Apparatus for continuously producing tofu

A manufacturing device and automatic technology, which is applied in the field of automatic and continuous tofu manufacturing devices, can solve the problems of time-consuming, complicated tofu preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

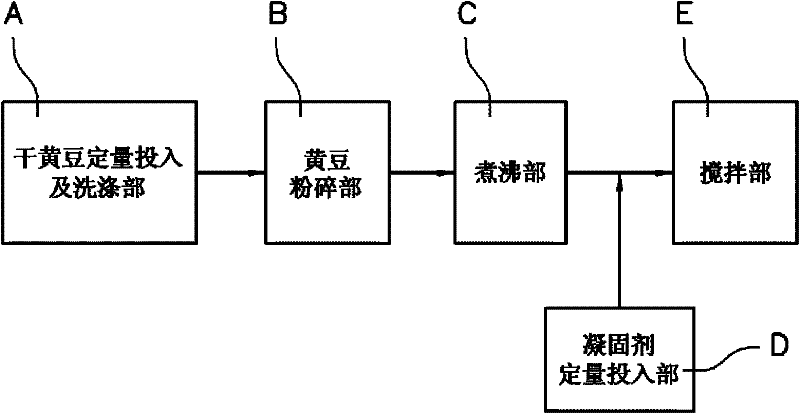

[0017] figure 1 It is a block diagram of the overall structure of the present invention, which includes: dry soybean quantitative input and washing part A, quantitative input and washing dry soybean; soybean crushing part B, crushing the above-mentioned washed soybean with a millstone; centrifugal separation part F, separating bean dregs and Soybean milk; boiling part C, boil the separated by the above centrifugal separation part F to the set temperature; coagulant quantitative input part E, put in coagulant to coagulate the soybean milk boiled by the above boiling part C; stirring part D, stir and put in the coagulant of soy milk to make tofu.

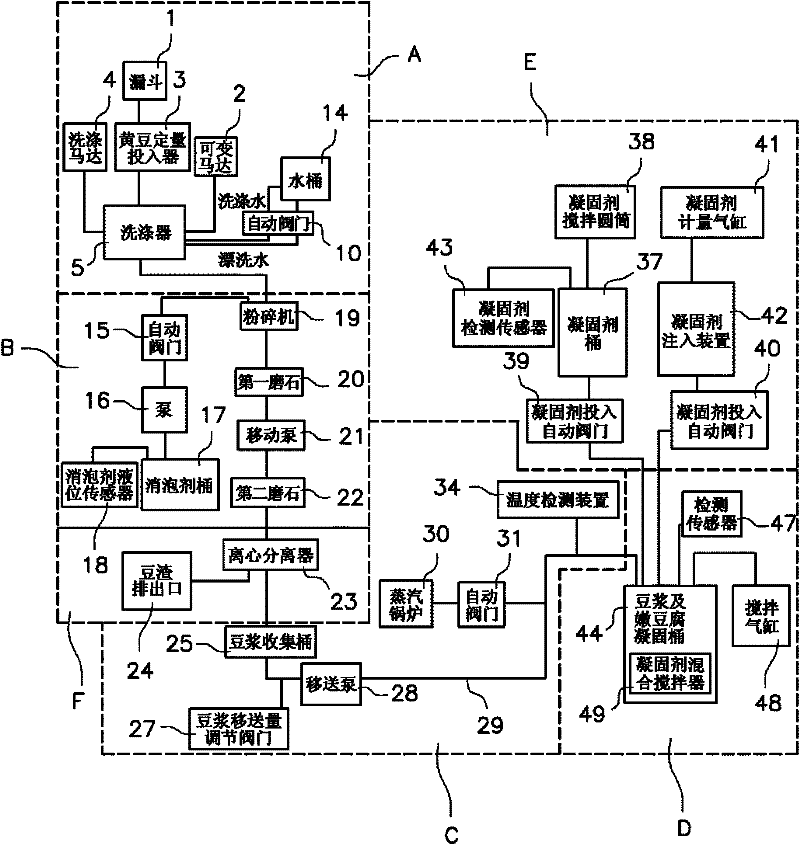

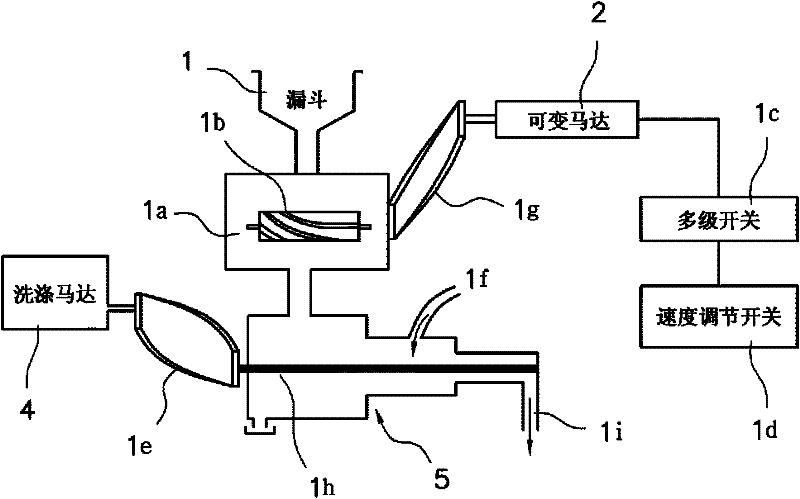

[0018] figure 2 for figure 1 The detailed structure diagram, wherein, dry soybean quantitative input and washing part A includes: scrubber 5, washing dry soybean; washing motor 4, driving the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com