Textile machinery for manufacturing cross-wound bobbin

A cross-winding bobbin and textile machinery technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of unfavorable and efficient continuous production, waste of time, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

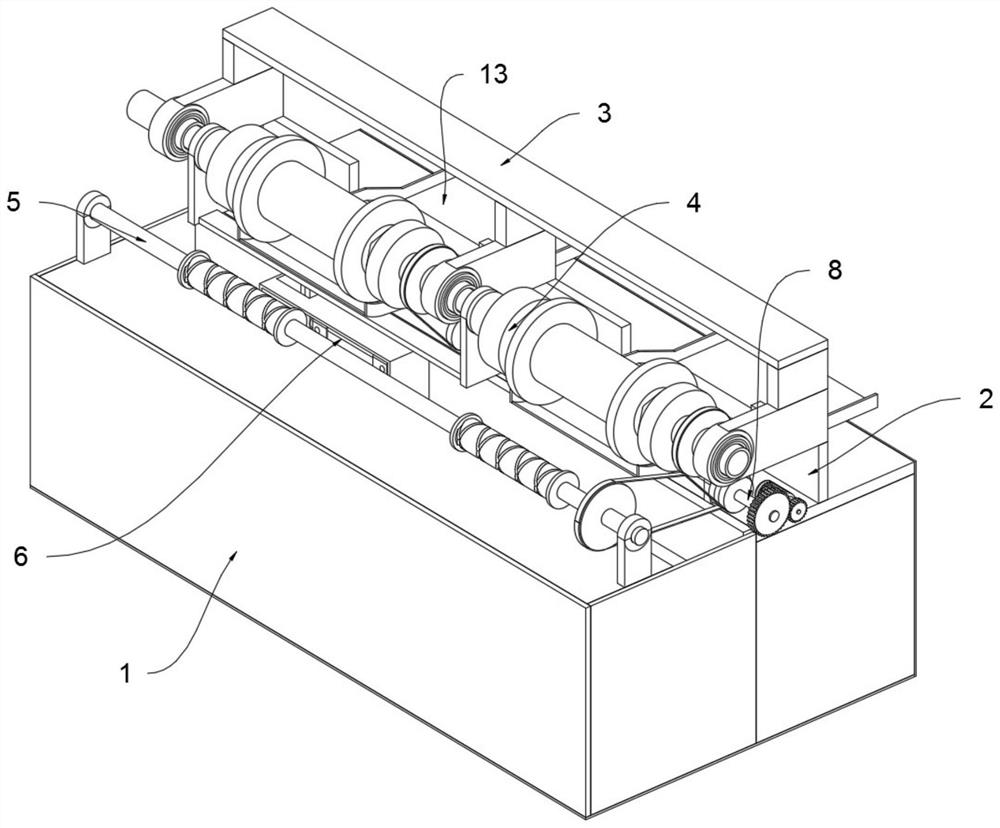

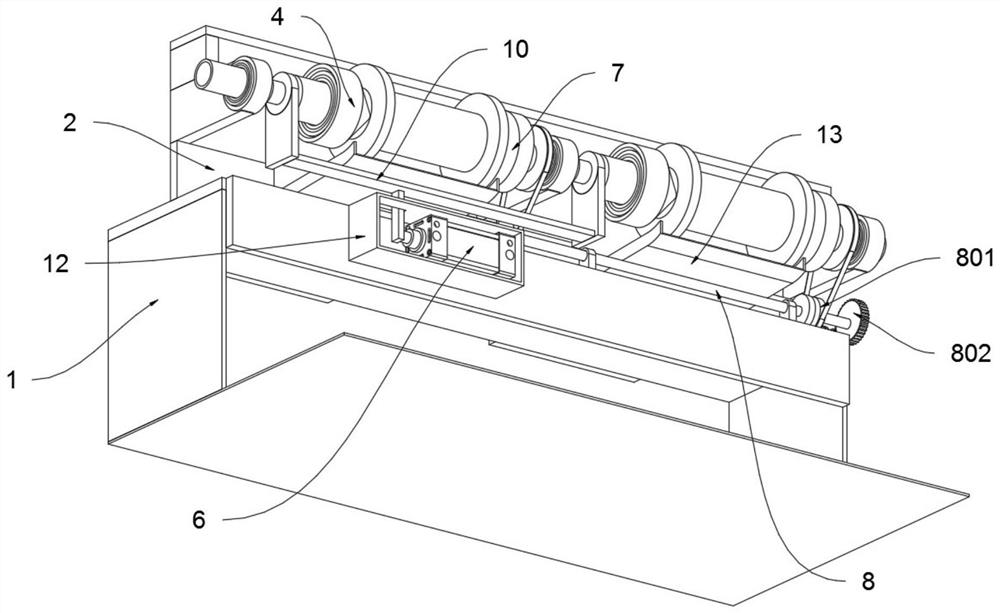

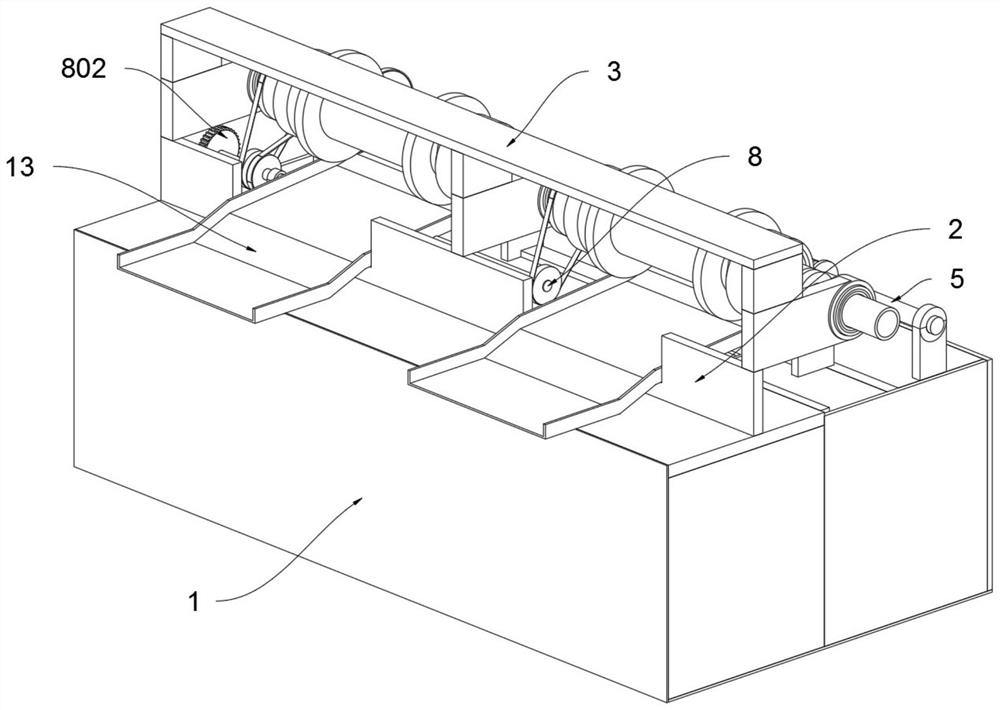

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a textile machine for manufacturing cross-winding bobbins, which includes a winding machine main body 1, an upper bracket 3, a reciprocating screw 5, a cylinder 6, a fixed top block 7, a transmission shaft 8, a driving member 9, and a movable guide cylinder 11. Placement frame 12, discharge plate 13; shaft frame 2 is fixedly connected to the rear of the upper surface of winding machine main body 1; upper bracket 3 is fixedly connected above shaft frame 2; the shaft of fixed top block 7 is rotatably connected to The front of the shaft frame 2; the reciprocating lead screw 5 is connected to the front side of the upper surface of the winding machine main body 1 through bearing rotation; the cylinder 6 is fixedly connected to the front surface of the winding machine main body 1 by screws, and the output shaft of the cylinder 6 The lower connecting frame 1001 that is fixedly connected to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com