Waterborne acrylic modified alkyd antirust paint and preparation method thereof

A technology of alkyd anti-rust paint and water-based acrylic, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc. It can solve the problems of poor hardness of the coating film, poor water resistance, slow drying, etc., and achieve high cost performance and water resistance. Good performance, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

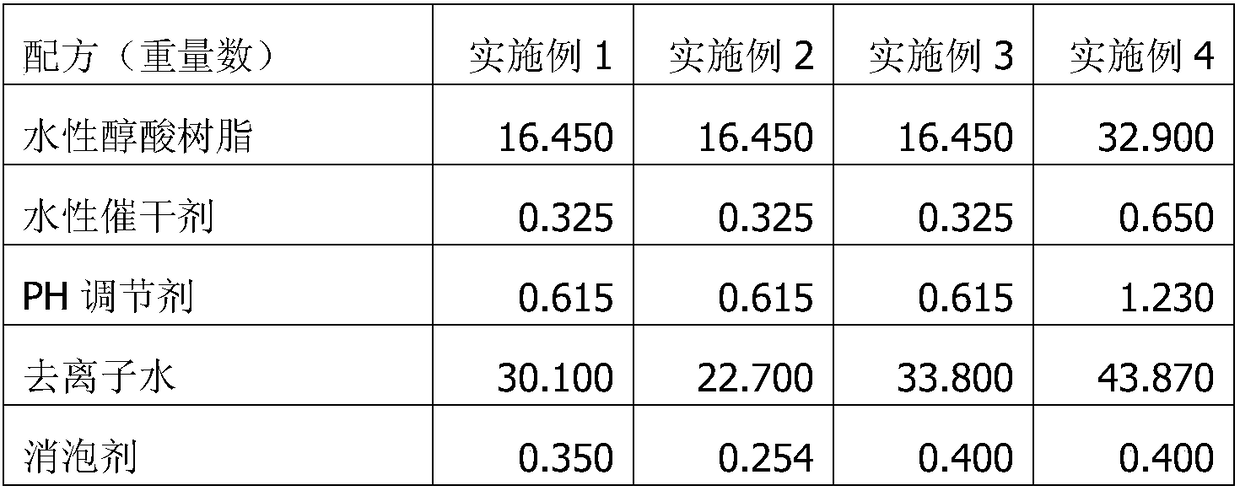

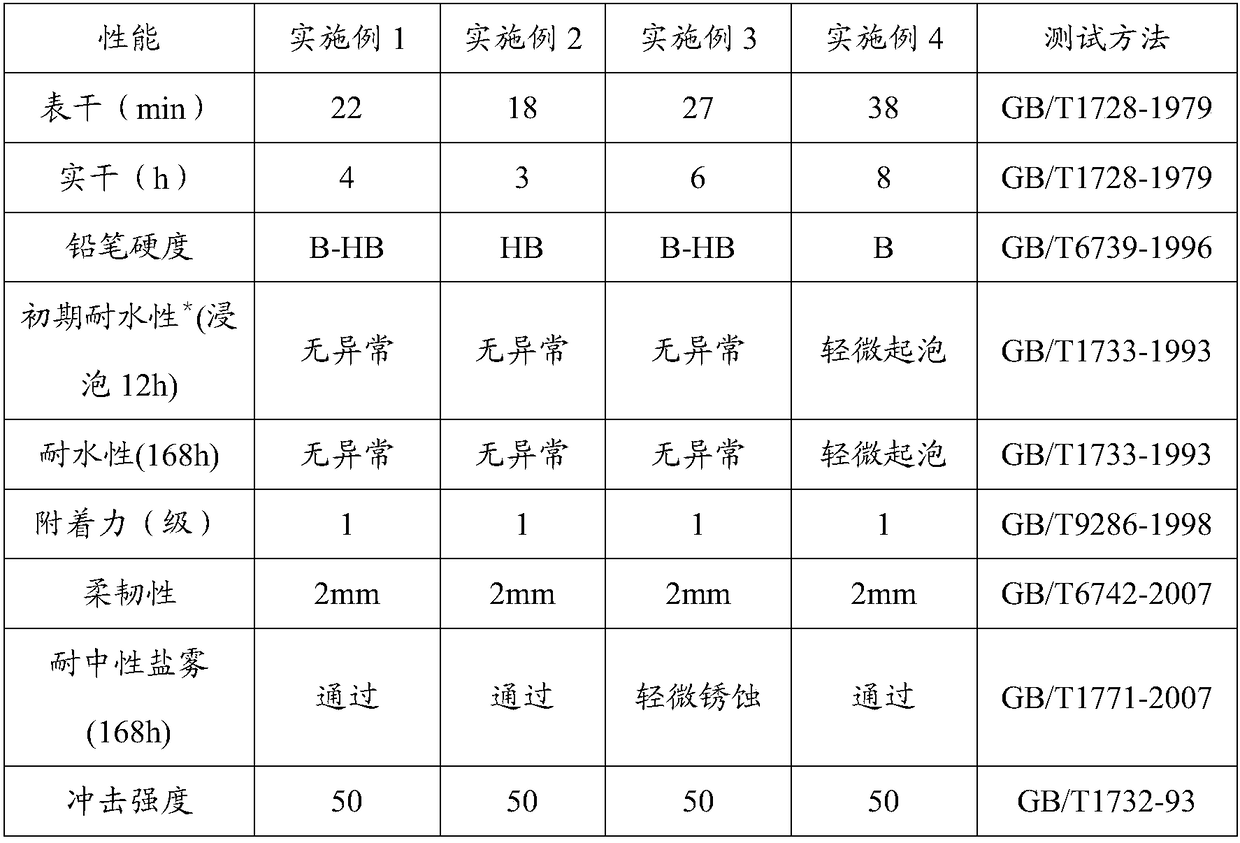

[0031] In order to better understand the present invention, the technical solution of the present invention will be described in detail below with specific examples, but the present invention is not limited thereto.

