Glycerin evaporation device and evaporation method thereof

An evaporation device and glycerin technology, which is applied in the direction of evaporation, multi-effect evaporation, separation methods, etc., can solve the problems of low purity of glycerin and low energy utilization rate, and achieve the effects of energy saving, cost reduction and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

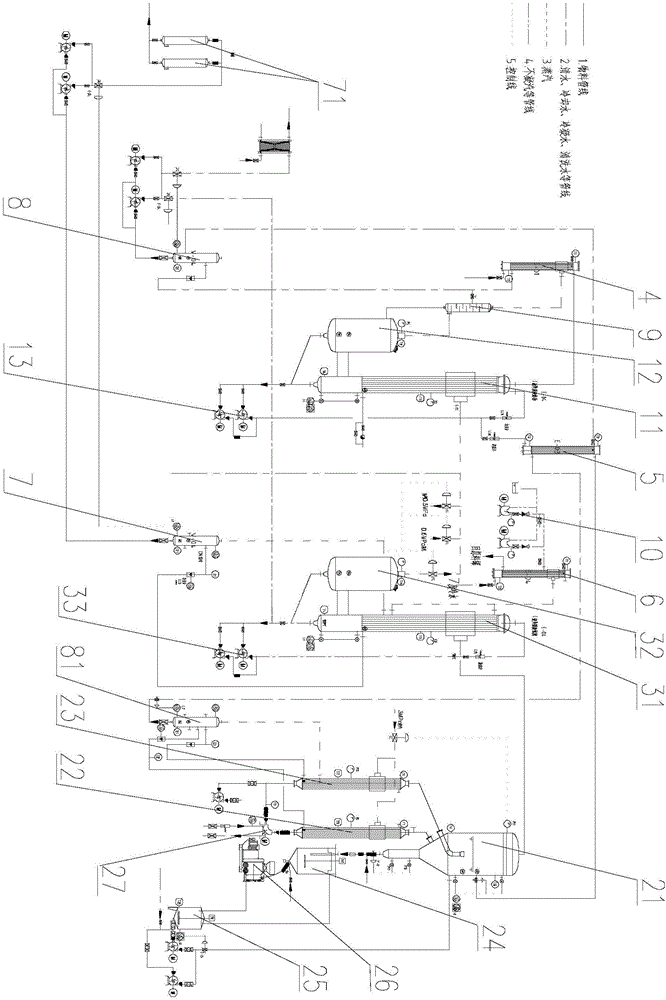

[0030] Such as figure 1 As shown, a glycerin evaporation device includes a first preheater 4, a first evaporation unit, a second preheater 5, a forced circulation evaporation unit, and a second evaporation unit connected in sequence;

[0031] The first evaporation unit includes a first falling film heat exchanger 11 and a first falling film evaporation chamber 12. The upper tube box of the first falling film heat exchanger 11 communicates with the upper end of the tube pass of the first preheater 4, and the first The lower tube box of the falling film heat exchanger 11 is in communication with the first falling film evaporation chamber 12, and the lower tube box of the first falling film heat exchanger 11 is also connected to the upper tube box of the first falling film heat exchanger 11 through an external tube The upper end of the first falling film evaporation chamber 12 communicates with the upper end of the shell side of the first preheater 4, and the lower end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com