Sheet feeder and image forming apparatus

A paper feeding device and paper technology, which are applied in the directions of object supply, transportation and packaging, and object separation, etc., can solve the problems of upper surface position control obstacles and other problems, and achieve the effect of easy control and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments according to the present invention will be described below with reference to the drawings.

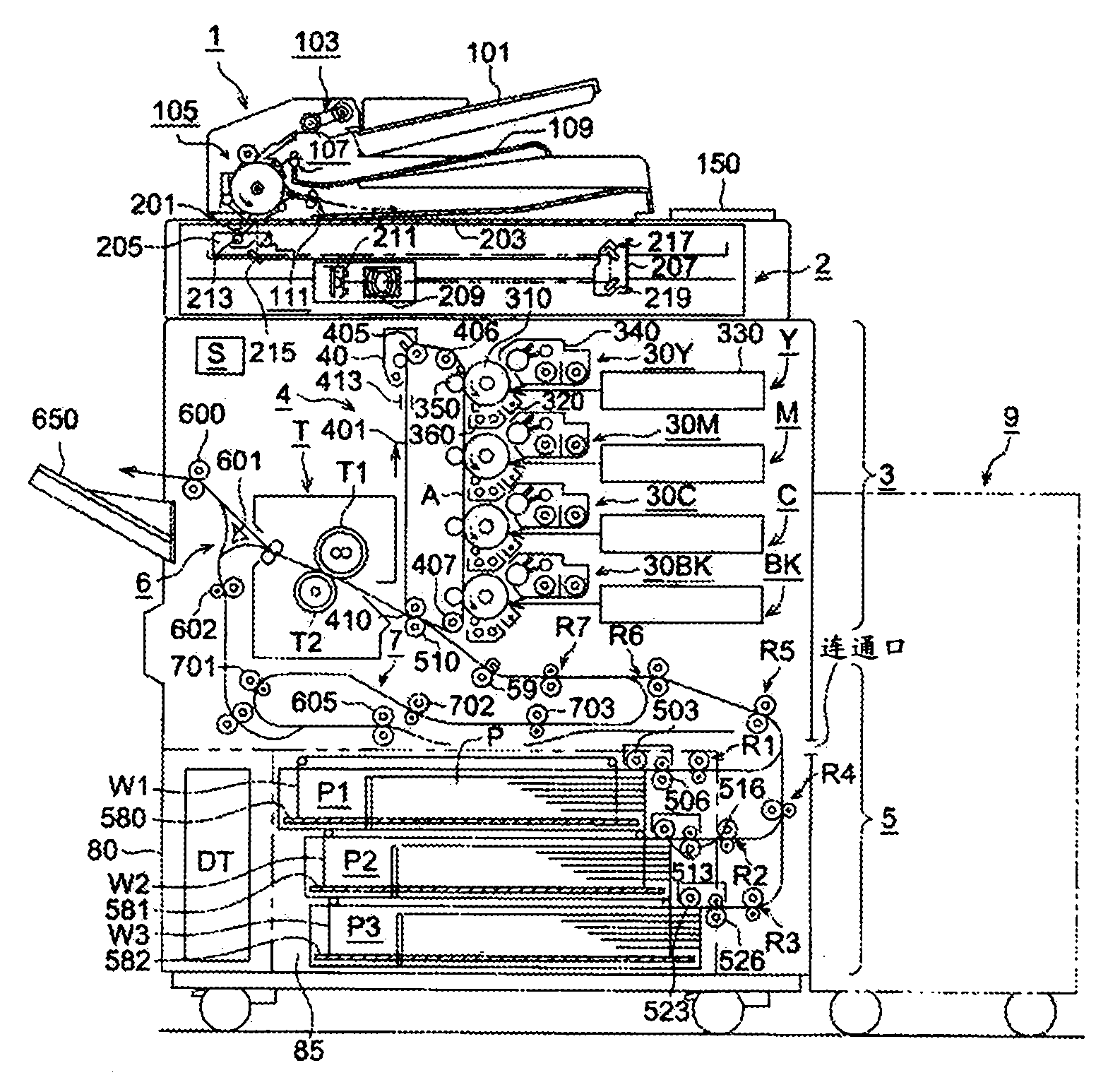

[0048] figure 1 It is a schematic diagram showing the configuration of an image forming apparatus including a digital color copier.

[0049] The image forming apparatus shown in the figure (sometimes referred to as “image forming apparatus main body” for convenience of description) has an automatic document feeder 1 on the upper part of the apparatus main body, and an image reading unit 2, an image forming unit 3, A belt setting section for the conveyor belt unit 4 , a paper feeding section 5 , a fixing device T, an inversion discharge / refeed section 6 , and an ADU 7 as an inversion conveyance section.

[0050]The automatic document feeder 1 is a device that feeds originals one by one to an image reading position, and discharges the originals whose images have been scanned to a predetermined position.

[0051] The automatic document feeder 1 has a document placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com