Patents

Literature

36 results about "Glycerol product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

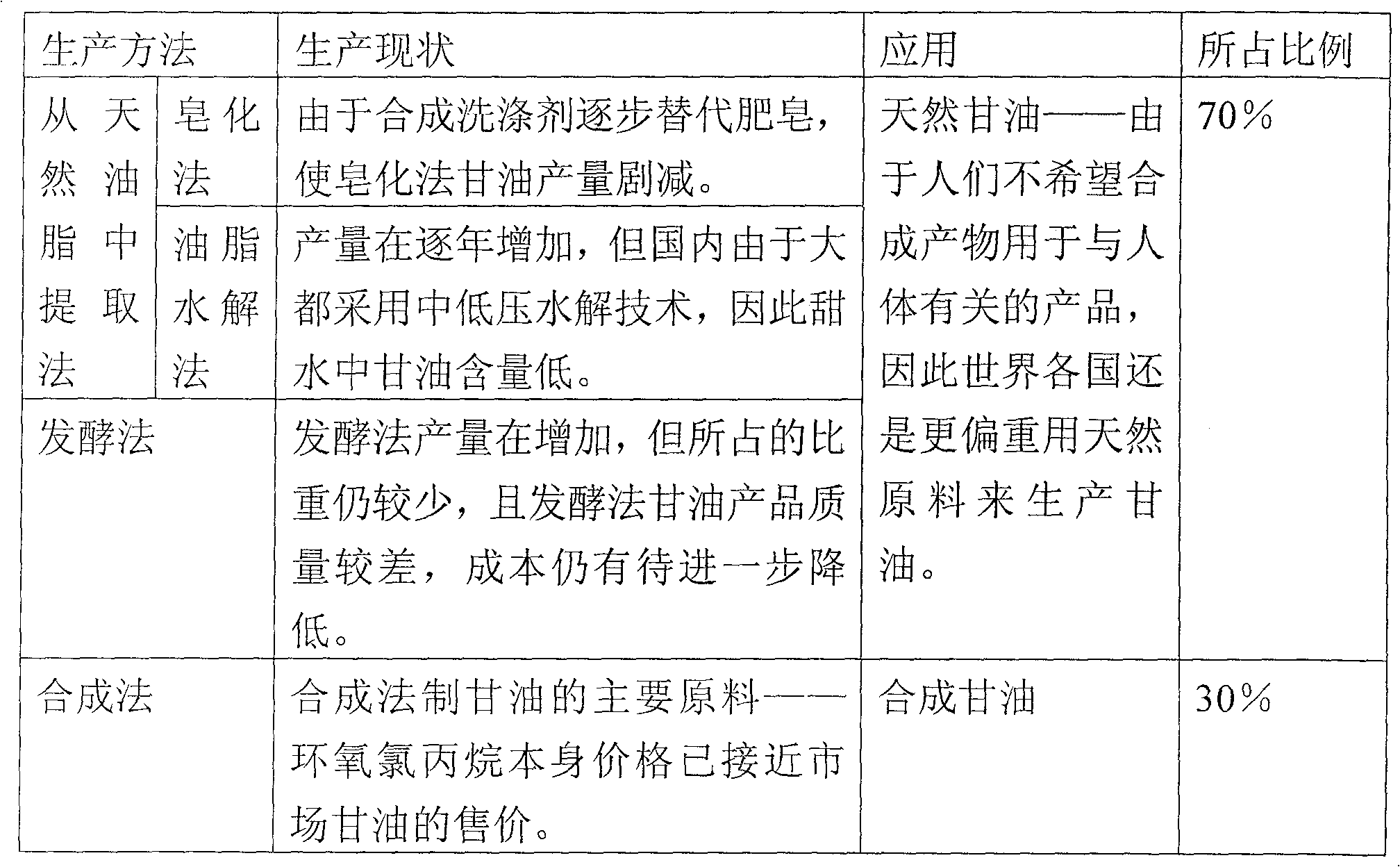

It’s produced as one of the by-products of soap-making, which involves the treatment of vegetable or animal fats with strong alkaline solutions; the production of biodiesel is also a process which produces glycerol as a side product. Synthetically, glycerol can be produced from propene, a three carbon alkene.

Method for preparing carbonic acid glyceride by catalytic reaction-azeotropic reification coupling

InactiveCN101717338AEasy to recycleAchieve recyclingPreparation from organic carbonatesMethyl carbonateGlycerol

The invention discloses a method for preparing carbonic acid glyceride by catalytic reaction-azeotropic reification coupling, and belongs to the technical field of fine chemistry. In the method, the catalytic reaction and the azeotropic rectification are finished in the same rectification tower; glycerol, dimethyl carbonate, a solid base catalyst and an azeotropic agent are added into a tower; the tower is heated while the raw materials are stirred; the tower operation temperature is between 60 and 120 DEG C; the tower top operation temperature is between 50 and 80 DEG C; a mixture of methanol and the azeotropic agent is taken out of the top of the tower in a reflux ratio of 2 to 6; the reaction time is 0.1 to 3 hours; the operational pressure of the top of the rectification tower is the normal pressure; the mol ratio of the dimethyl carbonate to the glycerol is 1-1.5:1; the reaction products in the tower are subjected to vacuum evaporation to remove the azeotropic agent and filtered to remove the catalyst; and finally the carbonic acid glyceride is obtained. The solid base catalyst in the method has the advantages of low in price, convenient recovery, and cyclically used. Due to the lower mol ratio of the methyl carbonate to the glycerol, the consumption of the methyl carbonate is lowered. The process for purifying the carbonic acid glycerol products is simple.

Owner:TSINGHUA UNIV

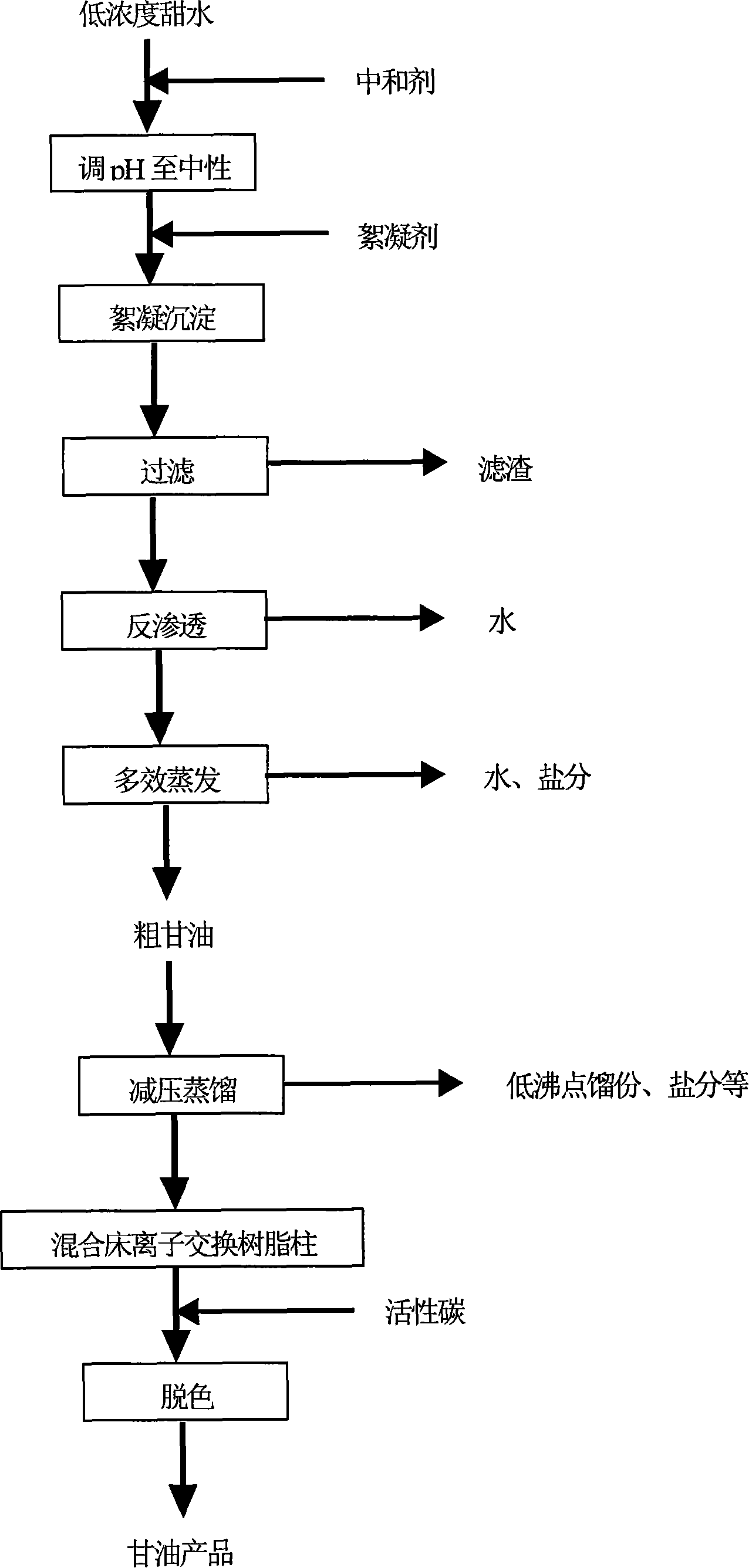

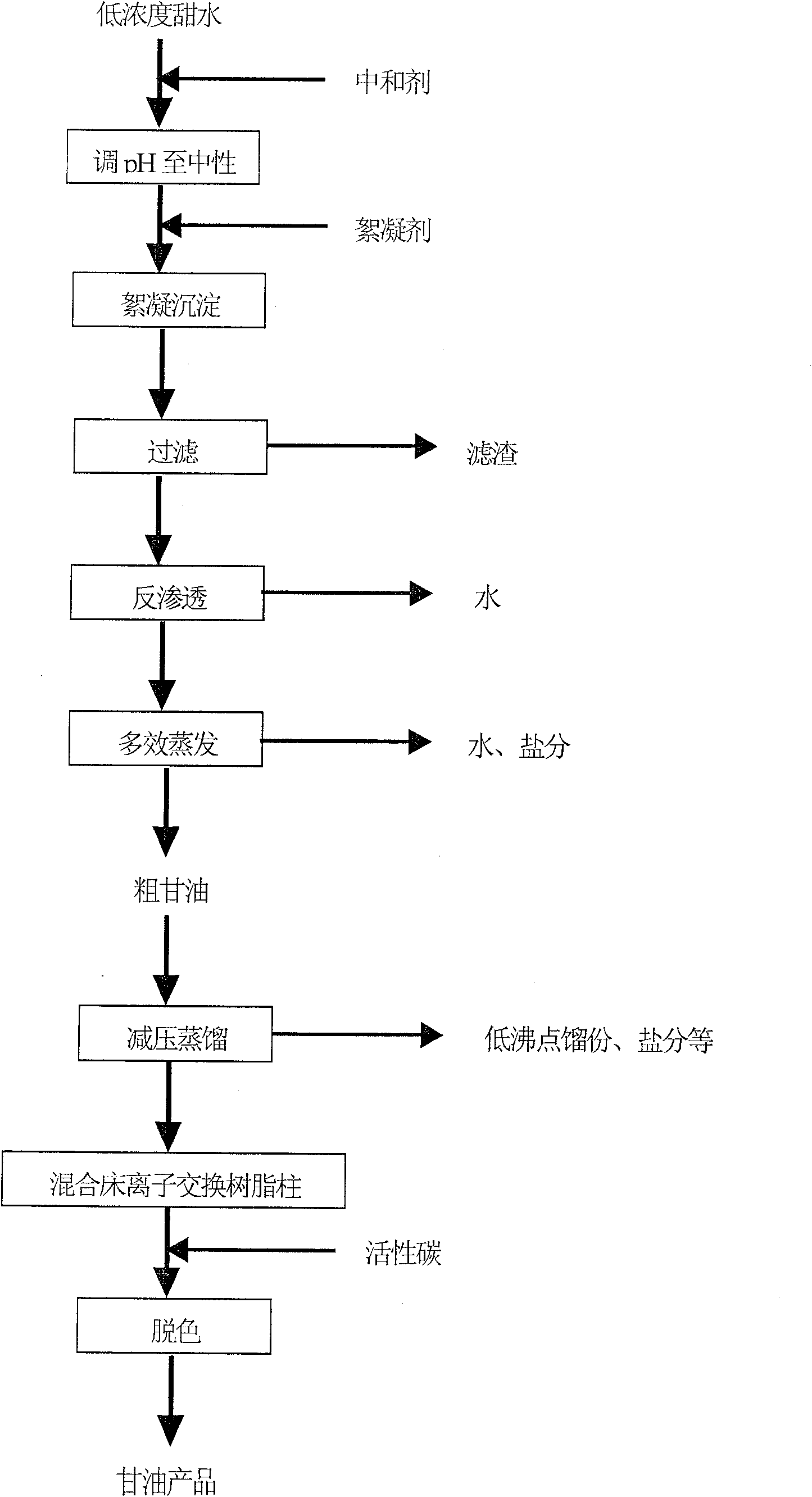

Hyperfiltration-distillation integration process for reclaiming glycerin from low-concentration sweet water

InactiveCN101139255AReduce energy consumptionLow costChemical industryHydroxy compound separation/purificationSocial benefitsDistillation

The present invention discloses an integration technics with anti-penetration and distillation to recycle a glycerin in low-concentration sweet water. The steps for the present invention are as follows: (1) the pH value for the low-concentration sweet water is adjusted to litmusless by using of a neutralization agent, and then a flocculating agent is added into the sweet water; after being deposited, the mixture is to be filtered; (2) the filter liquid is condensed into a condensing liquid through an anti-penetration film component in the pressure of 1-8MPa; the condensing liquid is vaporized with multi-aspects to get rid of water and part of salt; and then a coarse glycerin; (3) the coarse glycerin is decompressed, distilled, ion-exchanged with resin refining in a mixing bed, and decolored with an active carbon to create the glycerin product with the purity more than 98.5 percent. The present invention can be used in medicine industry and foodstuff industry and so on. The technics has the advantages of low resource consumption, large treatment quantity and low cost and so on. The present invention can not only bring much better economical benefit by changing uselessness into usefulness, but also has greater environmental and social benefit.

Owner:ZHEJIANG UNIV

Production of diesel oil from trench oil and methyl alcohol

Production of biological diesel oil from trench oil and methanol is carried out by esterifying trench oil with methanol at specific temperature and composite acid catalyst, ester exchange reacting to obtain fatty acid methyl ester and glycerine, phase splitting, and purifying to obtain the final product. It costs low and has less discharge capacity.

Owner:王建业 +1

Method for recovering unreacted alcohol from biodiesel product streams by flash purification

InactiveUS20080312468A1Reducing alcohol lossLower energy requirementsFatty acid esterificationPreparation by ester-hydroxy reactionBiodieselAlcohol

A method for making fatty acid esters by reacting triglycerides with an excess of alcohol in a pressurized environment, where the unreacted alcohol component is separated from the reaction product by a flash purification techniques. In this manner, the pressure of the product stream is significantly reduced to vaporize unreacted alcohol, which is then condensed for later reuse. The invention provides a cost-effective and convenient mechanism to simultaneously recycle excess alcohol and to purify ester product and / or glycerol product streams.

