An improved glycerol production process

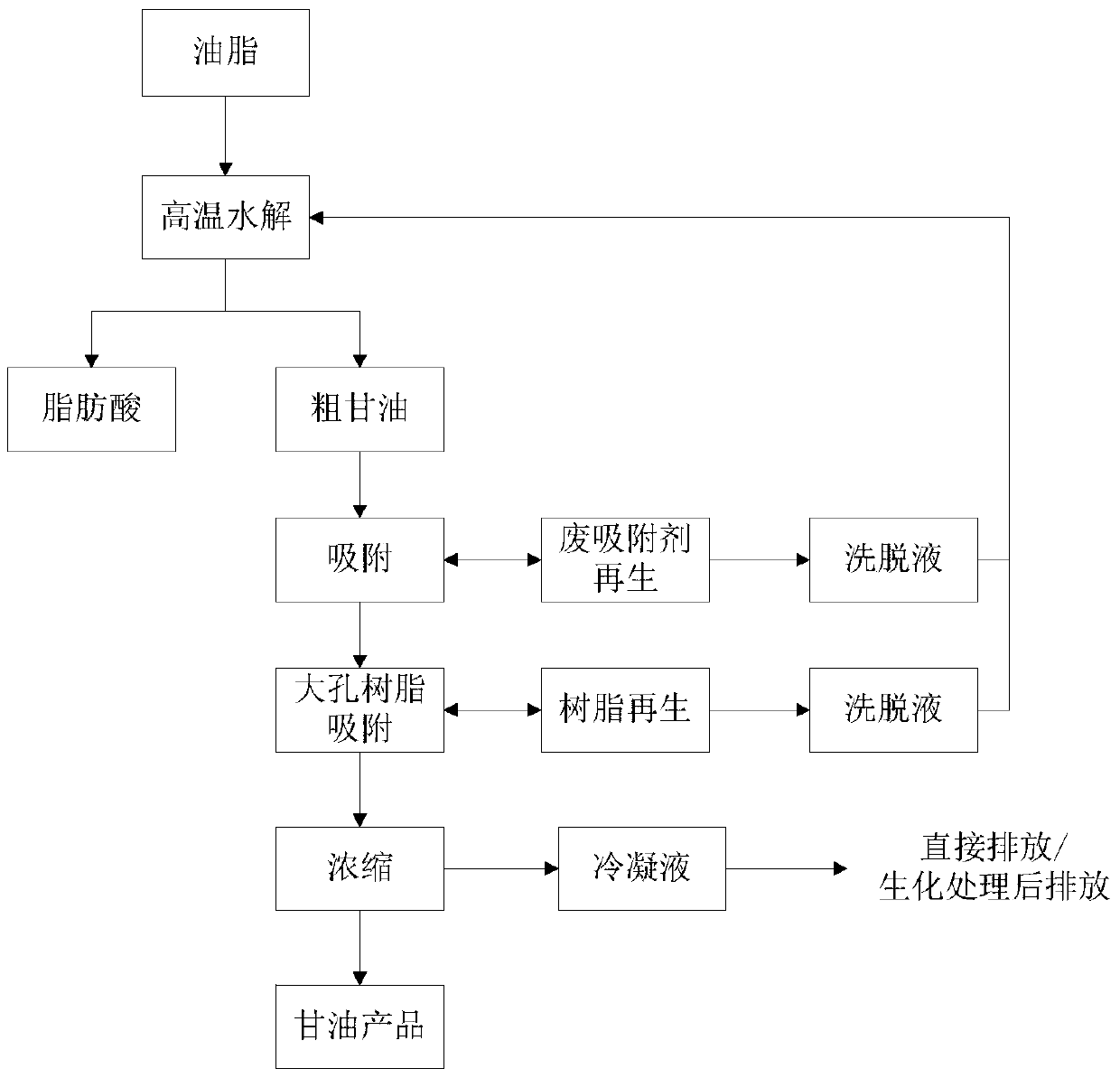

A production process and technology of glycerin, which is applied in the field of raw material process improvement in light industry, can solve the problems of complicated process and high input cost, and achieve the effects of simple process flow and operation, low input cost and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The crude glycerol solution and fatty acid produced by high-temperature hydrolysis in an oil factory. The crude glycerin solution is a dark gray turbid solution with a saponification value of 0.6-0.7mg / g, pH=4.0, and a glycerin content of 28.7%.

[0029] (1) Pretreatment: Add 0.3% activated carbon (based on the quality of the crude glycerin solution) to the crude glycerin solution, stir for 60 minutes, and filter to obtain a light yellow liquid;

[0030] Regeneration of waste activated carbon: Rinse the waste activated carbon with hot steam until the ultraviolet absorption peak in the eluent no longer changes, and the eluent is returned to the hydrolysis tank for high-temperature hydrolysis to prepare glycerin and fatty acids.

[0031] (2) Resin adsorption:

[0032] ①Column packing: Soak XDA-1 macroporous adsorption resin with ethanol for 4 hours, then pack the column, and elute the ethanol in the resin with clean water.

[0033] ②Column passage: Pass the obtained ligh...

Embodiment 2

[0037] The crude glycerol solution and fatty acid produced by high-temperature hydrolysis in an oil factory. The crude glycerin solution is a dark gray turbid solution with a saponification value of 0.6-0.7mg / g, pH=4.0, and a glycerin content of 28.7%.

[0038] (1) Pretreatment: Add 0.3% activated carbon (based on the quality of the crude glycerin solution) to the crude glycerin solution, stir for 60 minutes, and filter to obtain a light yellow liquid;

[0039] Regeneration of waste activated carbon: Rinse the waste activated carbon with hot steam until the ultraviolet absorption peak in the eluent no longer changes, and the eluent is returned to the hydrolysis tank for high-temperature hydrolysis to prepare glycerin and fatty acids.

[0040] (2) Resin adsorption:

[0041] ①Column packing: Soak HYA-106 macroporous adsorption resin with ethanol for 4 hours, then pack the column, and elute the ethanol in the resin with clean water.

[0042] ②Column passage: Pass the obtained li...

Embodiment 3

[0046] The crude glycerol solution and fatty acid produced by high-temperature hydrolysis in an oil factory. The crude glycerol solution is a dark gray turbid solution with a saponification value of 0.6-0.7, pH=4.0mg / g, and a glycerol content of 28.7%.

[0047] (1) Pretreatment: Add 0.3% activated carbon (based on the quality of the crude glycerin solution) to the crude glycerin solution, stir for 60 minutes, and filter to obtain a light yellow liquid;

[0048] Regeneration of waste activated carbon: Rinse the waste activated carbon with hot steam until the ultraviolet absorption peak in the eluent no longer changes, and the eluent is returned to the hydrolysis tank for high-temperature hydrolysis to prepare glycerin and fatty acids.

[0049] (2) Resin adsorption:

[0050] ①Column packing: Soak HYA-103 macroporous adsorption resin with ethanol for 4 hours, then pack the column, and elute the ethanol in the resin with clean water.

[0051] ②Column passage: Pass the obtained li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com