Preparation method of glycerol for injection

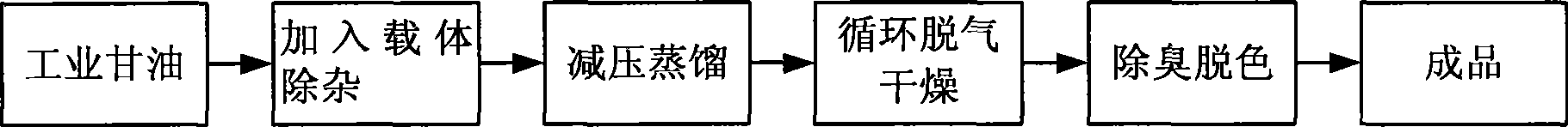

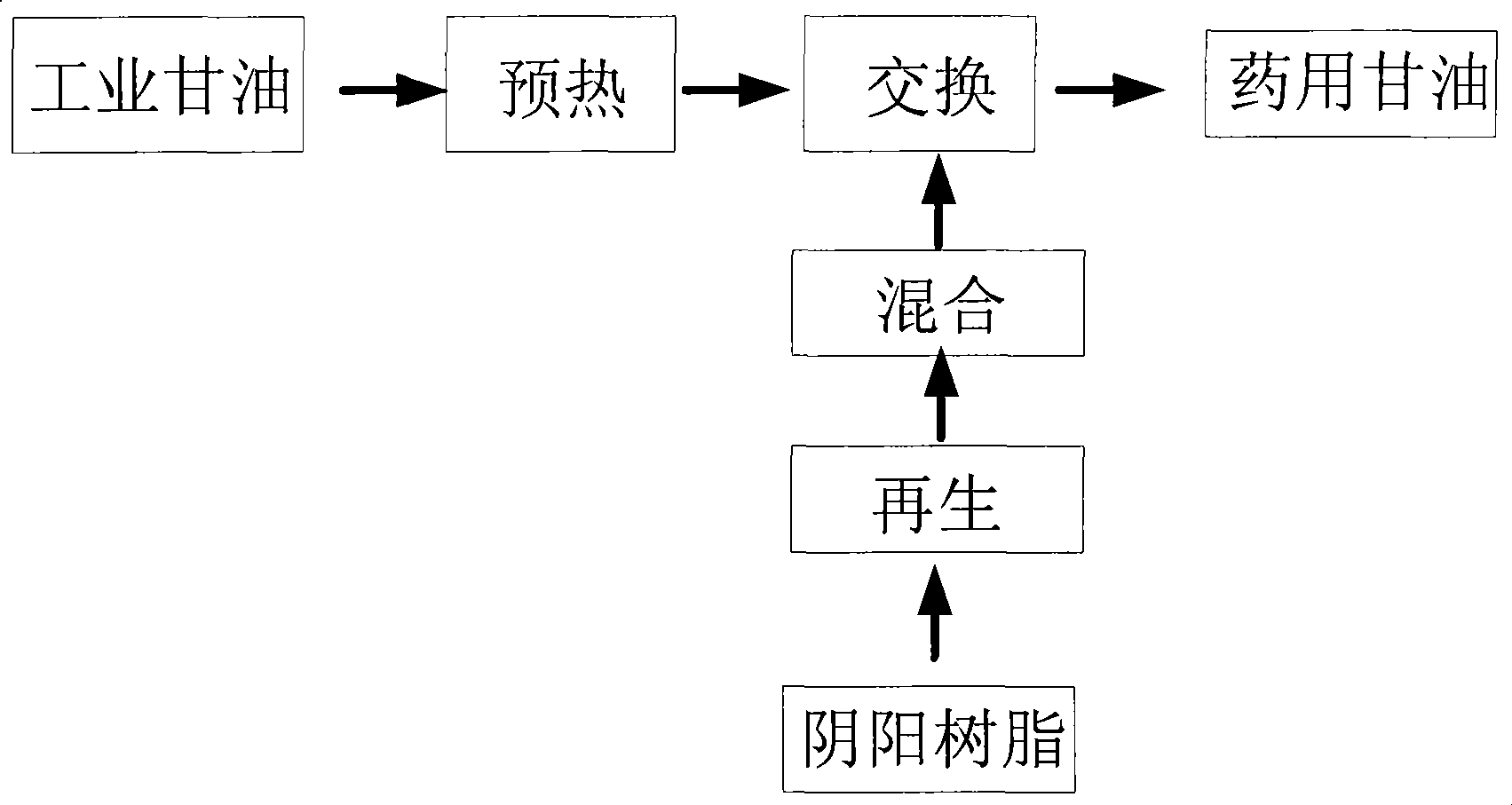

A technology of glycerin for injection, which is applied in the field of preparation of glycerin for injection, can solve the problems of high energy consumption, low recovery rate, and long time spent in the distillation method, and achieve the effect of simple separation device, high separation efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

