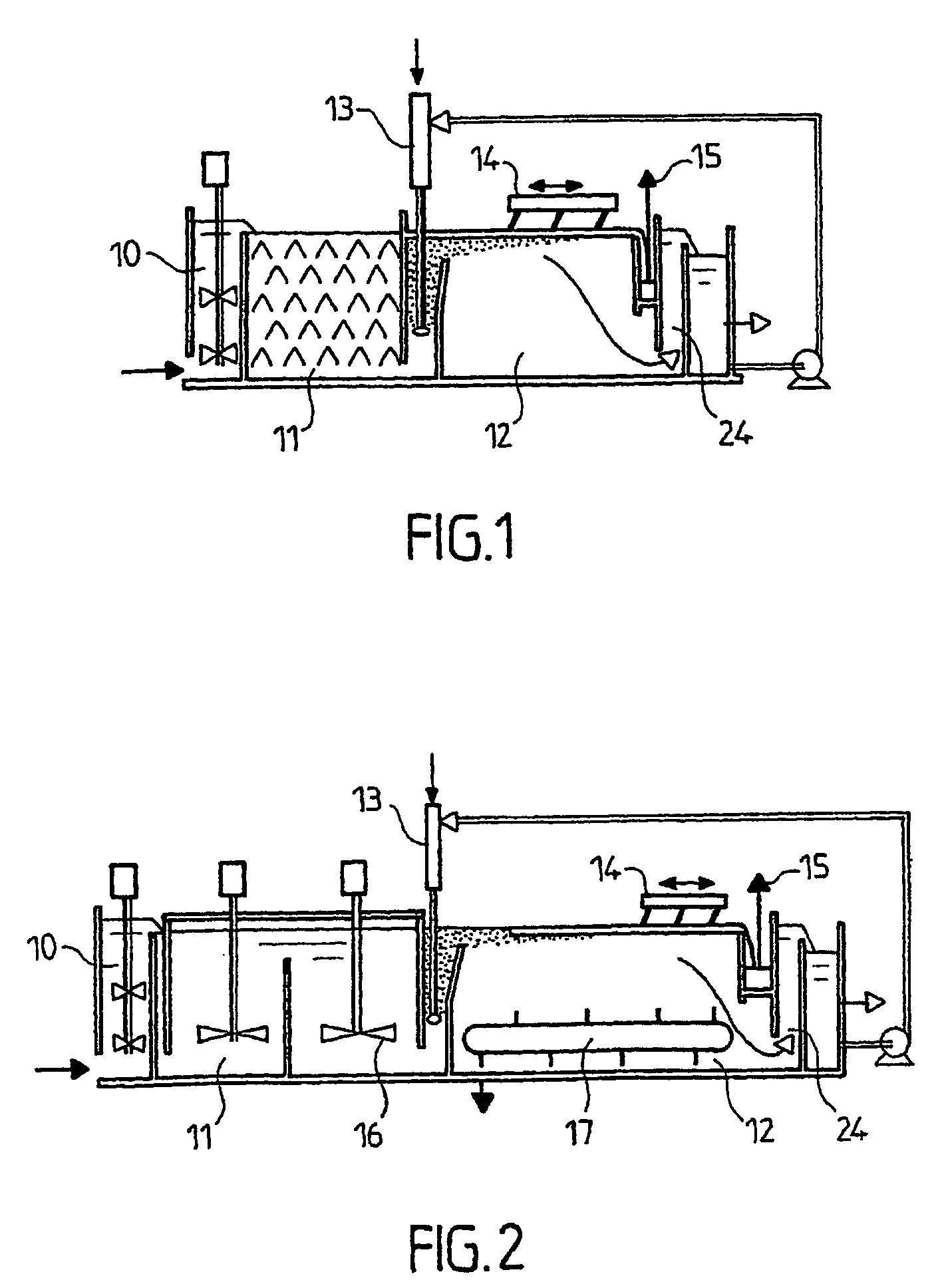

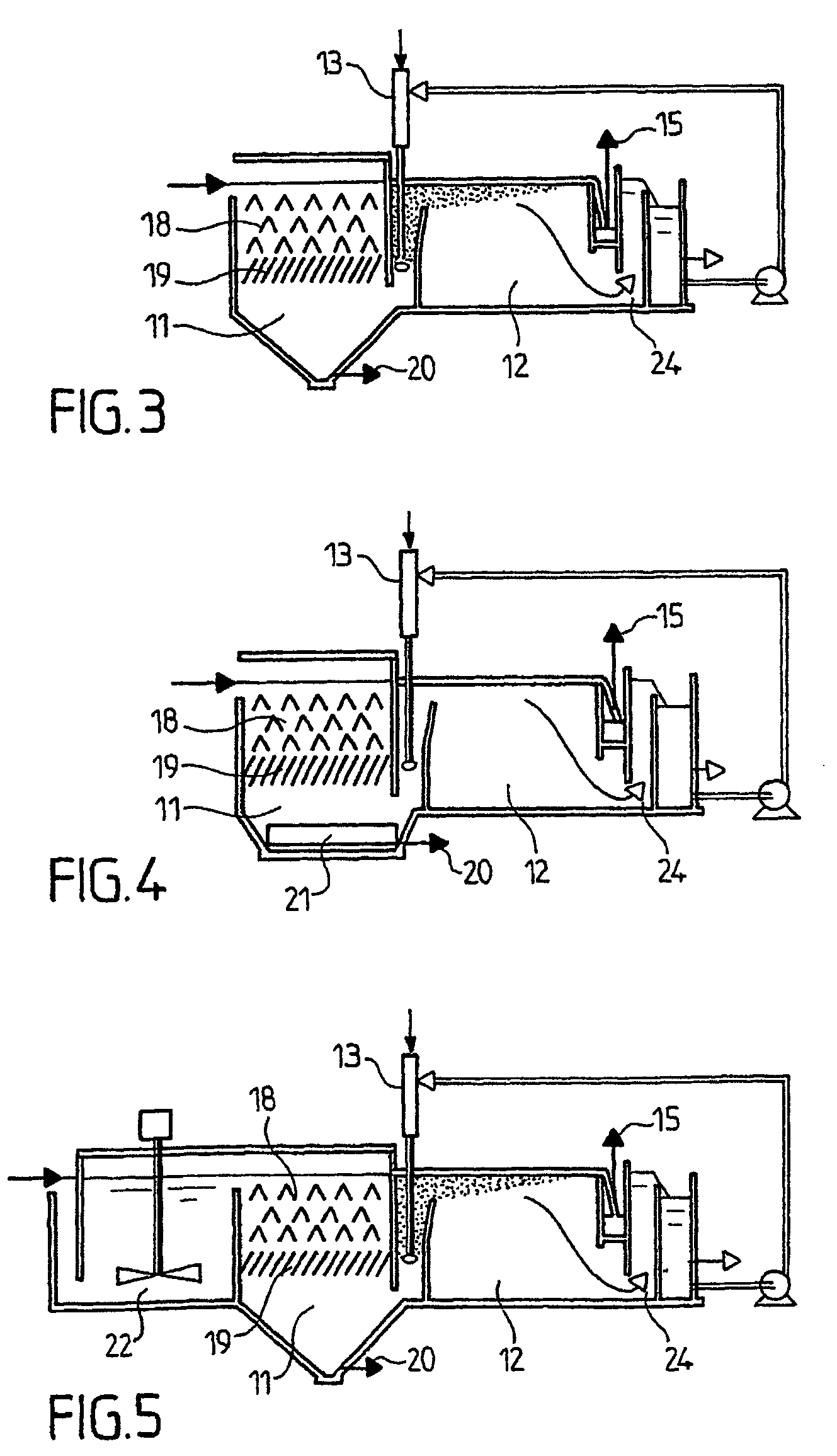

Method and device for clarification of liquids, particularly water, loaded with material in suspension

InactiveUS7175768B2Optimal qualityQuality improvementSolid sorbent liquid separationLiquid displacementContaminated waterHeavy particle

A method is disclosed for clarifying, by flotation, waters contaminated with suspended matter, wherein the clarification treatment takes place in two successive steps implemented in a single installation. The method principally involves flowing contaminated water through a downflow static flocculation step and then down through a lamellar settler separation step positioned directly below the downflow static flocculation step, the settling rates of the heavier particles of the lamellar settler separation step removing heavier particles from the water retained during the static flocculation / lamellar separation step being less than or equal to the settling rates of the floatable particles. The water which has passed through the static flocculation / lamellar settler separation step is then subjected to a flotation step which removes the light particles in the water of which the settling rate is lower than a flotation cutoff threshold.