Owner:ORBITEK

Method for refining biodiesel byproduct glycerin

InactiveCN101182281ASimple processImprove efficiencyHydroxy compound separation/purificationChemical industryBiodiesel

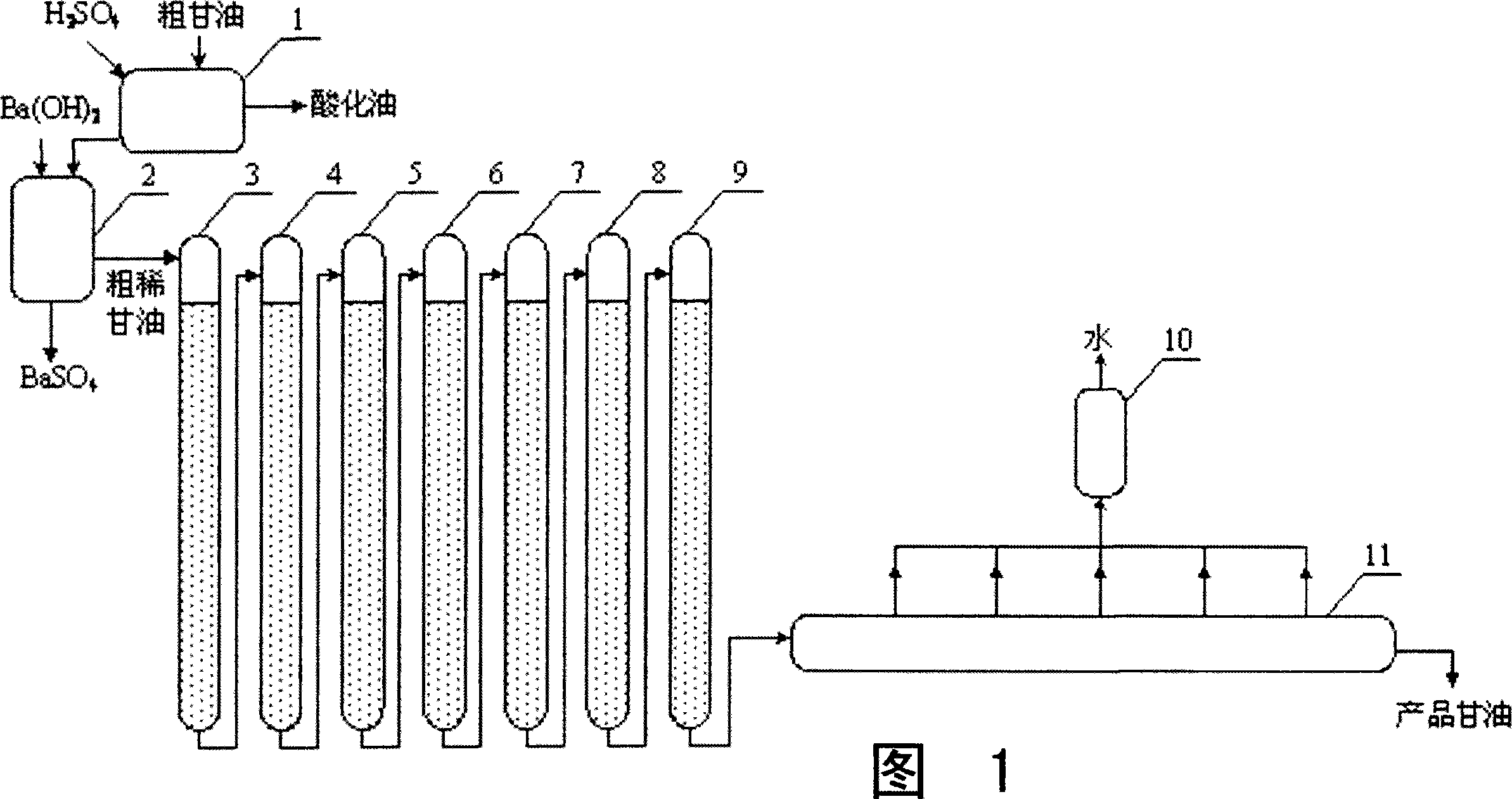

The invention provides a method of refining a biological diesel oil by-product of glycerol. The invention relates to the technical field of the oil and fat chemical industry and more particularly a method of refining the biological diesel oil by-product of the glycerol. The steps of the method are that crude glycerol produced during the production process of the biological diesel oil is added into a acidification reactor for the acidification treatment; acidified oil at the upper layer is returned to a biological diesel oil production system as the production materials of the biological diesel oil, and the glycerol at the lower layer is put into a neutralization reactor for the neutralization reaction; the glycerol layer is put into an ion exchange column for impurity removal to obtain the dilute solution of glycerol which contains water; the dilute solution of glycerol is put into a short-stroke pipeline evaporator for continuous evaporation and concentration to obtain the refined glycerol product. The technical process of the invention is simple; the efficiency is high; the investment is less; the quality of the obtained product is uniform; the invention can reduce the recycle cost of the glycerol and the production cost of the biological diesel oil.

Owner:KUNMING UNIV OF SCI & TECH

Method for recovering unreacted alcohol from biodiesel product streams by flash purification

InactiveUS7531688B2Reducing alcohol lossLower energy requirementsFatty acid esterificationOrganic compound preparationBiodieselAlcohol

Owner:ORBITEK

Method for purifying glycerin from biodiesel production by-products

ActiveCN109721471AReduce the burden onEfficient removalHydroxy compound separation/purificationBiodieselEvaporation

The invention relates to a method for purifying glycerin from biodiesel production by-products. The method comprises: diluting with methanol, removing part of inorganic salts, neutralizing by adding an alkali, adding an organic solvent insoluble or slightly soluble with glycerin and miscible with organic acids and other organic impurities, extracting, removing organic acids, partial pigments and other organic impurities, distilling to remove the methanol, diluting by adding water, purifying sequentially with an acidic cation exchange resin and an alkaline anion exchange resin, carrying out evaporation dehydration, and removing light components to obtain the high-purity glycerin product. According to the present invention, with the method, the pretreatment is performed with the inorganic acid before the ion exchange, such that the salt can be effectively removed while the excess alkali in the material liquid can be neutralized and part of the organic matters can be removed; the organicsolvent extracts the organic acid, part of the pigments and other organic impurities in the crude glycerin; with the treatment, the burden of the desalting in the subsequent ion exchange process is effectively reduced, and the pollution on the resin is reduced; and the purity of the purified glycerin is above 99.5%, the glycerin loss is low, and the purification yield can reach more than 95%.

