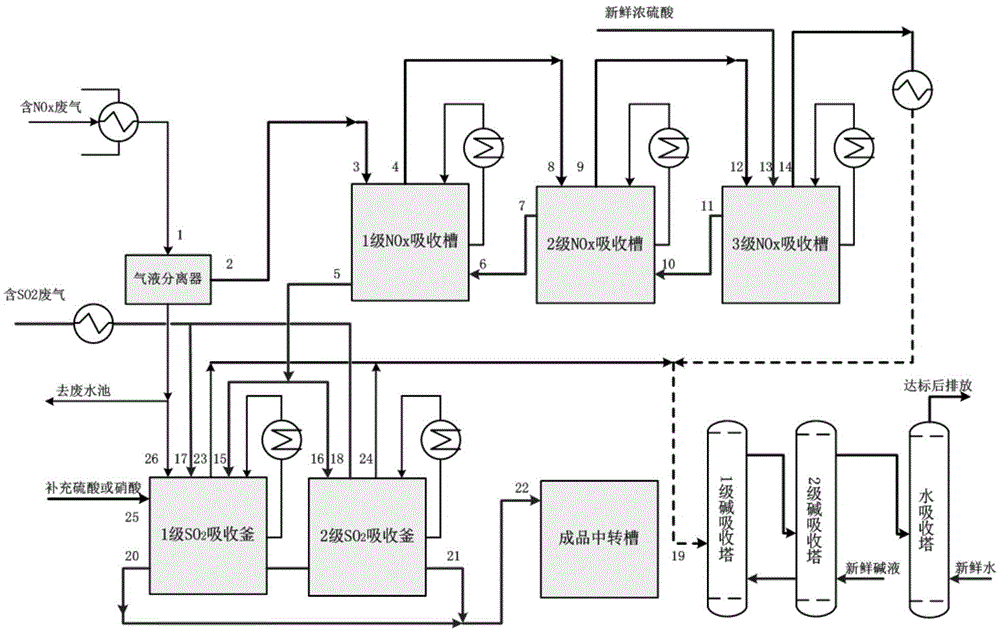

Resourceful treatment method and system for H acid production tail gas

A treatment method and technology of a treatment system are applied in the field of H acid synthesis, which can solve the problems of increasing the production cost of H acid and low economic value, and achieve the effects of improving secondary value, high treatment efficiency, and reducing waste gas treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

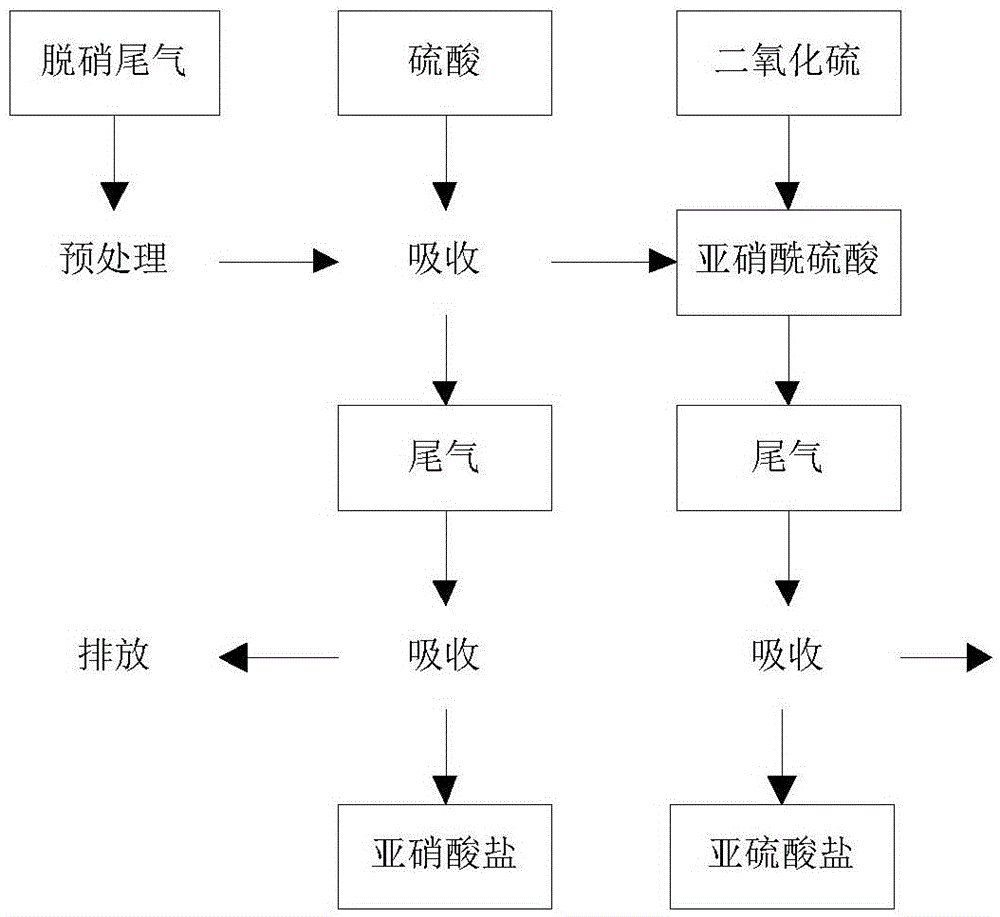

Method used

Image

Examples

Embodiment 1

[0066] The denitrification tail gas produced in the H acid production process has a temperature of 80°C and a volume concentration of nitrogen oxides in the tail gas of 10%.

[0067] 1) After cooling the above-mentioned denitrification tail gas to 25°C, absorb it with 98% concentrated sulfuric acid to obtain absorption liquid I and tail gas I. The absorption liquid I was dark yellow, and the mass concentration of nitrosyl sulfuric acid was 28%, and the mass concentration of nitric acid was 7%.

[0068] 2) The acid analysis tail gas (containing SO 2 exhaust gas) into the absorption liquid I obtained in step (1) to obtain absorption liquid II and tail gas II. During the control process, the temperature is 50-55° C., and the absorption liquid II is monitored online. When the content of nitrosyl sulfuric acid is 42% and the content of nitric acid is 0.13%, the reaction is terminated. During the reaction process, the color of the absorption solution gradually turns yellow, and fi...

Embodiment 2

[0071] H acid denitrification process, the nitrogen oxide gas generated during the denitrification process, the tail gas is brownish red, and the measured gas volume concentration is about 13%.

[0072] (1) Pass the denitration tail gas into 98% concentrated sulfuric acid for absorption, and the absorption temperature is 25°C. Absorption liquid I and tail gas I are obtained. It is measured that the content of nitrosyl sulfuric acid in the absorption liquid I is about 33%, the concentration of nitric acid is about 9.3%, and the color of the tail gas I changes from brownish red to red.

[0073] (2) Use the absorption solution I obtained in step (1) to absorb acid analysis tail gas, and keep the temperature of the absorption process at 50-55° C. to obtain absorption solution II and tail gas II. It is measured that in the absorption liquid II, the content of nitrosyl sulfuric acid is 40.8%, and the content of nitric acid is 0.007%. Reaching the industrial quality standard, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com