Owner:ONDEO DEGREMONT INC

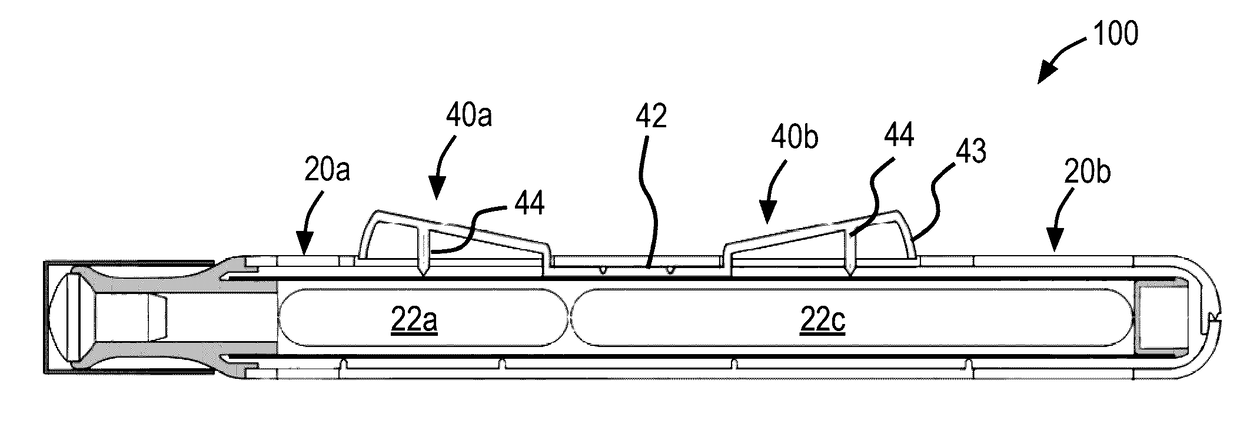

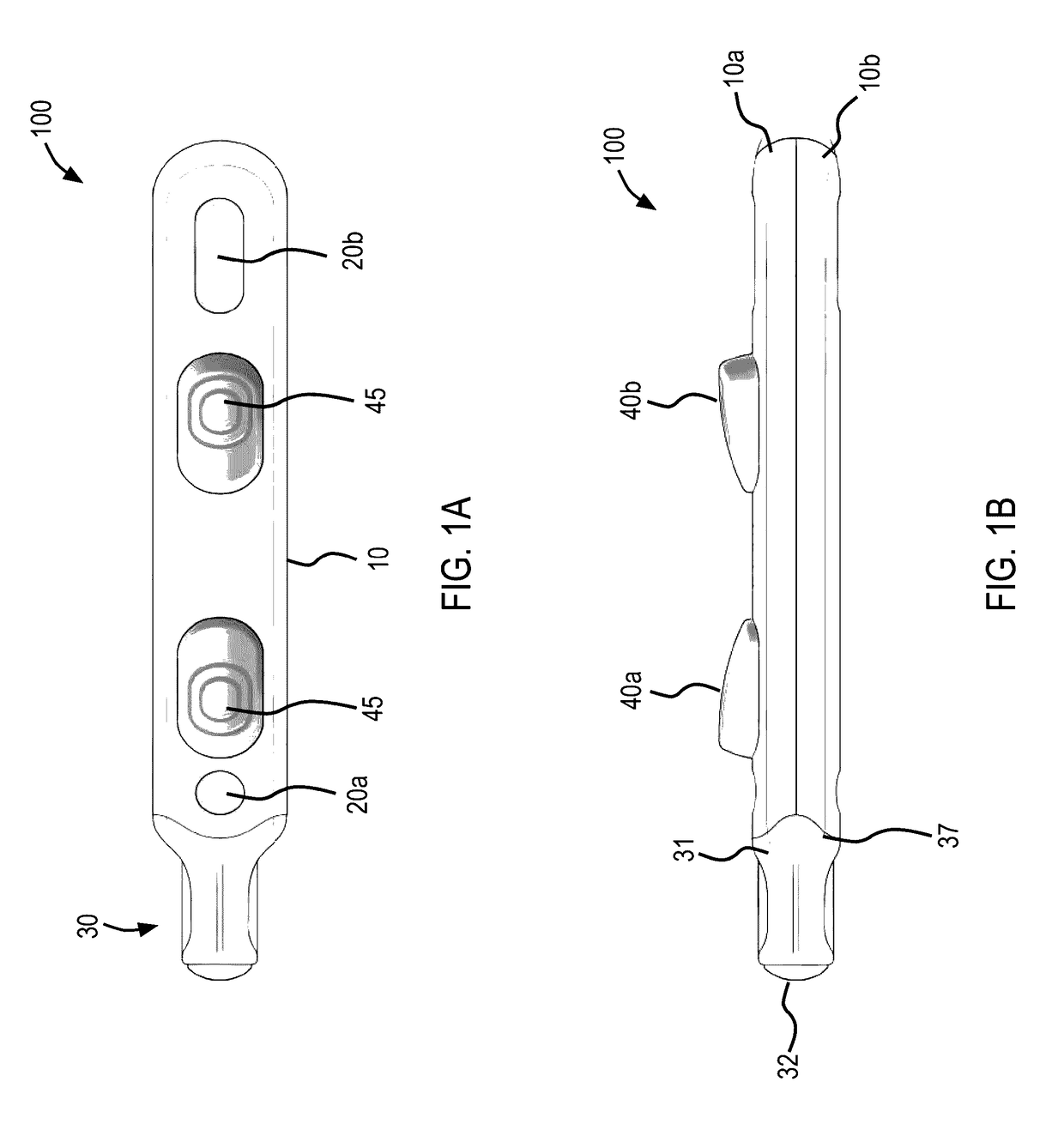

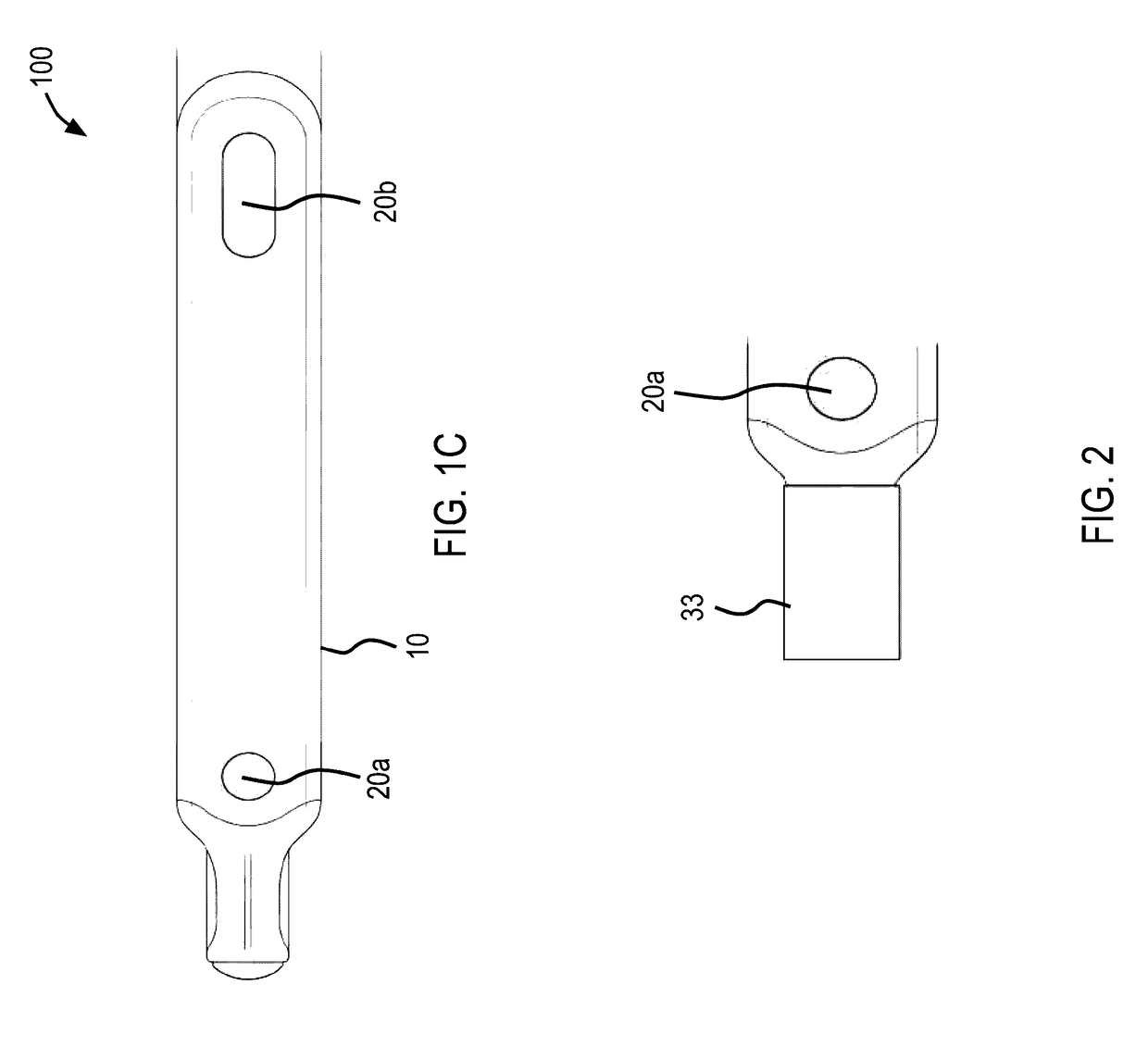

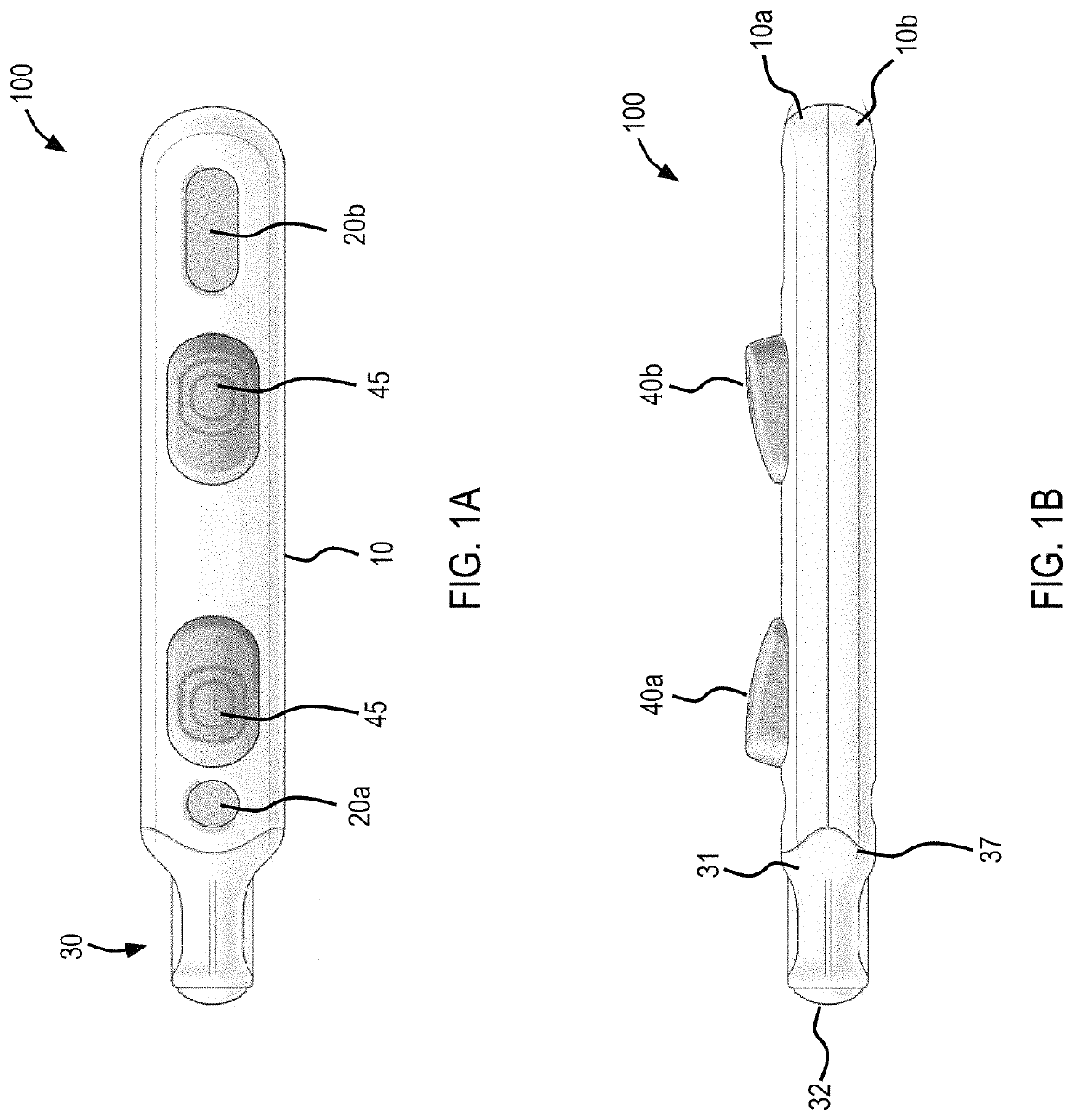

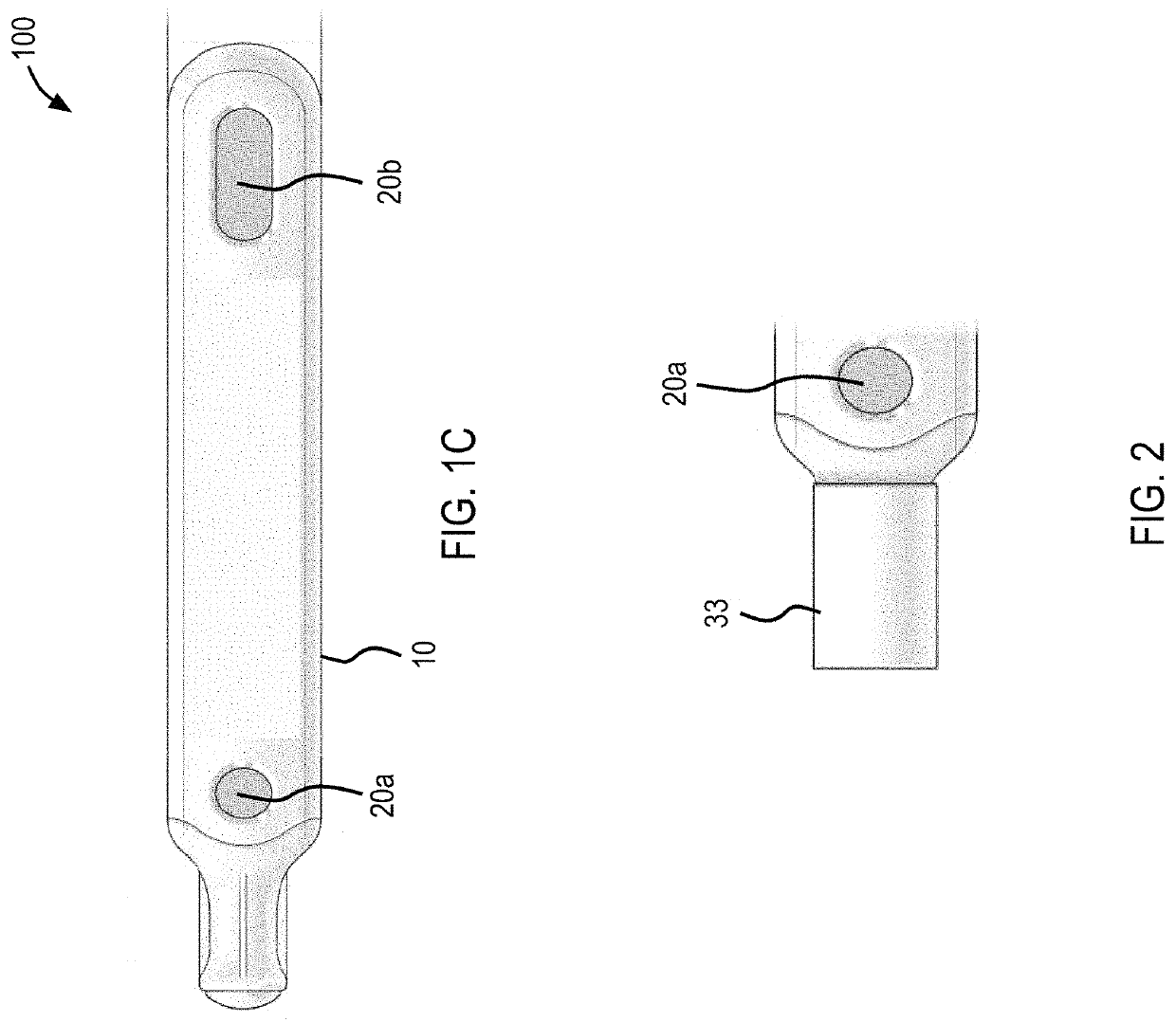

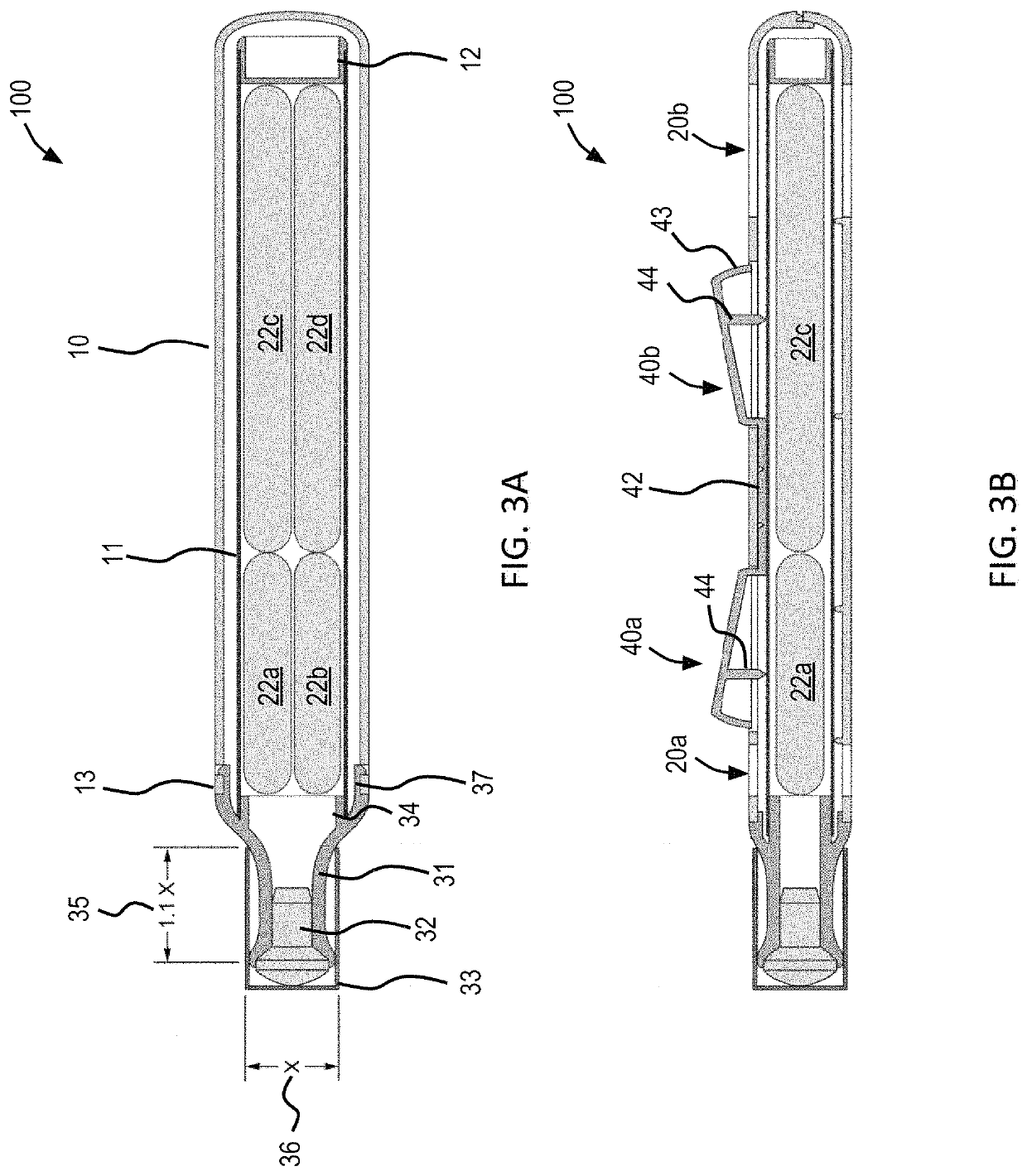

Method and apparatus for applying a topical solution

ActiveUS20170157379A1Reduce the possibilityUneven applicationEnergy modified materialsPharmaceutical containersBiological activationBiomedical engineering

