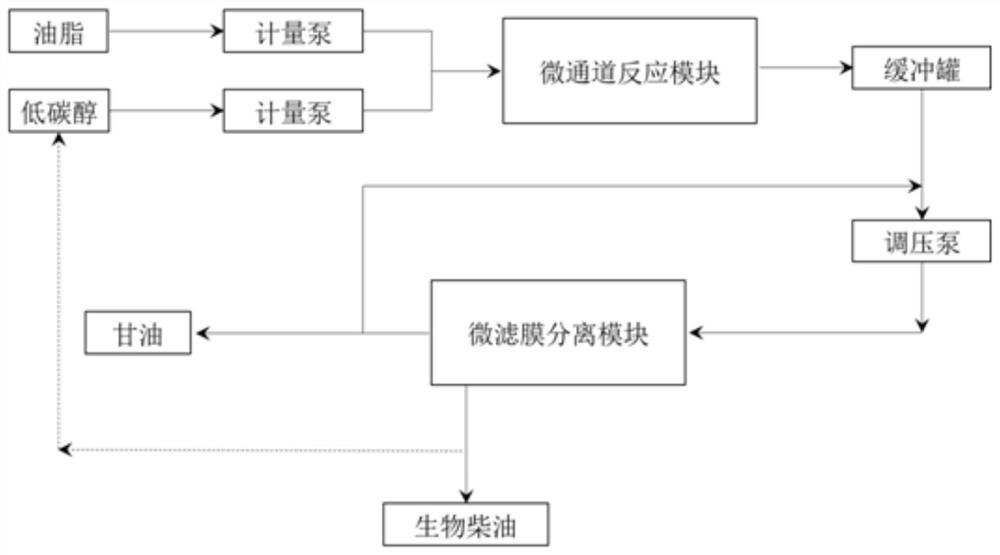

Continuous modular biodiesel preparation process

A technology of biodiesel and preparation technology, which is applied in the fields of biofuel, petroleum industry, fat oil/fat refining, etc. It can solve the problems of lack of flexibility and low efficiency of process operation, and achieve high efficiency of transesterification, process integration and high flexibility, The effect of high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Microchannel reaction module composition: 10 reaction tubes with an inner diameter of 5mm and a reaction zone length of 20cm are connected in parallel, and the catalyst in the tube is CaO (catalytic efficiency: 800kg biodiesel / kg catalyst); membrane separation module composition: 1 inner diameter 10mm, pore diameter 0.01μm microfiltration membrane module.

[0038] (2) Cottonseed oil and methanol are pumped into the microchannel reaction module with a molar ratio of 1:4 by a metering pump, the reaction temperature is controlled at 90°C, the pressure is 0.3Mpa, and the residence time is 25min, and the reaction solution is passed into the buffer tank;

[0039](3) The reaction solution in the buffer tank is pumped into the membrane separation module through the pressure regulating pump, and the temperature of the membrane separation module is controlled at 80°C, the transmembrane pressure difference is 30kPa, the circulation flow / production flow=1:0.1, and the permeation...

Embodiment 2

[0041] (1) Microchannel reaction module composition: 100 reaction tubes with an inner diameter of 0.05mm and a reaction zone length of 50cm are connected in parallel, and the catalyst in the tube is hydrotalcite (catalytic efficiency: 500kg biodiesel / kg catalyst); membrane separation module composition: 5 inner diameters of 6mm , Microfiltration membrane module with a pore size of 0.1 μm.

[0042] (2) Waste soybean oil and ethanol are pumped into the microchannel reaction module with a molar ratio of 1:3 by a metering pump, the reaction temperature is controlled at 70°C, the pressure is 0.2Mpa, and the residence time is 15min, and the reaction solution is passed into the buffer tank;

[0043] (3) The reaction solution in the buffer tank is pumped into the membrane separation module through the pressure regulating pump, the temperature of the membrane separation module is controlled at 50°C, the transmembrane pressure difference is 100kPa, the circulation flow / production flow=1:...

Embodiment 3

[0045] (1) Composition of microchannel reaction module: 1 reaction tube with an inner diameter of 10mm and a reaction zone length of 10cm, the catalyst in the tube is KF / hydrotalcite (catalytic efficiency: 2000kg biodiesel / kg catalyst); membrane separation module composition: 1 inner diameter of 7 channels (Channel inner diameter 3mm), microfiltration membrane module with pore size 1μm.

[0046] (2) Animal fat, n-propanol, and n-butanol are pumped into the microchannel reaction module by a metering pump at a molar ratio of 1:2:1.5. The reaction temperature is controlled at 120°C, the pressure is 0.4Mpa, and the residence time is 5min. Buffer tank;

[0047] (3) The reaction liquid in the buffer tank is pumped into the membrane separation module through the pressure regulating pump, the temperature of the membrane separation module is controlled at 10°C, the transmembrane pressure difference is 300kPa, the circulation flow / production flow=1:1, and the permeation flux is 290L / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com