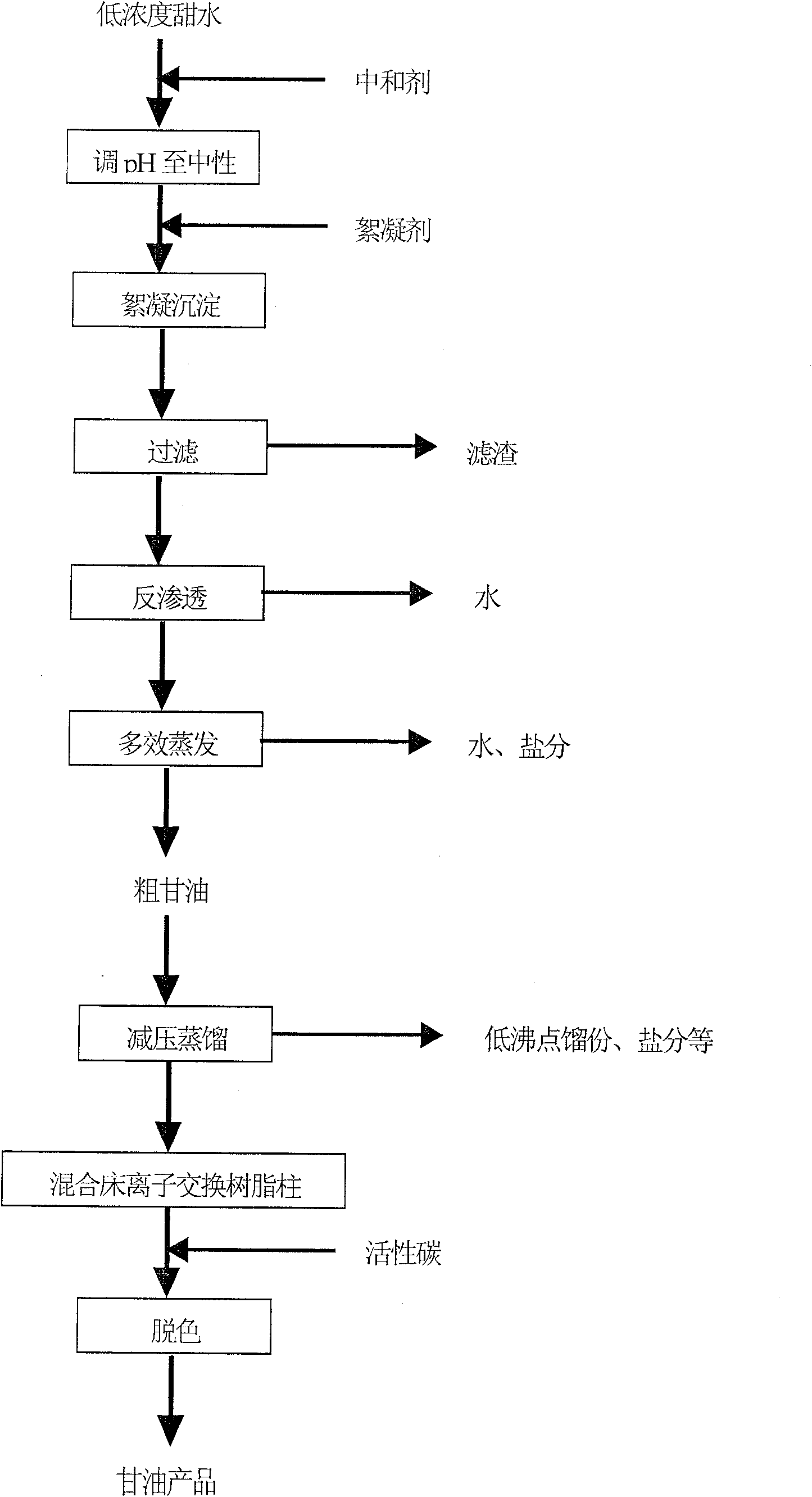

Hyperfiltration-distillation integration process for reclaiming glycerin from low-concentration sweet water