Owner:DUSA PHARMA INC

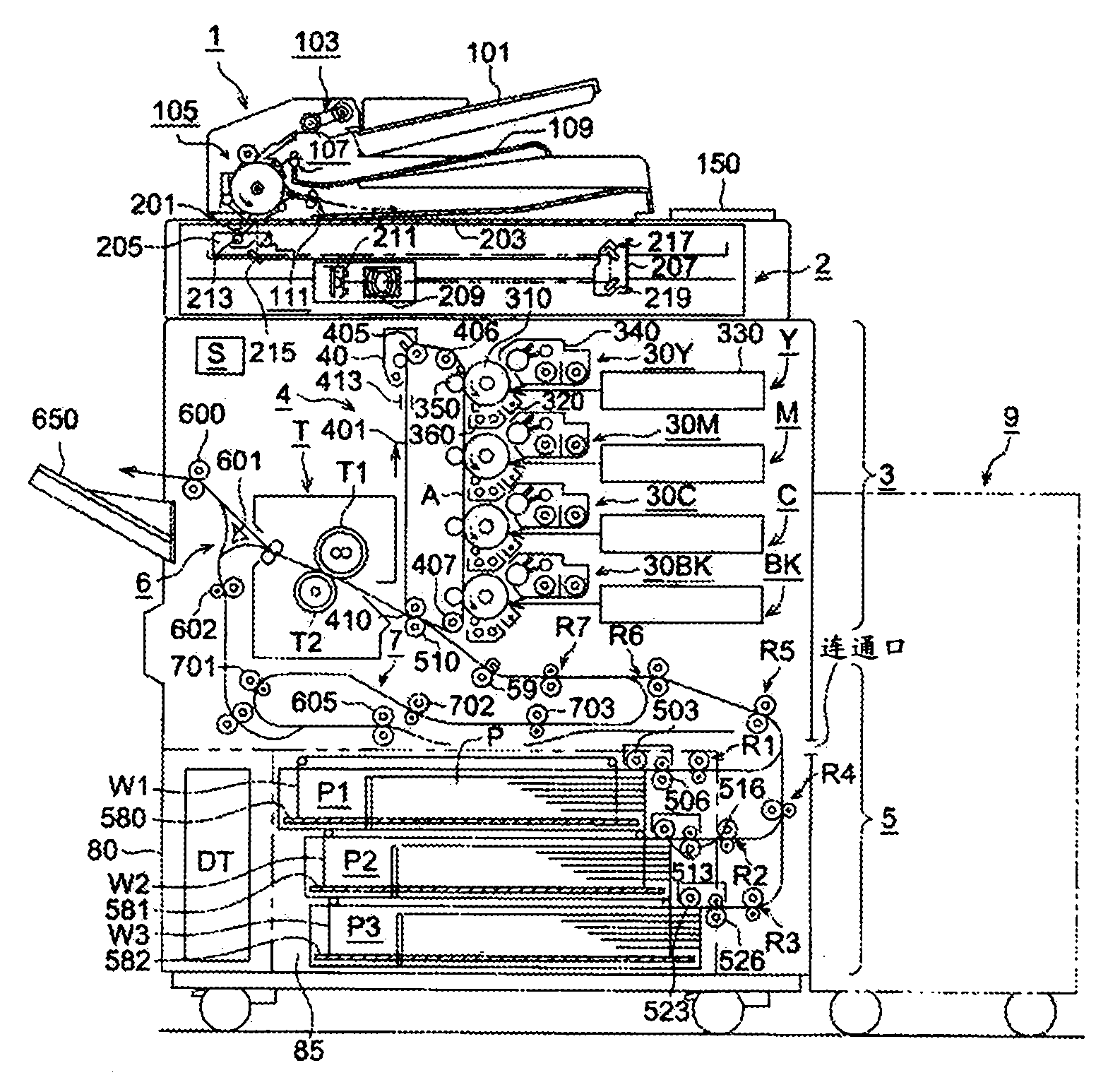

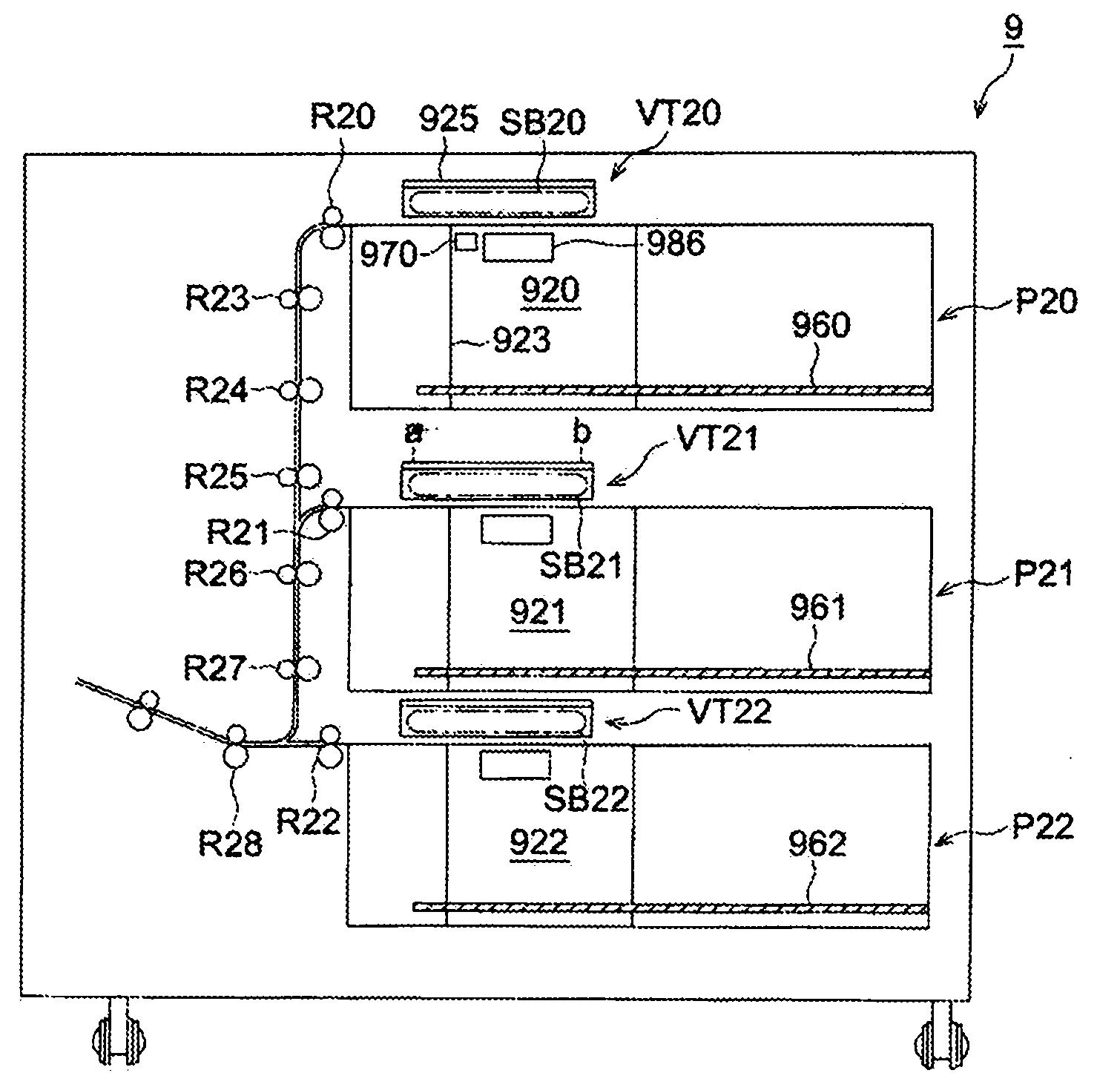

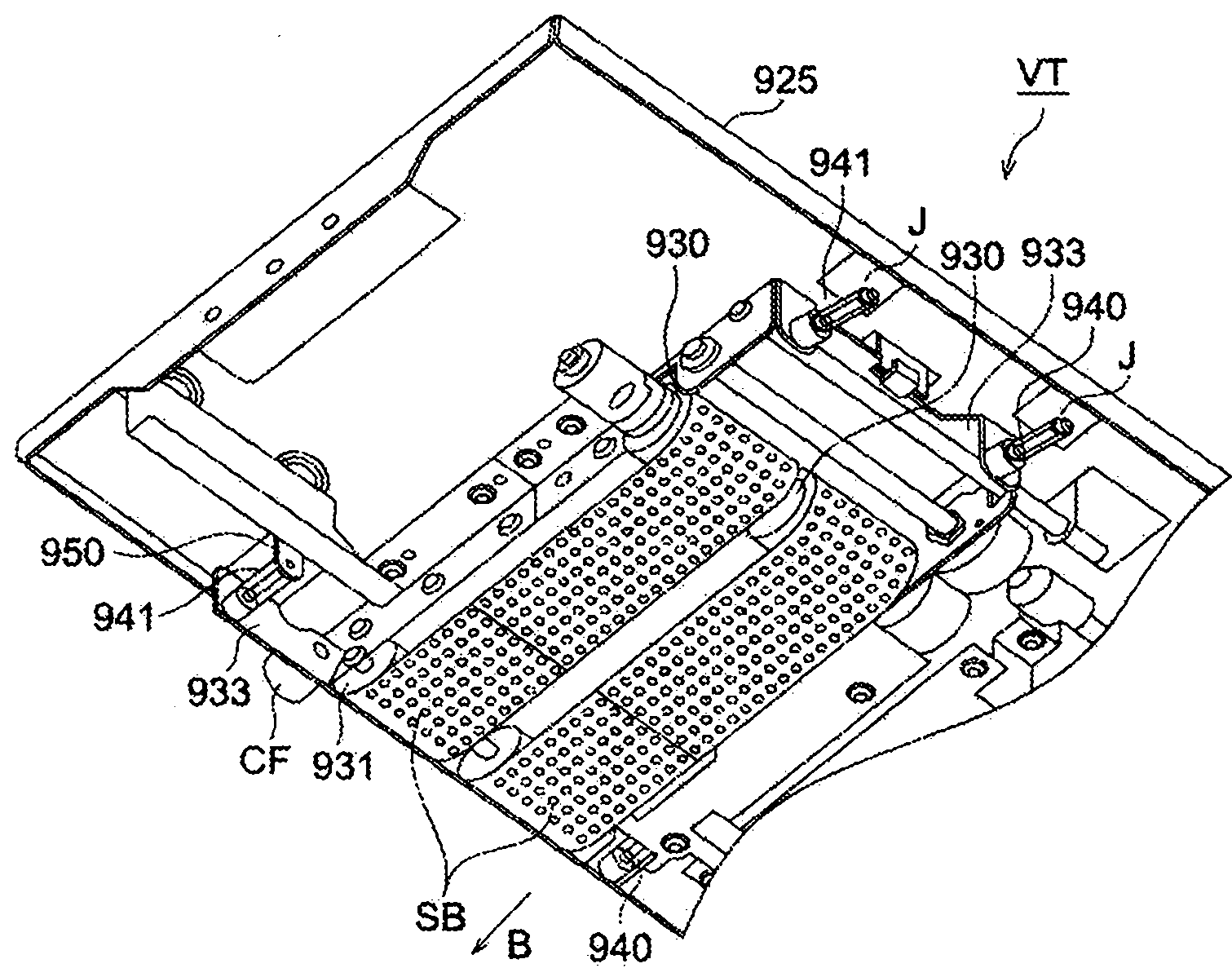

Sheet feeder and image forming apparatus

ActiveCN101910031AEasy to control upper limit positionSimple compositionArticle feedersArticle separationIntermediate stateEngineering

A sheet feeder comprising a sheet receiving section (P20) having an elevating / lowering plate (960), a member (920) for regulating the sides of sheets, an air blowing section (986) for blowing air toward the sides of sheets at upper levels out of the sheets received in the sheet receiving section, a sheet suction-conveyance section (VT20) installed above the sheet receiving section with a gap kept from the uppermost sheet of the sheets received in the sheet receiving section, a reflective sensor (970) for detecting the upper limit position of stacked sheets received in the sheet receiving section, and a control section for performing control to elevate the elevating / lowering plate when an output from the reflective sensor indicates an intermediate state provided between a sheet brought into a floating state by an air flow which is blown from the air blowing section, and a sheet maintaining the stacked state. As a result, stabilized sheet-feeding can be ensured even if a thick sheet of a small size is used, and the upper limit position of sheets can be controlled by a simple constitution.

Owner:KONICA MINOLTA BUSINESS TECH INC

Method and apparatus for applying a topical solution

ActiveUS10814114B2Reduce the possibilityUneven applicationEnergy modified materialsPharmaceutical containersMechanical engineeringAmpoule

Owner:DUSA PHARMA INC

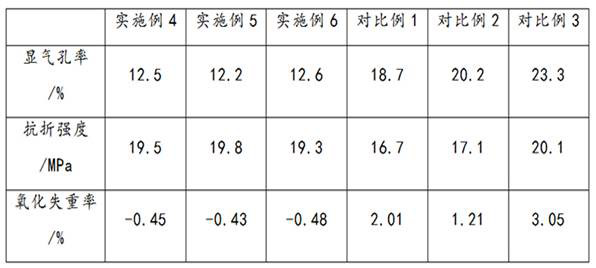

Low-water-absorption foamed cement

InactiveCN109265112AHigh strengthSlow down the rate of condensationCeramicwareFoaming agentFatty alcohol

The invention discloses low-water-absorption foamed cement. The low-water-absorption foamed cement is prepared from the following raw materials in parts by weight: 100 parts of cement, 1.8 to 2 partsof a foaming agent, 0.6 to 0.8 part of a foam stabilizer, 10 to 12 parts of a waterproof agent, 0.02 to 0.04 part of a naphthalene water reducer, 0.4 to 0.6 part of a reinforcing agent, and 45 to 50 parts of water, wherein the foaming agent is lauryl sodium sulfate and fatty alcohol polyoxyethylene ether sodium sulfate. The low-water-absorption foamed cement is good in waterproof performance, lowin water absorption rate and good in strength.

Owner:怀宁建国混凝土制品有限责任公司

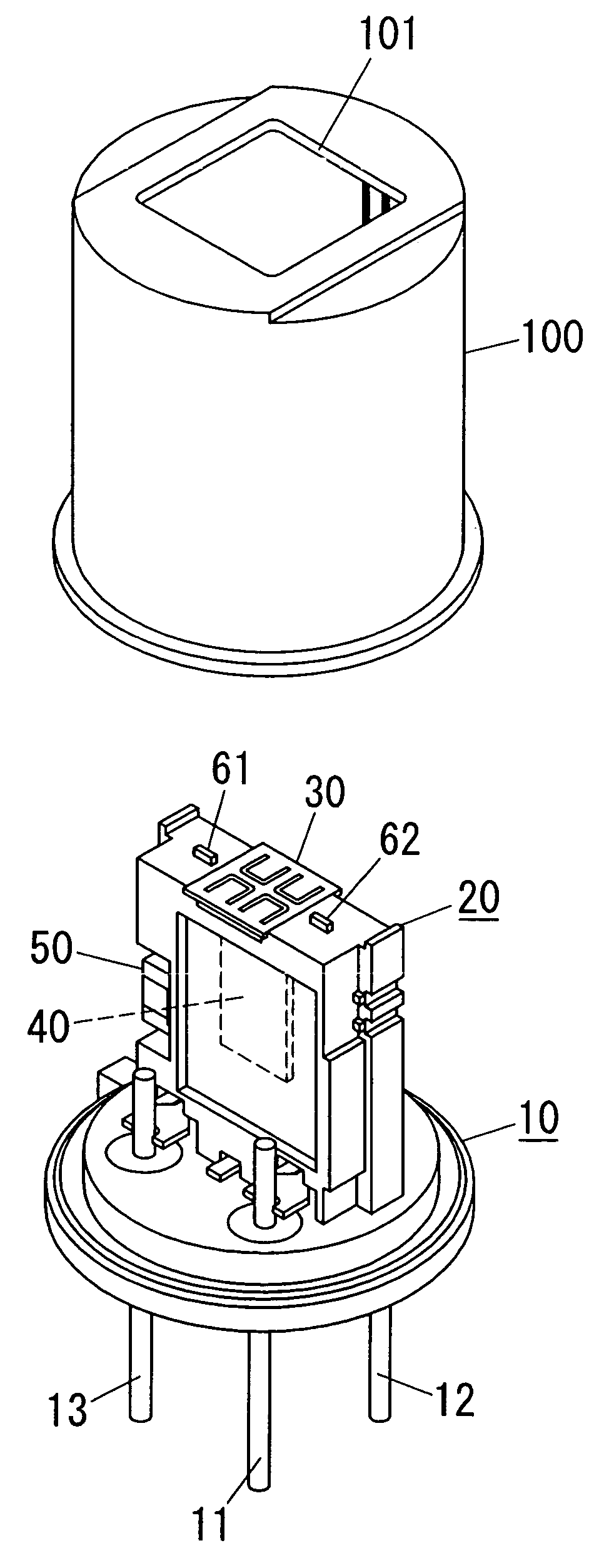

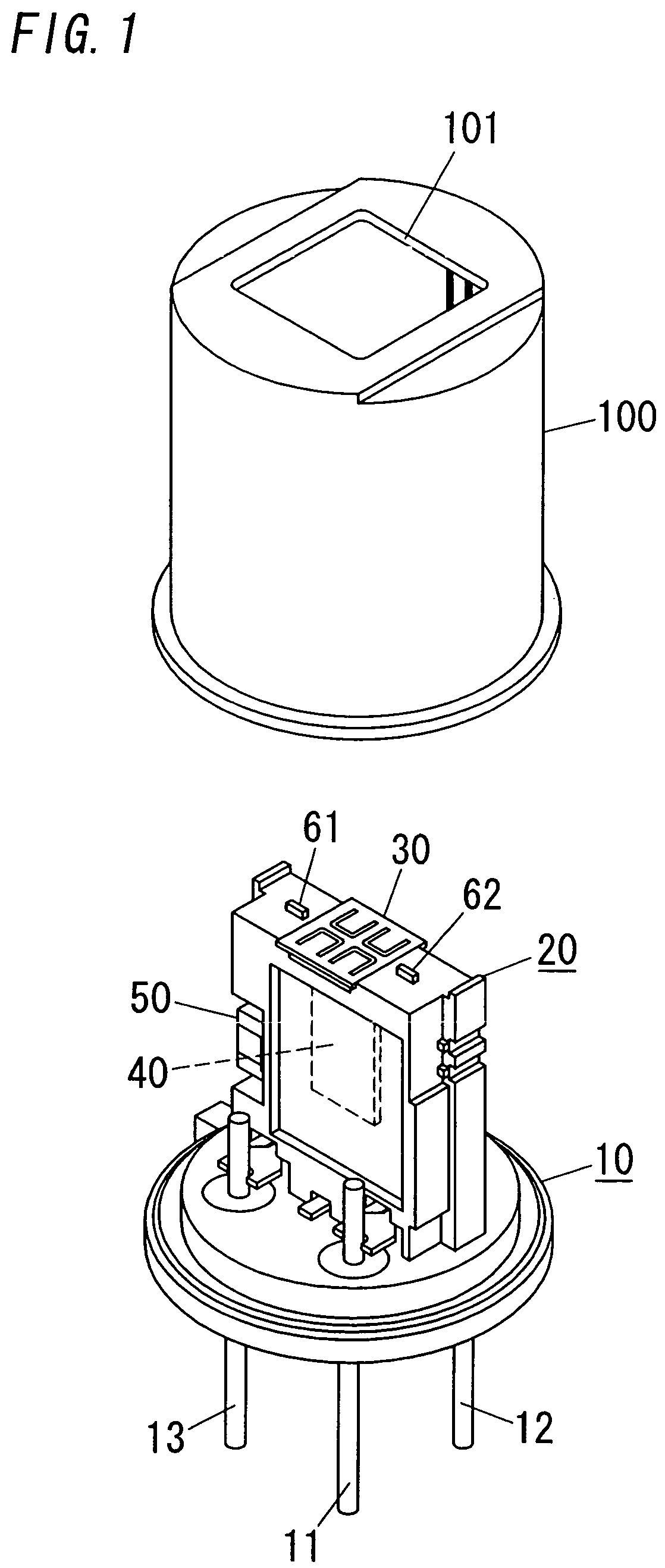

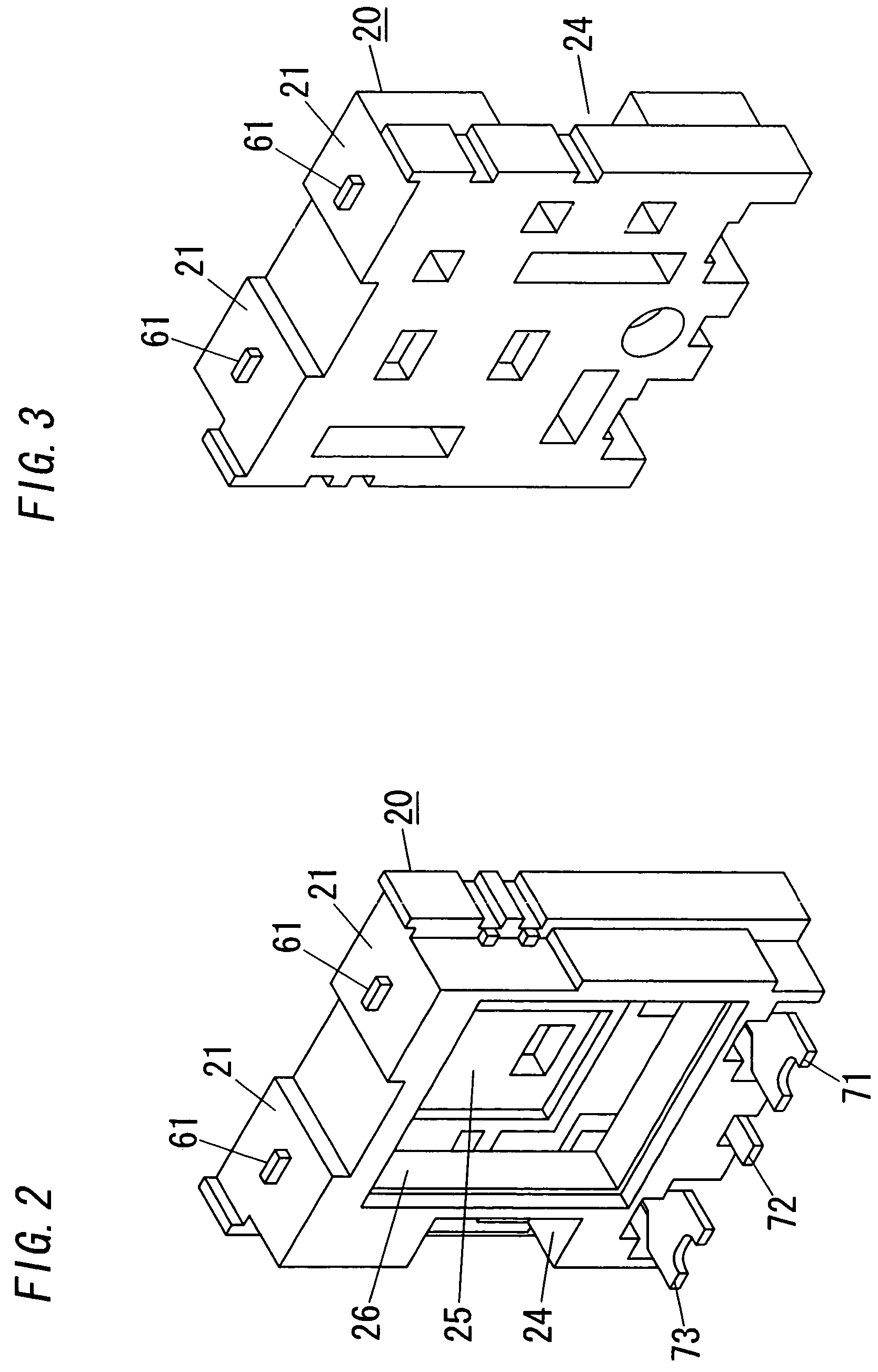

Infrared sensor package

InactiveUS7157709B2Low costSimple manufacturing processMaterial analysis by optical meansPyrometry using electric radation detectorsElectrical conductorPlastic materials

An infrared sensor package has a dielectric support which is molded from a plastic material to have a sensor mount for securing a pyroelectric element as well as an IC mount for securing an IC chip that processes a signal from the pyroelectric element. The support is molded over to be integral with metal parts. The metal parts include sensor conductors for interconnection of the pyroelectric element with the IC chip, and I / O conductors for interconnection of the IC chip with I / O pins. The sensor conductors as well as the I / O conductors are both molded into and integrally with the dielectric support.

