A kind of green treatment process of chlorophenyl glycerol dephenolization

A technology of chlorphenesin and treatment process, which is applied in ether preparation, ether separation/purification, organic chemistry, etc., can solve the problems of flammability, great harm, and ineffectiveness, reduce treatment cost, improve phenol removal efficiency, and process The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

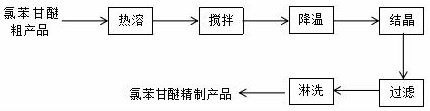

Image

Examples

Embodiment 1

[0021] 140g of the crude product of chlorophenyl glycerol obtained by the experimental synthesis, p-chlorophenol content of 4.22%, was added to 500g of 0.5% hot lye, the temperature was 75 ° C, the ratio of stirring to liquid level was 0.5, the rotating speed was 180r / min, and 25 ℃, air cooling, the cooling time is 3.5h, and the product is completely precipitated when it is lowered to room temperature. It is vacuum filtered at 0.09mpa, and 120g of deionized water is used to rinse three times to obtain a product filter cake. After drying, liquid phase analysis is used. The method is to measure the phenolic content of 80 ppm, and the above-mentioned product is processed as above to obtain a product, and the result of detecting the phenolic content is no, and the technical index requirement is met.

Embodiment 2

[0023] 150g of the crude product of chlorophenyl glycerol obtained by the experimental synthesis, p-chlorophenol content of 4.87%, was added to 520g of 0.8% hot lye, the temperature was 75°C, the ratio of stirring to liquid level was 0.6, the rotating speed was 190r / min, and 28 ℃, air cooling, the cooling time is 4.0h, and the product is completely precipitated when it is lowered to room temperature, vacuum filtration at 0.09mpa, 200g deionized water is used, and the product filter cake is obtained. After drying, liquid phase analysis is used. The method is to measure the phenolic content of 75 ppm, and the above-mentioned product is processed as above to obtain a product, and the phenolic content of the product is detected, and the result is no, and the process index requirement is met.

Embodiment 3

[0025] 120g of the crude product of chlorophenyl glycerol obtained by the experimental synthesis, p-chlorophenol content of 3.89%, was added to 480g of 0.58% hot lye, the temperature was 72 ° C, the ratio of stirring to liquid level was 0.58, the rotating speed was 166r / min, and 25 ℃, water cooling, the cooling time is 4.0h, and the product is completely precipitated when it is lowered to room temperature. It is vacuum filtered at 0.09mpa, and 130g of deionized water is used to rinse three times to obtain a product filter cake. After drying, liquid phase analysis is used. The method is to measure the phenol content of 68 ppm, and the above-mentioned product is processed as above to obtain a product, and the result of detecting the phenol content is no, and the process index requirement is met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com