Owner:CHINA PETROLEUM & CHEM CORP +1

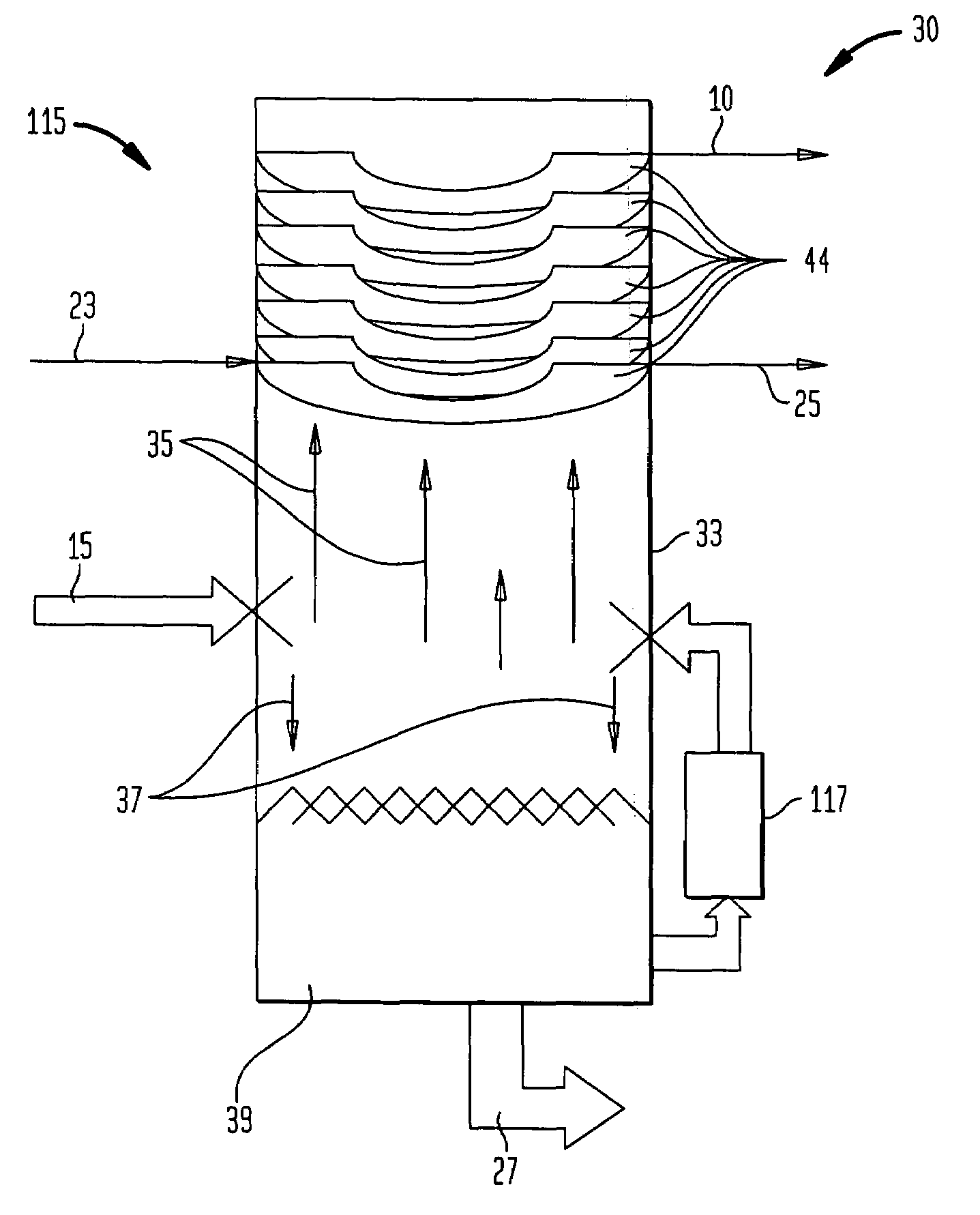

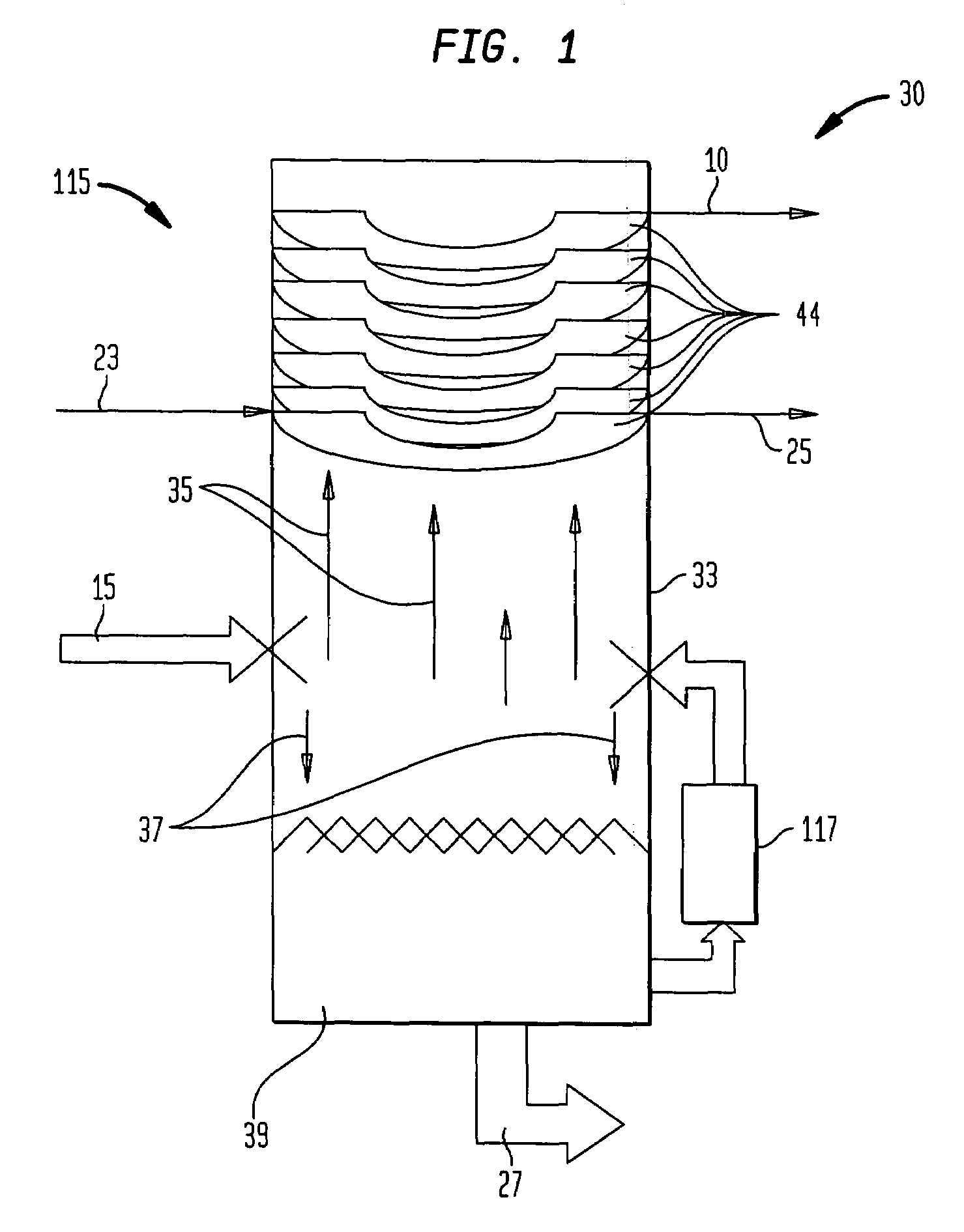

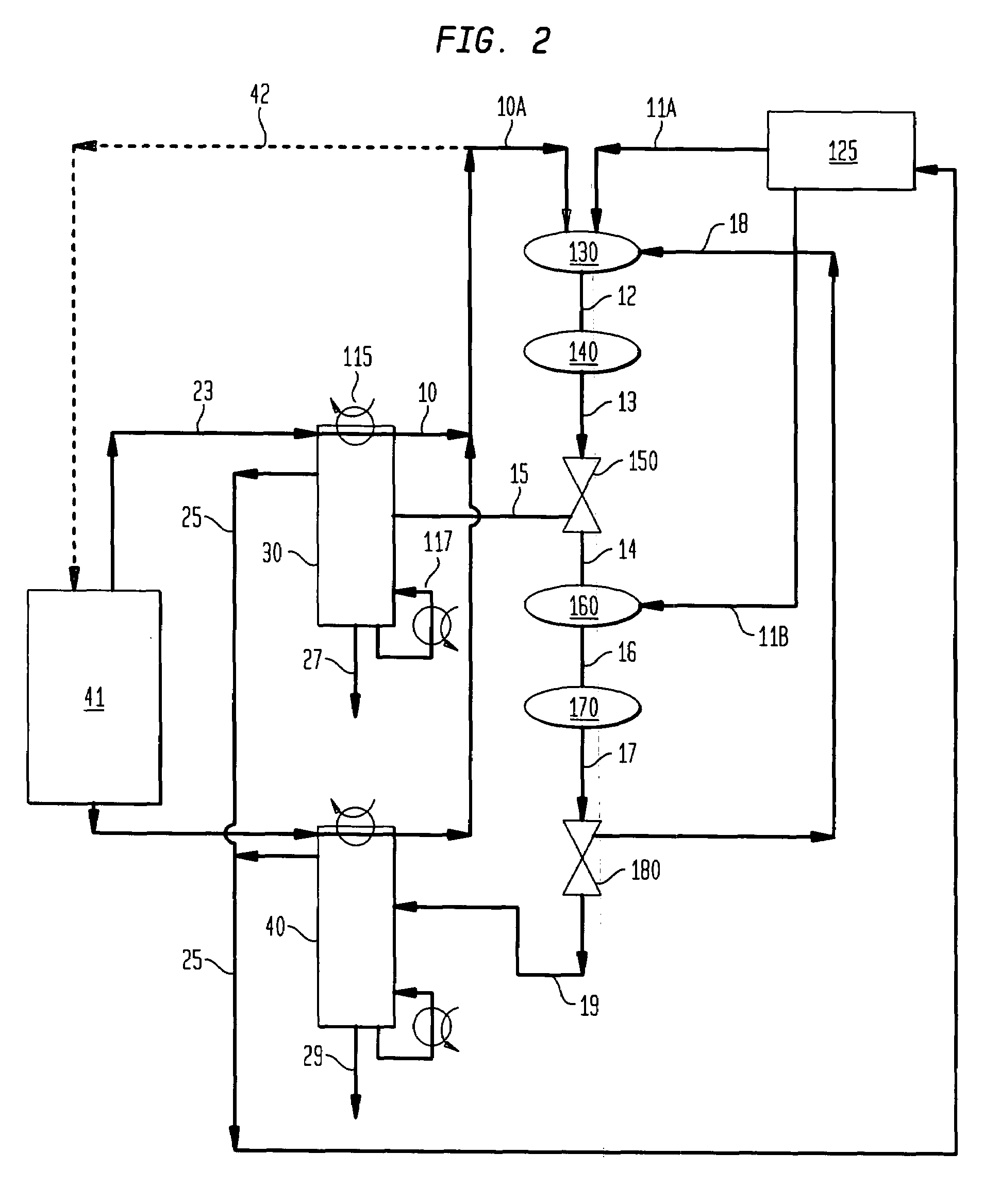

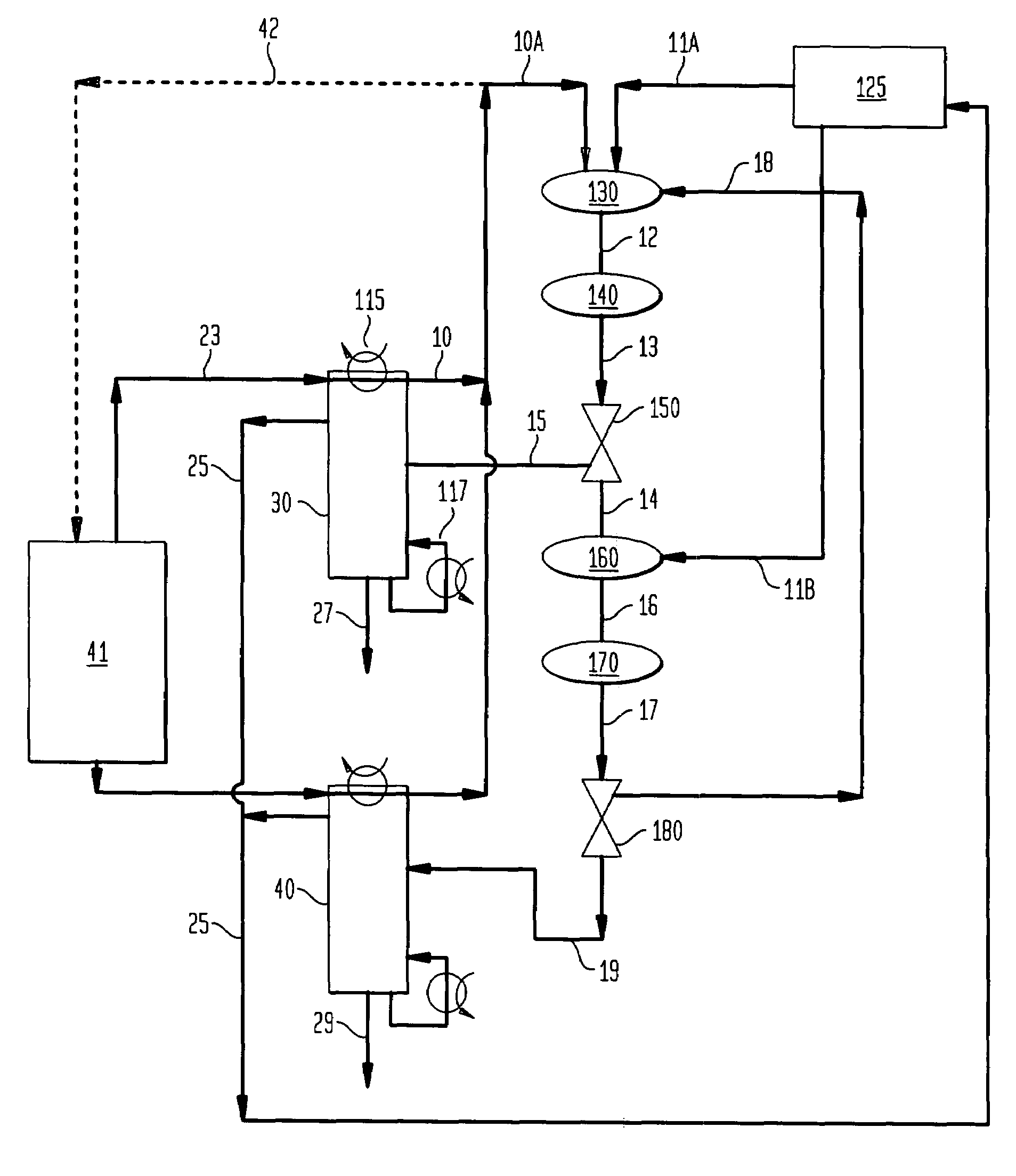

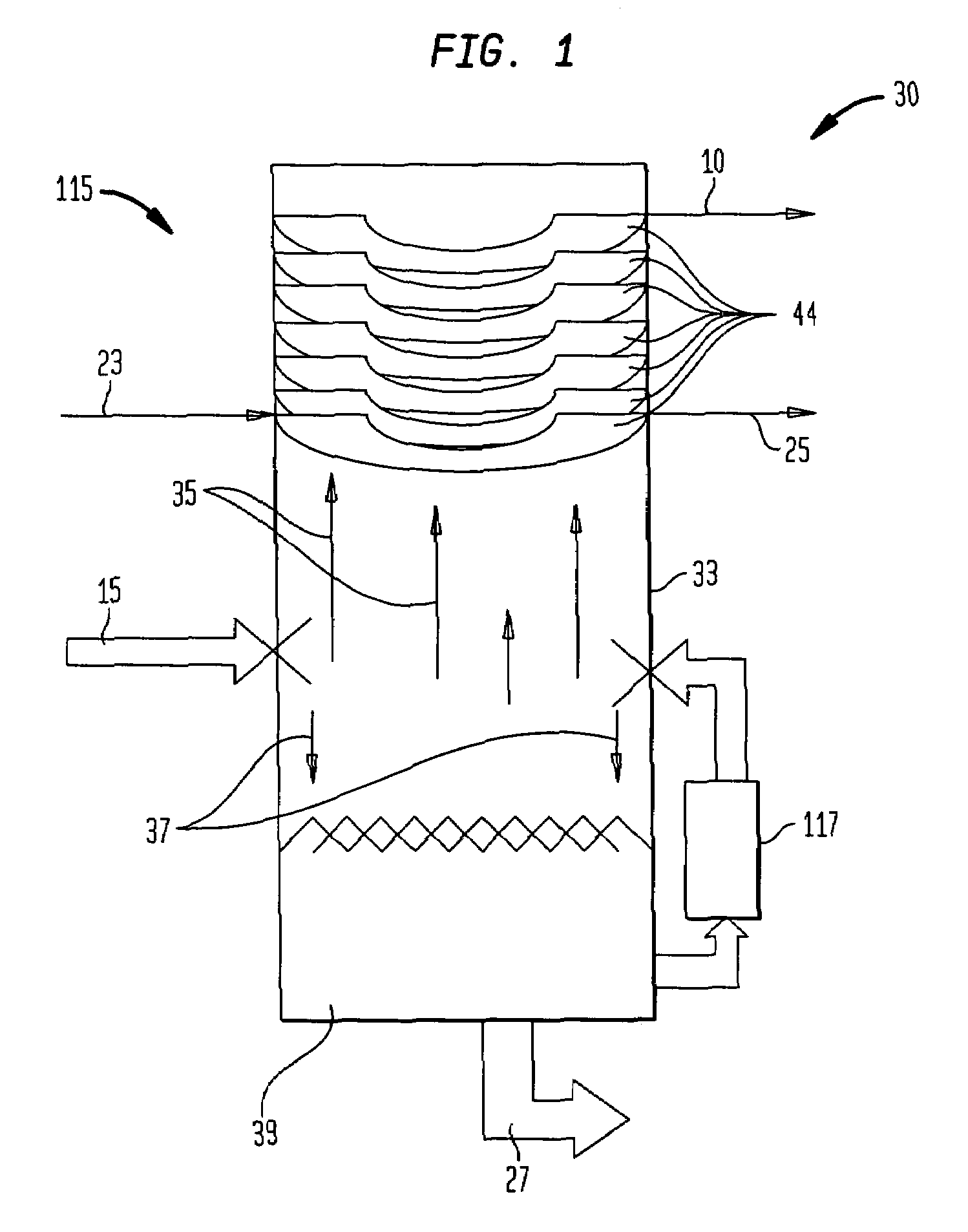

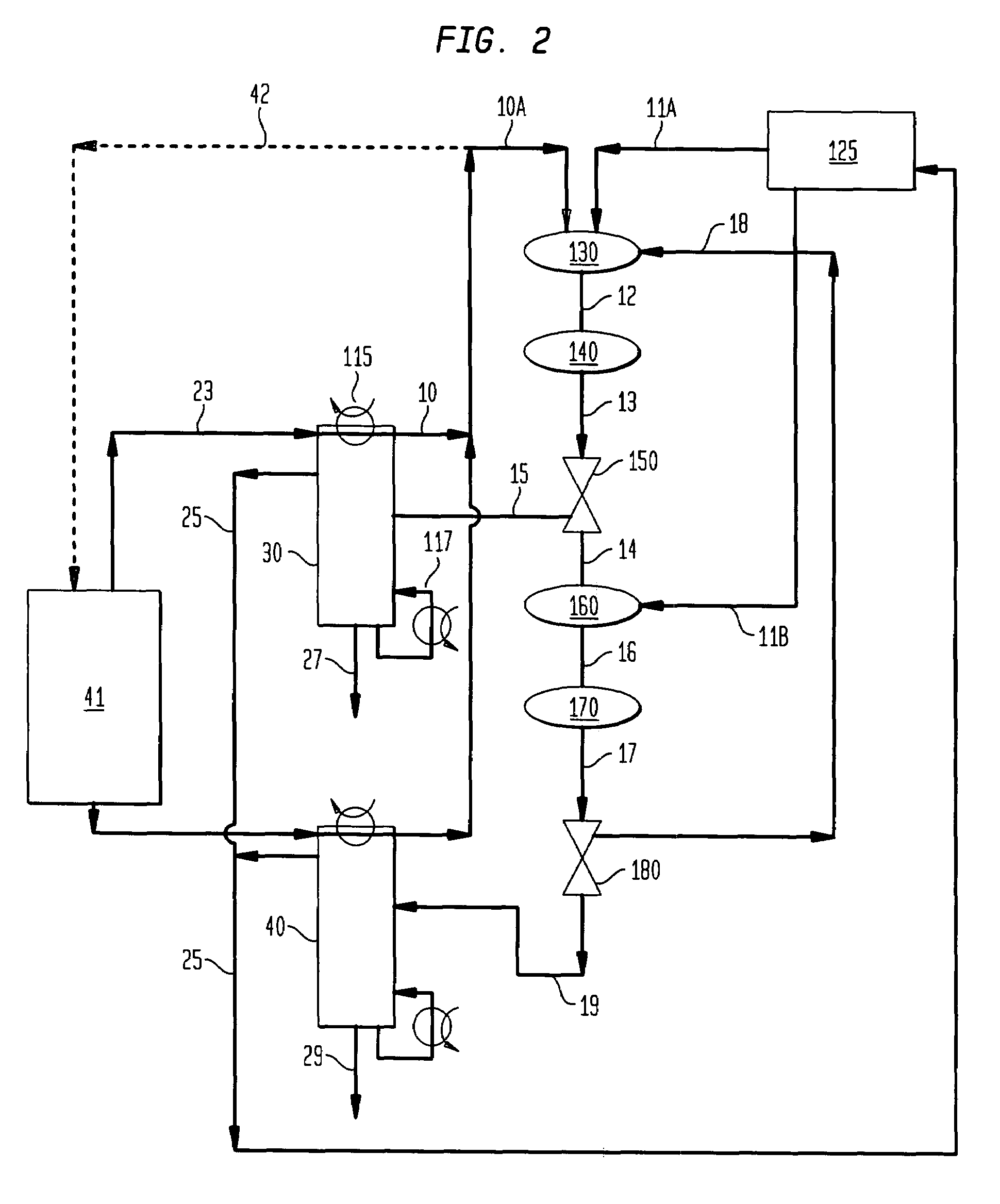

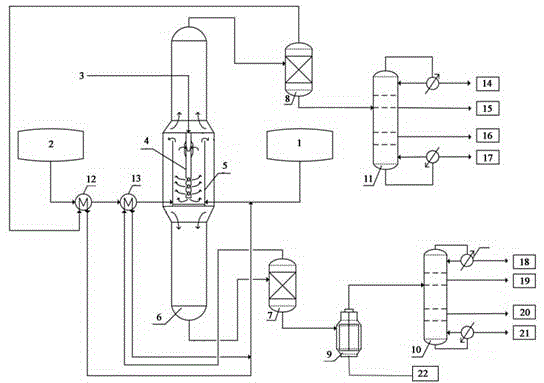

Super-high-efficiency lipid hydrolysis reactor and reaction process

ActiveCN104388194AIncreased phase boundary areaAchieve recyclingOxygen-containing compound preparationOrganic compound preparationLipid storageWater storage tank

The invention relates to a super-high-efficiency lipid hydrolysis reactor which comprises a raw material lipid storage tank, a water storage tank, a steam inlet tube, a gas-liquid ejection mixer, an inner cylinder, an outer cylinder, a glycerinum flash tank, a fatty acid flash tank, a scraper evaporator, a glycerinum rectifying column and a fatty acid rectifying tower. A high-temperature high-pressure steam power source is adopted, and a gas-liquid ejection mixer is taken as a compulsive material mixing, mass transfer and reaction key component. The invention further provides a reaction process of the reactor. By adopting the reactor, the phase boundary of lipid and water is greatly increased, so that the reaction time of hydrolysis is greatly shortened, on the basis, the reaction temperature and the pressure can be appropriately reduced, so that the energy consumption and the operation cost are reduced, and meanwhile the security coefficient of equipment is increased; the reactor can be used in the hydrolysis process of lipid consisting of different fatty acids, the different fatty acids and glycerinum water can be efficiently separated after the hydrolysis is completed, and a corresponding fatty acid product and a glycerinum product are obtained.