Owner:MATSUSHITA ELECTRIC WORKS LTD

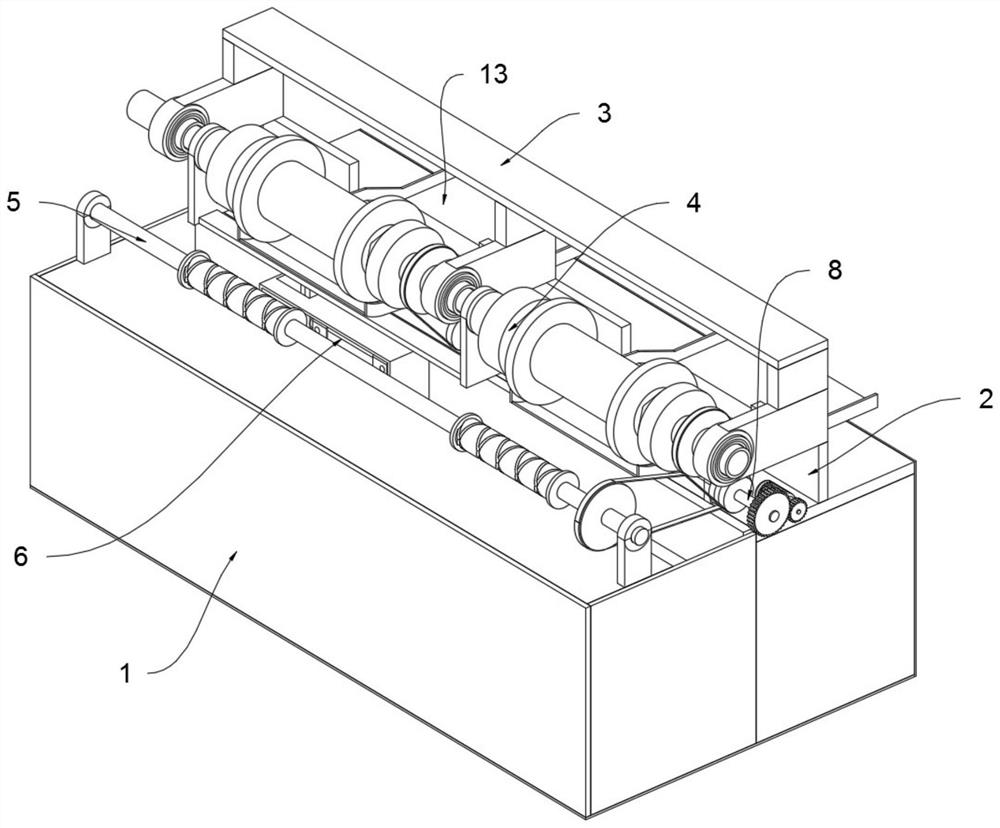

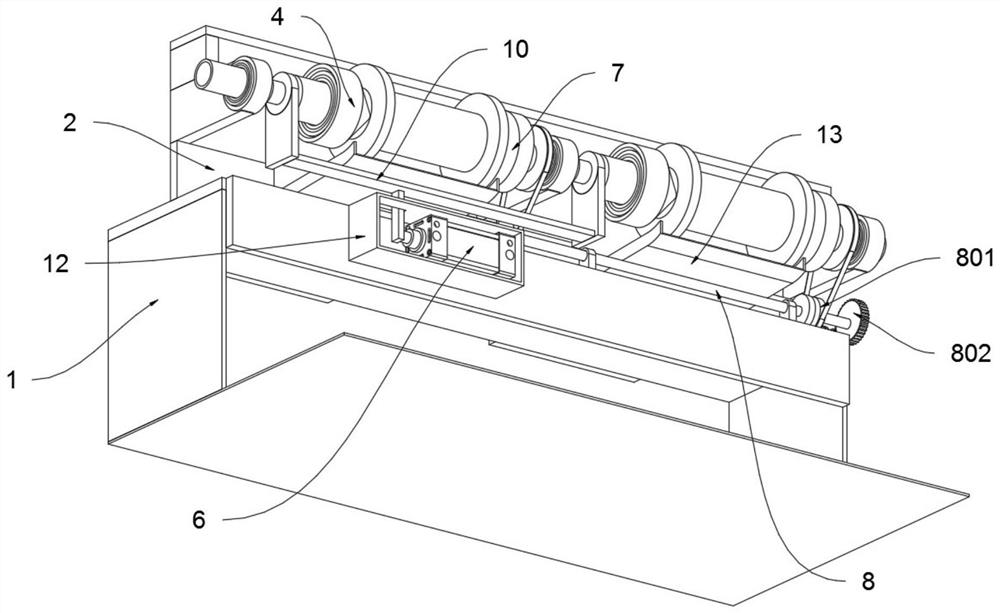

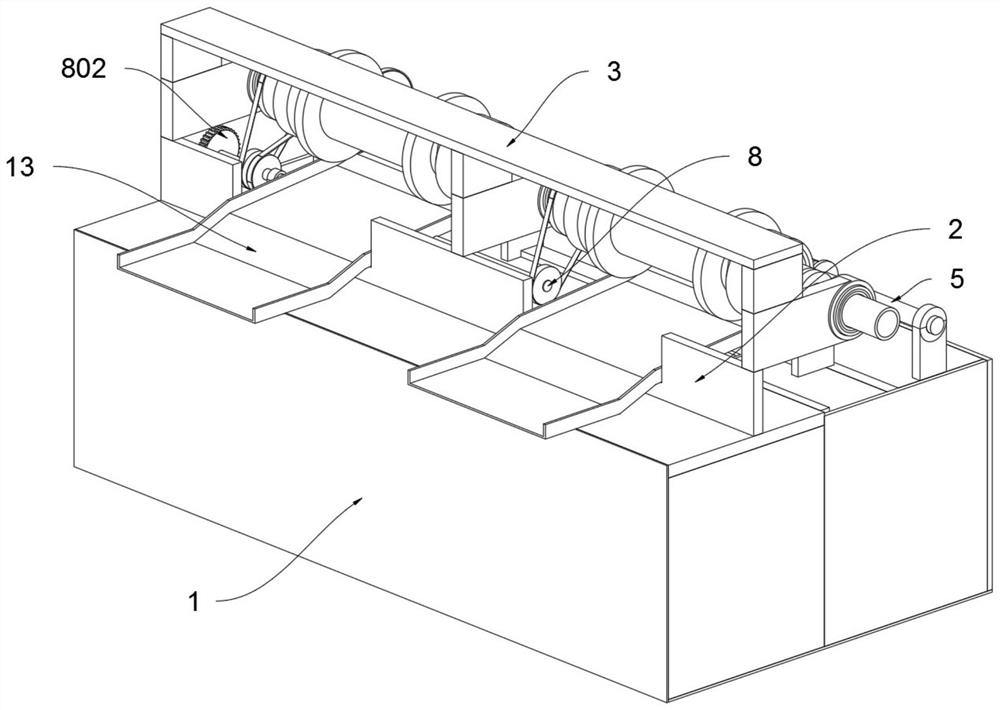

Textile machinery for manufacturing cross-wound bobbin

The invention provides textile machinery for manufacturing a cross-wound bobbin. The textile machinery comprises a winding machine body, an upper support, a reciprocating lead screw, an air cylinder,a fixing ejector block, a transmission shaft, a driving part, a movable guide cylinder, a placement frame and a discharging plate; a rotating shaft frame is fixedly connected to the rear portion of the upper surface of the winding machine body; the upper support is fixedly connected to the upper portion of the rotating shaft frame; a shaft of the fixing ejector block is connected to the front portion of the rotating shaft frame through a bearing in a rotating mode; the reciprocating lead screw is connected to the front side of the upper surface of the winding machine body through a bearing ina rotating mode; and the air cylinder is fixedly connected to the front surface of the winding machine body through screws, and an output shaft of the air cylinder is fixedly connected to a lower connecting frame of the reciprocating frame. It is observed that compared with an existing cross-wound bobbin winding device, the textile machinery has the advantages that the automatic discharging function is added, the bobbin discharging function on a bobbin finished product is achieved by adjusting the distance between clamping devices on the two sides, the manual dismounting time is saved, multi-station simultaneous production can be realized, and the production efficiency is greatly improved.

Owner:牧叶(温州)鞋业有限公司

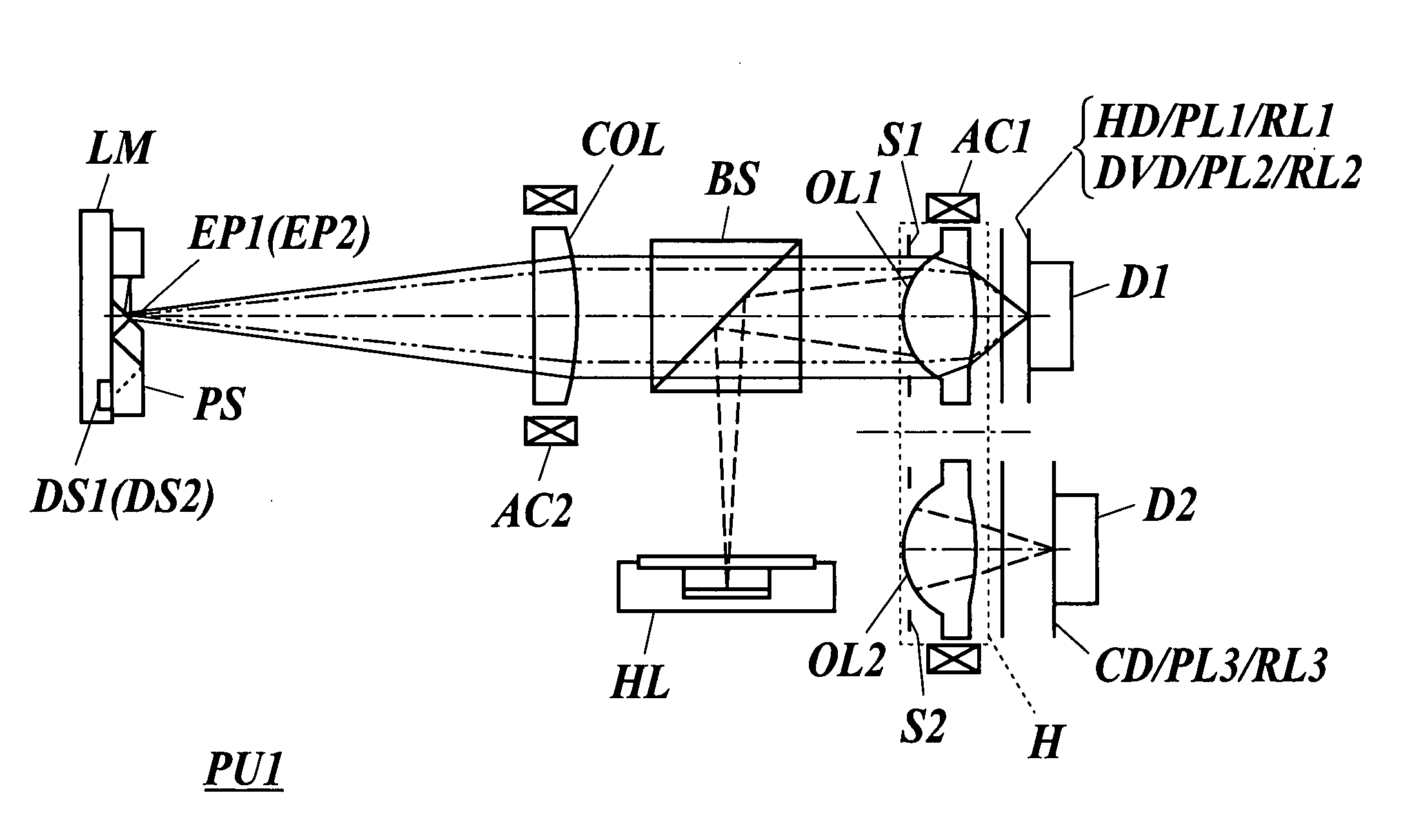

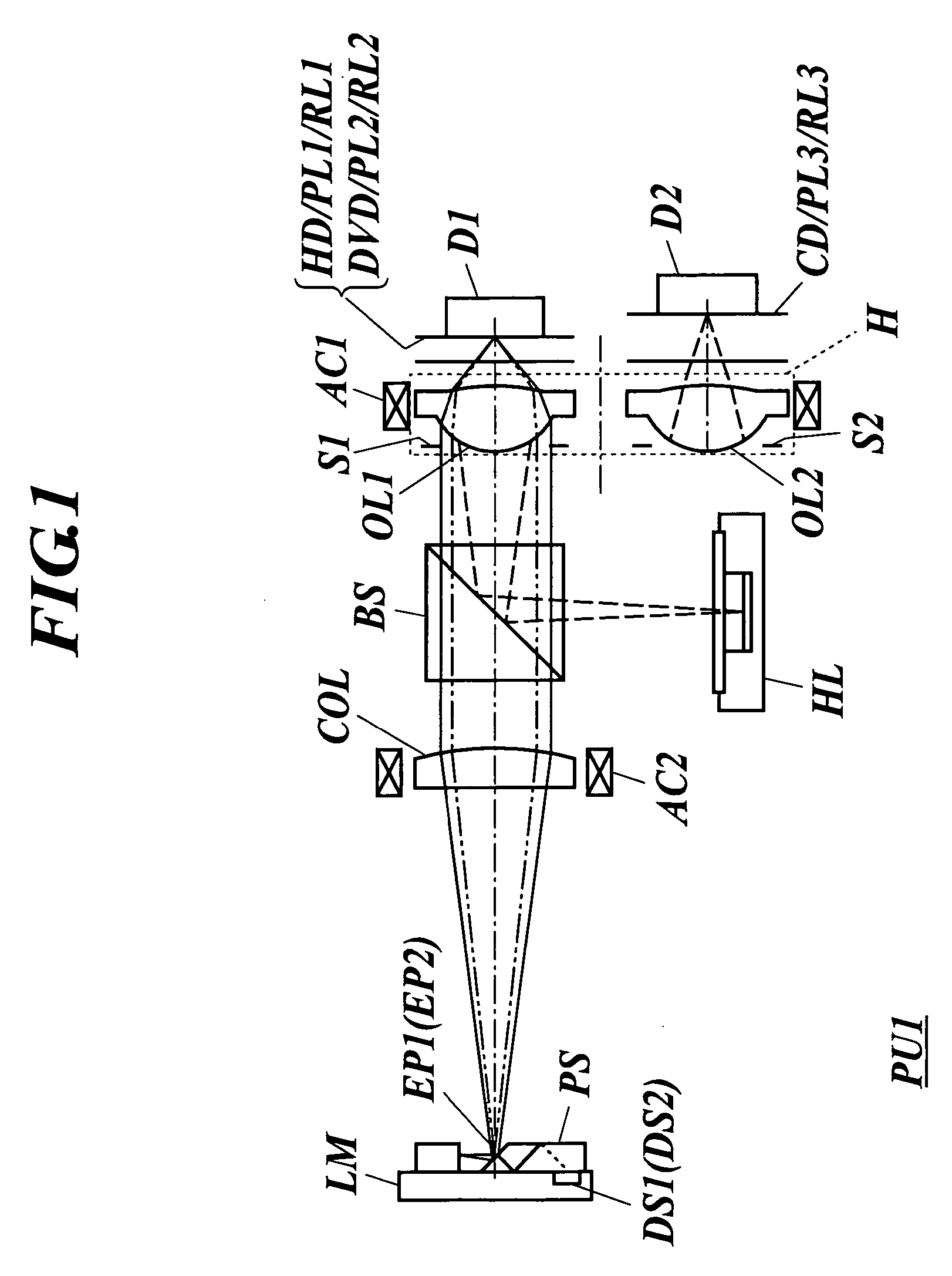

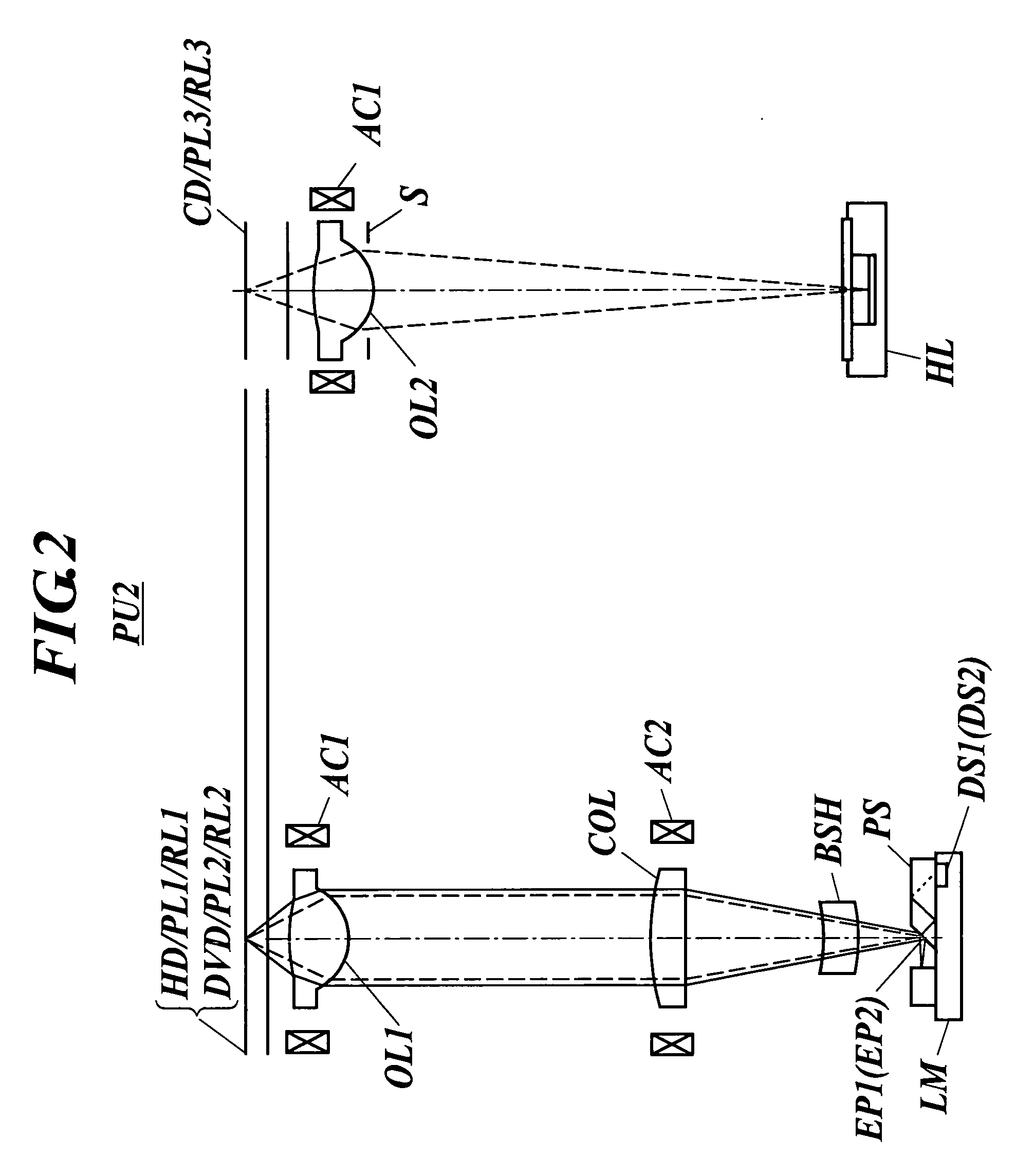

Optical pickup device

InactiveUS20060109771A1Compact structureInhibitionOptical beam sourcesRecord information storageOptical pickupLight beam

An optical pickup device, including: first, second and third light sources performing recording and / or reproduction of information for information recording surfaces of first, second and third optical information recording medium each having a protective substrate with a thickness t1, t2 and t3, respectively; a first objective optical system for guiding at least the first beam to the information recording surface of first optical information recording medium; second objective optical system provided separately from the first objective optical system, for guiding at least the third beam to information recording surface of the third optical information recording medium; and at least one light receiving element for detecting light reflected on the information recording surfaces of the first to third optical information recording media.

