Water-based coating material for galvanized steel plate, and preparation method thereof

A water-based paint, galvanized steel technology, applied in anti-corrosion paint, coating and other directions, can solve the problem of easy absorption and crystallization of paint, and achieve the effect of ensuring performance, improving weather resistance, and not easy to peel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

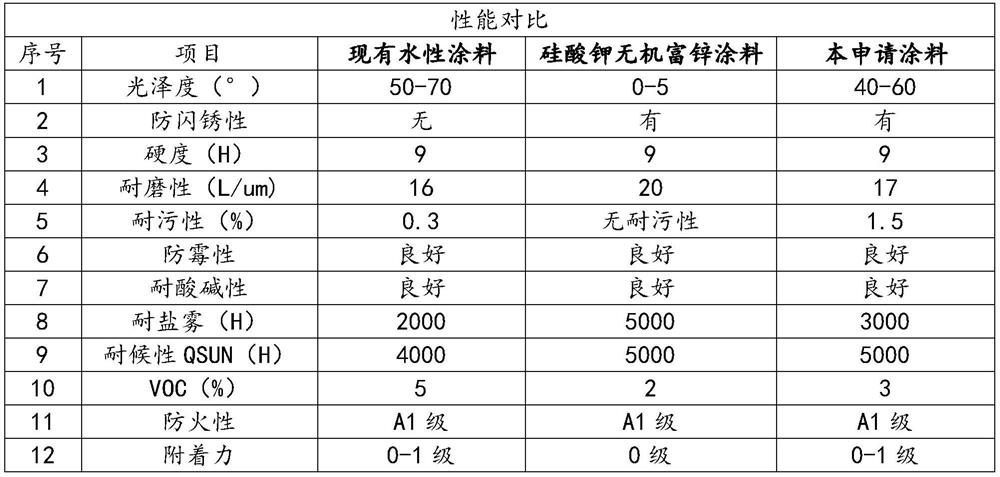

Image

Examples

Embodiment 1

[0023] A kind of water-based coating for galvanized steel sheet, comprises A component, B component and C component, and described A component is made of 15 parts by weight methyltrimethoxysilane, 1.1 parts by weight of white carbon black, 1.2 parts by weight It consists of sodium stearate; the B component consists of 20 parts by weight of cationic modified potassium silicate resin, 15 parts by weight of titanium dioxide, 3 parts by weight of kaolin, 3 parts by weight of talc, 0.5 parts by weight of silicone resin, 0.5 parts by weight of polystyrene Ether modified polysiloxane, 1 weight part ethylene glycol butyl ether, 0.5 weight part sodium dodecylbenzene sulfonate, 3 weight parts photocatalyst, 20 weight parts water; C component is made up of 1 weight part organic acid and 1 part by weight of xylylguanidine.

[0024] The preparation method of this aqueous paint, comprises the steps:

[0025] (1) Preparation of component B: Cationic modified potassium silicate resin, titani...

Embodiment 2

[0028] A kind of water-based coating for galvanized steel sheet, comprises A component, B component and C component, and described A component is made of 17 parts by weight methyltrimethoxysilane, 1.3 parts by weight of white carbon black, 1.4 parts by weight Potassium stearate is composed; The B component consists of 22 parts by weight of cationic modified potassium silicate resin, 18 parts by weight of titanium dioxide, 6 parts by weight of talcum powder, 5 parts by weight of mica powder, 0.7 parts by weight of acrylate copolymer, 0.6 parts by weight of Parts by weight of organosiloxane, 1.4 parts by weight of lauryl alcohol ester, 0.7 parts by weight of cetyltrimethylammonium bromide, 5 parts by weight of photocatalyst, and 23 parts by weight of water; Component C consists of 1.5 parts by weight of organic acid and 1.5 parts by weight xylylguanidine composition.

[0029] The preparation method of this aqueous paint, comprises the steps:

[0030] (1) Preparation of componen...

Embodiment 3

[0033] A kind of water-based coating for galvanized steel sheet, comprises A component, B component and C component, and described A component is made of 18 parts by weight methyltrimethoxysilane, 1.7 parts by weight of white carbon black, 1.7 parts by weight It consists of calcium stearate; the B component consists of 24 parts by weight of cationic modified potassium silicate resin, 22 parts by weight of titanium dioxide, 8 parts by weight of kaolin, 6 parts by weight of zinc oxide, 0.8 parts by weight of polydimethylsiloxane , 0.8 parts by weight polyether, 1.7 parts by weight diethylene glycol butyl ether, 0.9 parts by weight ethyl acetate, 7 parts by weight photocatalyst, 27 parts by weight water; C component is made up of 1.8 parts by weight organic acid and 1.8 parts by weight xylene base guanidine composition.

[0034] The preparation method of this aqueous paint, comprises the steps:

[0035] (1) Preparation of B component: cationic modified potassium silicate resin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com