Production technique of medical pure glycerin from crude glycerin by ester exchange method

A production process, crude glycerin technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve problems not suitable for large-scale industrial production, reduce alkalinity, reduce production costs, reduce side effects The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

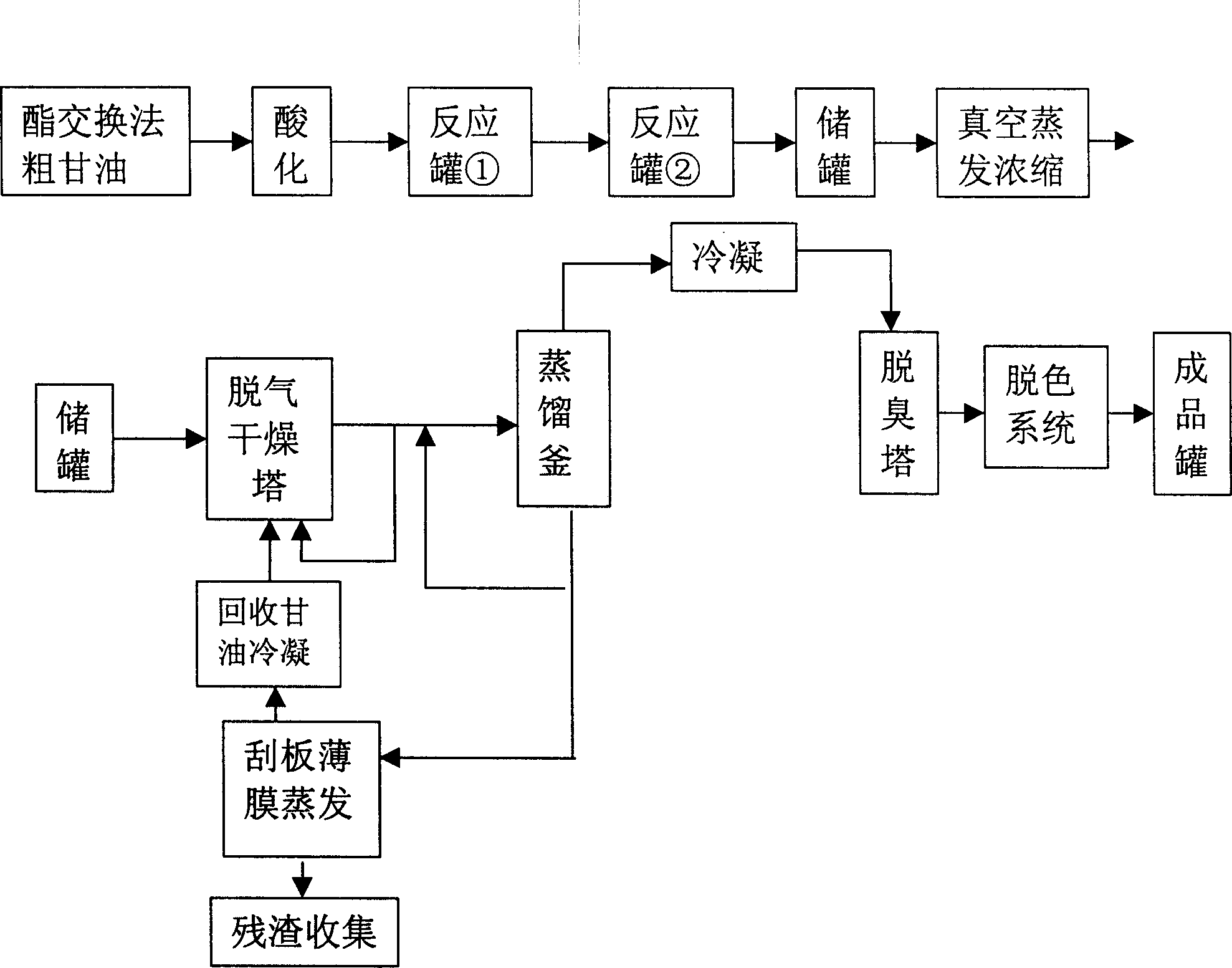

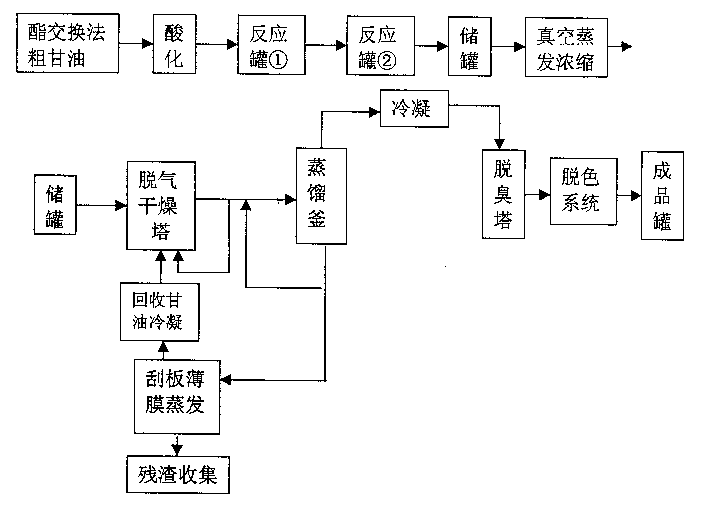

[0009] Such as figure 1 As shown, a production process of crude glycerin by transesterification method to produce medicinal pure glycerin, the crude glycerin by transesterification method is first acidified with concentrated sulfuric acid, the pH is 6, the acidification time is 1 hour and 10 minutes, and the temperature is controlled at 85°C .

[0010] Treat the acidified crude glycerin by transesterification with chemical agent, put the acidified crude glycerin by transesterification into the reaction tank ①, heat to 98°C, add calcium oxide or calcium hydroxide accounting for 2.5% of the mass of the raw material to remove free fatty acids and most of SO 4 2- , using the generated precipitation to adsorb and settle methyl esters, colloids, pigments, etc.; the treated substances are circulated and filtered through a filter press and sent to the reaction tank ②, heated to 98°C, and 1.2% barium hydroxide is added to account for the mass of raw materials Reagent to remove SO 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com