Method for improving mechanical property of aluminum bronze

An aluminum bronze and performance technology, applied in the field of aluminum bronze, can solve the problem of aluminum bronze containing dross and aluminum bronze anti-corrosion, etc., and achieve the effects of increasing gloss, maintaining compactness and stability, and maintaining fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

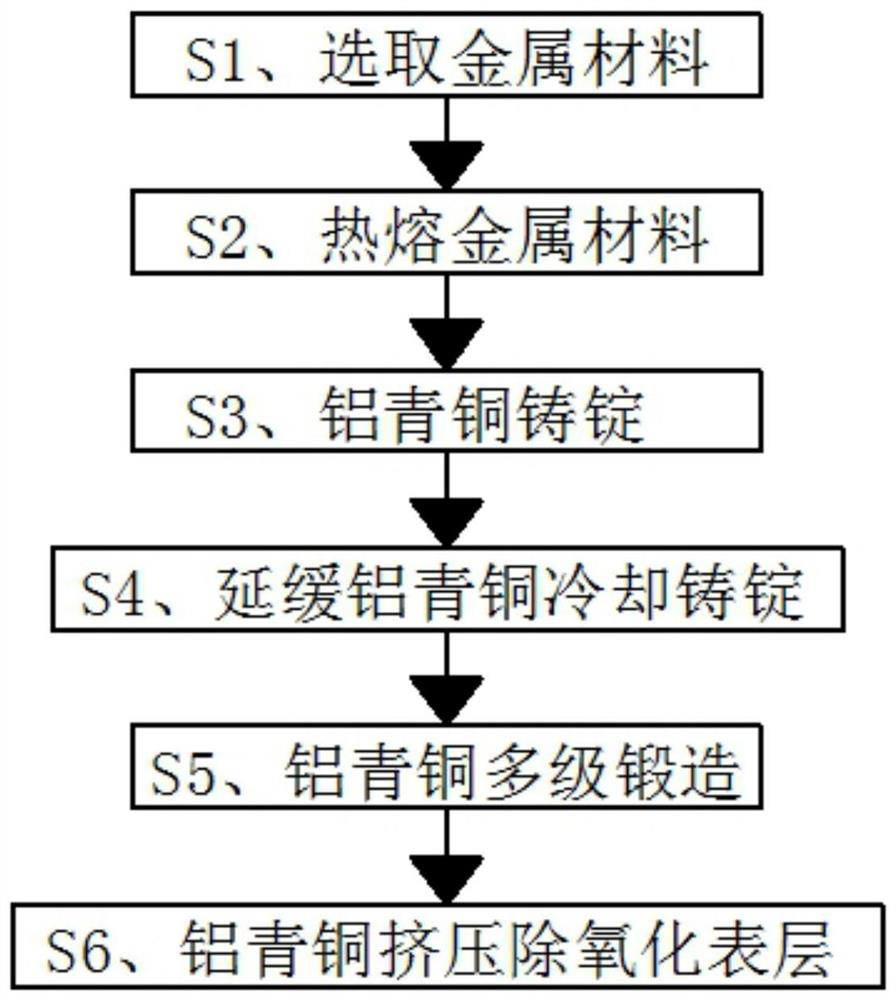

[0026] A method for improving the mechanical properties of aluminum bronze, characterized in that it comprises the following steps:

[0027] S1. Select metal materials: select the following metal materials, namely aluminum, iron, manganese, zinc, nickel, chromium, titanium, niobium and the balance copper, and the mass percentages of the selected metal materials are: aluminum: 8%, iron: 0.6%, manganese: 1.6%, zinc: 0.5%, nickel: 0.4%, chromium: 1%, titanium: 1.2% and niobium: 2%;

[0028] S2, hot-melt metal material: put the metal material in S1 into the melting furnace for hot-melting, the temperature of the melting furnace is kept at 1800°C, and put 10% alkaline earth metal compound into the melting furnace when the metal is hot-melting;

[0029] S3. Aluminum bronze ingot casting: Put the hot-melted aluminum bronze solution into the interior of the graphite tank, and then sprinkle a covering agent on the metal surface, and the thickness of the covering agent is 0.8mm;

[003...

Embodiment 2

[0042] A method for improving the mechanical properties of aluminum bronze, characterized in that it comprises the following steps:

[0043]S1. Select metal materials: select the following metal materials, namely aluminum, iron, manganese, zinc, nickel, chromium, titanium, niobium and the balance of copper, and the mass percentages of the selected metal materials are: aluminum: 10%, iron: 1.5%, manganese: 3%, zinc: 1.5%, nickel: 1%, chromium: 2%, titanium: 2.2% and niobium: 4%;

[0044] S2, hot-melt metal material: put the metal material in S1 into the melting furnace for hot-melting, the temperature of the melting furnace is kept at 2000°C, and put 25% alkaline earth metal compound into the melting furnace when the metal is hot-melting;

[0045] S3. Aluminum bronze ingot casting: Put the hot-melted aluminum bronze solution into the interior of the graphite tank, and then sprinkle a covering agent on the metal surface, and the thickness of the covering agent is 1.6mm;

[0046...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com