Deep purification method of high-purity glycerol

A purification method, glycerin technology, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., to achieve the effects of reduced separation cost, short production cycle, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

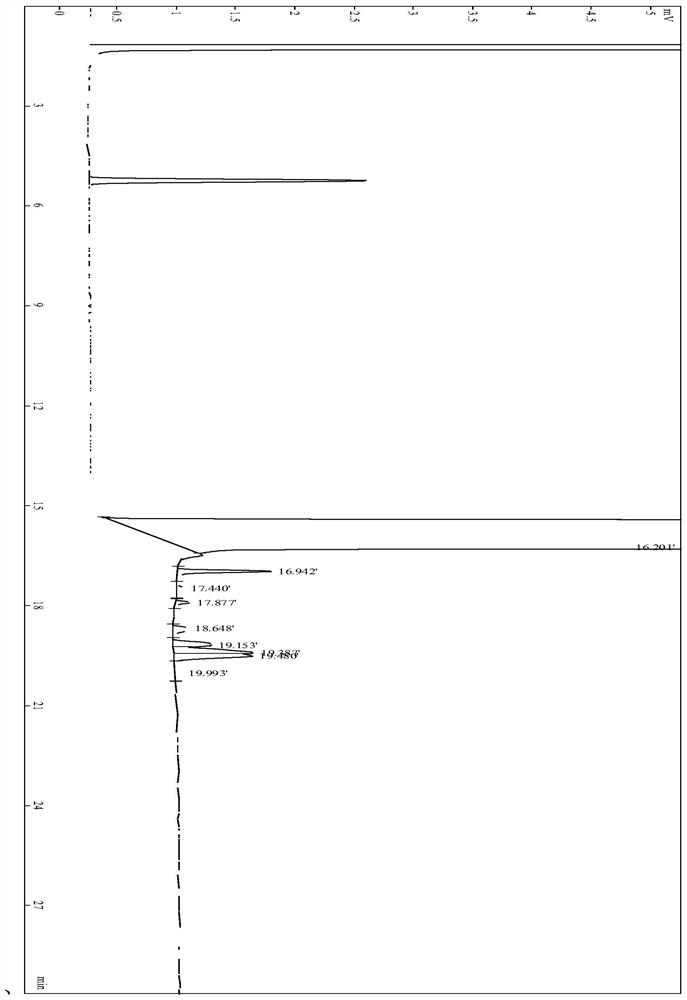

[0034] The solvent used in high-speed countercurrent chromatography in this example is a mixed solution of n-heptane-isopropanol-water, and the ratio by volume is n-heptane:isopropanol:water=6:6:2, oscillate evenly, and stand to separate To obtain a two-phase mixed solution, collect the upper phase solvent and the lower phase solvent separately, and place them in an ultrasonic oscillator for ultrasonic degassing treatment; the lower phase solvent is used as the mobile phase, and the upper and upper phase solvents are used as the stationary phase; the high-speed countercurrent chromatograph After preheating for 30 minutes, pump the stationary phase at a flow rate of 60 mL / min, and when the liquid pumped out of the waste liquid bottle reaches 30-50) mL, start the main engine, adjust the speed to 400 rpm, and pump the mobile phase at a flow rate of 10 mL / min; When the mobile phase and the stationary phase in the waste liquid bottle are clearly separated, open the injection valve, ...

Embodiment 2

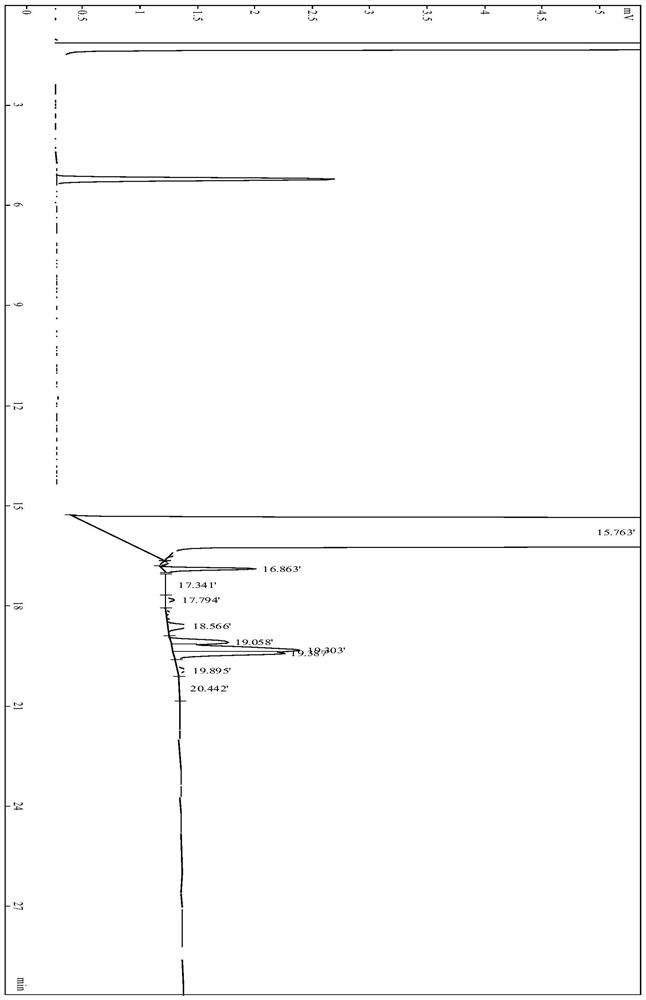

[0045] The solvent used in the high-speed countercurrent chromatography in this example is petroleum ether-ethanol-ethyl acetate mixed solution, and the volume ratio is petroleum ether:ethanol:ethyl acetate=6:3:1. The upper and lower phase solvents were collected separately, and placed in an ultrasonic oscillator for ultrasonic degassing. The lower phase of the solvent is used as the mobile phase, and the upper phase of the solvent is used as the stationary phase. After preheating the high-speed countercurrent chromatograph for 30 minutes, pump the stationary phase at a flow rate of 50mL / min; when the liquid pumped out of the waste liquid bottle reaches 30-50mL, start the main engine, adjust the speed to 500rpm, and pump the liquid at a flow rate of 15mL / min. When the mobile phase and the stationary phase in the waste liquid bottle are clearly separated, open the injection valve, inject 80 g of the sample raw material solution (glycerin raw material 2#) at 15 mL / min, collect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com