Fatty acid methyl ester biodiesel production method and production device thereof

A fatty acid methyl ester and biodiesel technology, which is applied in fatty acid esterification, biofuels, chemical instruments and methods, etc., can solve the problem of high cost, achieve an increase in transesterification rate, rich sources of raw materials, and stable production process equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

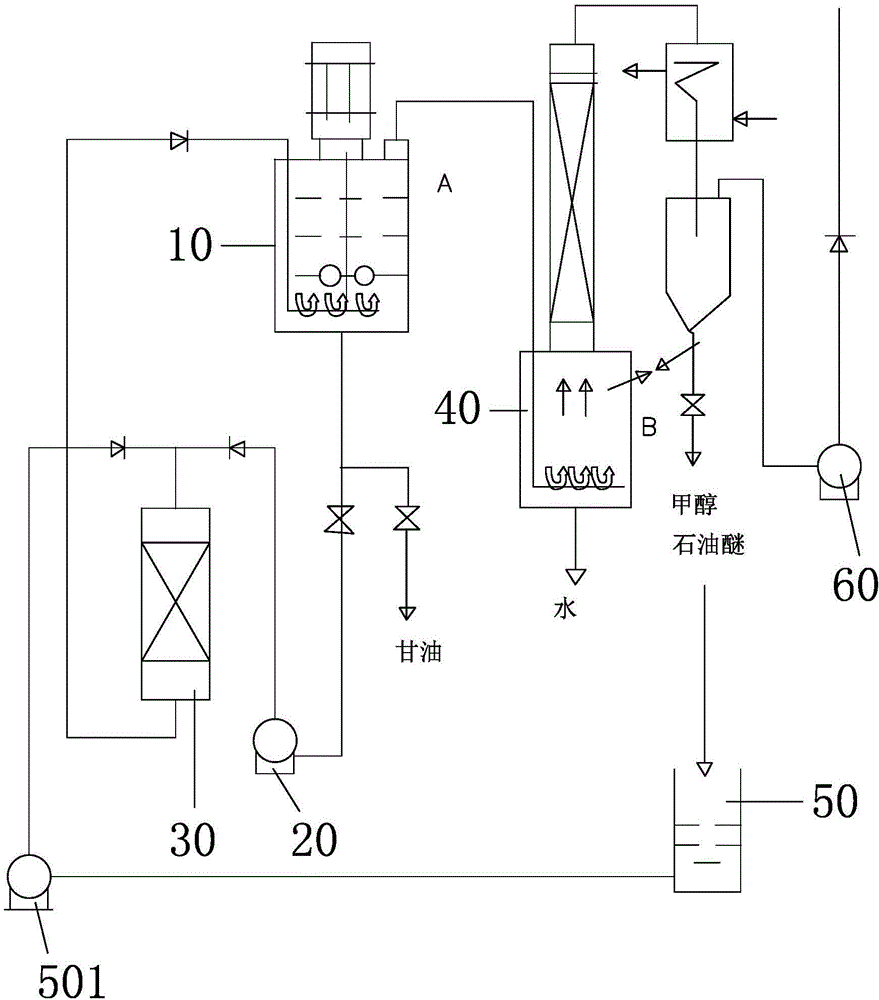

[0027] combine figure 1 And the introduction of above-mentioned structure, we describe in detail fatty acid methyl ester biodiesel production method of the present invention, and this production method comprises the following steps:

[0028] A. Select grease and co-solvent, the percentage by weight is 60% respectively, and the co-solvent is 20%. Add the grease and co-solvent to the reaction kettle at normal temperature and pressure, and stir for 30 minutes. The internal structure of the grease is affected by the mutual dissolution of the co-solvent. destroy;

[0029] B. Add methanol to the mixture in step A, and its weight percentage is 20%. After adding, heat it while stirring. The heating temperature is 100°C. After that, the mixture in the reactor is input to the mixing In the tank, the mixing tank is equipped with a solid acid catalyst;

[0030] After C, grease, co-solvent, methyl alcohol are mixed with solid acid catalyst, backflow in the reaction kettle in the step A,...

Embodiment 2

[0035] combine figure 1 And the introduction of above-mentioned structure, we describe in detail fatty acid methyl ester biodiesel production method of the present invention, and this production method comprises the following steps:

[0036] A. Select grease and co-solvent, the percentage by weight is 60% respectively, and the co-solvent is 20%. Add the grease and co-solvent to the reaction kettle at normal temperature and pressure, and stir for 35 minutes. The internal structure of the grease is affected by the mutual dissolution of the co-solvent destroy;

[0037] B. Add ethanol to the mixture in step A, and its weight percentage is 20% of the oil mass ratio. After adding, it is heated under the condition of stirring, and its heating temperature is 100 ° C. After that, the mixture in the reactor is heated The oil pump is input into the mixing tank, and the mixing tank is equipped with a solid acid catalyst;

[0038] After C, grease, co-solvent, ethanol are mixed with soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com