Glycerol production process based on Candida krusei

A Candida and culture medium technology, applied in the direction of microorganism-based methods, fermentation, microorganisms, etc., can solve the problems of affecting the yield of glycerin extraction, low conversion rate of sugar and sugar, and high cost of water and electricity, so as to save electricity consumption and Cooling water consumption, high quality, and the effect of reducing environmental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the acquisition of high temperature resistant Candida krusei

[0031] Screening of mutant strains with high glycerol production

[0032](1) Bacteria suspension preparation and mutagenesis treatment: in 100mL seed medium / 250mL Erlenmeyer flask, 1 ring of slanted fungus, cultured at 30-35°C, 90-120r / min for 16-20h, centrifuged to collect bacteria, sterile Wash several times with normal saline and dilute for later use. Take 4mL of bacterial suspension, irradiate with 15-20W UV lamp power for 10-20s.

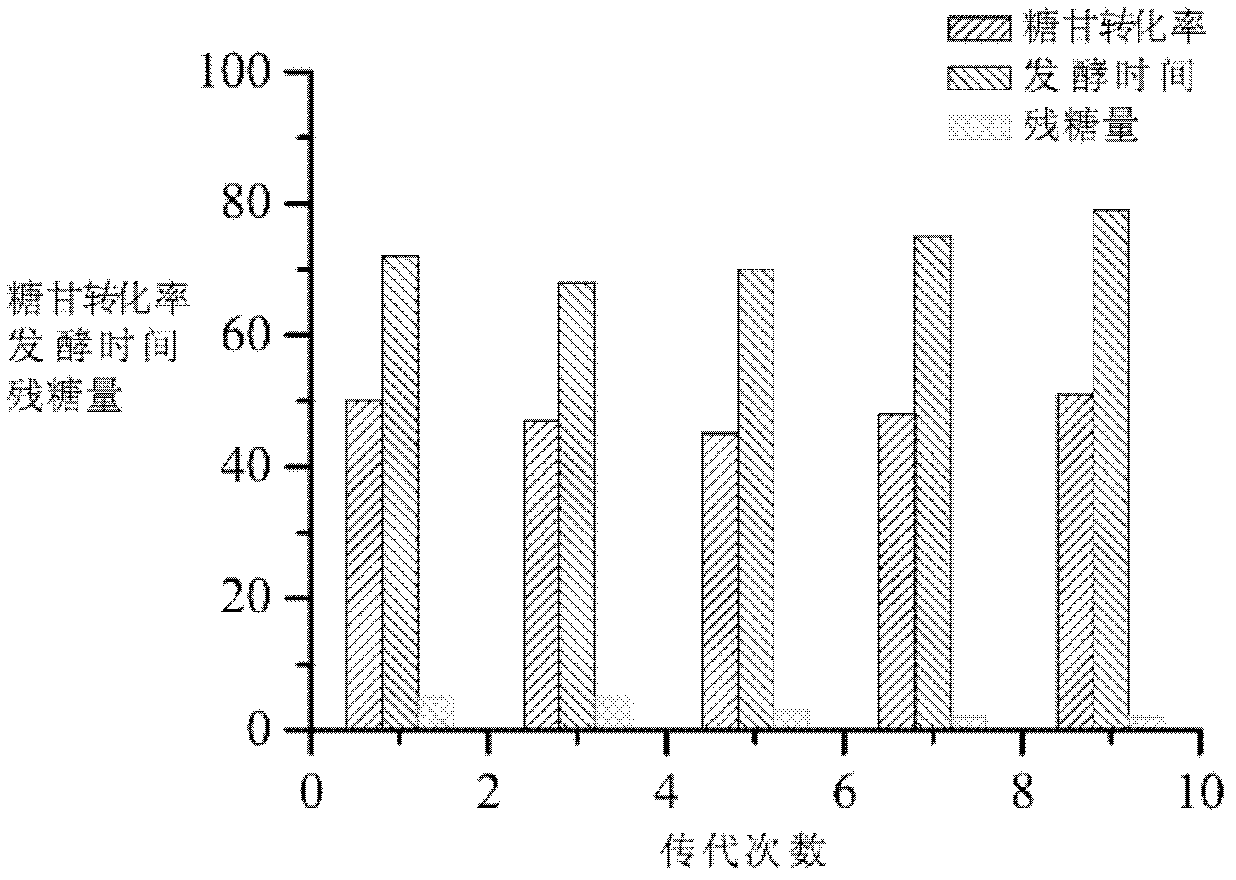

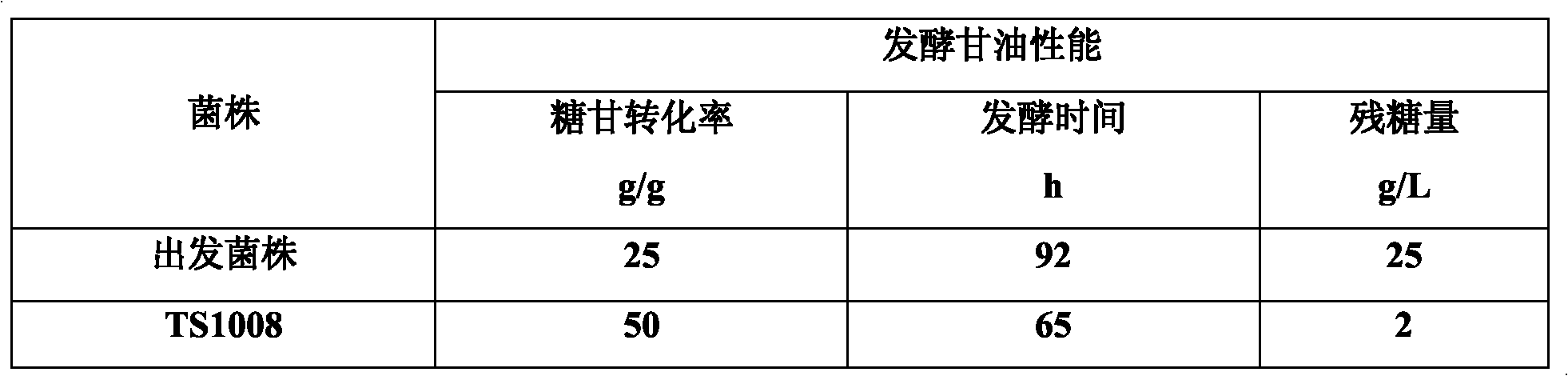

[0033] (2) Primary screening and secondary screening: put the mutagenized bacterial suspension into the screening medium containing 400-500g / L glucose and 70-90g / L osmotic agent, wrap in a black paper dish, 35°C-45°C Cultivate at constant temperature for 46-52h, repeat 3 times. Select large colonies for shake flask fermentation, measure biomass, sugar-sweet conversion rate, fermentation time and residual sugar content, and comprehensively screen to determine ...

Embodiment 2

[0039] Example 2: Synthesis of glycerol in a 30L fermenter