Owner:NANJING UNIV

Treatment method of glycerol as by-product of biodiesel

ActiveCN105585449AThe method steps are simpleReduce energy consumptionOrganic compound preparationHydroxy compound separation/purificationMicroorganismBiodiesel

The invention discloses a treatment method of glycerol as a by-product of biodiesel. The treatment method includes the following steps: 1) acidifying the glycerol as the a by-product of the biodiesel, allowing the by-product glycerol to stand for layering, and obtaining a subnatant; 2) adding organic alcohol to the subnatant, uniformly mixing the liquid, and performing solid-liquid separation to obtain a glycerol clear liquid; 3) adding water to the glycerol clear liquid to dilute the glycerol clear liquid, performing electrodialysis desalination, and then rectifying the liquid and collecting a bottom residue which is the product. The glycerol product can be used for microorganism fermentation. The treatment method is simple in process and is easy to achieve industrial application.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

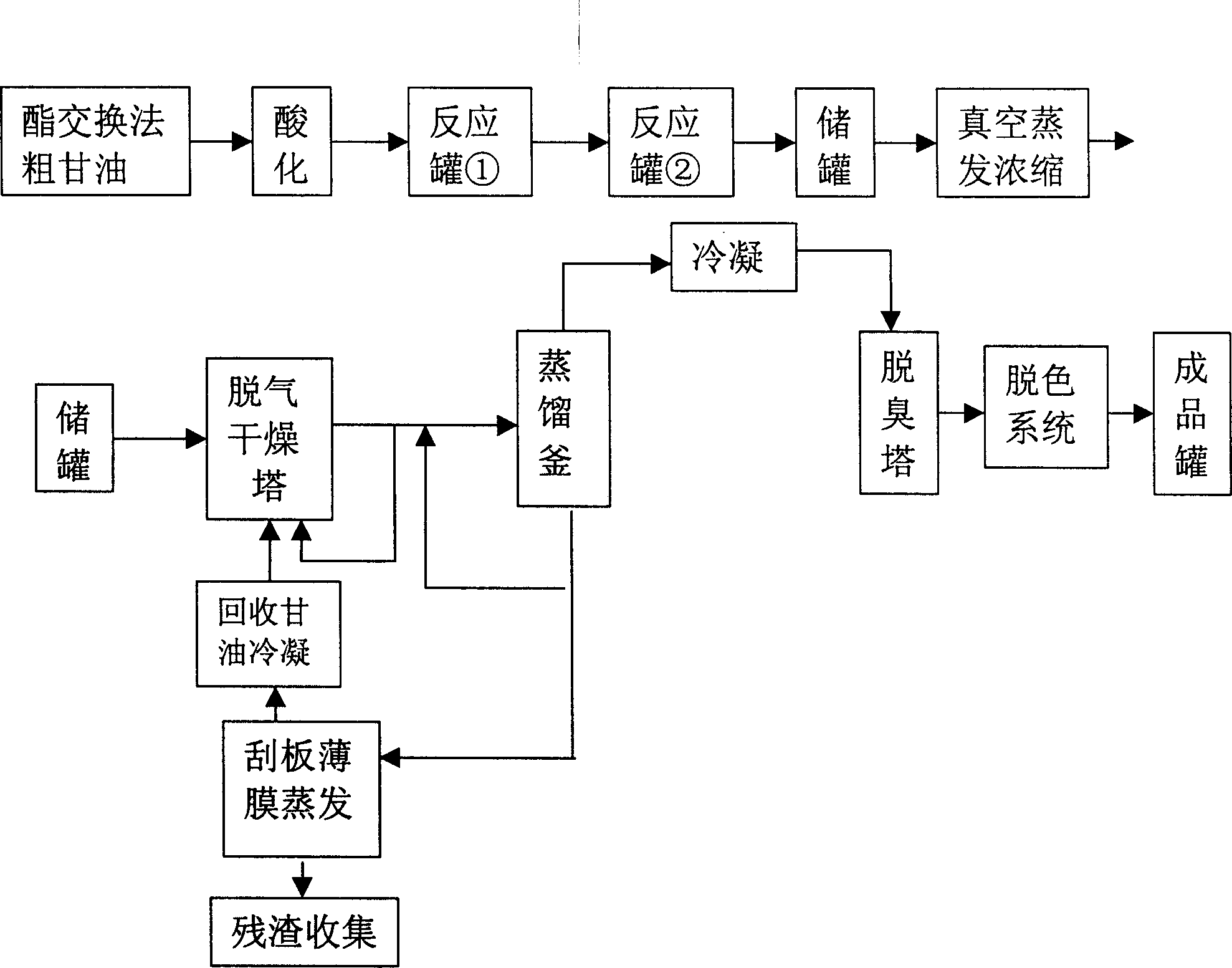

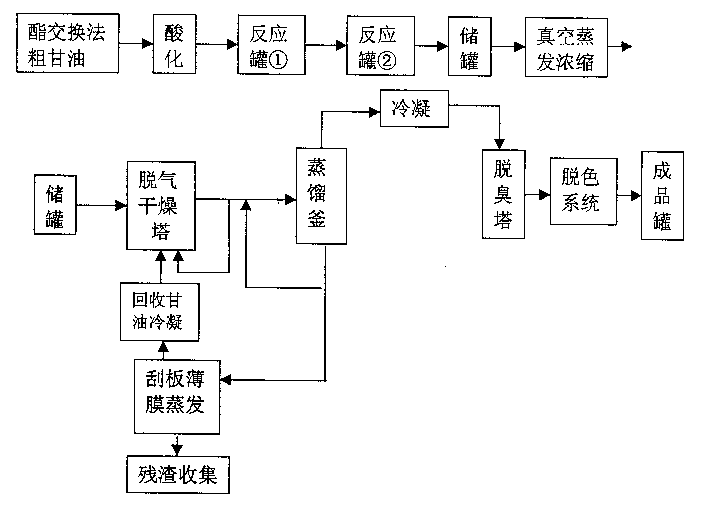

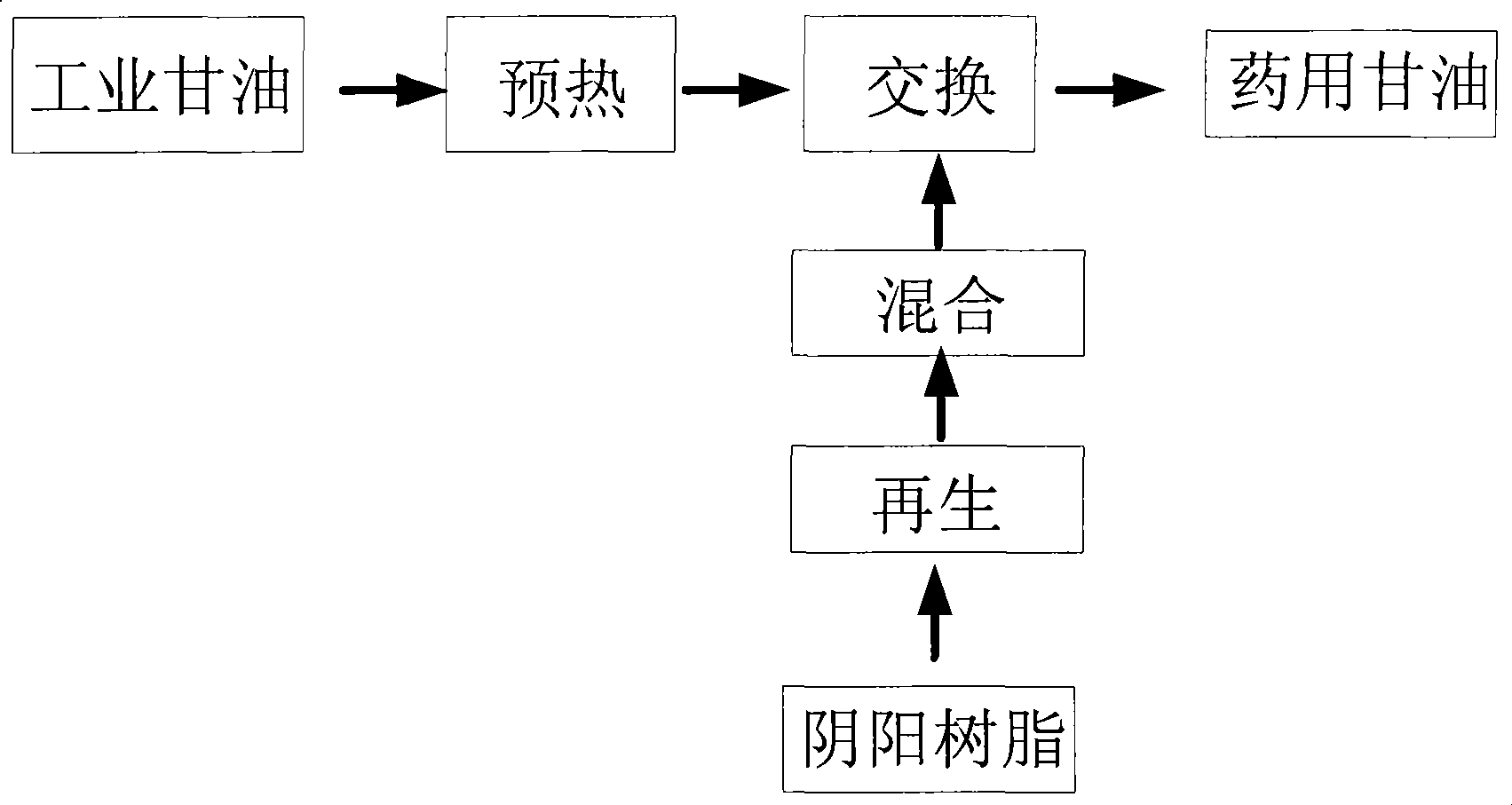

Production technique of medical pure glycerin from crude glycerin by ester exchange method

InactiveCN1459441AReduce alkalinityLess side effectsOrganic compound preparationHydroxy compound preparationGlycerolColloid

A process for preparing medical-pure glycerine from the ester exchange process crude glycerine includes such steps as acidifying by concentrated sulfuric acid, treating with medicament for removing impurities including fatty acid, methyl ester, colloid, pigment, etc., then vacuum concentrating to form crude glycerine, cyclic degassing and drying, cyclic distilling, deodoring and decoloring to obtain the medical-pure glycerine. Its advantage is high purity up to 99.5% or more.

Owner:杨宏

A kind of treatment method of biodiesel by-product glycerin

ActiveCN105585449BThe method steps are simpleReduce energy consumptionOrganic compound preparationHydroxy compound separation/purificationBiodieselAlcohol

The invention discloses a treatment method for biodiesel by-product glycerol. The method includes the following contents: (1) acidifying the biodiesel by-product glycerin, standing for stratification, and taking the lower clear liquid; (2) adding organic alcohol to the lower clear liquid obtained in step (1), mixing evenly, and solidifying After liquid separation, glycerin clear liquid is obtained; (3) The glycerin clear liquid obtained in step (2) is added for dilution, electrodialysis is performed for desalination, and then rectification, and the residue is collected as the product. The glycerin product obtained by the method can be used for microbial fermentation, has a simple process and is easy to realize industrial application.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

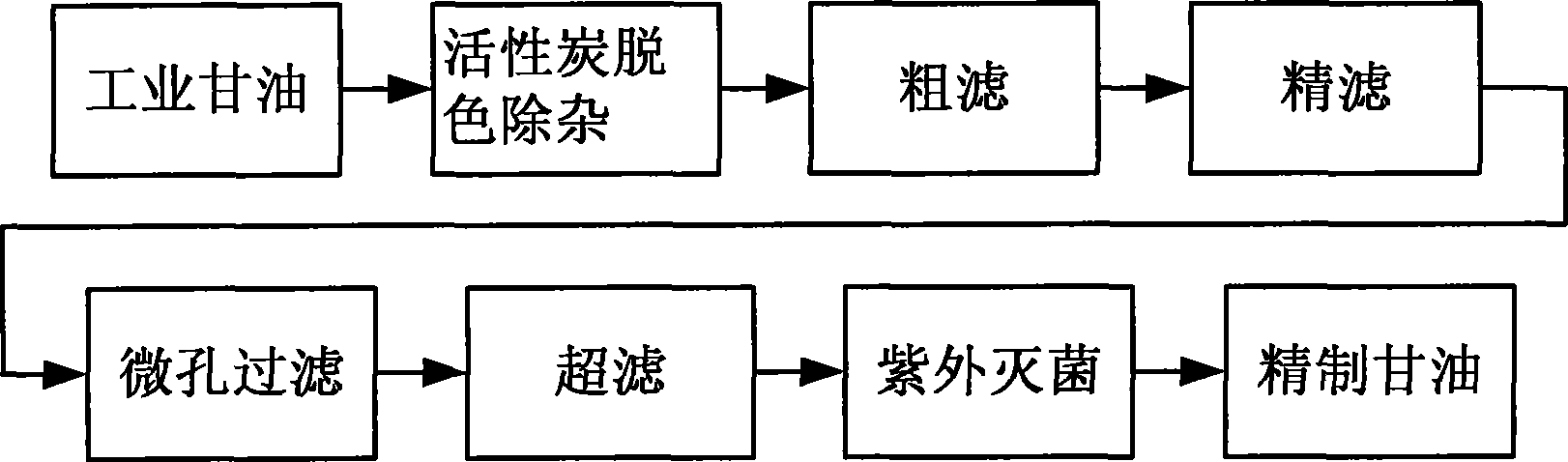

Preparation method of glycerol for injection

ActiveCN101445425AWon't decomposeEfficient decompositionHydroxy compound separation/purificationUltrafiltrationFiltration

The invention discloses a preparation method of glycerol for injection. The method is characterized by comprising the following steps: firstly, pre-treating the crude glycerol to remove impurities with the particle size larger than 0.45 micron in advance; allowing the pretreated solution to pass through an ultrafiltration membrane; finally, sterilizing the ultrafiltered ultrafiltrate by ultraviolet radiation to remove minute quantities of bacteria from the ultrafiltrate to obtain the refined glycerol. The pre-treating process sequentially comprises decolorization and impurity removal by active carbon, rough filtration, fine filtration and millipore filtration. The glycerol product prepared by the method can reach the injection standard.

Owner:HUNAN ER KANG PHARMA

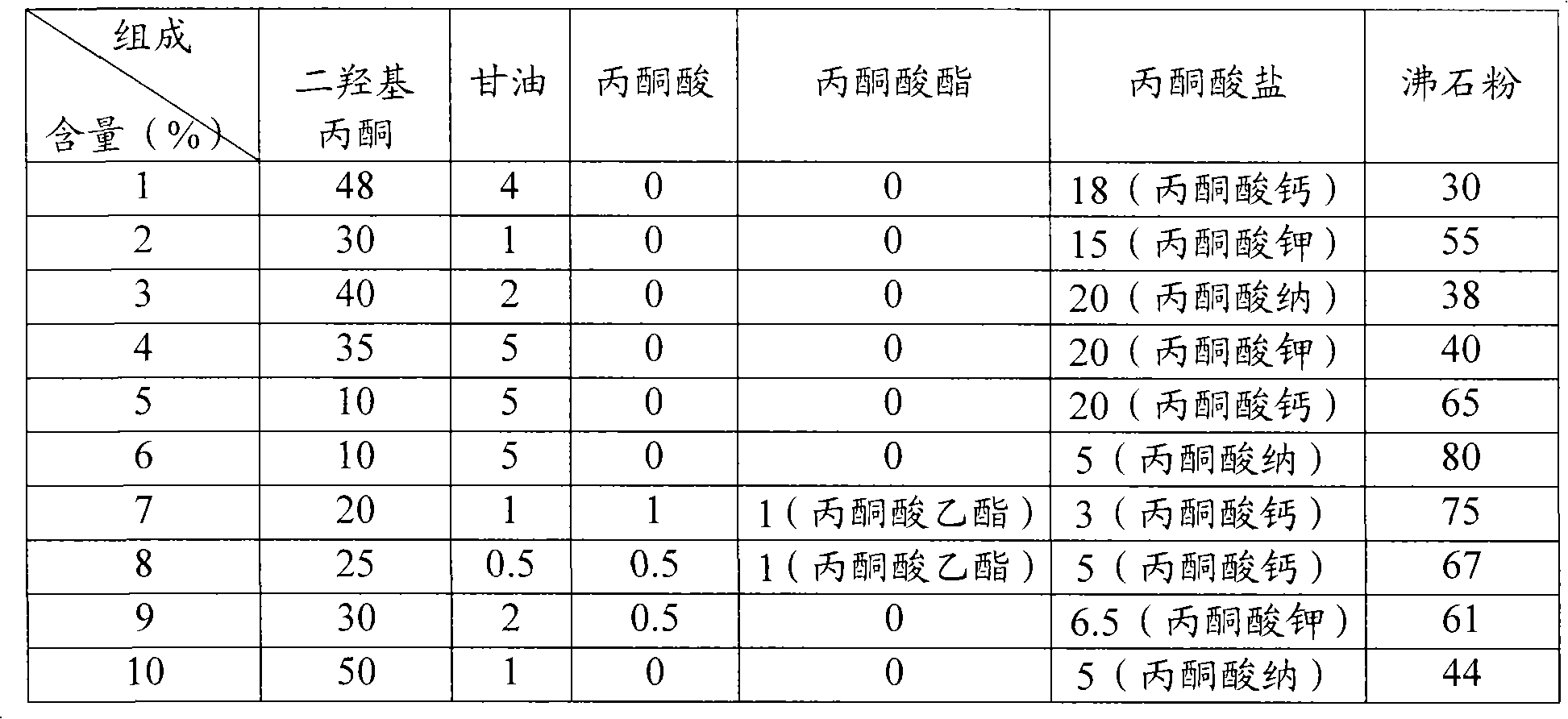

Lean-type feed additive and application thereof

ActiveCN101524119ATo promote metabolismFacilitate depositionAnimal feeding stuffAccessory food factorsAdditive ingredientMicrobial transformation

The invention provides a lean-type feed additive and application thereof. The feed additive comprises the ingredients with the following weight proportions: 10%-50% of dihydroxyacetone, 5%-20% of pyruvic acid compound, 0.1%-5.0% of glycerol, and zeolite power being the rest. The feed additive of the invention can significantly promote animal lipid metabolism and promote protein deposition; key materials such as dihydroxyacetone and pyruvic acid microbe are adopted in the additive for transforming glycerol products, therefore, the production condition is moderate, and process is simple, product is environment friendly and can be biologically degraded, with no harm to human body.