Owner:KONICA MINOLTA OPTO

Position controller for removable optical element

InactiveUS8830583B2Improve accuracyKeep it compactTelevision system detailsPrintersRotational axisOptical axis

A position controller for a removable optical element in an optical system includes an advancing / retracting ring; a removable optical element holding member supported by the advancing / retracting ring and rotatable about a first rotational axis between an insertion position on the optical axis and a removed position; an insertion holder which holds the removable optical element holding member at the insertion position; a removal drive member supported by the advancing / retracting ring and rotatable about a second rotational axis between an insertion allowance position and a forced removing position; and an insertion / removal controller. A rotational radius from the second rotational axis to a contact point between the removable optical element holding member and the removal drive member is greater than a rotational radius from the first rotational axis to the contact point.

Owner:HOYA CORP

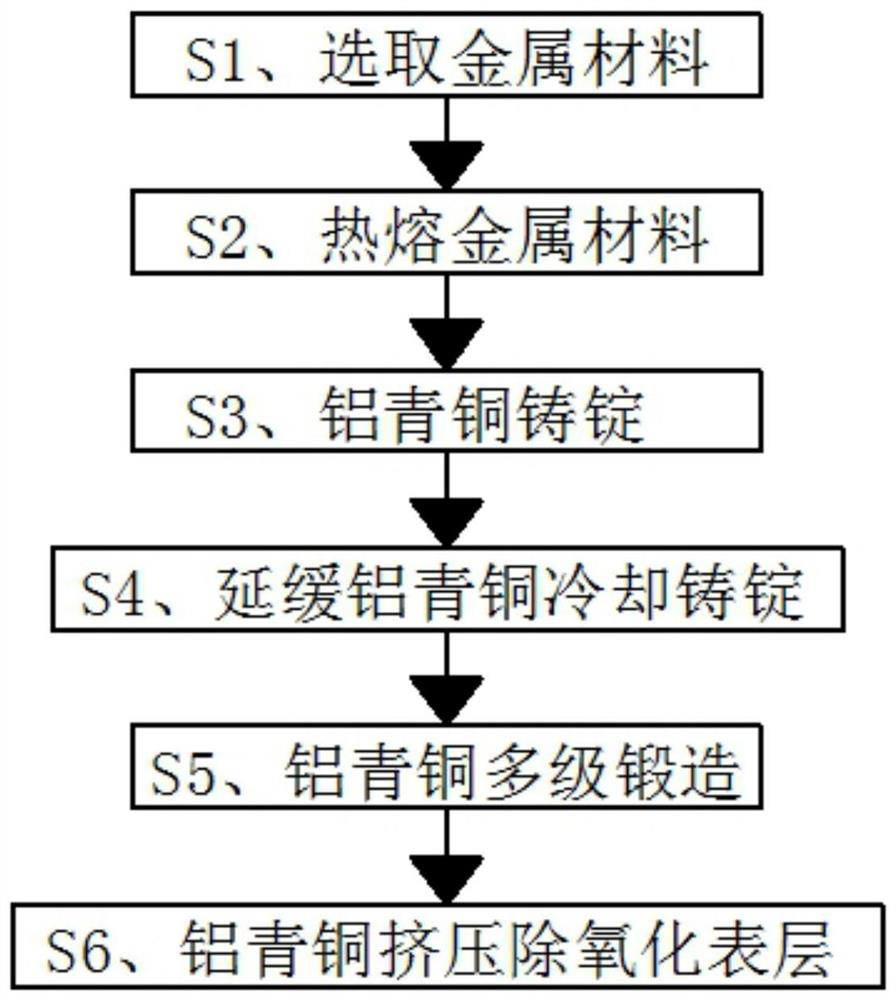

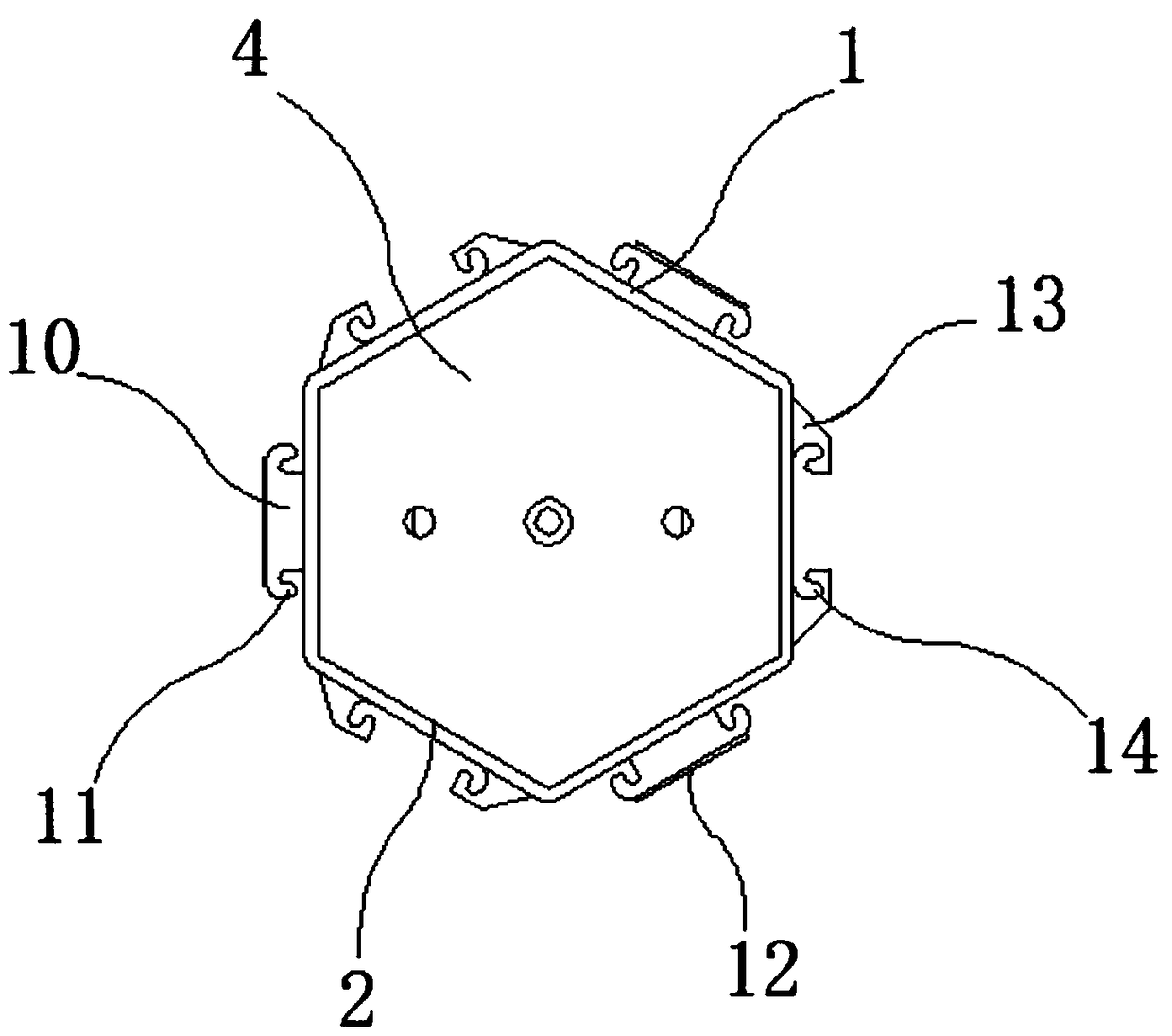

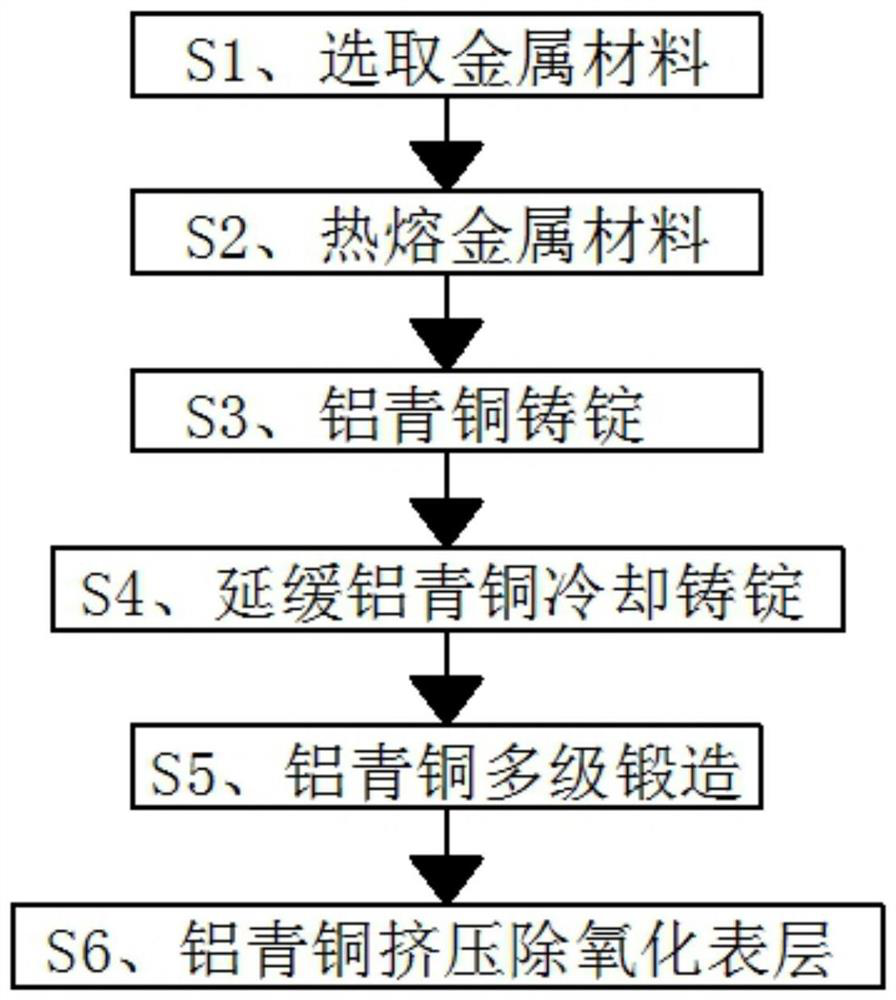

Method for improving mechanical property of aluminum bronze

The invention discloses a method for improving the mechanical property of aluminum bronze. The method comprises the following steps that S1, a metal material is selected; S2, the metal material is subjected to hot melting; S3, aluminum bronze ingot casting is carried out; S4, aluminum bronze cooling ingot casting is slowed; S5, aluminum bronze multistage forging is carried out; and S6, the aluminum bronze is extruded to remove an oxidation surface layer. According to the method, chromium, titanium and niobium are added into the aluminum bronze, so that the corrosion resistance of the aluminumbronze is increased; zinc and nickel are added, so that the glossiness of the surface of the aluminum bronze is increased; alkaline earth metal compounds are added in the hot melting process of an aluminum bronze raw material so that slag in an aluminum bronze solution can be adsorbed and precipitated at the bottom of a smelting furnace, and then the slag in the aluminum bronze can be filtered andremoved; when the aluminum bronze solution is not subjected to ingot casting forming, a covering agent is added, so that the connection of the aluminum bronze is achieved and the fluidity of the surface of the aluminum bronze is kept; and multistage forging and quenching are adopted, so that the compactness and stability of an aluminum bronze structure are kept.

Owner:贵溪骏达特种铜材有限公司

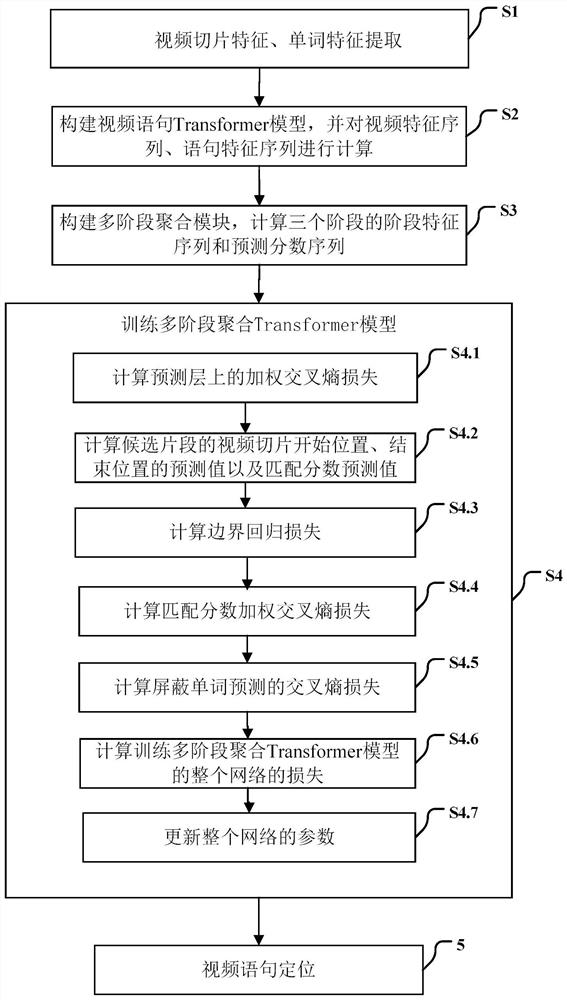

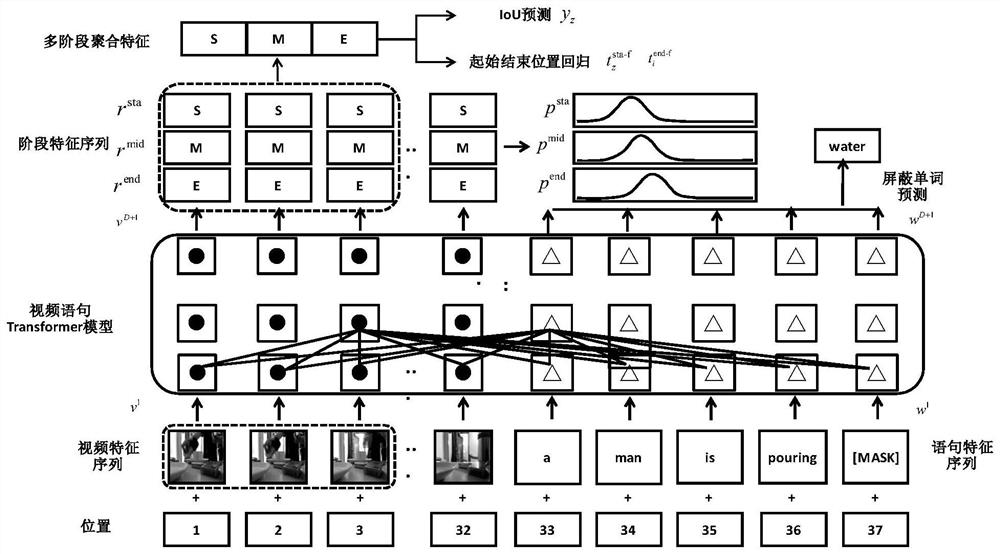

Video statement positioning method based on multi-stage aggregation Transformer model

ActiveCN112488063AKeep it compactMaintain efficiencyCharacter and pattern recognitionNeural architecturesAlgorithmEngineering

The invention discloses a video statement positioning method based on a multi-stage aggregation Transformer model, and in the video statement Transformer model, each video slice or word can adaptivelyaggregate and align information from all other video slices or words in two modes according to the semantics of the video slice or word. Through multi-layer superposition, finally obtained video statement joint representation has rich visual language clue capture capability, and finer matching can be realized. In the multi-stage aggregation module, the stage characteristics of the starting stage,the stage characteristics of the intermediate stage and the stage characteristics of the ending stage are connected in series to form the characteristic representation of the candidate segment. Because the obtained characteristics representation captures the specific information of different stages, the method is very suitable for accurately positioning the starting position and the ending position of the video clip. The two modules are integrated together to form an effective and efficient network, and the accuracy of video statement positioning is improved.

