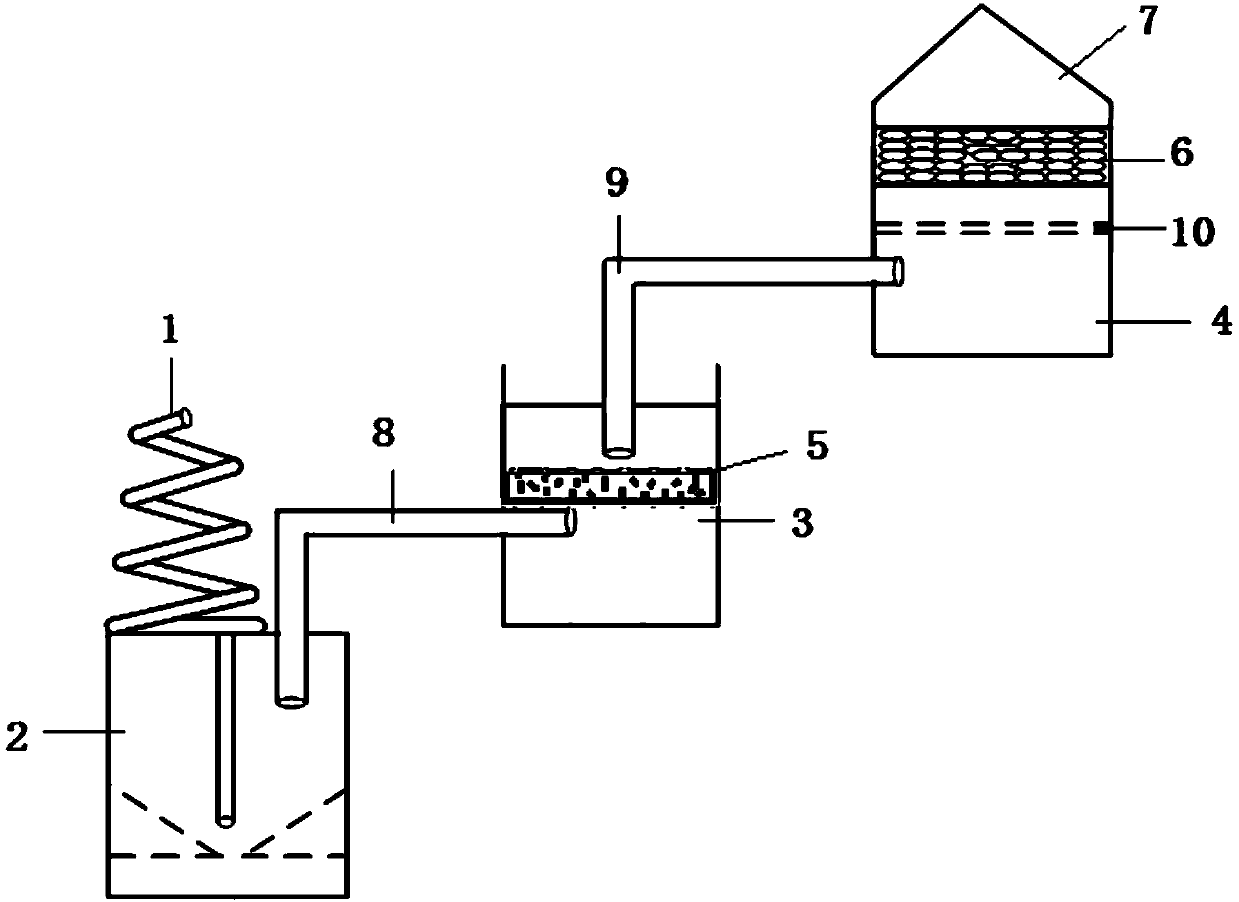

Equipment for directly producing arsenic by utilizing high-arsenic dust and production method

An arsenic fume and direct technology is applied to the equipment and production field for directly producing arsenic by using high arsenic fume and dust, which can solve the problems of difficult to achieve clean and safe production, use of hazardous chemicals, long process flow, etc. Injury of toxic substances, effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Using arsenic-containing tin fumes as raw materials (the main element content is As60%, Sn5%, Pb1.17%), the temperature of the DC furnace is controlled at 1200 ° C ± 50 ° C, and the control furnace pressure parameters are: -20 ~ -10Pa, can get the content of Tin slag with arsenic content less than 4%, the tin content in the slag is higher than 8%, the direct recovery rate of tin is higher than 80%, the grade of diarsenic trioxide is above 95%, the temperature of the deoxidation device is controlled at 700-800°C, and the reduction-condensation metal arsenic is integrated The temperature of the chemical device is controlled at 800°C±50°C, and the obtained metal arsenic product contains 99.94% arsenic.

Embodiment 2

[0030] Using arsenic-containing tin fumes as raw materials (the main element content is As55%, Sn6%, Pb2.36%), the temperature of the DC furnace is controlled at 1000°C±100°C, and the control furnace pressure parameters are: -5~0Pa, and the arsenic-containing The amount of tin slag is less than 4%, the tin content in the slag is higher than 8%, the direct recovery rate of tin is higher than 80%, the grade of diarsenic trioxide is above 95%, the temperature of the deoxidation device is controlled at 700-800°C, and the reduction and condensation of metal arsenic are integrated The temperature of the device is controlled at 700°C±50°C, and the obtained metal arsenic product contains 99.94% arsenic.

Embodiment 3

[0032] Using white smoke as raw material (the main element content is As40%, Cu6%, Pb7%, Zn5%), the temperature of the DC furnace is controlled at 1300°C ± 50°C, and the control furnace pressure parameter is: -5 ~ 0Pa, the arsenic content can be obtained Less than 4% copper slag, the copper content in the slag is higher than 10%, the direct recovery rate of copper is higher than 80%, the grade of diarsenic trioxide is above 95%, the temperature of the deoxidation device is controlled at 700-800°C, and the reduction-condensation metal arsenic integrated device The temperature is controlled at 750°C±50°C, and the obtained metal arsenic product contains 99.91% arsenic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com