Owner:ZHEJIANG UNIV OF TECH

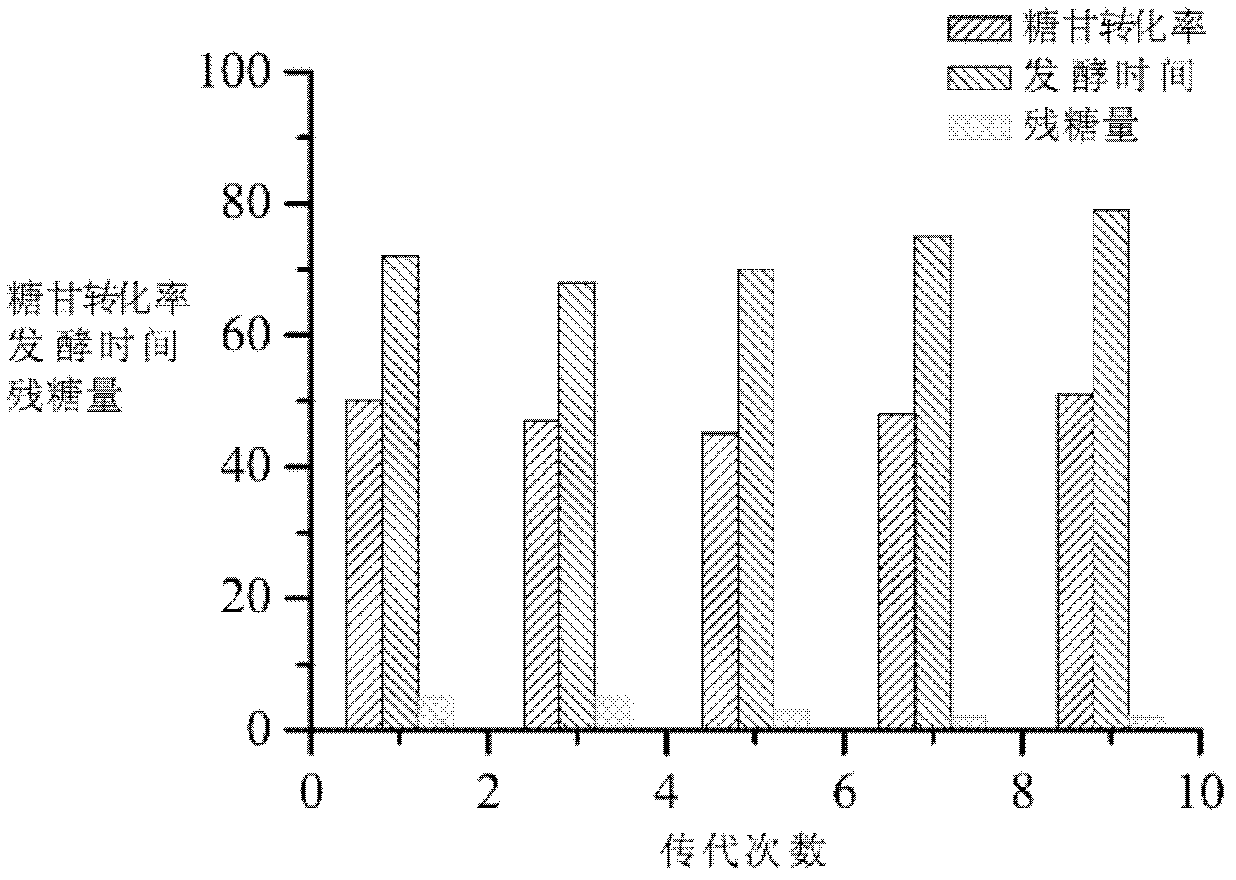

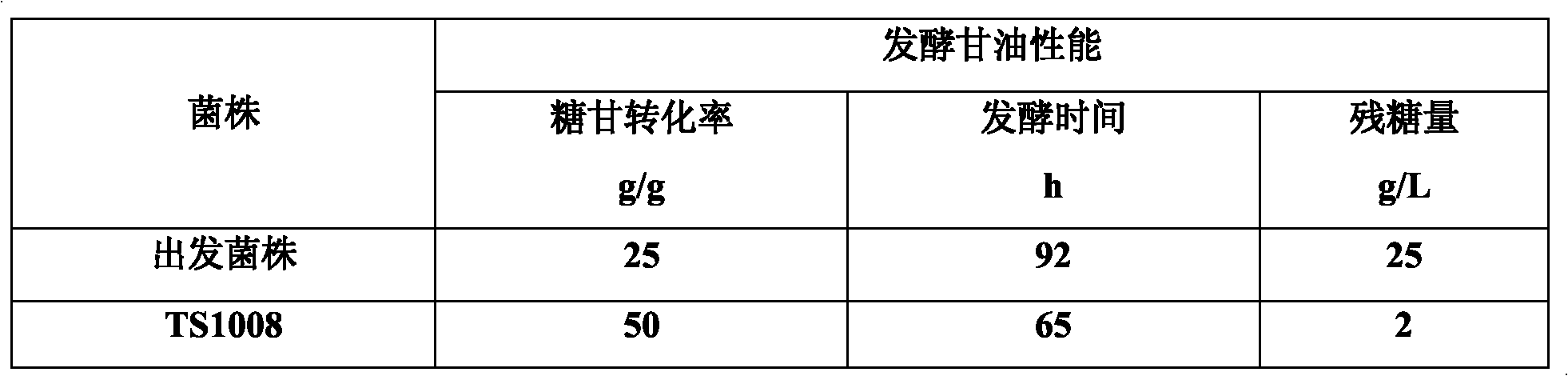

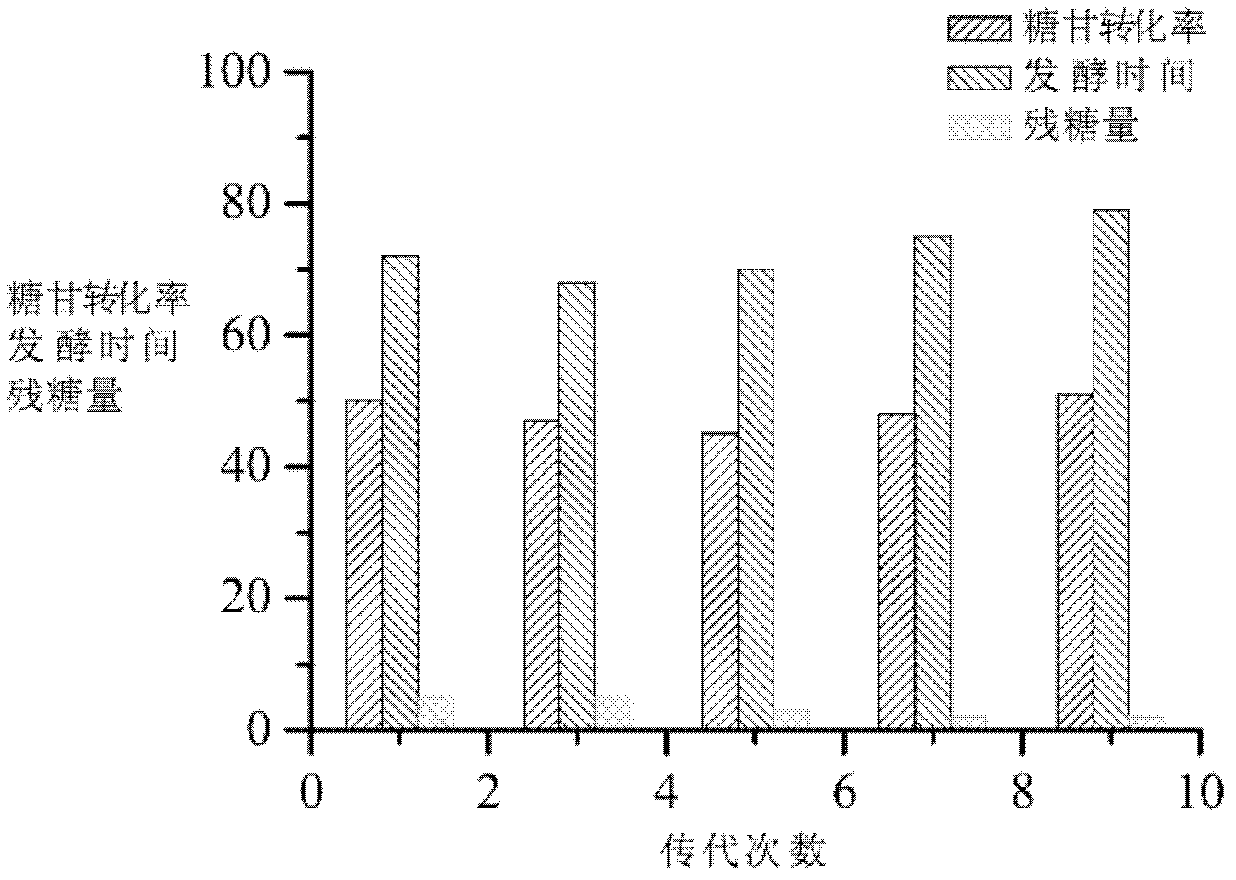

Glycerol production process based on Candida krusei

ActiveCN102277307AHigh temperature resistance hasNo assimilationFungiMutant preparationYeastMicroorganism

The invention discloses a candida-krusei-based glycerol production process, which belongs to the technical field of microbial glycerol production. The candida krusei strain TS1008 was collected in China Center for Type Culture Collection on August 10, 2011, and the collection number of the strain is CCTCC No.M2011285. The production process can improve the glycerol conversion rate in a fermentation process and the quality of the final glycerol product, and also can save energy and reduce pollutant emission in a production process for realizing energy-saving and emission-reducing production ofsafer high-quality glycerol.

Owner:上海天源植物制品有限公司

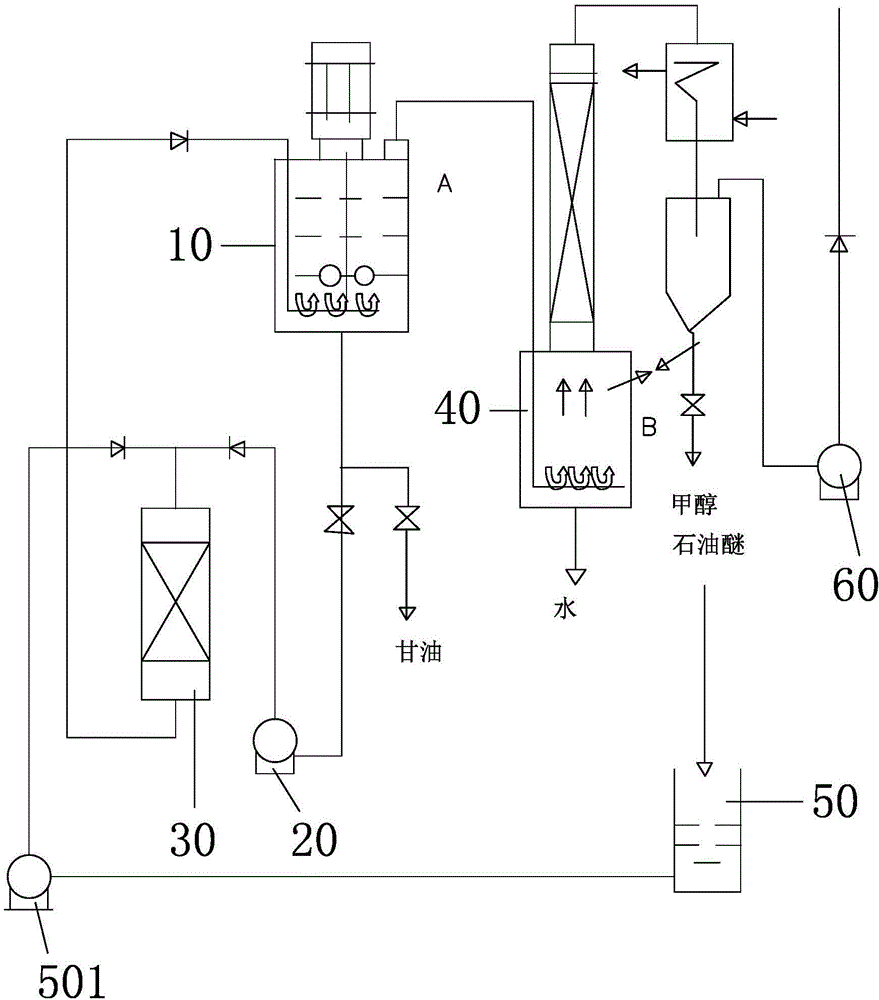

Glycerin evaporation device and evaporation method thereof

ActiveCN106362426AIncrease added valueLow costEvaporators with forced circulationMultiple-effect evaporationEvaporationGlycerol

The invention relates to the technical field of glycerin purification, in particular to a glycerin evaporation device and an evaporation method thereof. The glycerin evaporation device comprises a first preheater, a first evaporation unit, a second preheater, a forced cyclic evaporation unit and a second evaporation unit which are sequentially connected, wherein crude glycerin firstly passes through the first evaporation unit, the glycerin content of the crude glycerin is improved to above 95%, then the crude glycerin is put in the forced cyclic evaporation unit, the forced cyclic evaporation unit is utilized to produce glycerin steam, the glycerin steam enters the second evaporation unit, the second evaporation unit is utilized to collect glycerin steam heat and liquify glycerin steam, the glycerin content of the liquified glycerin steam is above 99.5%, the second evaporation unit converts the glycerin steam heat into a steam heat source of the first evaporation unit, glycerin steam heat is effectively utilized, energy sources are saved, and meanwhile a high-purity glycerin product can be obtained.

Owner:常州中源工程技术有限公司

Fatty acid methyl ester biodiesel production method and production device thereof

InactiveCN105368582ARich sourcesWide applicabilityFatty acid esterificationBiofuelsTrans esterificationPtru catalyst

The invention discloses a fatty acid methyl ester biodiesel production method and a production device thereof and relates to the technical field of biodiesel. According to the method, oil, cosolvent, alcohol and solid acid catalyst are selected, and the components are heated, stirred and subjected to a circular reaction in a reaction and distillation device to prepare fatty acid methyl ester biodiesel. The method has the advantages that the components are relatively simple, a production process device is very stable, the method is a renewable energy source synthetic route, the fatty acid methyl ester biodiesel production method and the production device of the production method are used in batches and are popular with users and accepted by the users, raw material adaptability is wide, an esterification and ester exchange reaction is completed in the same solid catalyst, waste acid emission is avoided, excessive acid, solvents and reaction water can be recycled and repeatedly used, three wastes are not emitted in the production process, the side product of glycerinum can directly serve as a raw glycerinum product and be used as a glycerinum pyrolysis gas raw material, and the raw material utilization rate is 99% or above.