[0032] The preparation method of the water-based acrylic acid modified alkyd antirust paint of following embodiment, comprises the following steps successively:

[0033] (1) Add the formulated amount of water-based alkyd resin, water-based drier and pH regulator at 600rpm and stir at a high speed until the mixture is evenly mixed, then slowly add deionized water, and continue to disperse for 10-15 minutes to obtain a varnish;

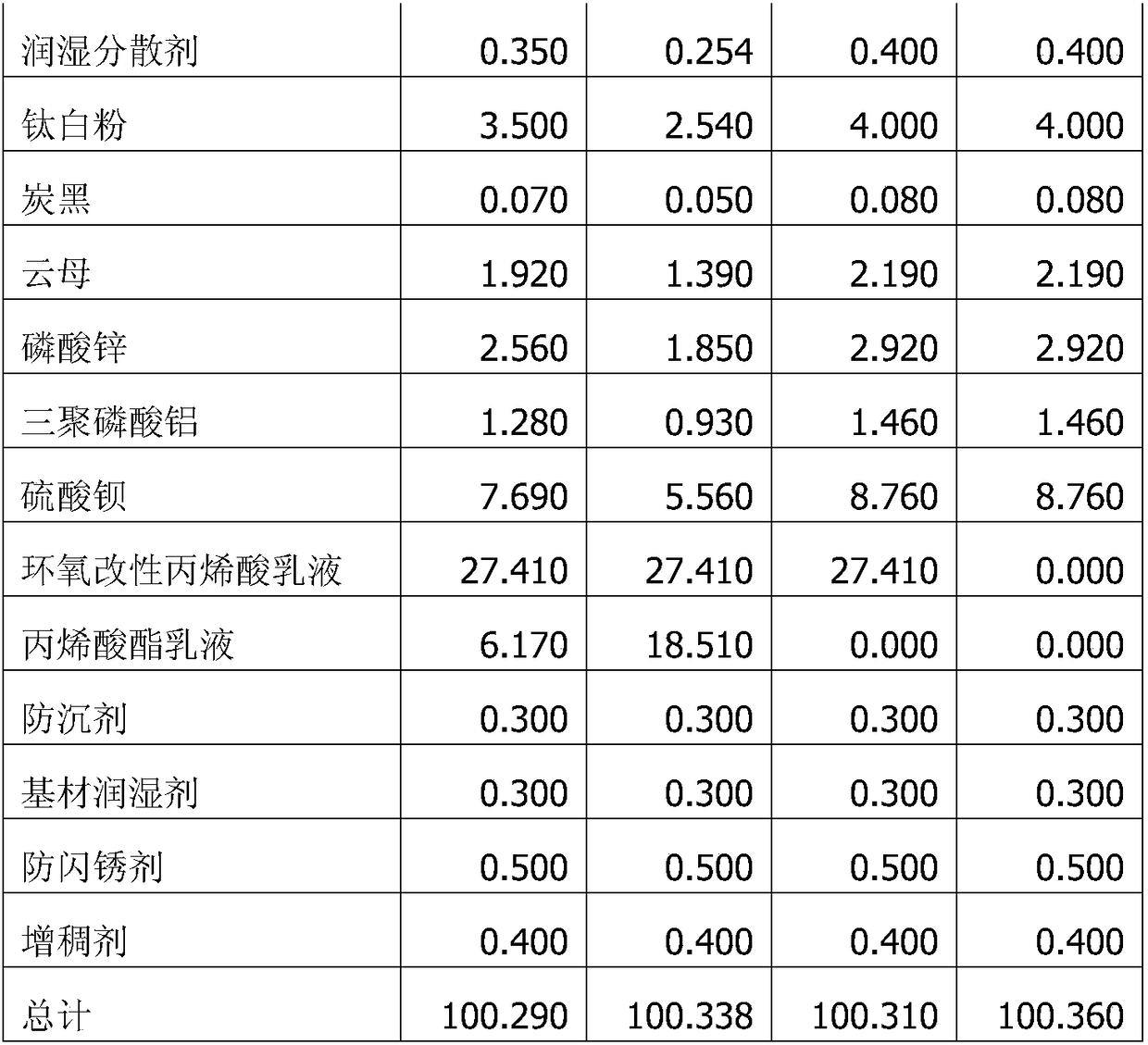

[0034] (2) Add defoamer, wetting and dispersing agent, titanium dioxide, carbon black, mica, zinc phosphate, aluminum tripolyphosphate, barium sulfate in sequence, disperse at 600rpm for 10-20min at a high speed until evenly mixed, and then use a sand mill to grind until Fineness≤20μm;

[0035] (3) Use a 100-mesh filter cloth to filter th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com