Graphite carbon based saggar

A technology of graphite carbon and base sag, applied in the field of graphitic carbon base saggar, can solve the problems of easy corrosion of the saggar, low reference density, damage to the structure of carbon composite materials, etc. The effect of increasing structural density and avoiding high temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

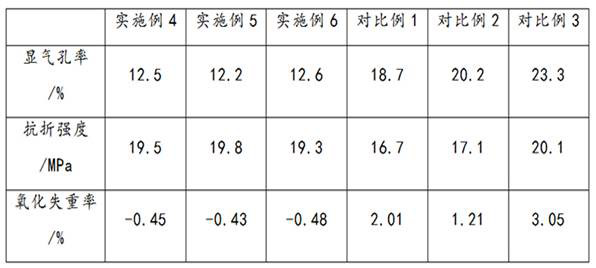

Examples

Embodiment 1

[0025] The preparation method of the binder comprises the following steps:

[0026] (1) Add 0.1g of aminosilane coupling agent and 100g of deionized water into the reaction flask, stir mechanically evenly, add 100g of silicon powder, stir evenly, heat up to 60°C, and keep the reaction for 1h;

[0027] (2) adding a phenolic resin polymer to the solution obtained in step (1), the phenolic resin polymer is obtained by polymerizing phenol and formaldehyde in a molar ratio of 1:1, the mass ratio of silicon powder to phenol is 1:10, and the temperature is raised to 80 ° C , heat preservation reaction 1h, get the binder.

Embodiment 2

[0029] The preparation method of the binder comprises the following steps:

[0030] (1) Add 0.3g of aminosilane coupling agent and 200g of deionized water into the reaction flask, stir mechanically evenly, add 100g of silicon powder, stir evenly, heat up to 70°C, and keep the reaction for 2h;

[0031] (2) adding a phenolic resin polymer to the solution obtained in step (1), the phenolic resin polymer is obtained by polymerizing phenol and formaldehyde in a molar ratio of 1:1, the mass ratio of silicon powder to phenol is 1:10, and the temperature is raised to 85 ° C , holding the reaction for 2h to obtain the binder.

Embodiment 3

[0033] The preparation method of the binder comprises the following steps:

[0034] (1) Add 0.5g of aminosilane coupling agent and 300g of deionized water into the reaction flask, stir mechanically evenly, add 100g of silicon powder, stir evenly, raise the temperature to 80°C, and keep the reaction for 3h;

[0035] (2) adding a phenolic resin polymer to the solution obtained in step (1), the phenolic resin polymer is obtained by polymerizing phenol and formaldehyde in a molar ratio of 1:1, the mass ratio of silicon powder to phenol is 1:10, and the temperature is raised to 90 ° C , holding the reaction for 3h to obtain the binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com