Owner:李卫教

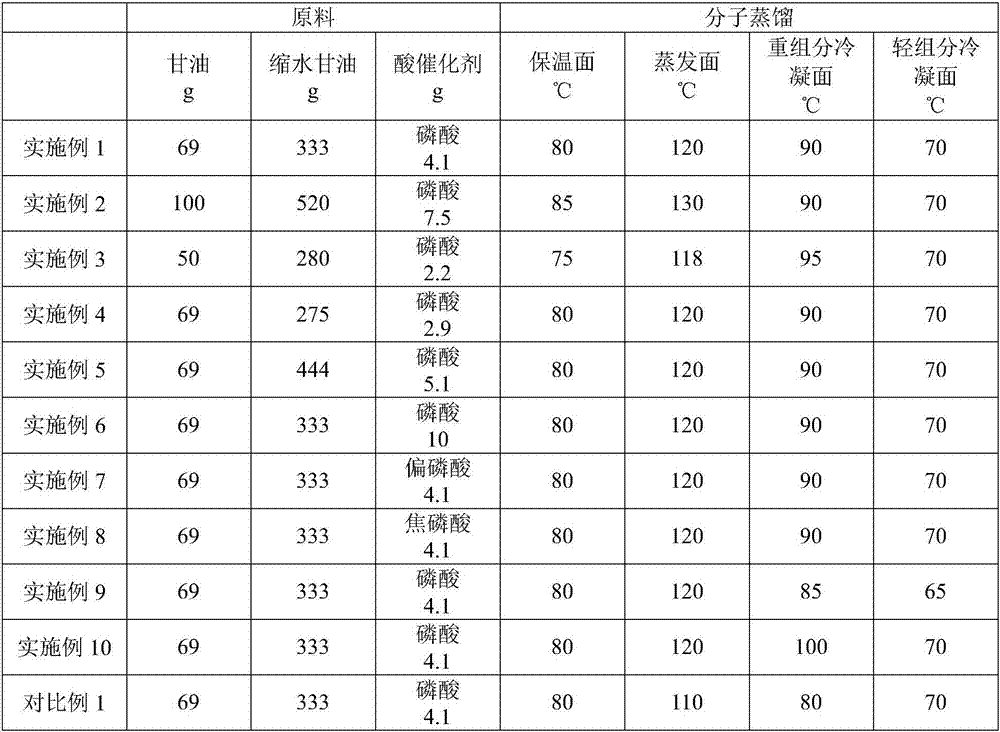

Polyglycerol-10 and preparation method thereof

InactiveCN107235830AHigh purityEase of industrial productionEther separation/purificationEther preparation from oxiranesDistillationGlycerol

The invention relates to the field of polyglycerol synthesis, in particular to polyglycerol-10 and a preparation method thereof. The preparation method of polyglycerol-10 comprises the following steps: (1) a crude polyglycerol product is prepared from glycerol and glycidol through a polymerization reaction in presence of an acid catalyst; (2) the polymerization reaction product is neutralized, a neutralization product is distilled by molecular distillation equipment, and the obtained heavy constituent is polyglycerol-10, wherein the heavy constituent condensing surface set by the molecular distillation equipment is at the temperature of 85 DEG C or higher, the light constituent condensing surface is at the temperature of 65-90 DEG C, and the heavy constituent condensing surface is higher than the light constituent condensing surface. With adoption of the method, the polyglycerol-10 product with higher purity is prepared with high yield by means of molecular distillation, and the method is beneficial to industrial production.

Owner:GUANGDONG HEJI BIOTECH CO LTD

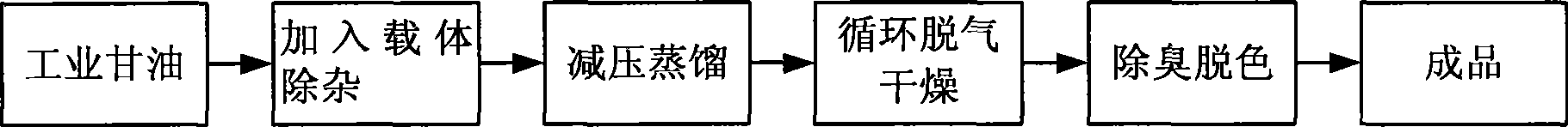

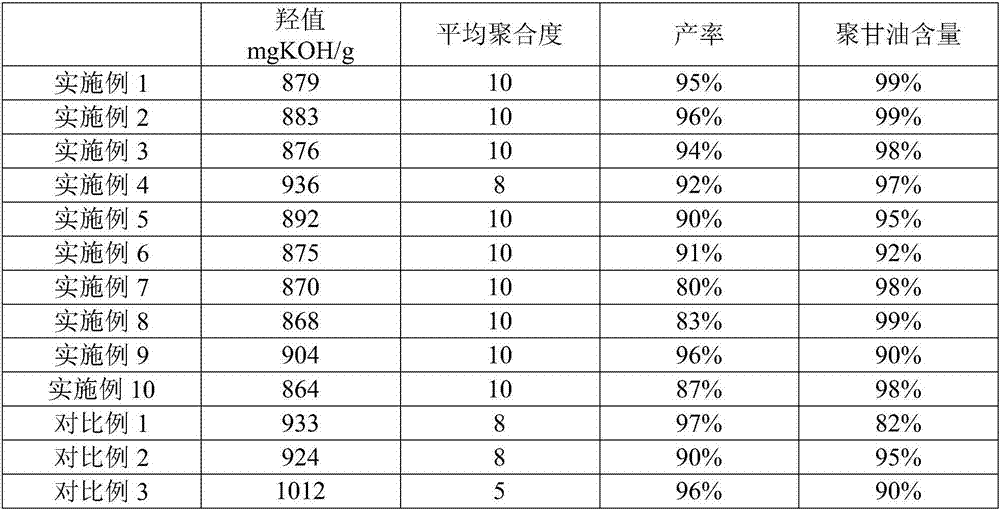

An improved glycerol production process

ActiveCN105585423BSimple processEasy to operateHydroxy compound separation/purificationDistillationGlycerol

The invention discloses an improved glycerol production technology. Grease is subjected to pyrohydrolysis to obtain a crude glycerol solution and fatty acid; the improved glycerol production technology is characterized in that crude glycerol solution purification comprises the following steps of 1 pretreatment, wherein an adsorbing agent is put into the crude glycerol solution, and reacting under stirring is performed to remove grease impurities in the crude glycerol solution; 2 resin adsorption, wherein filtrate obtained in the step 1 is adsorbed through a macroporous resin adsorption column, and a pure glycerol solution is obtained; 3 glycerol concentration, wherein a glycerol solution obtained in the step 2 is subjected to reduced pressure distillation and concentration and high-temperature evaporation or thin-film evaporation to obtain a glycerol product, and condensate is directly drained or drained after being subjected to biochemical treatment. Eluant obtained after the waste adsorbing agent and the macroporous adsorption resin are regenerated flows back to a hydrolysis kettle to continuously produce glycerol and fatty acid through pyrohydrolysis. According to the improved glycerol production technology, by adopting the macroporous adsorption resin to purify and prepare glycerol, not only is the problem that in a traditional technology, residual calcium blocks pipeline equipment due to the fact that CaO is adopted to neutralize and purify glycerol avoided, but also three wastes generated in a reclamation recycling technology can achieve full utilization of resources.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

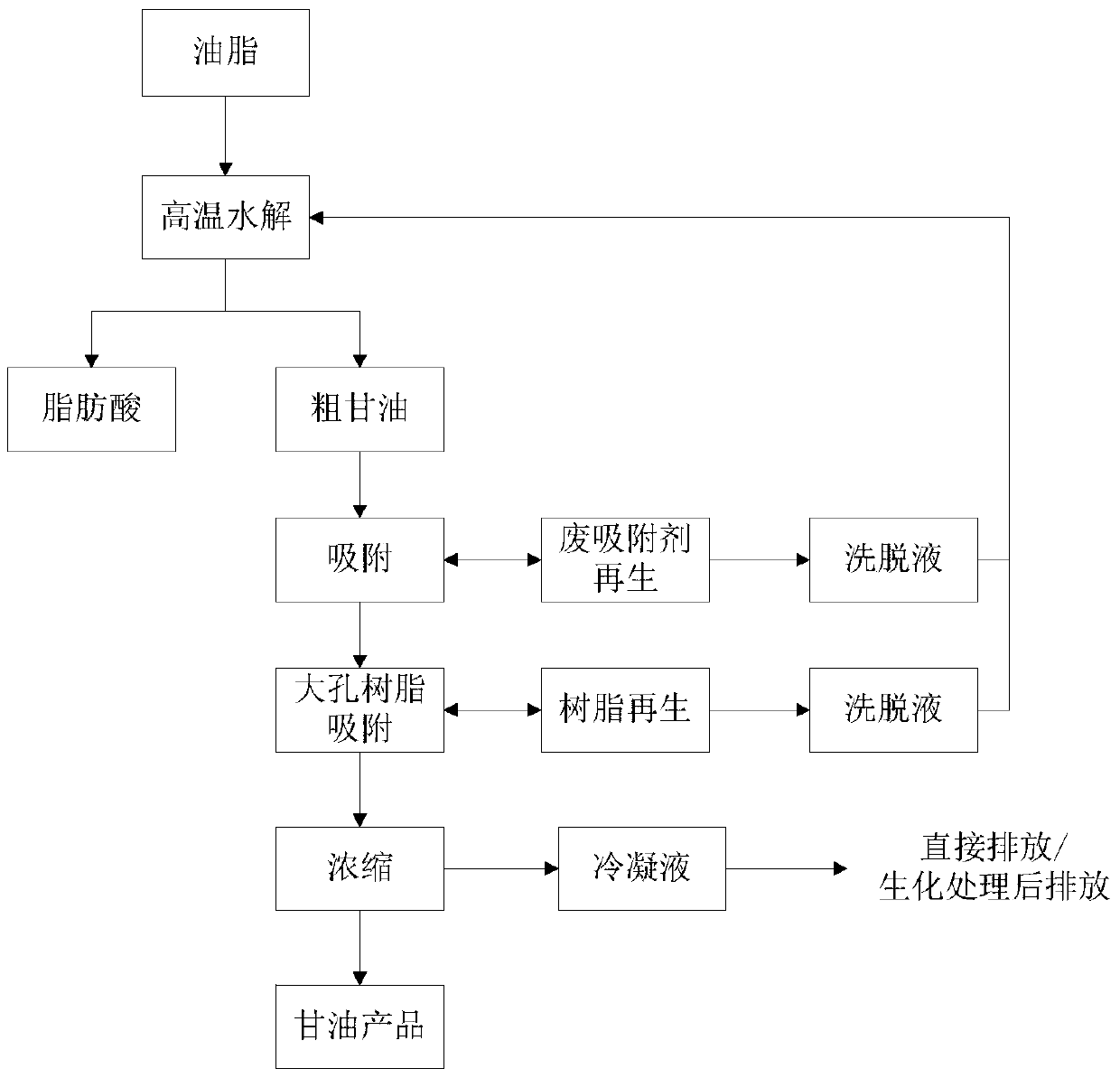

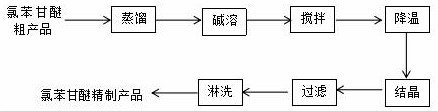

A kind of green treatment process of chlorophenyl glycerol dephenolization

ActiveCN111153780BEvenly dispersedEvenly meltedEther separation/purificationChlorobenzeneEngineering

A green treatment process for dephenolization of chlorophenyl glycerol, the crude product of chlorophenyl glycerol is dissolved in a hot alkaline solution with a mass of 3 to 5 times, the temperature is 60 to 80 DEG C, the stirring speed is 100 to 300 r / min, and the mixture is stirred with The liquid level height ratio is 0.3 to 1, and the cooling time is 2 to 5 hours. When the temperature of the material drops to room temperature, the product is precipitated. The constant precipitation temperature is 25 ℃ for 1 to 3 hours, and it is allowed to stand for 0.5 hours. Pressure vacuum filtration, using 1 to 3 times the amount of filter cake to deionize at room temperature, so that the treatment is completed, the phenolic content of the product is below 100ppm, the product is processed again according to the above steps, the phenolic content of the product can be achieved. The loss rate does not exceed 3%. The invention simplifies the treatment process for removing phenol from the chlorophenyl glycerol product, improves the efficiency of removing phenol, is green and safe, the waste liquid is easy to treat, reduces the treatment cost, and creates conditions for its industrial application. The process realizes high dephenolization efficiency, green safety, no flammable, non-toxic solvent, low energy consumption, less waste liquid, and easy disposal.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

A kind of purification method of chlorophenyl glycerol

ActiveCN111138250BChemically stablePhenol content noEther separation/purificationChlorobenzenePurification methods

A method for purifying chlorophenyl glycerol, comprising the following steps: after the reaction is completed, a crude product of chlorophenyl glycerol is obtained, under the protection of nitrogen, heating with an electric heating mantle, a distillation flask, and a Y-shaped distillation head with a glass packing ring under a vacuum degree of 0.095 Mpa or more , collect 216-218 ℃ fraction products, reuse the front fraction, and treat the residue harmlessly. The distillate product is dissolved in a certain amount of lye solution, crystallized by cooling, filtered, and the amount of the mother liquor is about 3-4 times that of the product, and the filter cake is heated and dried in a vacuum step to obtain a product with a content of more than 99.8%. The content of p-chlorophenol is There is no test result, and the product yield is 70%. The process of the invention simplifies the refining process of the chlorophenyl glycerol product, shortens the time, improves the efficiency, reduces the amount of waste liquid, the waste liquid is easy to handle, reduces the processing cost, is green and safe, and has little environmental harm, and is created for its industrial application. condition.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

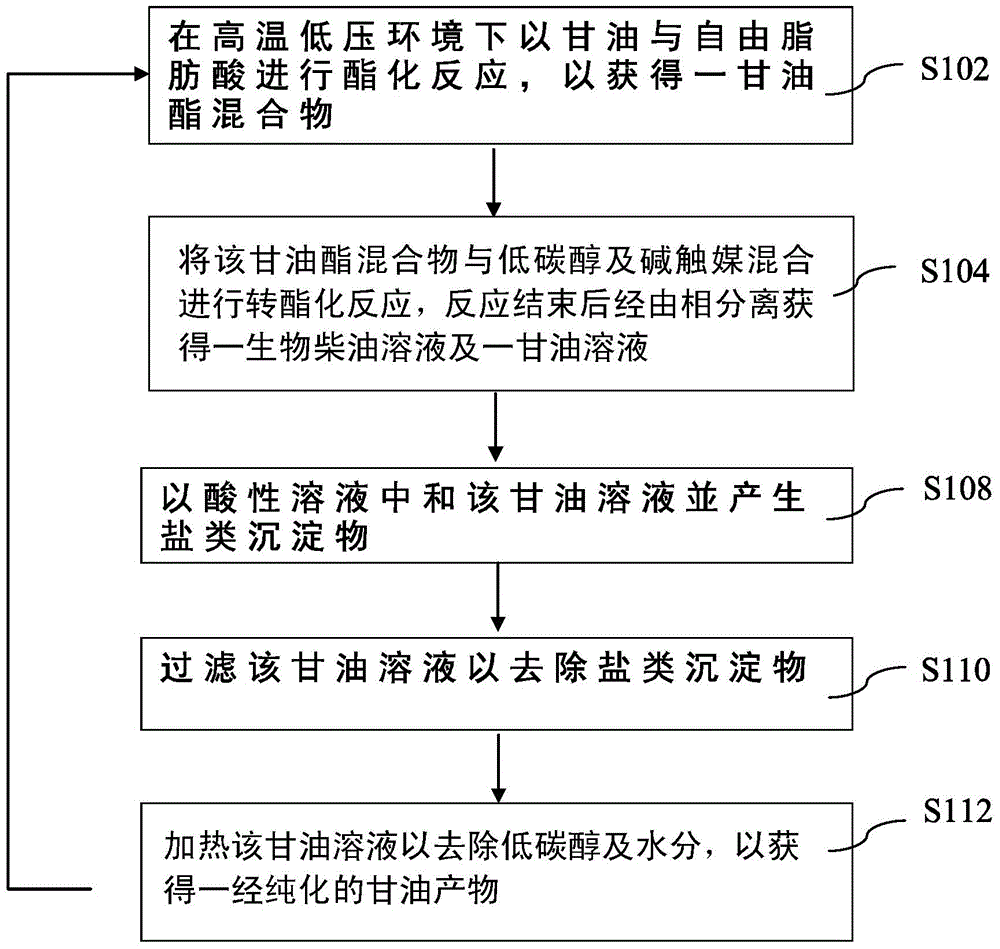

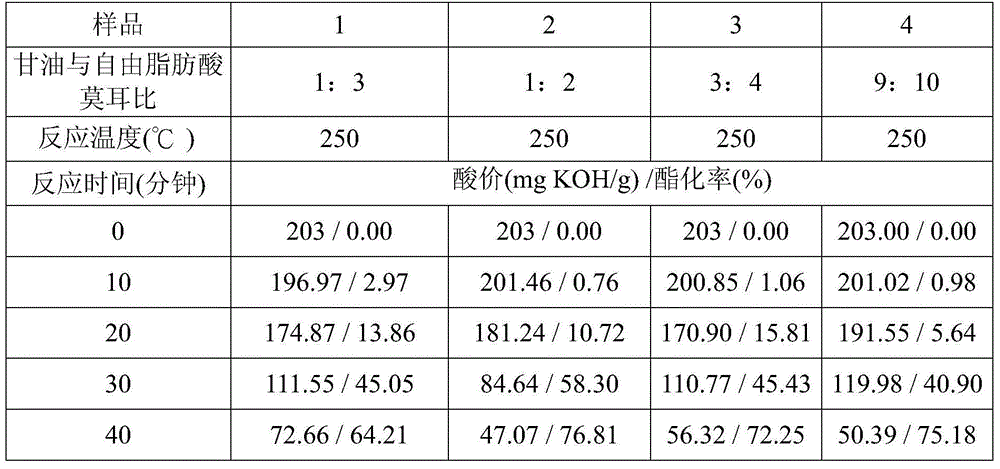

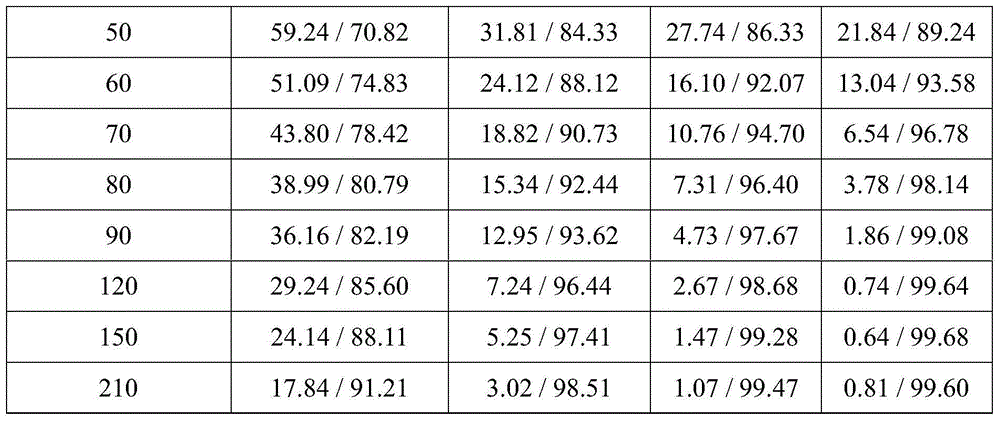

Method for circulating preparation of biodiesel

InactiveCN104611140AEquipment corrosion improvementImprove pollution environmentFatty acid esterificationOrganic compound preparationBiodieselAlcohol