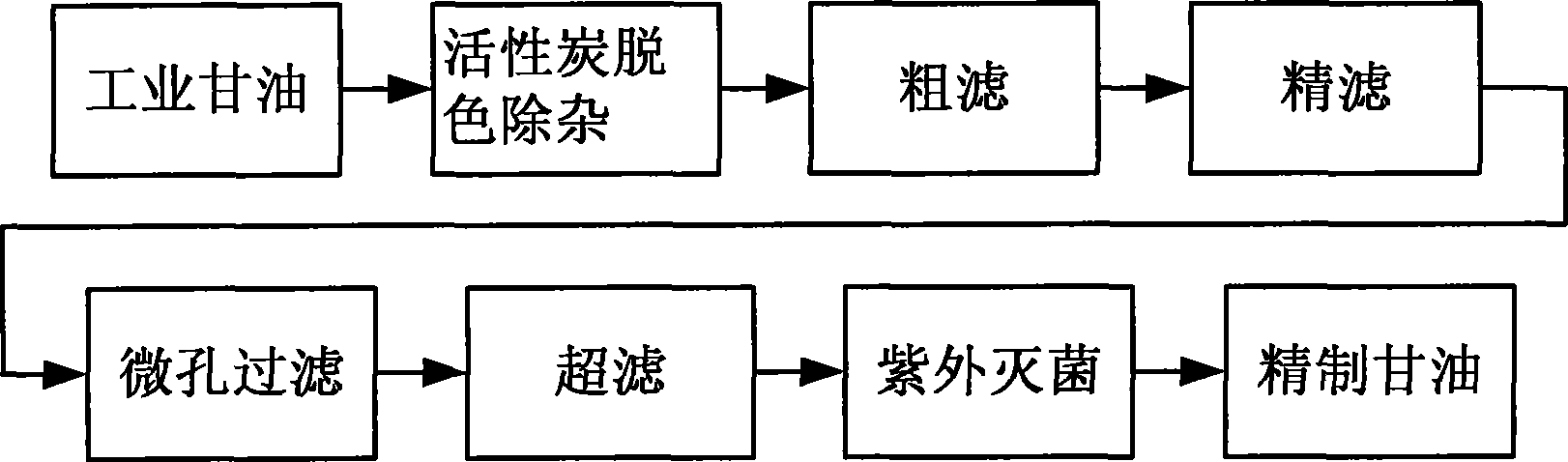

Method used

Image

Examples

Embodiment 1

[0039] Add industrial glycerin to the reaction kettle, stir and raise the temperature to 90-95°C, add activated carbon, the amount of activated carbon added is 0.5% of the weight of glycerin, turn on vacuum insulation and stir for 30 minutes. After the heat preservation is over, filter it through a 400-mesh bag filter and enter the storage tank while it is still hot. When the temperature of the feed liquid in the storage tank is controlled at 80°C to 85°C, it is then filtered through an 800-mesh bag filter, and then pretreated by a drug pump pressurized microfilter before entering the ultrafilter. Control the inlet pressure of the ultrafilter to 1.75Mpa, and the linear velocity of the hollow fiber material to 1m / s. The concentrated solution passing through the ultrafilter is returned to the storage tank for ultrafiltration again, and the filtrate is sterilized by an ultraviolet sterilizer to obtain glycerin for injection. The purity of the finished glycerin is 99.86%, and the...

Embodiment 2

[0041] Add industrial glycerin to the reaction kettle, stir and raise the temperature to 90-95°C, add activated carbon, the amount of activated carbon added is 0.5% of the weight of glycerin, turn on vacuum insulation and stir for 30 minutes. After the heat preservation is over, filter it through a 400-mesh bag filter and enter the storage tank while it is still hot. When the temperature of the feed liquid in the storage tank is controlled at 80°C to 85°C, it is then filtered through an 800-mesh bag filter, and then pretreated by a drug pump pressurized microfilter before entering the ultrafilter. Control the inlet pressure of the ultrafilter to 2.49Mpa, and the linear velocity of the hollow fiber material to 3m / s. The concentrated solution passing through the ultrafilter is returned to the storage tank for ultrafiltration again, and the filtrate is sterilized by an ultraviolet sterilizer to obtain glycerin for injection. The purity of the finished glycerin is 99.75%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com