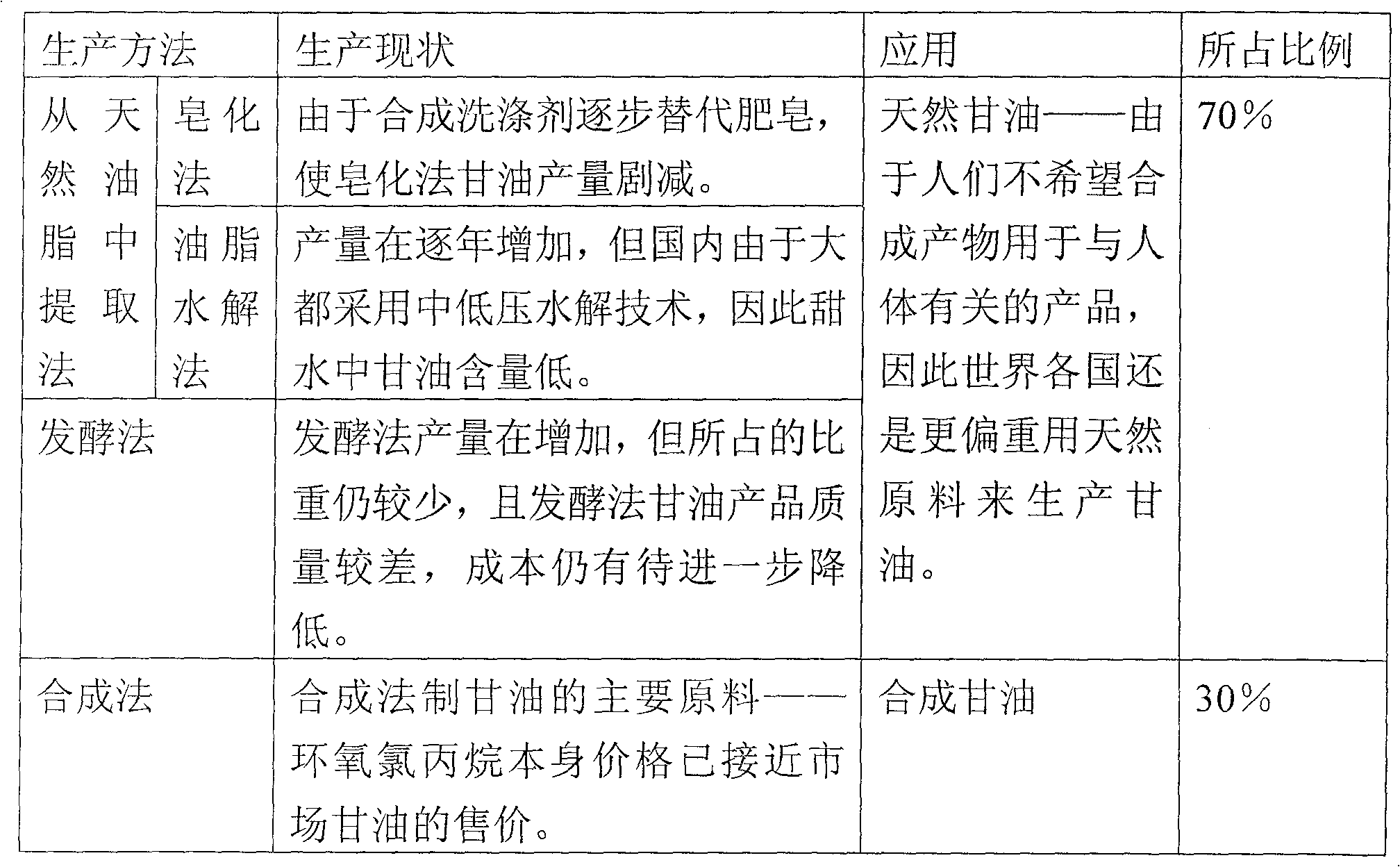

A low-concentration, reverse osmosis technology, applied in the field of reverse osmosis-distillation integrated process, can solve the problems of wasting glycerin resources, environmental pollution, and difficulty in self-protection, and achieve the effects of large processing capacity, low energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Take 100kg of acidic sweet water with a glycerin content of 1.1% (mass percentage, the same below), add quicklime to neutralize it to neutrality, then add polyferric sulfate, flocculate and settle and filter; the filtrate is passed through a plate cellulose acetate asymmetric membrane under a pressure of 1MPa The components are concentrated by reverse osmosis to obtain a concentrated liquid with a glycerin concentration of 1.4%. The concentrated liquid is evaporated to remove water and part of the salt to obtain crude glycerin; the crude glycerin is refined by vacuum distillation and mixed bed ion exchange resin column at an operating pressure of 2mmHg (201×7 type strongly basic styrene-based anion exchange resin and 001×7 type strongly acidic styrene-based cation exchange resin are mixed in a volume ratio of 1:2) and activated carbon are decolorized to obtain 0.88kg of glycerin product, with glycerin in the product The content of glycerin is 98.6%, and the recovery rate of ...

Embodiment 2

[0033] Take 100kg of acidic sweet water with 2.0% glycerin content, add sodium hydroxide solution to neutralize it, then add polyaluminum trichloride, flocculate and settle and filter; the filtrate is concentrated by reverse osmosis of plate polyamide composite membrane module under pressure of 2MPa A concentrated liquid with a glycerol concentration of 3.6% is obtained. The concentrated liquid is evaporated by three-effect evaporation to remove water and part of the salt to obtain crude glycerin; the crude glycerin is purified by vacuum distillation and mixed bed ion exchange resin column under the operating pressure of 4mmHg (201×7 Type strongly basic styrene-based anion exchange resin and 001×7 type strongly acidic styrene-based cation exchange resin at a volume ratio of 1:1) and activated carbon to obtain 1.74kg of glycerin product. The content of glycerin in the product is 98.7%. The recovery rate of glycerol is 85.9%.

Embodiment 3

[0035] Take 100kg of alkaline sweet water with 1.8% glycerin content, add sulfuric acid solution to neutralize it, then add alum, flocculate and settle and filter; the filtrate is concentrated by reverse osmosis of plate polybenzimidazolone membrane module under pressure of 3MPa to obtain glycerin Concentrated solution with a concentration of 4.4%. The concentrated solution is evaporated by double-effect evaporation to remove water and part of the salt to obtain crude glycerin; crude glycerin is purified by reduced pressure distillation and mixed bed ion exchange resin column at an operating pressure of 6mmHg (201×7 type strong Alkaline styrene-based anion exchange resin and 001×7 type strong acidic styrene-based cation exchange resin are mixed in a volume ratio of 2:1) and activated carbon are decolorized to obtain a glycerin product of 1.54kg. The content of glycerin in the product is 98.5%. The recovery rate was 84.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com