Owner:GUIZHOU UNIV

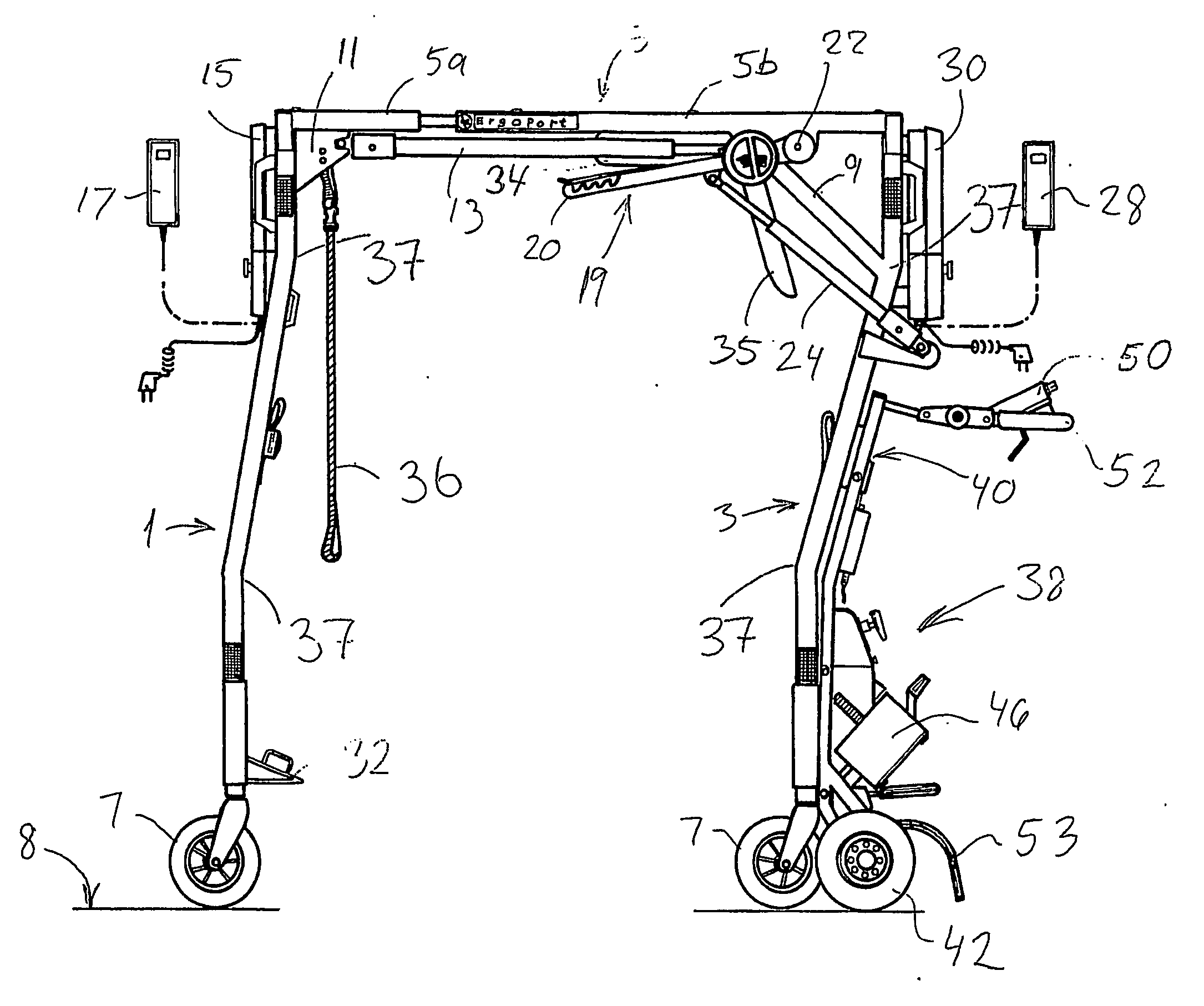

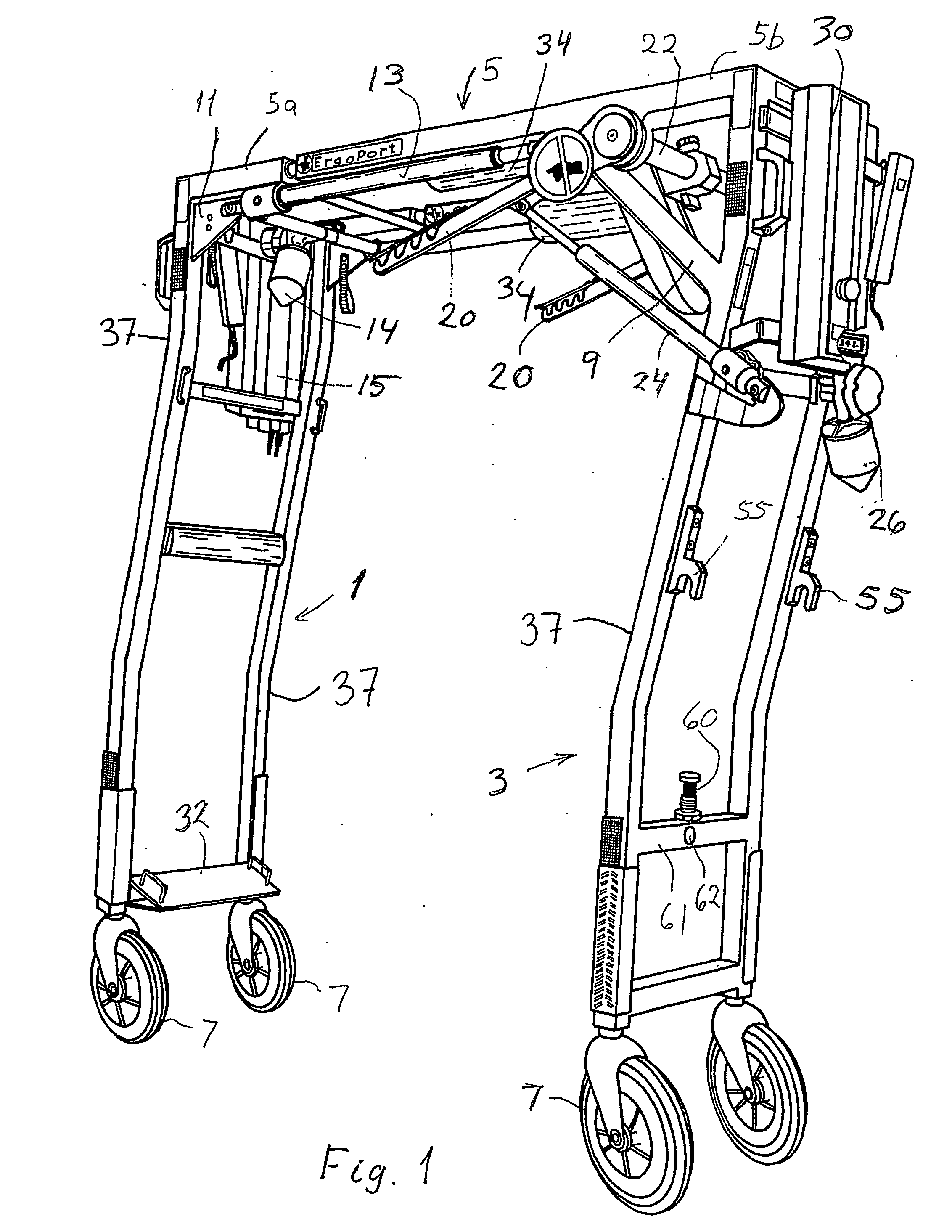

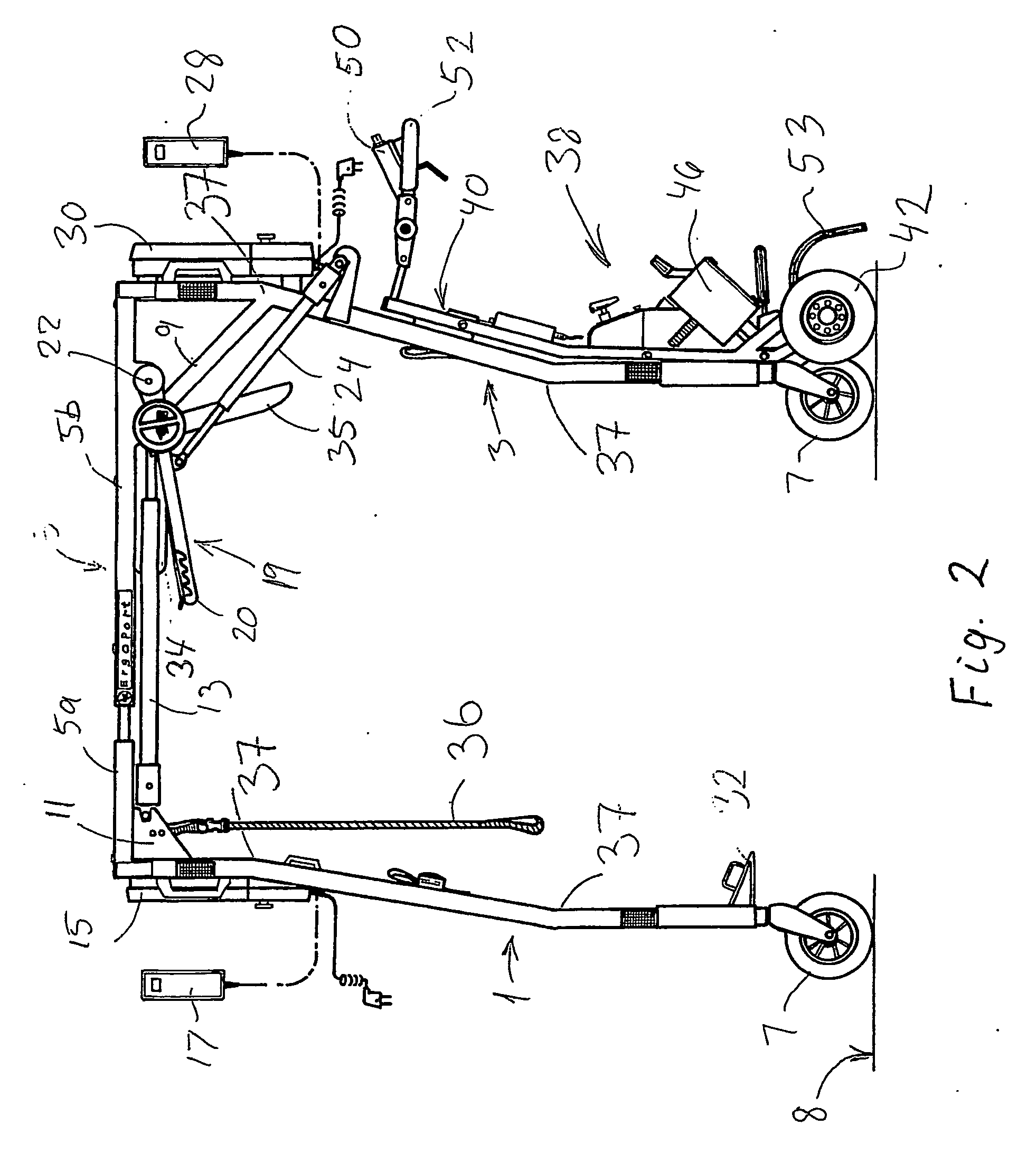

Hoisting and transporting apparatus for disabled persons

InactiveUS20070059141A1Avoid excessive loadsAvoid strainHarvestersNursing bedsEngineeringMechanical engineering

An apparatus for hoisting and transporting a disabled person is made up of a frame having a top section supported by front and rear end sections, the frame being provided with swivelling wheels for horizontal movement. The frame is without framework in the lower part between the end sections and the top section is composed of mutually telescoping parts for adjusting the length between the end sections. Thereby it is possible to move the apparatus in between fixed seat rows, e.g. in an airplane, for taking up or putting down a disabled person that may be suspended from arms in a sling seat below the top section. Undesired and hazardous work positions on the part of aiding assistants are thus avoided as well as excessive strain on the assistants, and the disabled person is also provided a more dignified handling.

Owner:U B LET

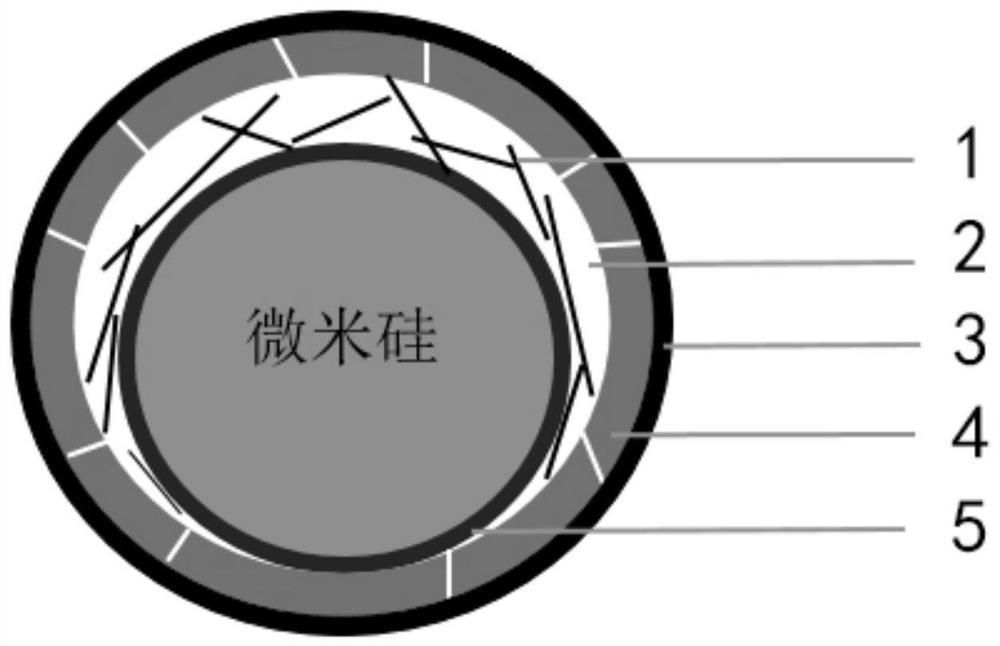

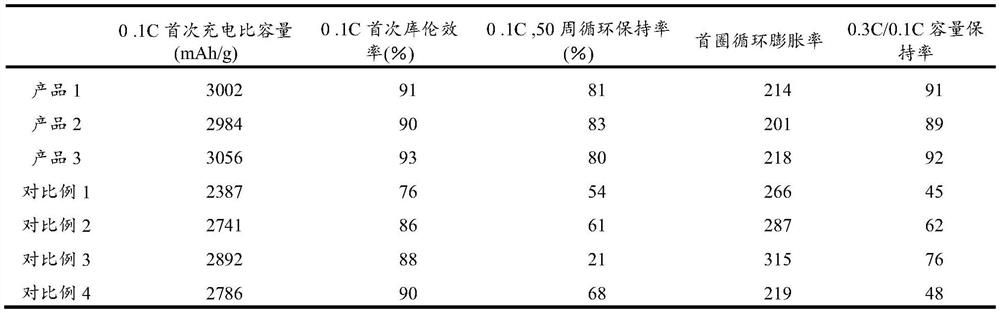

Micron silicon composite material and preparation method and application thereof

ActiveCN114267839AIntegrity guaranteedImprove cycle stabilityCell electrodesSecondary cellsCarbon coatingLithium-ion battery

The invention provides a micron silicon composite material as well as a preparation method and application thereof, and belongs to the technical field of lithium ion batteries. The micron silicon composite material is of a core-shell structure and sequentially comprises micron silicon, a first coating layer, a cavity layer, a second coating layer and a third coating layer from inside to outside, the first coating layer and the second coating layer are carbon coating layers, the third coating layer is a compact carbon coating layer, a cavity layer is arranged between the second coating layer and the third coating layer, and a conductive agent is contained in the cavity layer. According to the micron silicon composite material, a volume expansion space is reserved for embedding lithium into silicon, so that the carbon coating layer is prevented from being broken due to the volume expansion of lithium when the silicon is embedded, the integrity of the composite material is maintained, and the cycling stability of the micron silicon composite material is improved. The invention further discloses a preparation method and application of the composite material, the preparation method is simple and easy to implement, and the prepared negative electrode is good in electrochemical performance.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Robot joint member, dynamic joint and robot with heat dissipation structure

ActiveUS20210339407A1Keep it compactImprove thermal conductivityProgramme-controlled manipulatorJointsCapillary TubingRobot dynamic

The present disclosure provides a robot joint member, a dynamic joint and a robot with a heat dissipation structure. The joint member has a hollow barrel structure disposed to sleeve a heat source component, and a plurality of phase change heat dissipation units; the phase change heat dissipation unit comprises a phase change working medium, a capillary material and a sealed phase change cavity; heat dissipation auxiliary ribs are arranged on a periphery of the barrel wall of the joint member and a side of the phase change heat dissipation unit away from the heat source component; and the heat dissipation auxiliary ribs define a plurality of gas flow channels with cross sections gradually reduced along a gas flow direction. The joint member has can quickly eliminate the heat accumulation of the joint power source, and can keep a compact structure of the dynamic joint of the robot.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Integrated compressor/expansion engine

InactiveUS7841205B2Smaller, more compact, and less expensiveSave energyDomestic cooling apparatusCompression machines with non-reversible cycleDrive shaftEngineering

A multi cylinder compressor / expansion engine having a centrally mounted drive shaft. A cylinder barrel is mounted on the drive shaft and both the cylinder barrel and the drive shaft rotate about a common axis. There is a plurality of cylinders in the cylinder barrel with pistons disposed in each of the cylinders. Some of the cylinders are compression cylinders and some of the cylinders are expansion cylinders. The compression cylinders discharge a fluid at a first high pressure from the engine. The expansion cylinders receive fluid at a second pressure which provides energy to the engine thereby reducing the energy required for the engine to rotate the drive shaft.

