Preparation method of leather-imitating automobile leather

An automotive leather and imitation leather technology, applied in chemical instruments and methods, vehicle components, lamination, etc., can solve the problems of high cost, difficult to accept low-end passenger cars, etc., to meet the needs, easy post-processing, soft touch comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

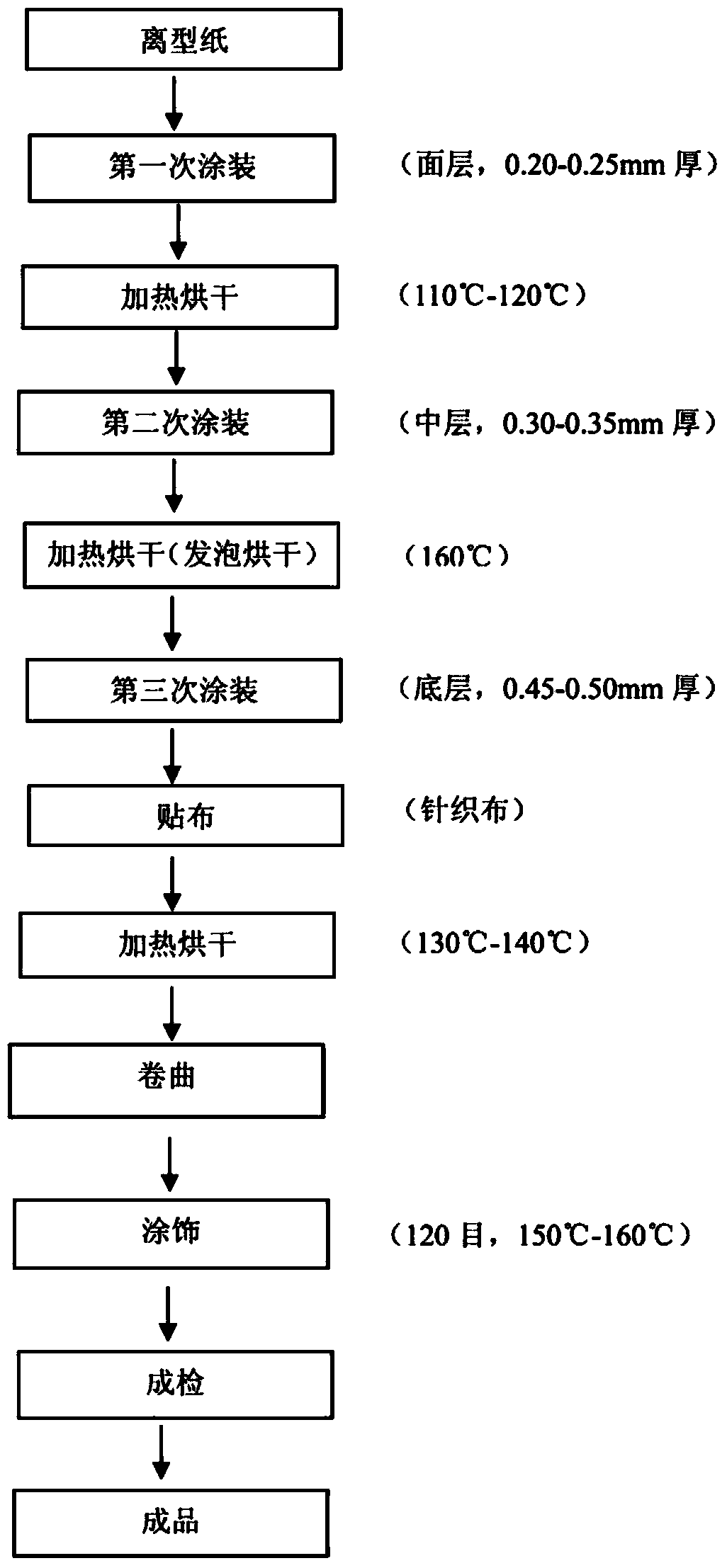

[0024] like figure 1 Shown, a kind of preparation method of imitation leather automobile leather comprises the following steps:

[0025] 1) According to the use of automobile leather, design PU formula to prepare slurry, apply the slurry on the release paper to form a coating, complete the first coating process, and heat and dry to obtain the surface layer of automobile leather;

[0026] 2) Add bridging agent, leveling agent, flame retardant, and microsphere foaming agent to the high-solid resin, and stir evenly; apply the homogeneously mixed material to the automobile leather surface layer obtained in step 1) to form Coating, complete the second coating process, and heat and dry (foaming and drying) to prepare the middle supporting foam layer;

[0027] 3) coat the slurry prepared by the PU formula on the intermediate supporting foam layer obtained in step 2) to form a coating, and complete the third coating process;

[0028] 4) Bonding the coating formed in step 3) to the b...

