A method for improving the mechanical properties of aluminum bronze

A technology of aluminum bronze and high performance, which is applied in the field of aluminum bronze, can solve the problems of aluminum bronze containing dross, aluminum bronze anti-corrosion, etc., and achieve the effect of increasing gloss, maintaining compactness and stability, and increasing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

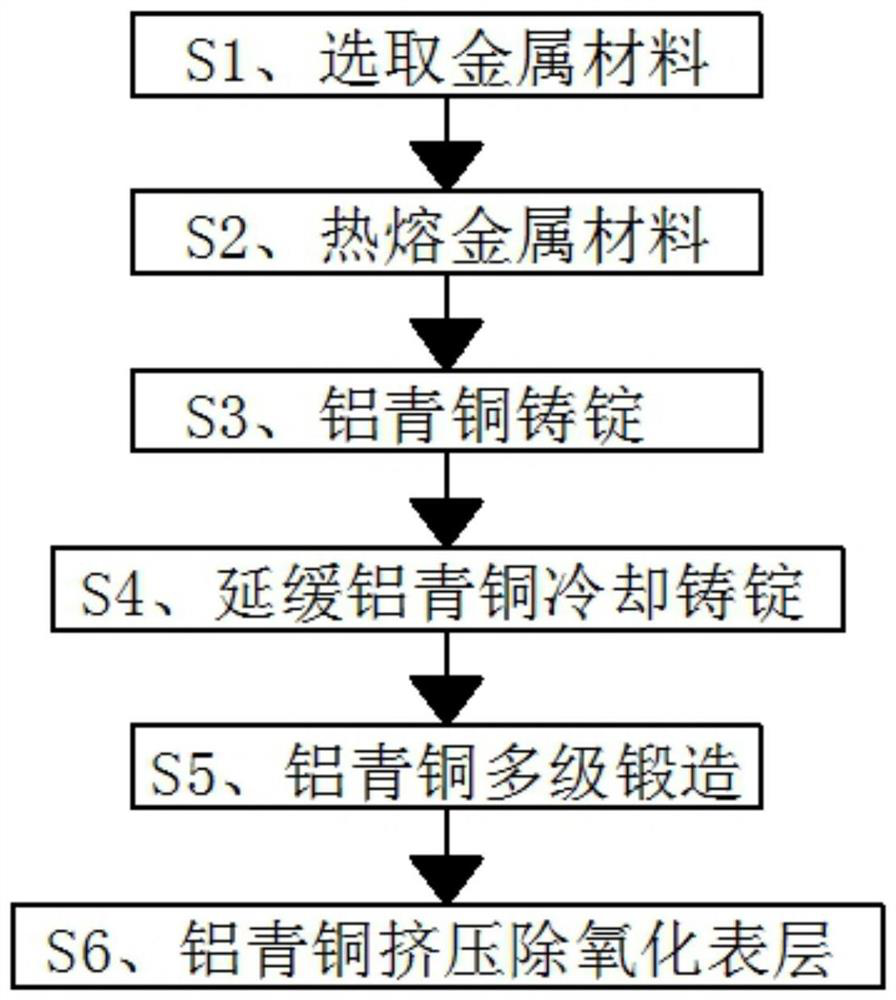

[0026] A method for improving the mechanical properties of aluminum bronze, characterized in that it comprises the following steps:

[0027] S1. Select metal materials: select the following metal materials, namely aluminum, iron, manganese, zinc, nickel, chromium, titanium, niobium and the balance copper, and the mass percentages of the selected metal materials are: aluminum: 8%, iron: 0.6%, manganese: 1.6%, zinc: 0.5%, nickel: 0.4%, chromium: 1%, titanium: 1.2% and niobium: 2%;

[0028] S2, hot-melt metal material: put the metal material in S1 into the melting furnace for hot-melting, the temperature of the melting furnace is kept at 1800°C, and put 10% alkaline earth metal compound into the melting furnace when the metal is hot-melting;

[0029] S3. Aluminum bronze ingot casting: Put the hot-melted aluminum bronze solution into the interior of the graphite tank, and then sprinkle a covering agent on the metal surface, and the thickness of the covering agent is 0.8mm;

[003...

Embodiment 2

[0042] A method for improving the mechanical properties of aluminum bronze, characterized in that it comprises the following steps:

[0043]S1. Select metal materials: select the following metal materials, namely aluminum, iron, manganese, zinc, nickel, chromium, titanium, niobium and the balance of copper, and the mass percentages of the selected metal materials are: aluminum: 10%, iron: 1.5%, manganese: 3%, zinc: 1.5%, nickel: 1%, chromium: 2%, titanium: 2.2% and niobium: 4%;

[0044] S2, hot-melt metal material: put the metal material in S1 into the melting furnace for hot-melting, the temperature of the melting furnace is kept at 2000°C, and put 25% alkaline earth metal compound into the melting furnace when the metal is hot-melting;

[0045] S3. Aluminum bronze ingot casting: Put the hot-melted aluminum bronze solution into the interior of the graphite tank, and then sprinkle a covering agent on the metal surface, and the thickness of the covering agent is 1.6mm;

[0046...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com