The present invention discloses a method for circulating preparation of biodiesel. The method comprises that: (a) glycerol and a free fatty acid are subjected to an esterification reaction under a high temperature and low pressure environment so as to obtain a glyceride mixture; (b) the glyceride mixture, low carbon alcohol and an alkaline catalyst are mixed and are subjected to a transesterification reaction, and phase separation is performed after completing the reaction so as to obtain a biodiesel solution and a glycerol solution; (c) an acid solution is adopted to neutralize the glycerol solution so as to produce salt precipitate; (d) the glycerol solution obtained in the step (c) is filtered to remove the salt precipitate; and (e) the glycerol solution obtained in the step (d) is heated to remove the low carbon alcohol and the water so as to obtain the purified glycerol product. According to the present invention, the esterification reaction can be performed without additionally addition of the acid catalyst, and the glycerol product can be recovered to carry out circulating preparation of the biodiesel so as to reduce the biodiesel production cost.

Owner:NAT TAIPEI UNIV OF TECH

Deep purification method of high-purity glycerol

ActiveCN111909001AEasy to separateIncrease the chromatographic speedHydroxy compound separation/purificationChromatographic separationStationary phase

The invention discloses a deep purification method of high-purity glycerol, and the method comprises the following steps: carrying out high-speed counter-current chromatography separation on a glycerol raw material, collecting eluent in different time periods, and collecting glycerol eluent; and carrying out low-temperature reduced pressure distillation on the collected glycerol eluent to recoverthe solvent, thereby obtaining the high-purity glycerol. The invention provides a deep purification method of high-purity glycerol, which ensures effective separation of glycerol from glyceraldehyde,formaldehyde and other reducing substances, fatty acid and dipolyglycerol in the glycerol crude product, thereby obtaining high-purity glycerol, and ensuring that the total amount of miscellaneous peaks in the final glycerol product is less than or equal to 0.01%, the content of aldehyde and reducing substances is less than or equal to 0.5 ppm, and the content of fatty acid and ester is less thanor equal to 0.1 mL. Since the stationary phase and fluidity of the high-speed counter-current chromatography are both liquids and can be recycled, compared with the conventional chromatographic separation, the process has the advantages of no solid carrier adsorption loss and high sample recovery rate; no stationary phase consumables are consumed, and the separation cost is reduced. Compared witha conventional process, the process has the advantages of being convenient to operate, short in production period and high in yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

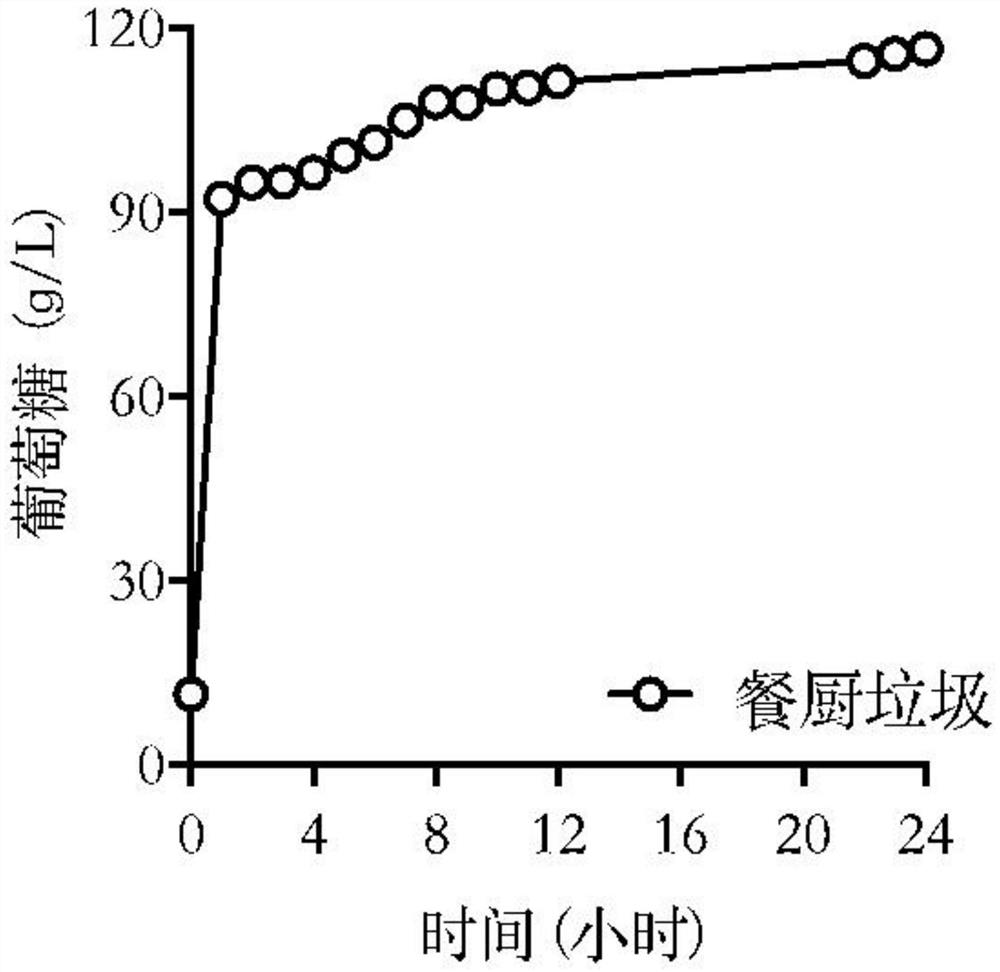

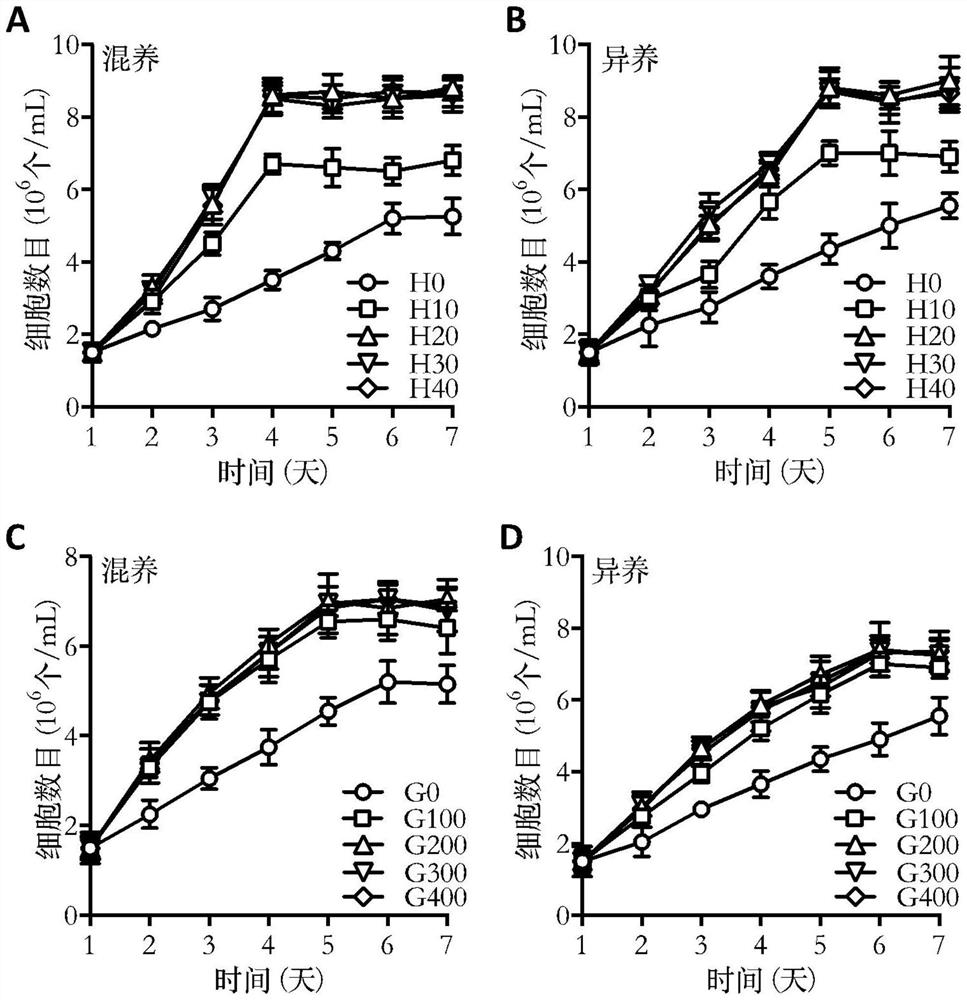

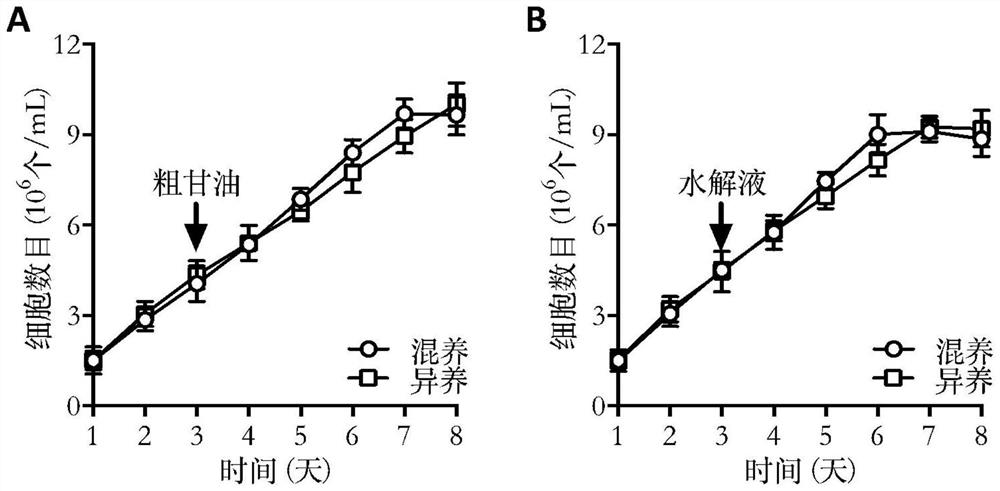

Microalgae culture medium and application thereof

ActiveCN112680359AWide and low costLow costUnicellular algaeMicroorganism based processesBiotechnologyHydrolysate

The invention belongs to the technical field of microalgae culture, and particularly relates to a microalgae culture medium and application thereof. The first aspect of the invention provides the microalgae culture medium. The microalgae culture medium comprises a carbon source, KH2PO4, MgSO4.7H2O, potassium citrate, vitamin B1, vitamin B12 and water, wherein the carbon source is selected from kitchen waste hydrolysate and / or glycerol products; and the water is selected from seawater or fresh water. The second aspect of the invention further discloses application of the microalgae culture medium in promoting microalgae proliferation and promoting microalgae polysaccharide accumulation. According to the microalgae culture medium and the application thereof, the accumulation of microalgae biomass and microalgae polysaccharide can be remarkably promoted, and the microalgae culture medium is high in microalgae culture efficiency, low in cost and wide in industrial application prospect.

Owner:JINAN UNIVERSITY

Production technology of edible-grade glycerin

InactiveCN106928024AHigh purityReduce moisture contentHydroxy compound separation/purificationFood additiveFiltration

The invention relates to the field of food additives, in particular to a production technology of edible-grade glycerin. The glycerin produced through high-temperature treatment and ion exchange by adopting an evaporation method can effectively remove polysaccharide and fatty acid in glycerin fermentation liquor, the purity of the glycerin product is improved, and the production requirements of the edible glycerin are meet. According to the method, the processes of dilution, decoloration, suction filtration and the like in a traditional technology are omitted, therefore, equipment is simplified, operation is convenient, the quality is stable, the production cycle is shortened, the consumption and the cost are both significantly reduced, the production efficiency is high, and the production technology is suitable for large-scale production and can be widely applied to the edible glycerin production field.

Owner:GUANGXI UNIV

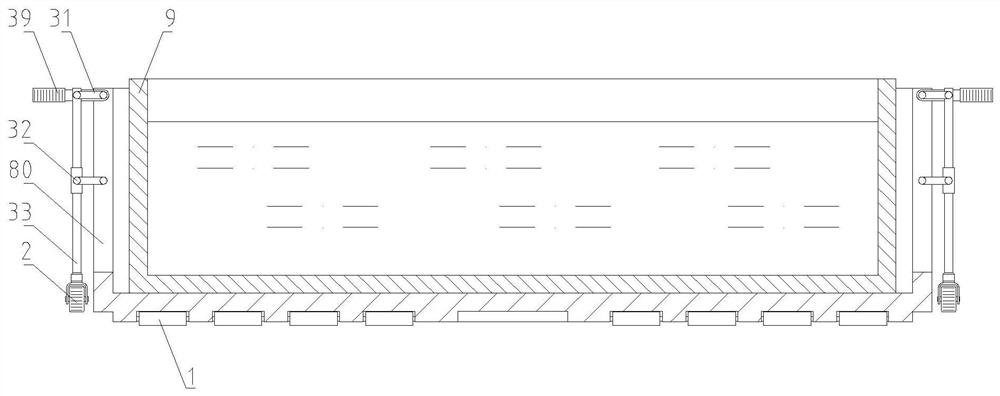

Glycerin product lever detection and transfer equipment

ActiveCN111086545BEasy to adjust the angleReduce difficultyLarge containersMaterial testing goodsGlycerolMechanical engineering

Owner:安徽诚宁油脂科技有限公司

Preparation method of pale rosin glyceryl ester

The invention discloses a preparation method of pale rosin glyceryl ester. The preparation method comprises the following steps: under the protection of inert gas, heating to dissolve rosin, adding glycerol, a catalyst and a water-carrying agent, adding a C4+ olefin solution into the reaction kettle, stirring uniformly, and gradually heating to react; and stopping introducing the inert gas, filtering to remove the catalyst, removing the impurity liquid, and collecting the product. The rosin glycerol product has the advantages of light color, high softening point and favorable crystallization resistance.

