Treatment method of waste water produced in process for producing caprolactam by utilizing toluene method

A treatment method, the technology of caprolactam, is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of ineffective recycling, difficult treatment, complex chemical composition, etc., and achieve Good environmental and economic benefits, good combustion calorific value, simple recovery method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

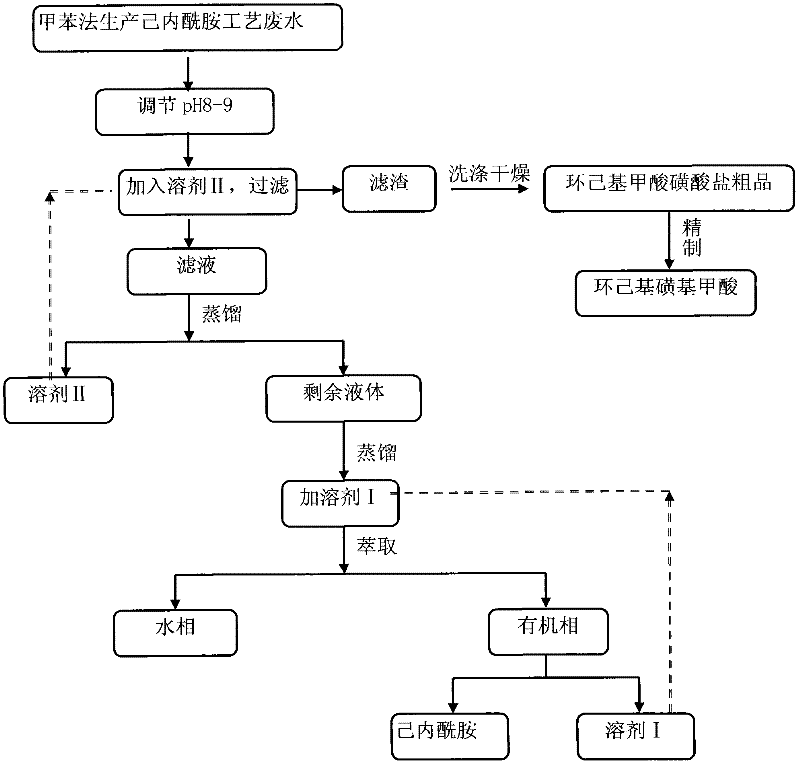

Method used

Image

Examples

Embodiment 1

[0027] Get 100g of toluene method to produce caprolactam process waste water, adjust the pH value to 8-9 with 20% (mass percentage) NaOH solution under room temperature and normal pressure, add solvent II acetone 60g, have solid to separate out, filter in batches, collect filtrate and filter residue, filter residue Wash with 2 g of anhydrous methanol until off-white, dry at 40-50°C, and weigh to obtain 9 g of crude cyclohexyl formic acid sulfonate.

