Grinding device for coffee machine

A grinding device and coffee machine technology, applied in beverage preparation devices, applications, household appliances, etc., can solve the problems of inconsistent coffee quality, inability to control the particle size of ground coffee powder, and the inability to automatically adjust the thickness of coffee powder, etc., to achieve the realization of humanity The effect of modernization and intelligent setting, simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

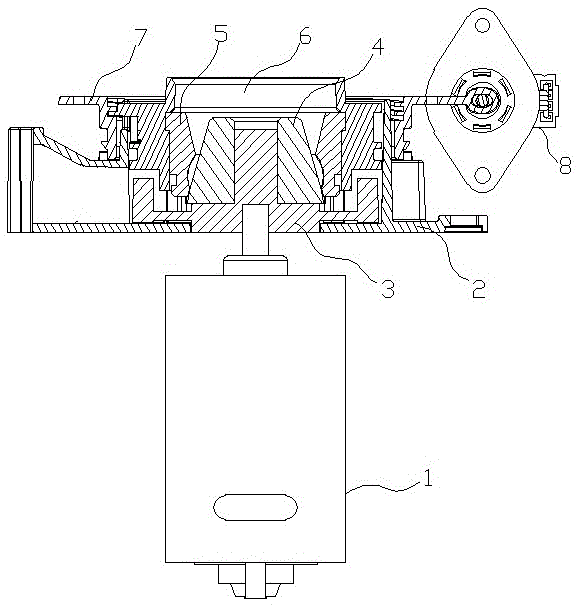

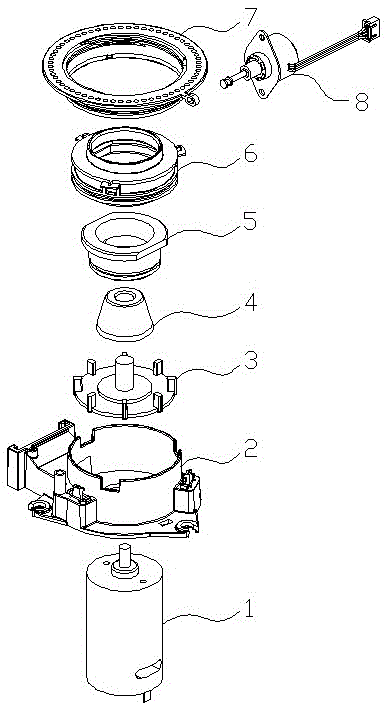

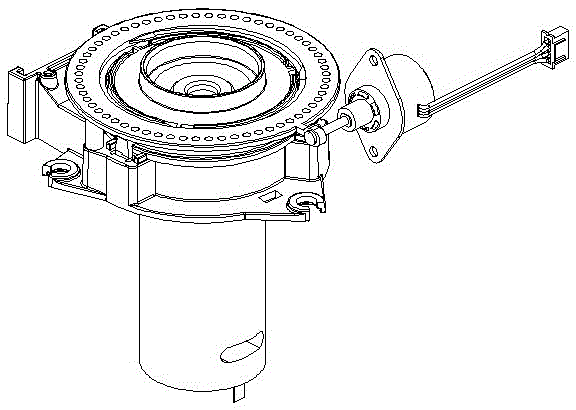

[0020] like figure 1 , figure 2 and image 3 As shown, a grinding device for a coffee machine of the present invention includes a driving motor 1, a coffee powder pusher 3, an inner grinder knife 4, and an outer grinder knife assembly, and the coffee powder pusher 3 is arranged on the drive motor 1 On the output shaft, the bean grinder inner knife 4 is arranged on the coffee powder propeller 3, the bean grinder outer knife assembly is arranged on the upper end of the bean grinder inner knife 4, and there is a gap between the bean grinder outer knife assembly and the bean grinder inner knife 4 ; The bean grinding outer knife assembly includes the grinding bean outer knife 5, the outer knife fixing seat 6 and the adjustment device for adjusting the gap between the grinding bean outer knife 5 and the grinding bean inner knife 4, and the grinding bean outer knife 5 is arranged on the outer knife fixing seat 6, the adjusting device is arranged on the upper end of the outer knife...

Embodiment 2

[0024] The rest are the same as in Embodiment 1, except that a clutch is also included, and the clutch is arranged between the bean grinder inner knife 4 and the coffee powder propeller 3 . In order to prevent small stones or other hard objects from blocking the rotation of the bean grinder inner knife 4, a clutch structure is also designed between the bean grinder inner knife 4 and the coffee powder propeller 3. When the bean grinder inner knife 4 is blocked, the grinder inner knife 4 can be blocked. Knife 4 is disengaged from drive motor 1.

Embodiment 3

[0026] The rest are the same as in Embodiment 1, except that there are four thread structures. There is at least one annular thread structure 9, and different numbers are set according to different design requirements.

[0027] The beneficial effect of adopting this technical solution is: the physical actual value of the gap between the inner knife and the outer knife can be accurately controlled by the adjusting device, thereby controlling the size of the coffee powder particles, and the thickness of the powder used for each cup of coffee is consistent, thereby ensuring brewing coffee Excellent quality, simple structure and reliable performance, realizing the humanization and intelligent setting of the fully automatic coffee machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com