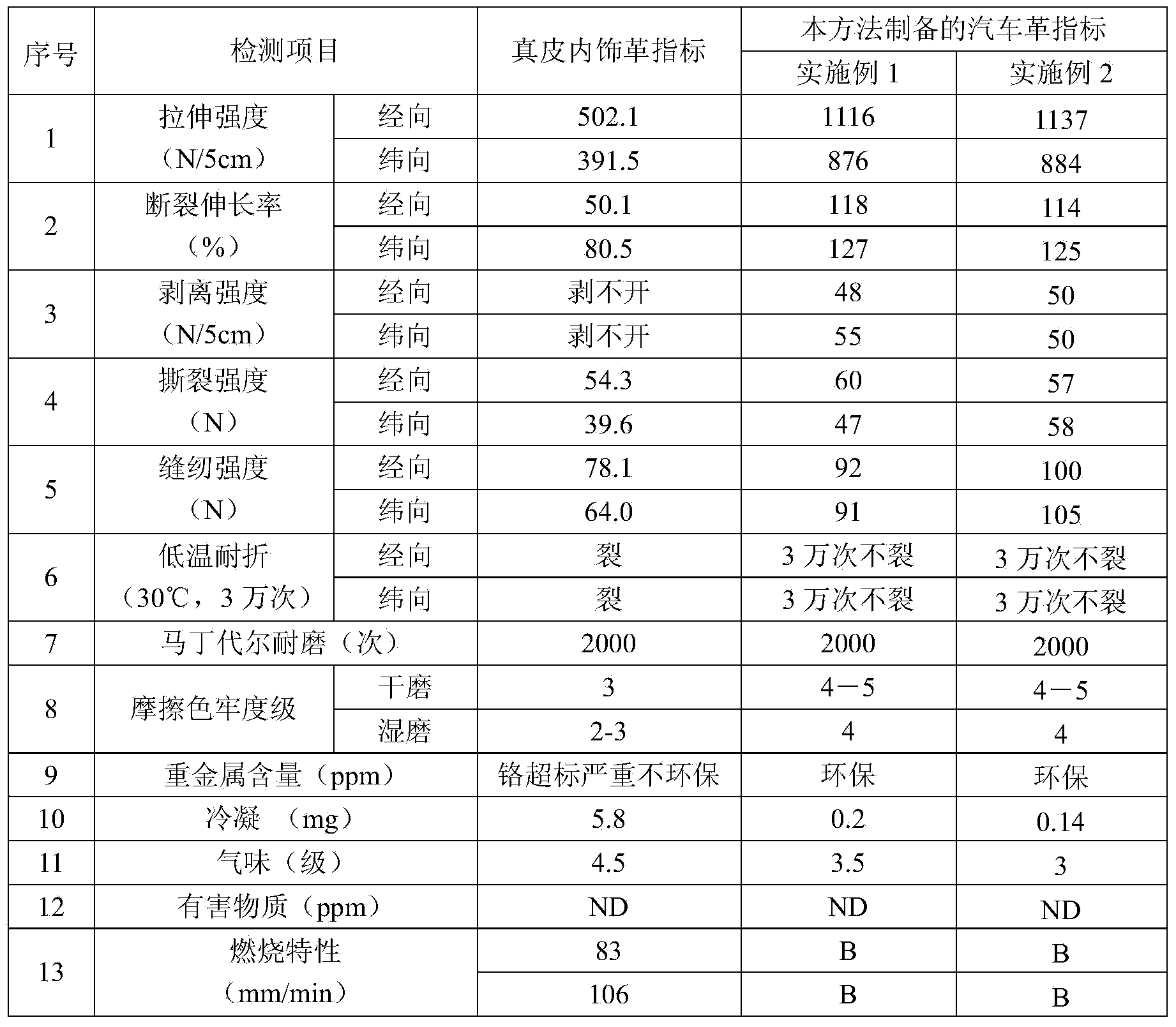

Embodiment 1

[0033] According to the purpose of the prefabricated automobile leather, the formula of common PU is designed, and the formula is: 100 parts by weight of common dry surface layer resin, dimethylformamide of 50 parts by weight, ethyl acetate of 40 parts by weight, 10 parts by weight of The mixed material of the color paste, the paste is coated on the release paper to form a coating, and the first coating process is completed. The thickness of the coating needs to be controlled within the range of 0.20-0.25mm, preferably 0.25mm, and at 110-120°C Heated in an oven for 3 minutes and dried to obtain a car leather surface layer. Add 7 parts by weight of bridging agent, 0.5 parts by weight of leveling agent, 15 parts by weight of flame retardant, and 1 part by weight of microsphere foaming agent into 100 parts by weight of high-solid resin, and stir evenly, wherein, The bridging agent is JF-B-NY75, the leveling agent is 9565, the flame retardant is halogen-free flame retardant (HT-21...

Embodiment 2

[0036]The formulation of water-based PU is designed according to the purpose of the pre-manufactured automobile leather. Water-based PU is water-based polyurethane. The slurry is coated on the release paper to form a coating, and the first coating process is completed. The thickness of the coating is preferably controlled at 0.15- within the range of 0.18mm, and adopt 80-130°C gradient temperature heating and drying in an oven, the drying time is 5 minutes, and the vehicle speed is controlled below 5 m / min to obtain the automobile leather surface layer. Add 7 parts by weight of bridging agent, 0.5 parts by weight of leveling agent, 15 parts by weight of flame retardant, and 1 part by weight of microsphere foaming agent into 100 parts by weight of high-solid resin, and stir evenly, wherein, The bridging agent is JF-B-NY75, the leveling agent is 9565, the flame retardant is halogen-free flame retardant (HT-219B) TPU, and the microsphere foaming agent is TX-40; apply the above uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com