Owner:WHITEMOSS

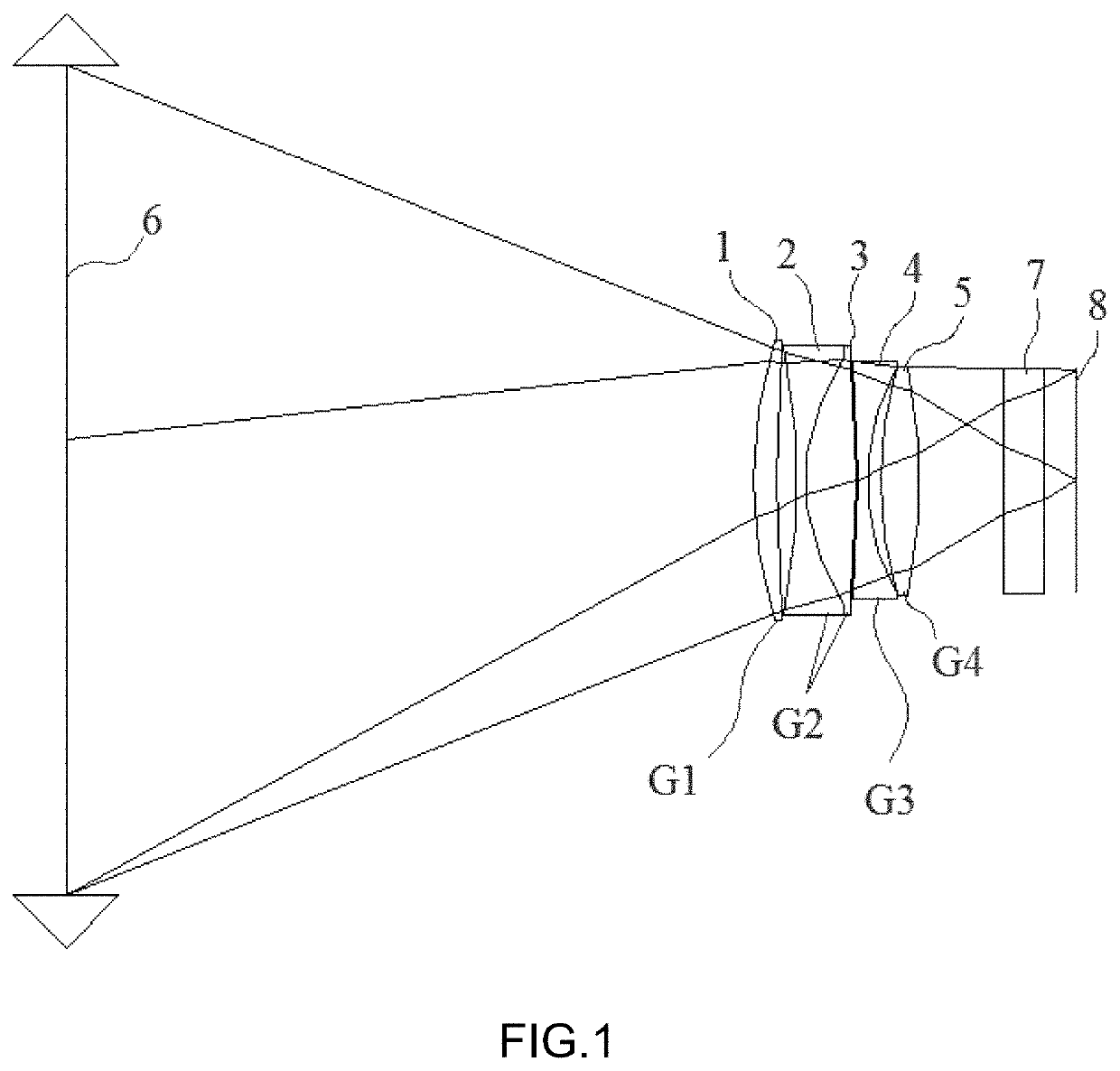

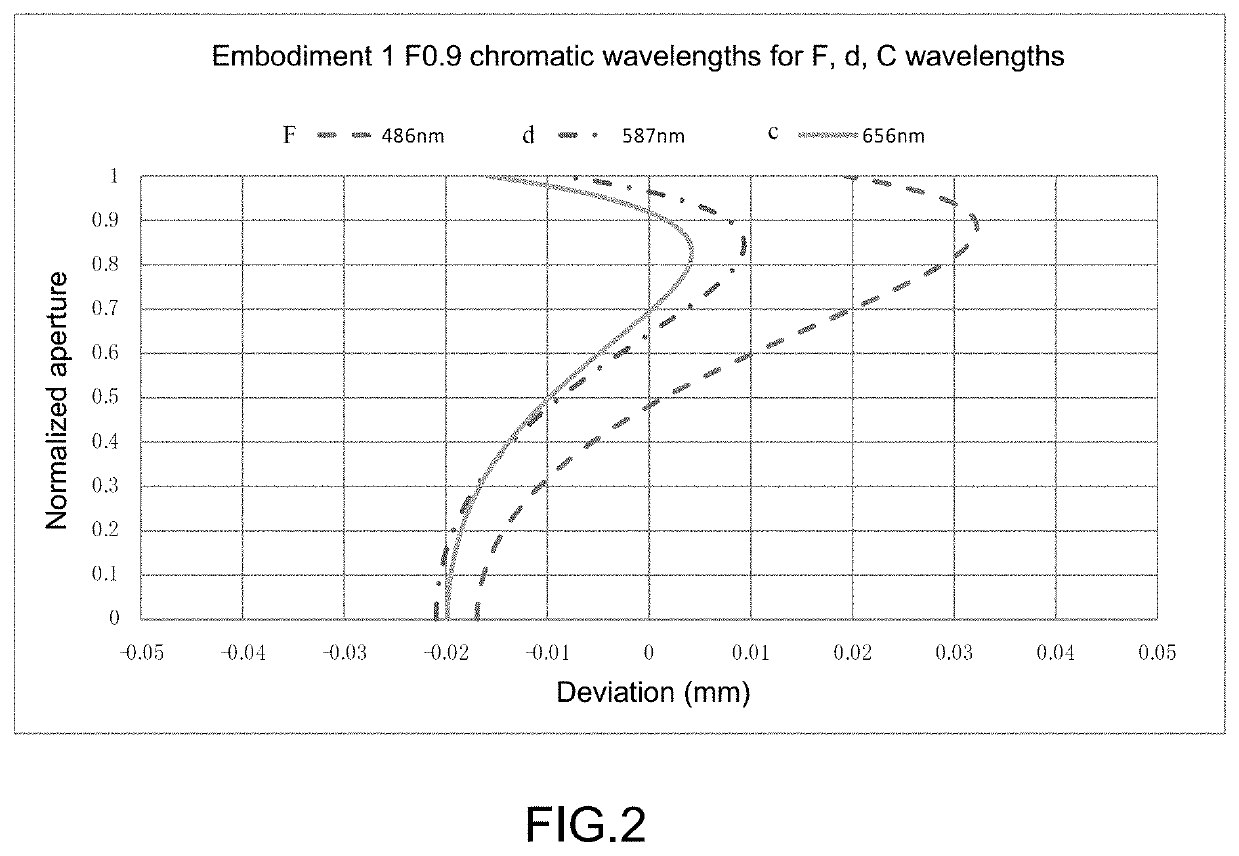

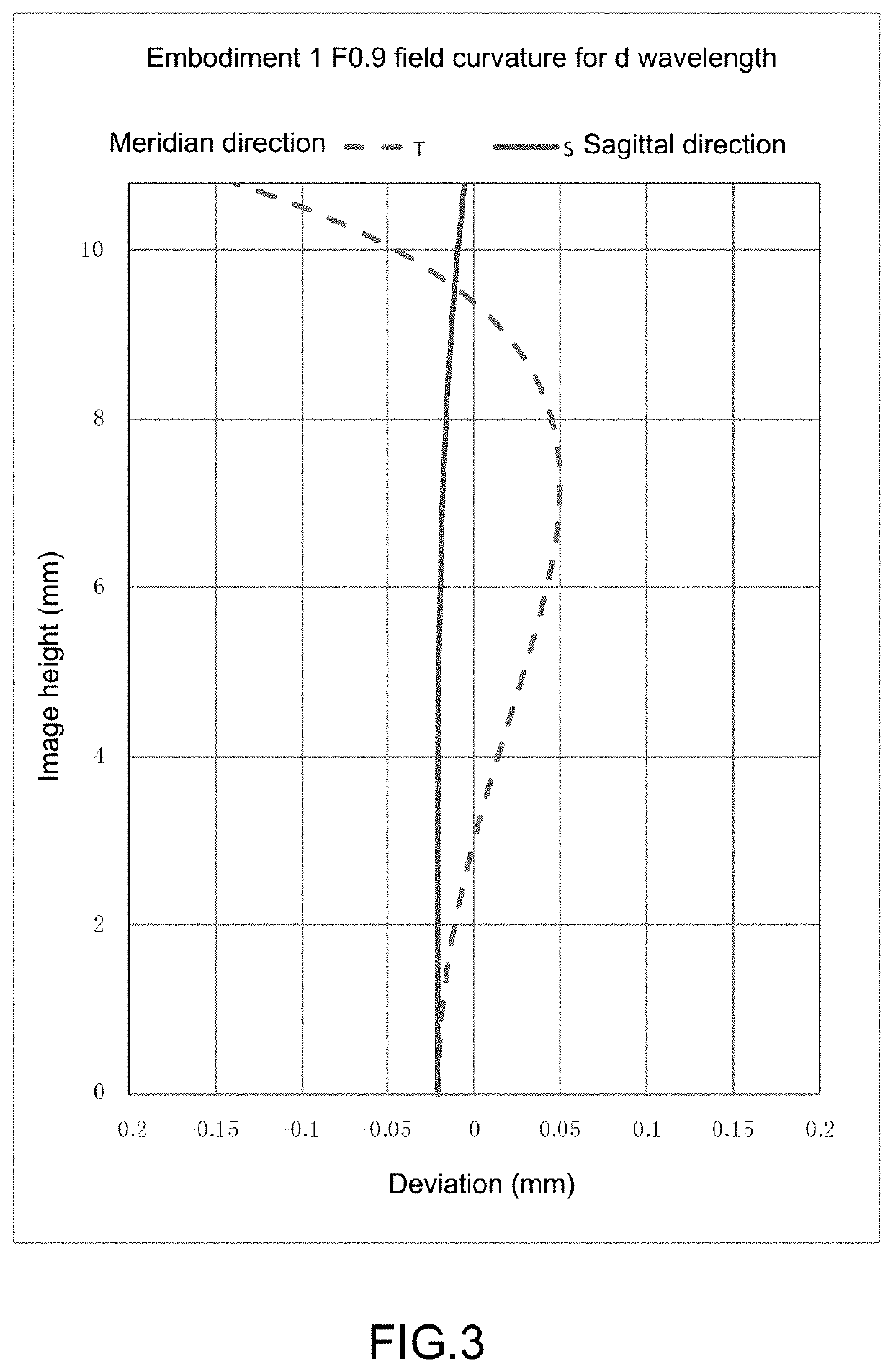

Lens attachment of reduced focus and increased light admittance

ActiveUS20220003967A1Compact structureMinimize aggravation of chromatic aberrationTelevision system detailsColor television detailsOphthalmologyMicroscope objective

A lens attachment, used with an objective lens, including from object side to image side, a first lens element with positive power, a second lens element with negative power, a third lens element with positive power, a fourth lens element with negative power, and a fifth lens element with positive power; the second and third lens elements form a doublet by adhesive; at least two of the third, fourth and fifth lens elements are anomalous dispersion lenses.

Owner:SHENZHEN JUEYING TECH CO LTD

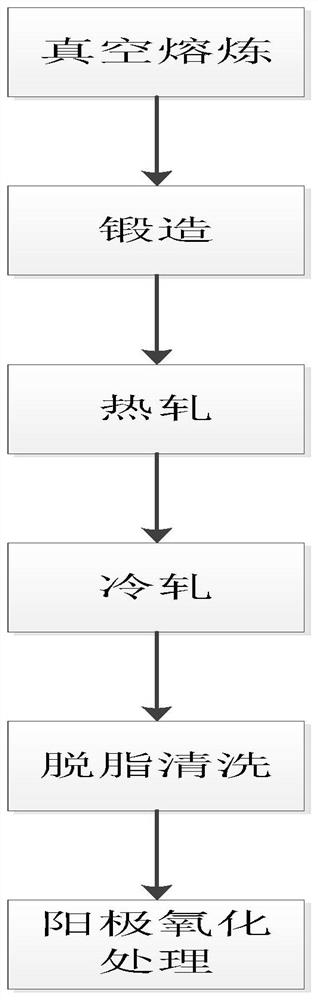

Preparation method of wide pure titanium foil coiled tape

PendingCN114405995ALow content of impurity elementsHigh puritySurface reaction electrolytic coatingFurnace typesNumerical controlMaterials processing

The invention provides a preparation method of a wide pure titanium foil coiled tape, and belongs to the technical field of titanium material processing. 0A-grade sponge titanium is adopted as a raw material, two times of vacuum consumable electrode furnace smelting are carried out, oxide skin on the surface of a plate blank is removed through a numerical control milling machine, and micro cracks on the surface of the plate blank are polished through grinding equipment, so that the produced plate blank is uniform in tissue size and few in internal defect, and a solid foundation is laid for obtaining high-quality and high-yield plates; next, the plate blank is subjected to hot rolling, annealing shot blasting acid pickling, cold rolling acid pickling, secondary acid pickling annealing, surface rolling oil stain removal on a degreasing line and whole roll annealing in a vacuum bell-type furnace, and after the process treatment is conducted, the prepared titanium foil coiled material is more uniform in structure, the forming width is increased, the mechanical property is tested, the titanium foil coiled material is rolled into the (0.1-0.3) * 1530 * Cmm cold rolling titanium foil material through a 20-roller rolling mill; the mechanical property consistent with that of a finished product generated by a narrow rolling mill is kept, the production efficiency and the yield of the coiled tape are improved, and the production cost is reduced.

Owner:新疆湘润新材料科技有限公司

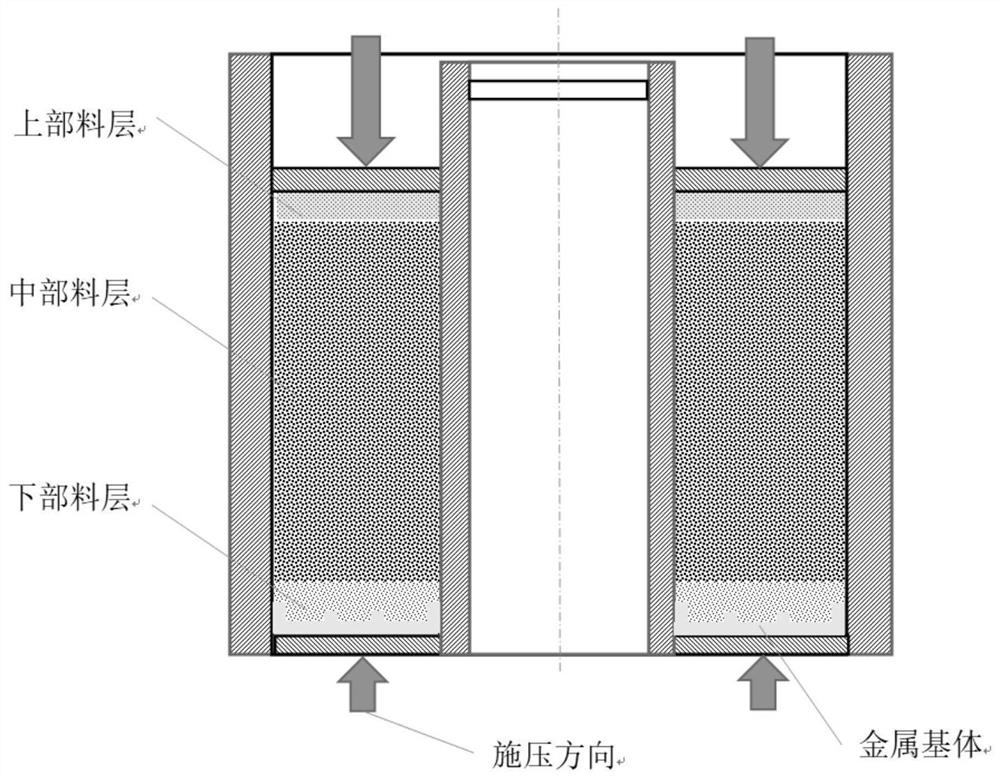

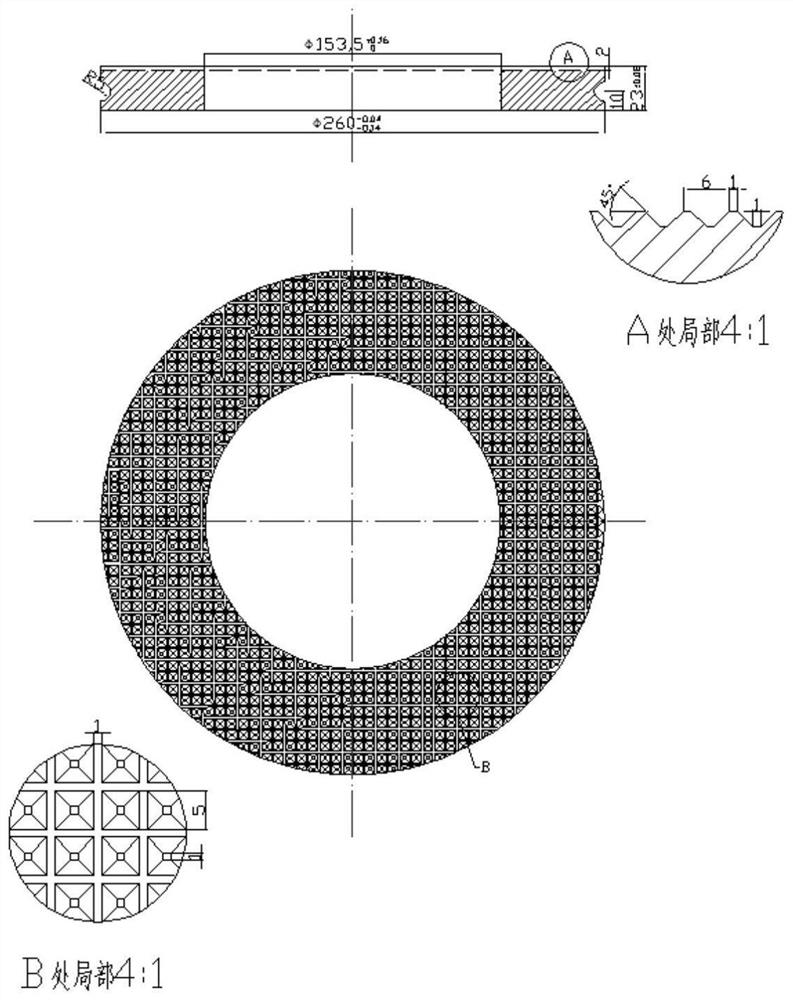

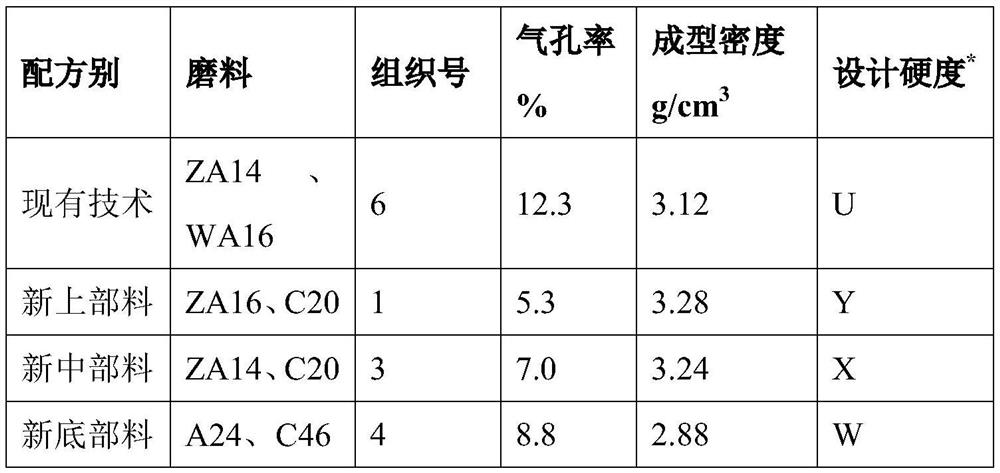

Multi-layer feeding process method of hot-press grinding rail grinding wheel

ActiveCN112917403BImprove wear resistanceAvoid churnAbrasion apparatusGrinding devicesManufacturing technologyHigh density

The invention discloses a multi-layer feeding process method for a hot-press grinding rail grinding wheel, which belongs to the technical field of grinding wheel manufacturing technology. Preliminarily solidified grinding wheel blank is formed by pre-pressing and hot pressing after mold closing, forming a hot extrusion material barrier layer with appropriate thickness on the upper and lower parts of the grinding wheel blank, so that each layer of the blank is under the same temperature and pressure conditions. Next, the barrier softening binder is squeezed out of the surface layer. The invention can prevent the loss of the binder of the high-hardness and high-density grinding wheel during hot pressing due to extrusion, maintains the high resin content and compactness of the grinding wheel as a whole, reduces the resin loss, and provides a prerequisite for the grinding wheel to further improve the wear resistance. condition.