[0040] Pick a ring of bacteria from a fresh slant and insert it into the seed medium (20% filling capacity of the Erlenmeyer flask), cultivate it at 35°C-45°C and 120rmp for 16h, after measuring the concentration of the bacteria, press 15% (v / v) The inoculum is connected to 21L sterile fermentation broth / 30L fermenter, the ventilation ratio is 0.75, the fermentation temperature is 35°C-45°C, the cultivation time is 70h, and the cooling water is saved by 40% in the process (compared with the fermentation temperature of 30°C), the mature fermentation broth The glycerol content in the medium is 14% (w / v), and the residual sugar content is 0.2%, wherein the formulations of the seed culture medium and the fermentation medium are as described in this specification. After the fermentation broth is filtered through the membrane, bacteria, colloidal substances, proteins, polysaccharides and monosaccharides are removed step by...

Embodiment 3

[0041] Embodiment 3: Synthetic glycerol in 300L fermentor

[0042] First, use a 30L seed tank for seed liquid culture, pick a ring of bacteria from a fresh slope and insert it into the seed medium (20% filling capacity of the triangular flask), cultivate it at 35°C-45°C, 110rmp for 16h, and measure the bacterial concentration Finally, insert 21L sterile seed culture medium / 30L seed tank according to 25% (v / v) inoculation amount, ventilation ratio 0.5, 35 ℃-45 ℃ culture 10h, after measuring bacterial concentration, according to 10%-15% (v / v) v) Insert 200L fermentation medium / 300L fermenter, stir at 200rpm, ventilation ratio 0.75, fermentation temperature 35°C-45°C, culture time 66h, to obtain 180L mature fermentation broth with glycerol content of 14.5%. After the same membrane filtration and distillation process as in Example 1, 28 kg of 99.2% glycerin was obtained, and 27.3 kg of finished glycerin was obtained by deodorization and decolorization. The product complies with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com