Composite clean liquid fuel and production method thereof

A technology for cleaning liquids and fuels, which is applied in the direction of liquid carbon-containing fuels, fuels, and the petroleum industry. It can solve the problems of low calorific value, high cost, and odor of fuels, and achieve high combustion calorific value, reduced volatilization, and convenient transportation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be realized through the following steps: adding bicyclodienyl iron into methanol and stirring evenly, fully mixing, adding sodium oxide into water and stirring evenly for 3-5 minutes. Mix the two liquids and stir for 5-10 minutes, then add acetic acid into it and stir, add ammonia water, xyleneamine, and sodium nitrate to ethanol and stir for 5 minutes to dissolve the two liquids generated above Introduce it into the reaction pot to react for 15-20 minutes and stir it, then filter it through the deep layer of the filter, and input it into the softening system for softening treatment, then pour it into the storage tank and settle for 40 minutes to become the finished product.

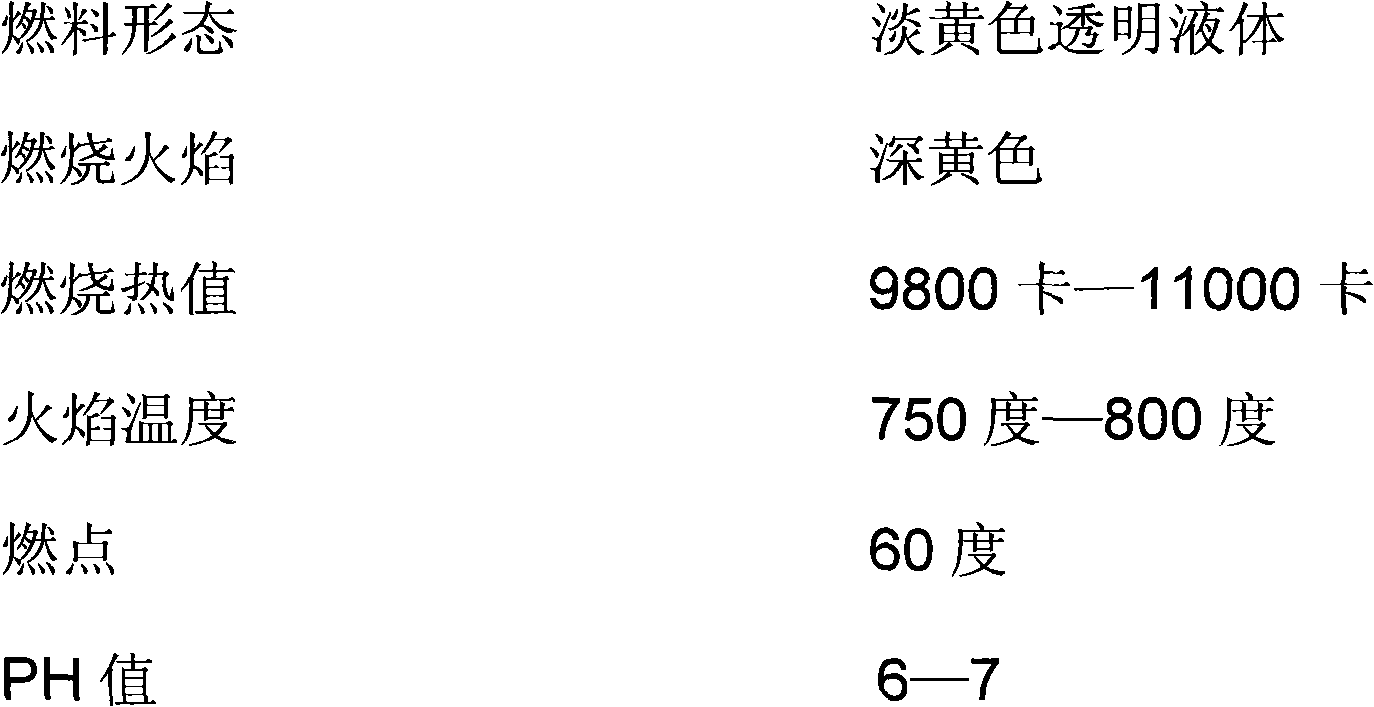

[0028] Chemical and combustion characteristics of the present invention are as follows:

[0029]

[0030] The invention has no peculiar smell when burning, does not irritate the eyes, has a delicate fragrance, and has high combustion calorific value, and is suitable fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com