Owner:江苏新砺河磨具科技有限公司

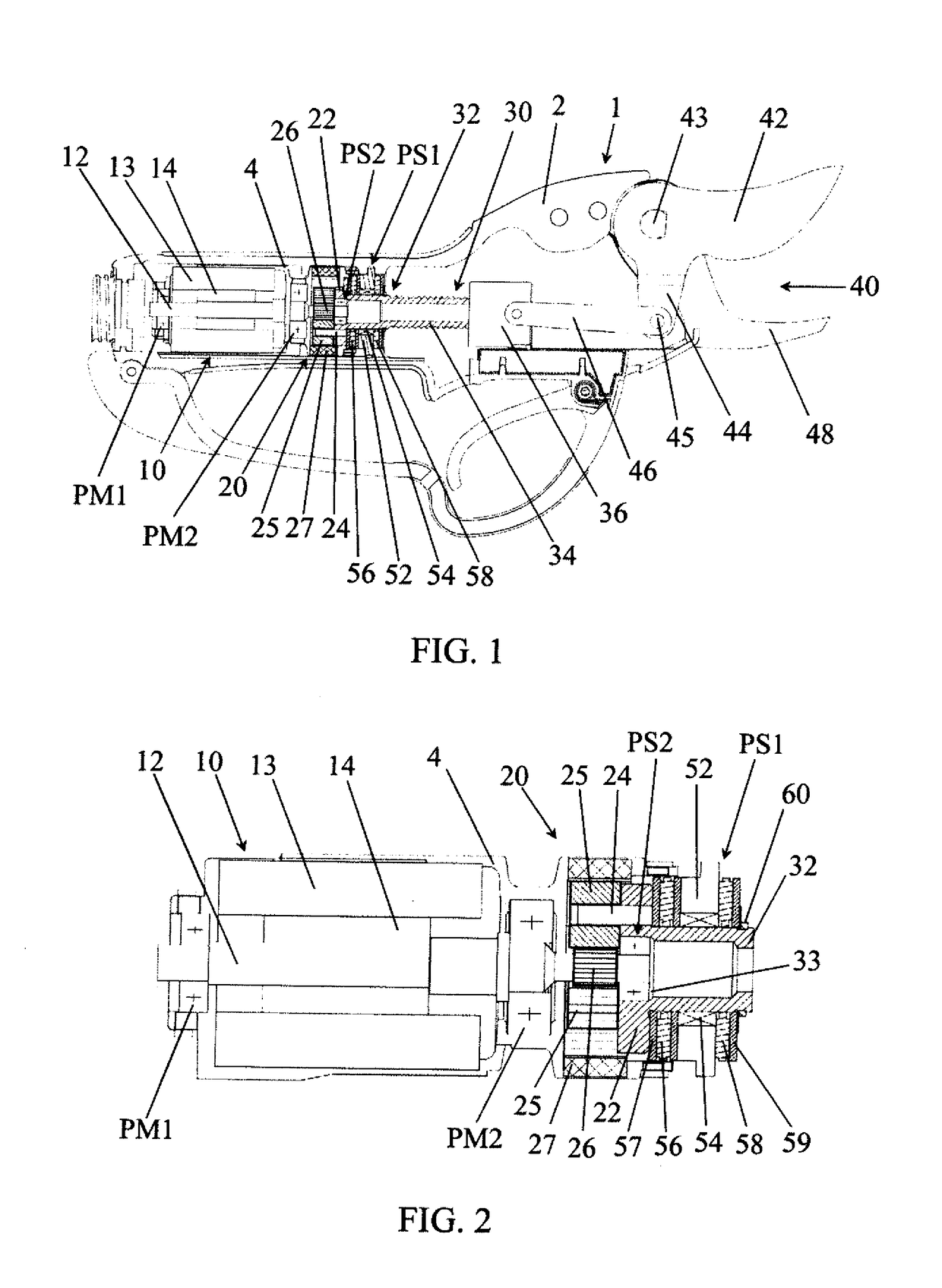

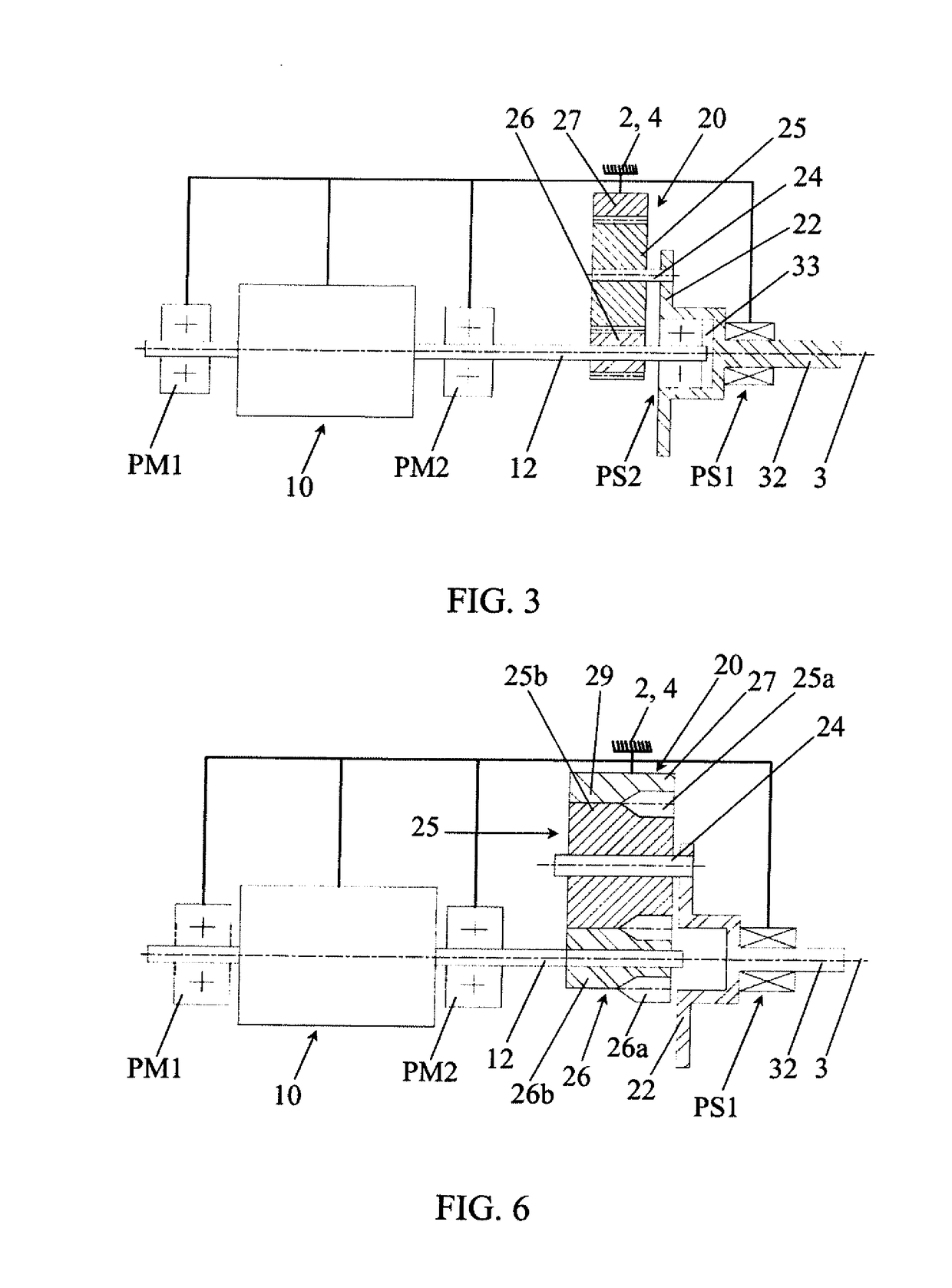

Portable power tool comprising an epicyclic reduction gear

A portable power tool including, within a housing: an electric motor having a drive shaft, an epicyclic reduction gear having planetary gears meshing with a central gear of the drive shaft of the electric motor, the reduction gear being provided with an output shaft that is rigidly connected to a ball screw of a ball screw / nut mechanism and is coaxial to the ball screw, and a support bearing connecting the output shaft to the housing. The tool includes at least one stabilization bearing axially offset relative to the support bearing. The stabilization bearing connects the output shaft of the epicyclic reduction gear to the housing by at least one intermediate part selected from: the drive shaft of the electric motor, planet-carrier axles of the epicyclic reduction gear, and epicyclic reduction gears of the epicyclic reduction gear. The structure is of use in shears, in particular sheet metal shears.

Owner:PELLENC SA

Graphite carbon based saggar

The invention discloses a graphitic carbon-based saggar, which relates to the technical field of saggar production, including a substrate and a coating on the surface of the substrate. Powder, the binder of 10-15 parts by weight; the coating layer includes the following raw materials by weight: 60-75 parts by weight of silicon carbide micropowder, 2-6 parts by weight of filler, 3-6 parts by weight of carbon powder. The coating prepared by the invention forms a transition connection layer rich in silicon carbide under high temperature conditions, the coating has a gradient of the silicon carbide concentration gradually increasing from the outside to the inside, a good bonding state is formed between the coating and the substrate, and the saggar is endowed with excellent Thermal shock resistance, the coating is not easy to be peeled off by thermal shock, ensuring the continuity and effectiveness of the anti-oxidative protection of the coating on the substrate.

Owner:长沙中瓷新材料科技有限公司

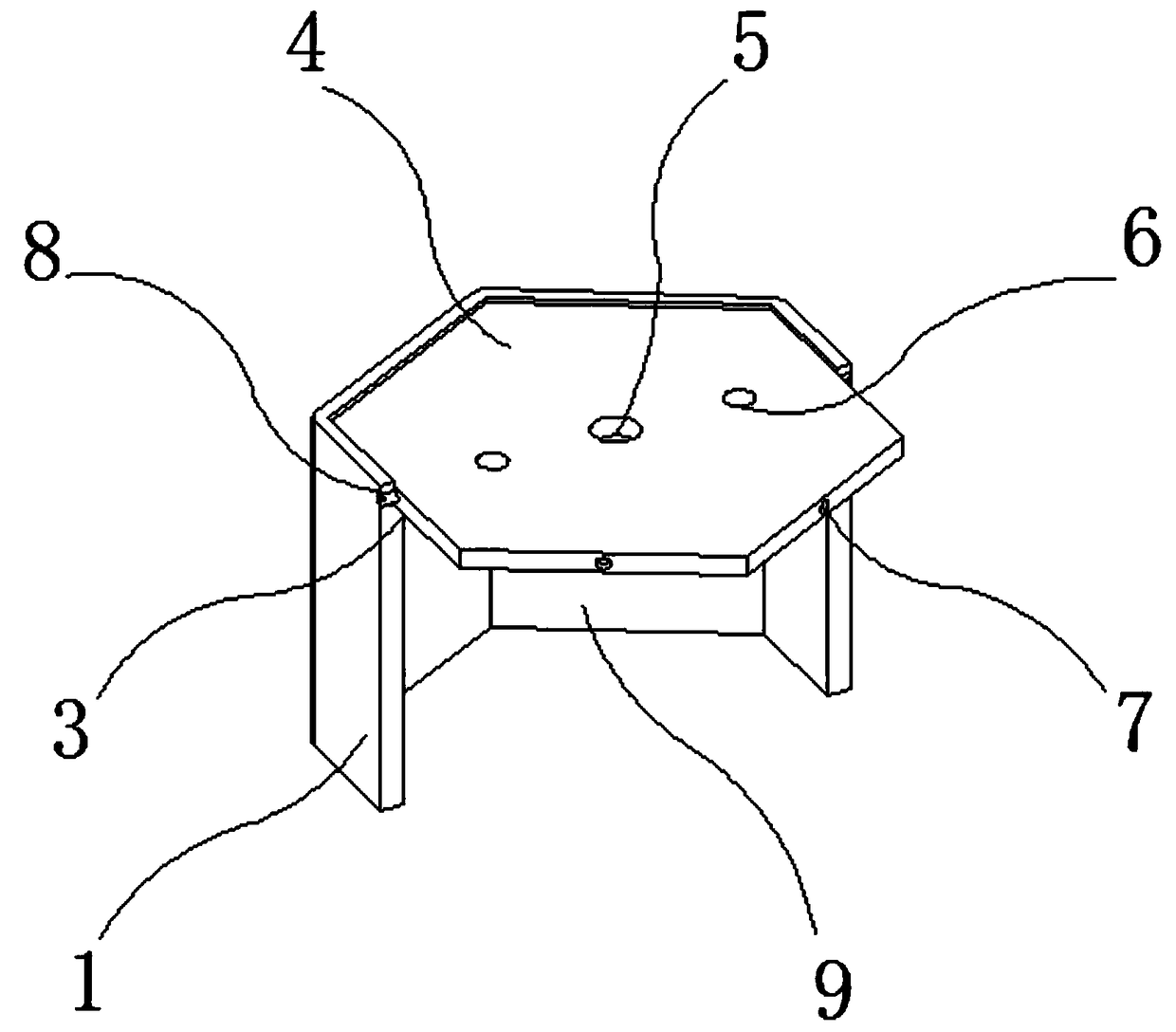

Novel steel plate pile even wall

ActiveCN109385991AImprove stabilityPrevent fallingBulkheads/pilesArchitectural engineeringSteel plates

The invention discloses a novel steel plate pile even wall and relates to the technical field of building engineering devices, in particular to a pile body and a fixing rack. An operation opening is formed in the top of the pile body, a bayonet groove is formed in the inner side of the operation opening, and a cover plate is installed in the middle of the bayonet groove; the cover plate is embedded in the bayonet groove, a rope penetration hole is formed in the upper surface of the cover plate, and vent holes are formed in the left and right sides of the rope penetration hole; a connection hole is formed in the lower portion of the operation opening, a fixing hole is formed in the outer side of the fixing rack, and the fixing rack is located at the outer side of the connection hole. According to the novel steel plate pile even wall, through a sealing structure formed by the cover plate and the bayonet groove, the operation opening of the top of the pile body is sealed, the cover plateis embedded in the bayonet groove, and the situation can be prevented that soil or other impurities fall in a center cylinder of the inner side of the pile body; through normal application of an interference device, the wall is damaged, and the reliability and safety of the wall are conveniently improved.

Owner:FOSHAN UNIVERSITY

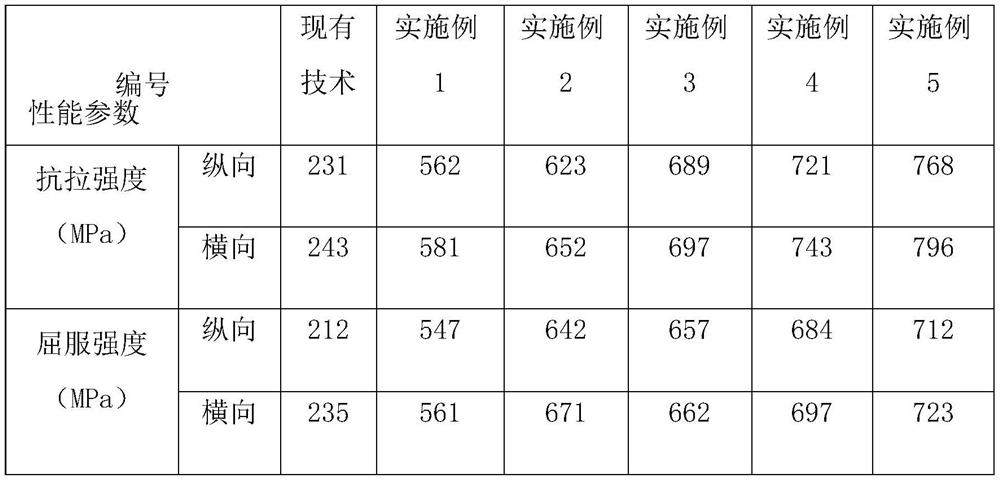

A method for improving the mechanical properties of aluminum bronze

The invention discloses a method for improving the mechanical properties of aluminum bronze; it includes the following steps: S1, selecting metal materials; S2, hot-melting metal materials; S3, casting aluminum bronze ingots; S4, delaying the cooling of aluminum bronze ingots; S5, Aluminum bronze multi-stage forging; S6, aluminum bronze extrusion to remove oxidation surface layer; the present invention realizes increasing corrosion resistance to aluminum bronze by adding chromium, titanium and niobium in aluminum bronze, and adds zinc and nickel to increase aluminum bronze surface Glossiness, adding alkaline earth metal compounds during the hot melting process of aluminum bronze raw materials, to achieve adsorption and precipitation of dross in the aluminum bronze solution at the bottom of the furnace, to filter out the dross inside the aluminum bronze, and in the aluminum bronze solution When the ingot is not formed, a covering agent is added to connect the aluminum bronze and maintain the fluidity of the aluminum bronze surface, and multi-stage forging and quenching are used to maintain the compactness and stability of the aluminum bronze structure.

Owner:贵溪骏达特种铜材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com