Polyglycerol-10 and preparation method thereof

A technology of polyglycerol and glycerin, applied in the field of polyglycerol-10 and its preparation, can solve the problems of short reaction time, high reaction temperature, many side reactions, etc., and achieve the effects of being beneficial to industrial production and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] One aspect of the present invention provides a method for preparing polyglycerol-10, the method comprising:

[0013] (1) In the presence of an acid catalyst, glycerol and glycidol are polymerized to obtain a polyglycerol crude product,

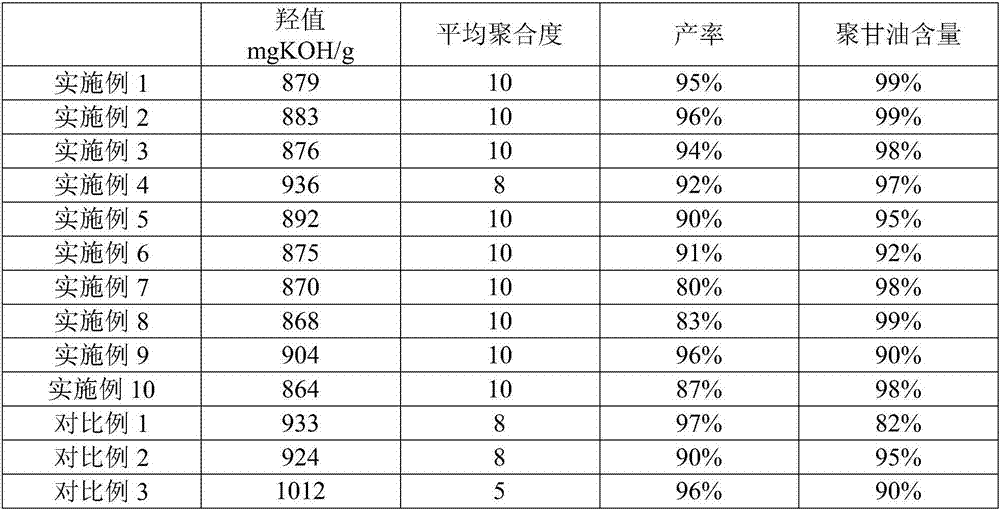

[0014] (2) neutralize the product of the polymerization reaction, and use molecular distillation equipment to distill the neutralized product, and the resulting heavy component is polyglycerol-10;

[0015] Wherein, the condensation surface of heavy components set by the molecular distillation equipment is above 85°C, the condensation surface of light components is 65-90°C, and the condensation surface of heavy components is higher than that of light components.

[0016] According to the present invention, polyglycerol-10 means a polyglycerol product with an average degree of polymerization of about 10.

[0017] According to the present invention, in step (1), glycidol can be called glycidol again, and its structure is In the present ...

Embodiment 1

[0033] This example is used to illustrate the polyglycerol-10 of the present invention and its preparation method.

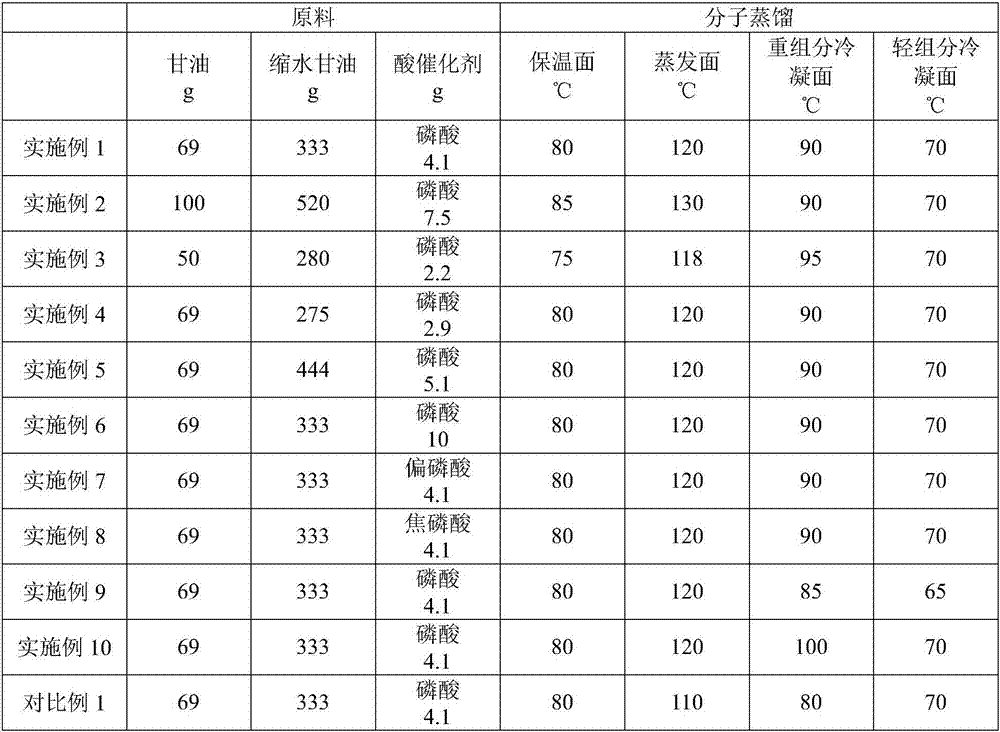

[0034] (1) Add glycerin and acid catalyst (see Table 1 for dosage and type) into the container, stir and heat up to 130°C, and keep stirring at constant temperature for 5 minutes; add glycidol (see Table 1 for dosage) dropwise to In the above mixed system, after the dropwise addition (about 15 minutes), keep the temperature of 130°C for 2 hours to obtain a light crystal yellow transparent viscous polyglycerol crude product;

[0035] (2) Heating the crude product of polyglycerol to dissolve, and adding 5% by weight of sodium hydroxide aqueous solution for neutralization, then transferring the crude product to molecular distillation equipment for purification operation, and the temperature setting includes heat preservation surface, evaporation surface and condensation surface (heavy component and heavy component), as shown in Table 1 for details. The heavy compo...

Embodiment 2

[0038] This example is used to illustrate the polyglycerol-10 of the present invention and its preparation method.

[0039] (1) Add glycerin and acid catalyst (see Table 1 for dosage and type) into the container, stir and heat up to 115°C, and continue stirring at constant temperature for 10 minutes; add glycidol (see Table 1 for dosage) dropwise to In the above mixed system, after the dropwise addition (about 15 minutes), keep the temperature of 115°C for 3 hours to obtain a light crystal yellow transparent viscous polyglycerol crude product;

[0040] (2) Heating the crude product of polyglycerol to dissolve, and adding 5% by weight of sodium hydroxide aqueous solution for neutralization, then transferring the crude product to molecular distillation equipment for purification operation, and the temperature setting includes heat preservation surface, evaporation surface and condensation surface (heavy component and heavy component), as shown in Table 1 for details. The heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com