Bean grinder convenient to clean

A bean grinder and cleaning technology, which is applied in coffee mills, spice mills, household appliances, etc., can solve the problems of inconvenient cleaning operation, unsafe use, deterioration and mildew, etc., and achieve reasonable structural design, improved sealing effect, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

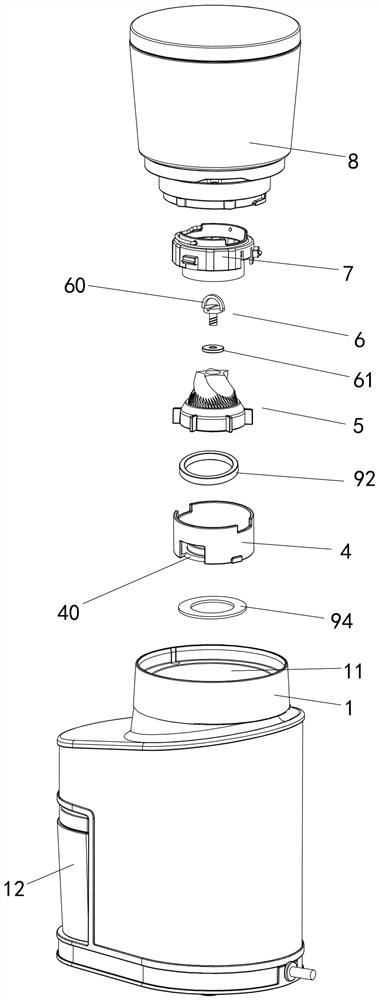

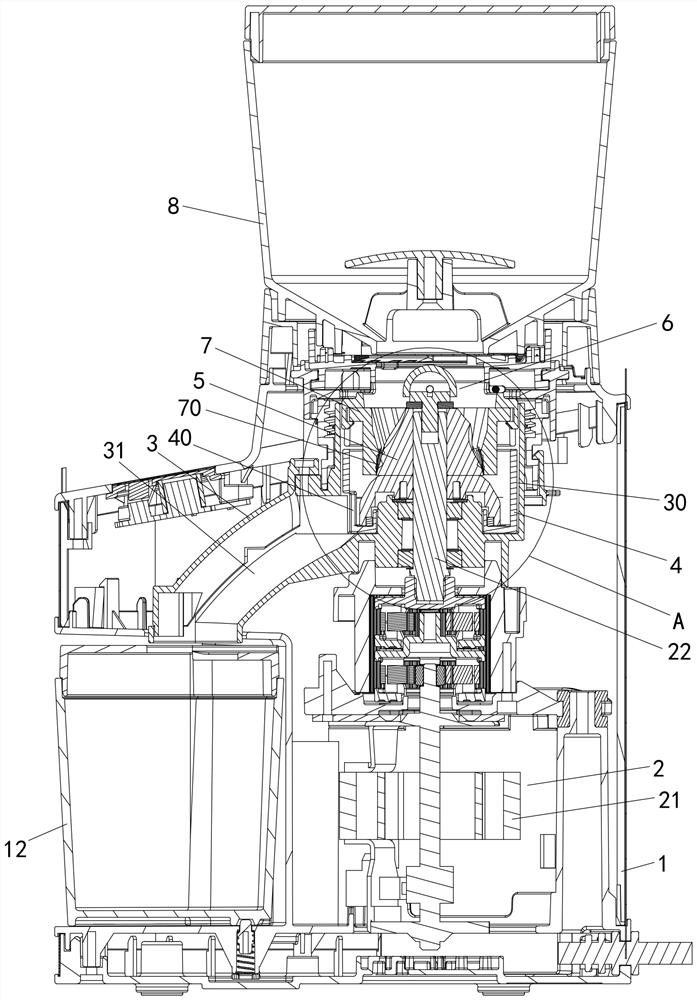

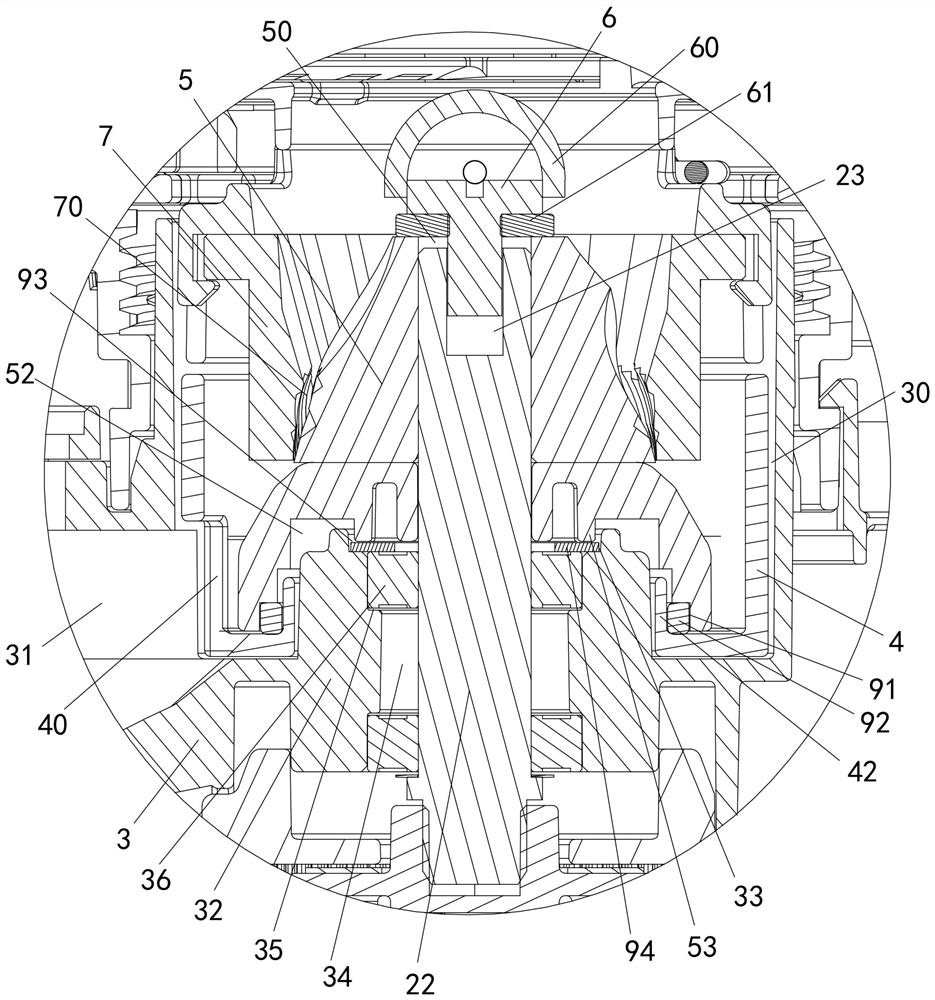

[0025] Embodiment one, see Figure 1-7 As shown, a bean grinder that is easy to clean includes a host 1, a driving device 2, a container support 3, a powder container 4, a lower cone grinding wheel 5, a hand-tightening fixture 6, an upper cone grinding wheel 7 and a bean filling container 8. The top of the main machine 1 is recessed with a fixing groove 11, and the container support 3 is fixed in the fixing groove 11. The inner cavity of the container support 3 forms a grinding chamber 30, and a powder outlet channel 31 extends on one side of the container support 3. The main machine 1 corresponds to the powder outlet channel 31. There are 12 powder cups.

[0026] In this embodiment, a mounting base 32 is formed on the bottom surface of the grinding chamber 30, a groove 33 is recessed on the top surface of the mounting base 32, and a through hole 34 is provided in the mounting base 32, and the top of the through hole 34 communicates with the groove 33, and the through hole 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com