Owner:WUZHOU CAYIN GUM

Hyperfiltration-distillation integration process for reclaiming glycerin from low-concentration sweet water

InactiveCN100556875CReduce energy consumptionLow costChemical industryHydroxy compound separation/purificationSocial benefitsDistillation

The present invention discloses an integration technics with anti-penetration and distillation to recycle a glycerin in low-concentration sweet water. The steps for the present invention are as follows: (1) the pH value for the low-concentration sweet water is adjusted to litmusless by using of a neutralization agent, and then a flocculating agent is added into the sweet water; after being deposited, the mixture is to be filtered; (2) the filter liquid is condensed into a condensing liquid through an anti-penetration film component in the pressure of 1-8MPa; the condensing liquid is vaporized with multi-aspects to get rid of water and part of salt; and then a coarse glycerin; (3) the coarse glycerin is decompressed, distilled, ion-exchanged with resin refining in a mixing bed, and decolored with an active carbon to create the glycerin product with the purity more than 98.5 percent. The present invention can be used in medicine industry and foodstuff industry and so on. The technics has the advantages of low resource consumption, large treatment quantity and low cost and so on. The present invention can not only bring much better economical benefit by changing uselessness into usefulness, but also has greater environmental and social benefit.

Owner:ZHEJIANG UNIV

A method for purifying glycerin from by-products of biodiesel production

ActiveCN109721471BReduce the burden onEfficient removalHydroxy compound separation/purificationBiodieselDistillation

A method for purifying glycerin from the by-products of biodiesel production. First, dilute with methanol, remove part of the inorganic salts, add alkali to neutralize, and then add glycerin insoluble or slightly soluble but miscible with organic acids and other organic impurities. Organic solvents, extraction, removal of organic acids, some pigments and other organic impurities; followed by distillation to remove methanol; diluted with water, followed by purification by acidic cation exchange resin and basic anion exchange resin, and then evaporated, dehydrated, and dehydrated Light components, to obtain high-purity glycerin products. The method of the present invention adopts inorganic acid pretreatment before ion exchange, while neutralizing excess alkali in the feed liquid and removing part of the organic matter, it can also effectively remove the salt therein; the organic solvent extracts the organic acid in the crude glycerin , some pigments and other organic impurities; the above treatments can effectively reduce the burden of desalination in the subsequent ion exchange process and reduce the pollution to the resin. The purity of the glycerin purified by the invention is above 99.5%, the loss of glycerin is small, and the purification yield can reach above 95%.

Owner:CHINA PETROLEUM & CHEM CORP +1

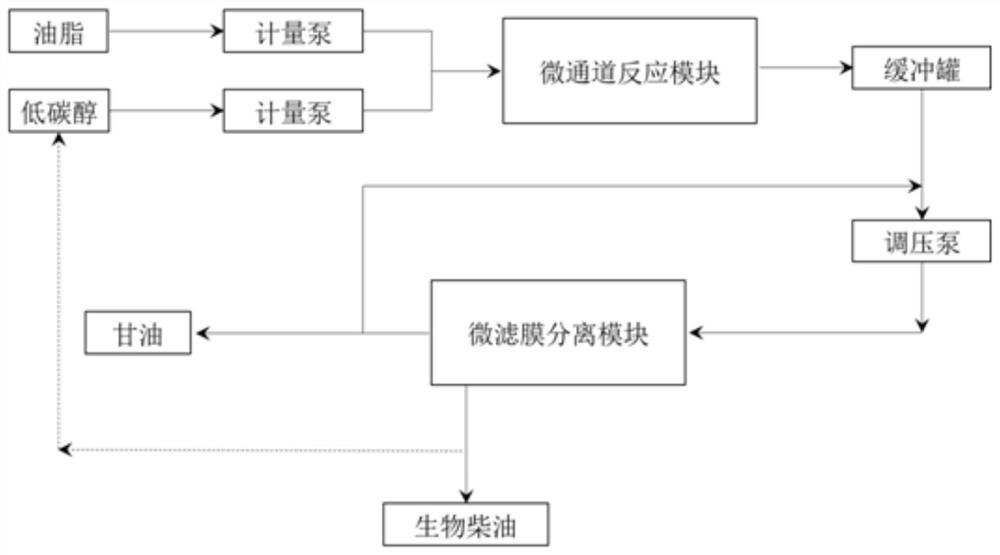

Continuous modular biodiesel preparation process

PendingCN113150877AHigh purityImprove efficiencyFatty acid esterificationBiofuelsBiodieselPtru catalyst

The invention relates to a continuous modular biodiesel preparation process, belonging to the technical field of green renewable energy sources. The continuous modular biodiesel preparation process is composed of a continuous microchannel reaction and microfiltration membrane separation. Specifically, the process comprises the following steps: 1) pumping grease and low-carbon alcohol into a microchannel reaction module dispersed with a heterogeneous basic catalyst through a metering pump according to a certain ratio, then allowing a formed mixture to flow into an intermediate buffer tank, pumping the mixture into a micro-filtration membrane separation module through a pressure regulating pump, and carrying out flash distillation on a discharged shell-pass penetrating fluid to obtain low-carbon alcohol, namely a biodiesel product; and 2) extracting a glycerol product from tube-pass discharge according to a certain recycle ratio, and refluxing the rest of the glycerol product to the front of the pressure regulating pump in a circulating manner. According to the process, the high-purity biodiesel product can be directly obtained, the content of glycerol in the product is less than 0.1%, high-efficiency production of the biodiesel at a low alcohol / oil ratio and high-efficiency low-energy-consumption separation of glycerol in the biodiesel product can be realized, and the process is high in modularization degree, low in energy consumption and capable of realizing high-efficiency preparation of biodiesel and flexible assembly of a refining system.

Owner:SOUTHEAST UNIV

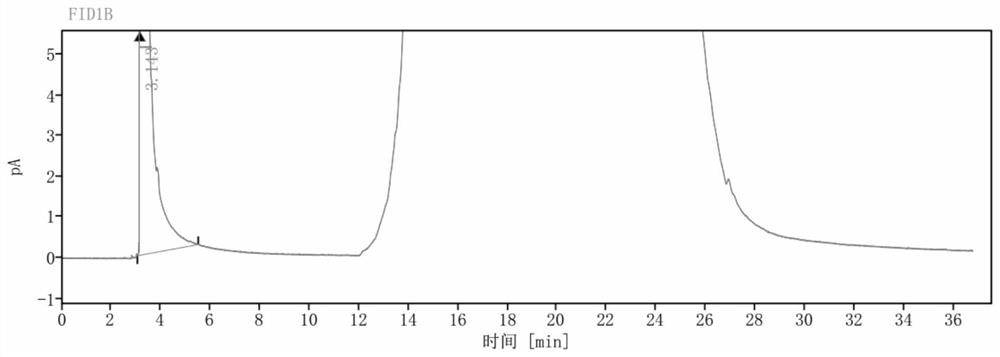

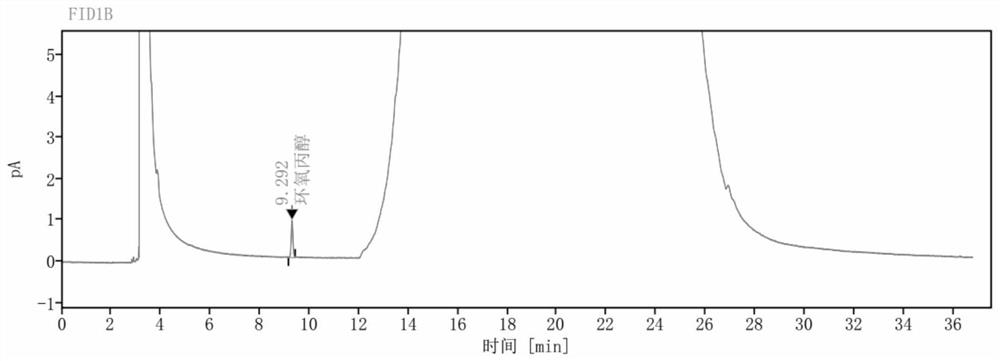

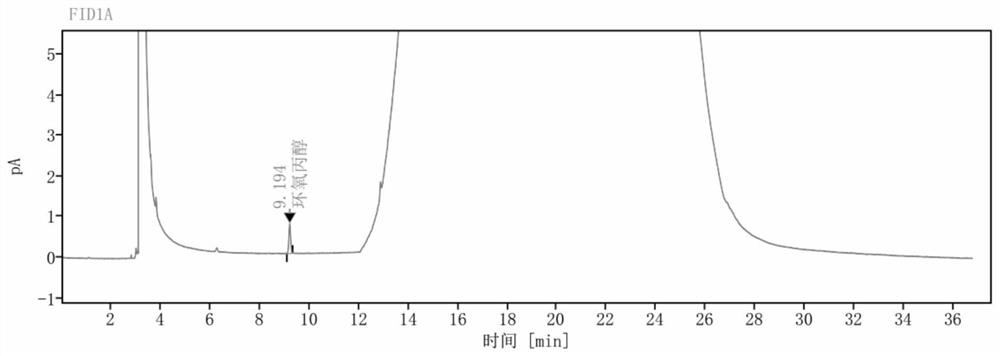

Method for determining glycidol in glycerine enema raw material

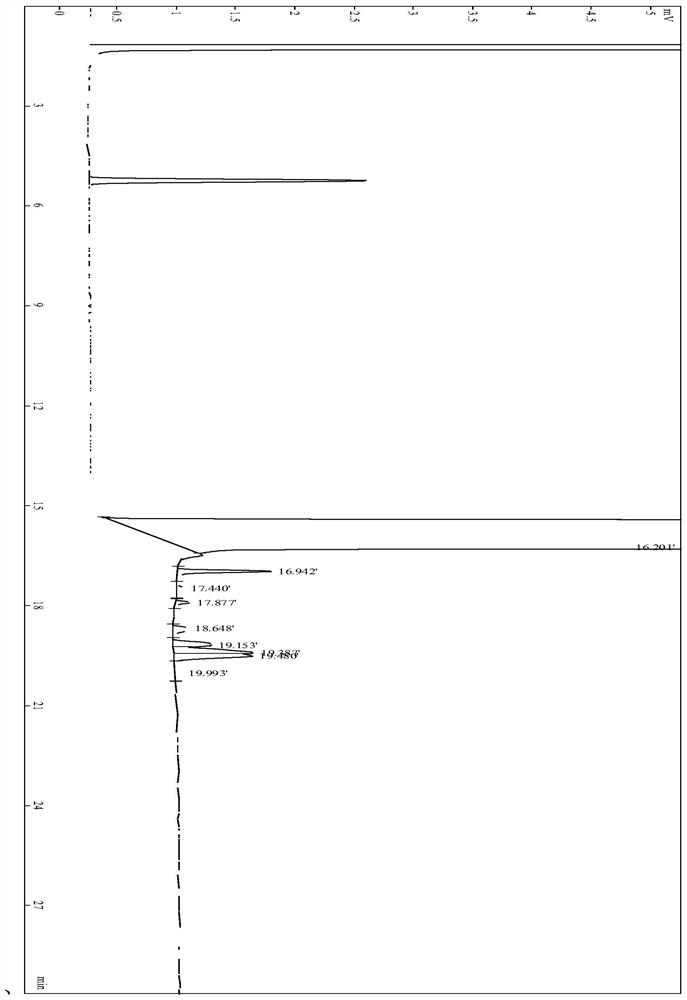

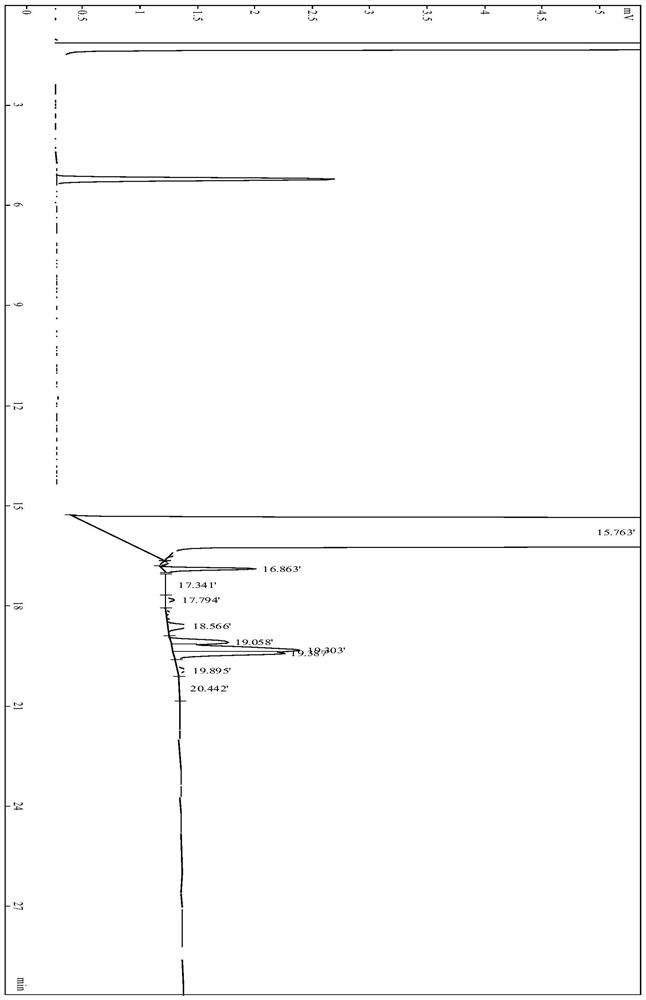

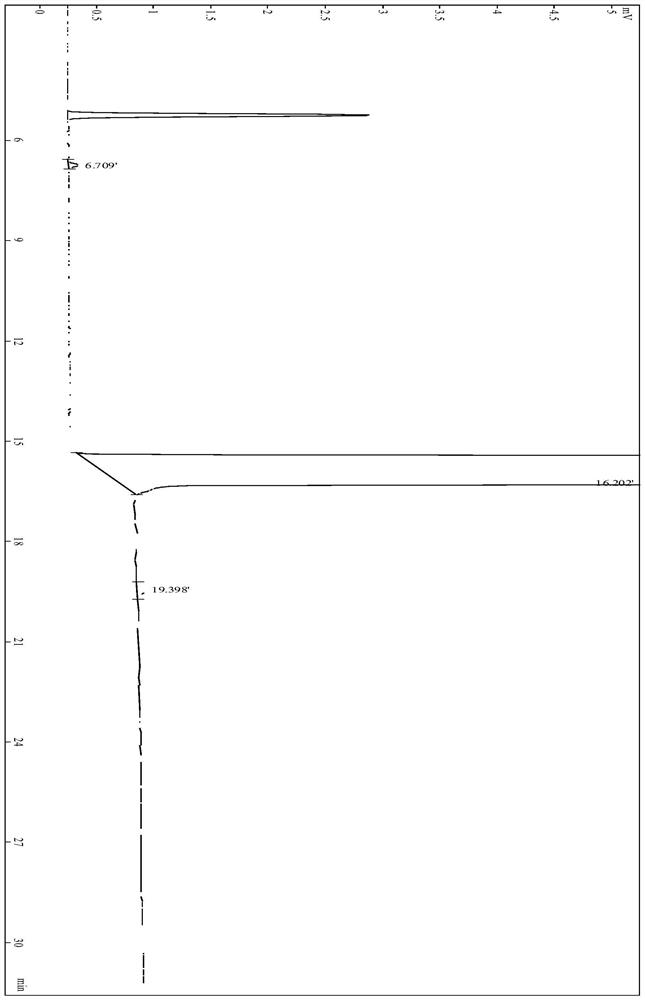

PendingCN112763601AInsufficiency of perfect detection methodMeet the detection requirements of the limit 0.002%Component separationPropanolVapor phase chromatography

The invention provides a method for determining glycidol in an glycerine enema raw material. The glycidol in the glycerine enema raw material is determined mainly through a gas chromatography method; methanol is adopted as a solvent for a sample; and therefore, safety and high applicability can be realized; a sample treatment method is convenient and rapid; an analysis method is simple, convenient and rapid; the separation capacity is high; a quantitative result is accurate; the recovery rate is high; the detection limit is 0.32 ng which is equivalent to 0.00008% of test concentration; the quantification limit is 0.79 ng which is equivalent to 0.00020% of test concentration; the detection requirement that the limit of glycidol in ICH M7 is 0.002% is met; a glycerine enema raw material quality control standard is improved; and the safety of glycerine enema products (containing glycerol) is improved.

Owner:FRONT PHARM PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com