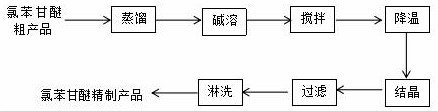

A kind of purification method of chlorophenyl glycerol

A technology of chlorphenesin and a refining method, which is applied in the field of antifungal and antibacterial agents, can solve the problems of large amount of purification solvent, flammable solvent, explosive and poisonous, etc., and achieve simplified purification treatment process, easy waste liquid, and reduced treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 150g of the crude product of chlorophenyl glycerol obtained by the experimental synthesis, with a product content of 90%, was added to a 500ml three-necked flask, heated by an electric heating mantle, nitrogen protection, decompressed by 0.095mpa, collected 216-218 ℃ fraction 125g, and then added the fraction to 380g, In 0.3% hot lye, the temperature is 75°C, the ratio of stirring to liquid level height is 0.6, the speed is 168r / min, the temperature is 25°C, air cooling, the cooling time is 3.5h, and the product is completely precipitated when it is lowered to room temperature, and vacuumed at 0.09mpa Filtration, using 100g of deionized water, and rinsing in three times to obtain a product filter cake. After drying, liquid phase analysis was used to determine the product content of 99.85%, and the phenol content was found to be no. The product yield is 90%, which meets the requirements of the invention process index.

Embodiment 2

[0029] 145g of the crude product of chlorophenyl glycerol obtained by the experimental synthesis, with a product content of 91%, was added to a 500ml three-necked flask, heated by an electric heating mantle, nitrogen protection, decompressed by 0.096mpa, collected 128g of 216-217 ℃ fraction, and then added the fraction to 400g, In 0.3% hot lye solution, the temperature is 75°C, the ratio of stirring to liquid level height is 0.62, the speed is 160r / min, the temperature is 25°C, air cooling, the cooling time is 3.5h, and the product is completely precipitated when it is lowered to room temperature, and vacuumed at 0.09mpa Filtration, using 100g of deionized water, and washing in three times to obtain a product filter cake. After drying, the product content was determined to be 99.88% by liquid phase analysis, and the phenol content was found to be no. The product yield is 91%, which meets the requirements of the invention process index.

Embodiment 3

[0031] 130g of the crude product of chlorophenyl glycerol obtained by the experimental synthesis, with a product content of 91%, was added to a 500ml three-necked flask, heated by an electric heating mantle, nitrogen protection, decompressed by 0.095mpa, collected 118g of 216-218 ℃ fraction, and then added the fraction to 420g, In 0.25% hot lye, the temperature is 75°C, the ratio of stirring to liquid level height is 0.6, the speed is 156r / min, the temperature is 25°C, air cooling, the cooling time is 3.5h, and the product is completely precipitated when it is lowered to room temperature, and the vacuum is 0.09mpa. Filtration, using 96g of deionized water, and washing in three times to obtain a product filter cake. After drying, liquid phase analysis was used to determine the product content of 99.79%, and no phenol content was detected. The product yield is 90.5%, which meets the requirements of the invention process index.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com