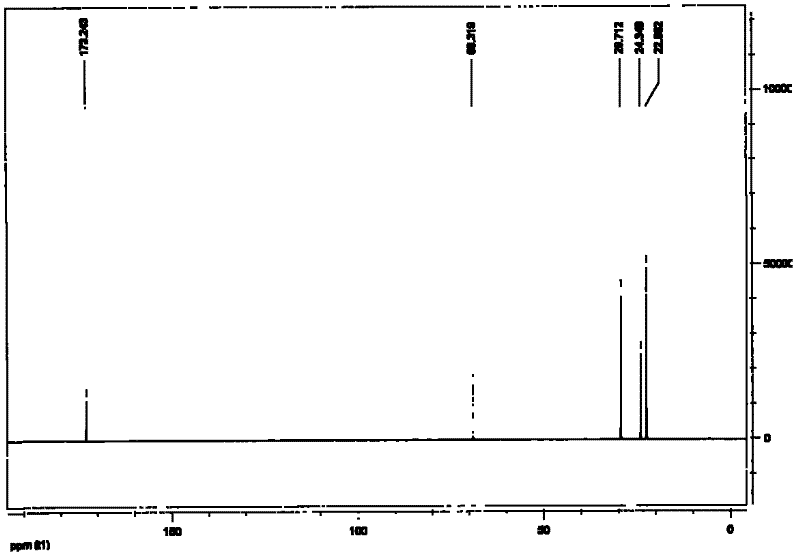

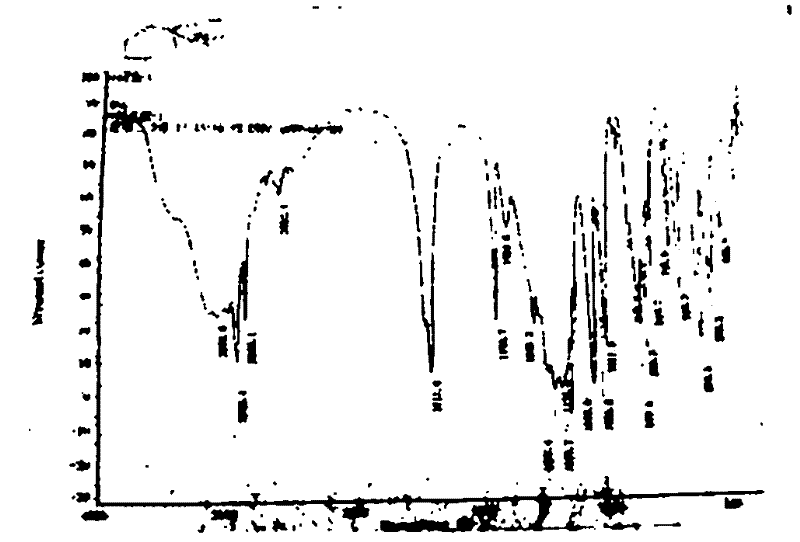

[0028] The collected filtrate is distilled under normal pressure, and the cut acetone of 50-70 ℃ is collected, which can be reused; the remaining liquid is distilled under reduced pressure (200-600mmHg) to remove 60% (mass percentage) moisture, and then at room temperature and normal pressure Add the solvent 1 toluene 7g of residue 20% (mass percentage) down, carry out extraction separation and obtain organic phase and water phase, concentrate organic phase, weigh after vacuum-drying treatment, through 1 HNMR, 13 CNMR and IR iden...

Embodiment 2

[0031] Take 100g of this organic wastewater, adjust the pH value to 8-9 with NaOH at room temperature and normal pressure, add solvent II acetone 80g, solids are precipitated, filter in batches, collect the filtrate and filter residue, and wash the filter residue with 2g of anhydrous methanol to off-white, 40 After drying at -50°C, it was weighed to obtain 11 g of crude cyclohexyl formic acid sulfonate.

[0032] Distill the collected filtrate under normal pressure, collect the distillate acetone at 50-70°C for reuse; distill the remaining liquid to remove 60% water (mass percentage) under reduced pressure (200-600mmHg), and then add it at room temperature and normal pressure Residue 20% (mass percentage) solvent Ibenzene 7g, carry out extraction separation to obtain organic phase and water phase, concentrate organic phase, obtain caprolactam 2.5g through vacuum drying. The aqueous phase was further concentrated and dried in vacuo to give 29 g of a black solid.

[0033] Take 1...

Embodiment 3

[0035] Take 100g of this organic wastewater, adjust the pH value to 8-9 with NaOH at room temperature and normal pressure, add solvent II acetone 120g, solids are precipitated, filter in batches, collect the filtrate and filter residue, and wash the filter residue with 2g of anhydrous methanol until off-white, 40 After drying at -50°C, it was weighed to obtain 12.5 g of crude cyclohexyl formic acid sulfonate.

[0036] Distill the collected filtrate under normal pressure, collect the distillate acetone at 50-70°C for reuse; distill the remaining liquid to remove 60% water (mass percentage) under reduced pressure (200-600mmHg), and then add it at room temperature and normal pressure The remaining 30% (mass percentage) solvent I cyclohexane 10g was extracted and separated to obtain an organic phase and an aqueous phase, the organic phase was concentrated, and 2.2 g of caprolactam was obtained through vacuum drying. The aqueous phase was further concentrated and dried under vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com