Method for refining biodiesel byproduct glycerin

A technology of biodiesel and by-products, applied in the field of oleochemical industry, can solve the problem of high cost of pure glycerin, and achieve the effects of uniform product quality, high efficiency and lower recovery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

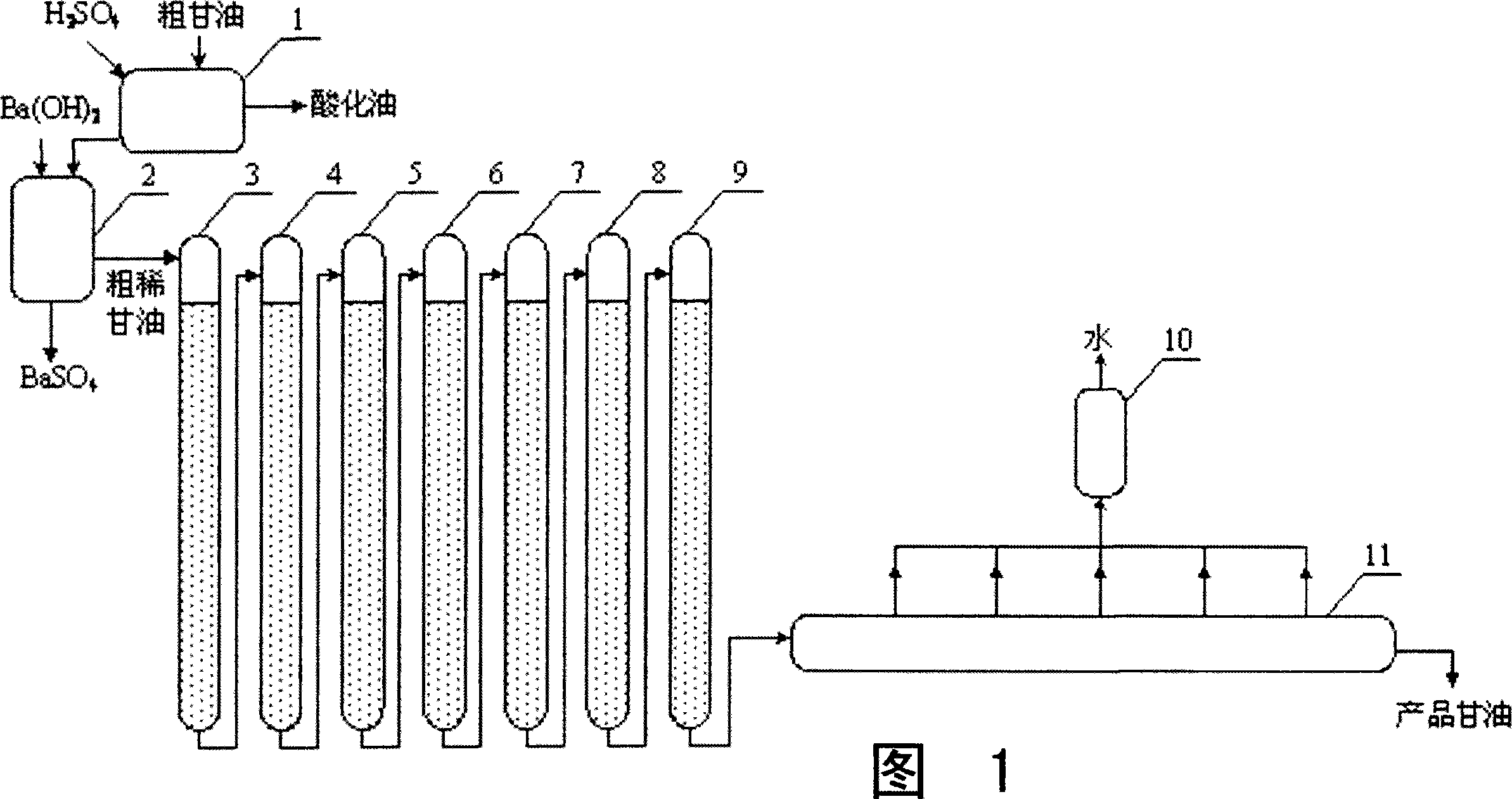

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The by-product glycerin that rapeseed oil prepares biodiesel produces is added in the acidification reactor, with 3mol L -1 H 2 SO 4 Adjust the pH to 5.2, acidify at 50±5°C for 30 minutes, and let stand to separate layers. The glycerol in the lower layer enters the neutralization reactor, with 3mol·L -1 Ba(OH) 2 Adjust the pH to 8.0, separate the precipitate, and the glycerol layer enters the ion exchange column to remove various impurities and then enters the short-distance pipeline evaporator for concentration and evaporation to obtain the product refined glycerin. The purity of the refined glycerin is 99.24%, the specific gravity (20°C) is 1.2630, no peculiar smell, and the chromaticity (Hazen) is 5.

Embodiment 2

[0019] Embodiment two: the by-product glycerin that Jatropha oil prepares biodiesel produces is added in the acidification reactor, with 3mol L -1 H 2 SO 4 Adjust the pH to 5.8, acidify at 60±5°C for 40 minutes, and let stand to separate layers. The glycerol in the lower layer enters the neutralization reactor, with 3mol·L -1 Ba(OH) 2 Adjust the pH to 8.0, separate the precipitate, and the glycerol layer enters the ion exchange column to remove various impurities and then enters the short-distance pipeline evaporator for concentration and evaporation to obtain the product refined glycerin. The purity of the refined glycerin is 99.65%, the specific gravity (20°C) is 1.2634, no peculiar smell, and the chromaticity (Hazen) is 5.

Embodiment 3

[0020] Embodiment 3: The by-product glycerin that waste oil prepares biodiesel produces is added in the acidification reactor, with 3mol L -1 H 2 SO 4 Adjust the pH to 5.5, acidify at 55±5°C for 35 minutes, and let stand to separate layers. The glycerol in the lower layer enters the neutralization reactor, with 3mol·L -1 Ba(OH) 2 Adjust the pH to 7.8, separate the precipitate, and the glycerin layer enters the ion exchange column to remove various impurities and then enters the short-distance pipeline evaporator for concentration and evaporation to obtain the product refined glycerin. The purity of the refined glycerin is 98.99%, the specific gravity (20°C) is 1.2627, no peculiar smell, and the chromaticity (Hazen) is 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com