Water-based epoxy micaceous iron oxide rustproof paint and preparation method thereof

An epoxy micaceous iron and water-based epoxy technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of environmental pollution, health hazards of workers, and technical difficulties, and achieve fast drying speed and weather resistance. And the effect of outstanding aging resistance and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

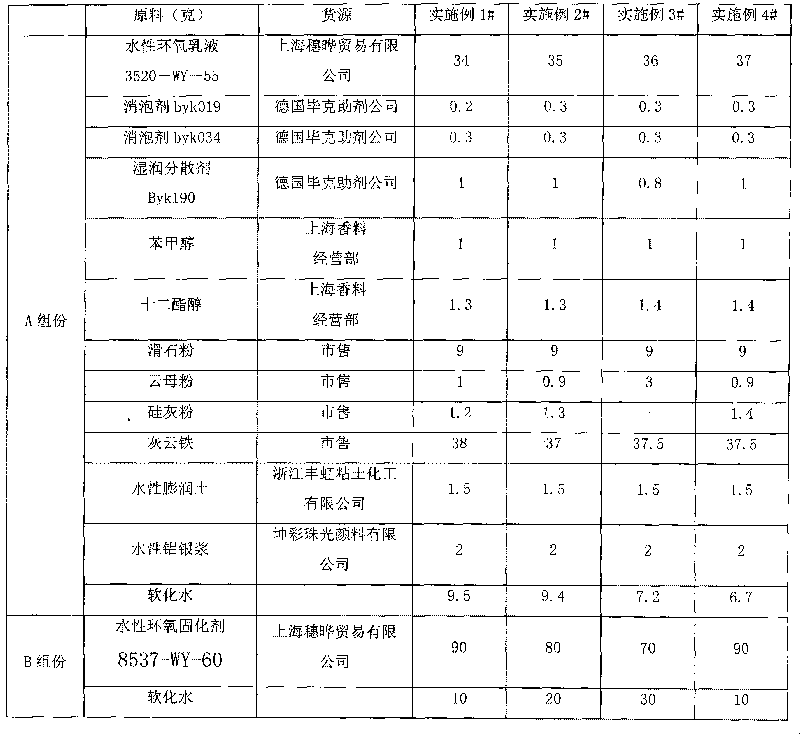

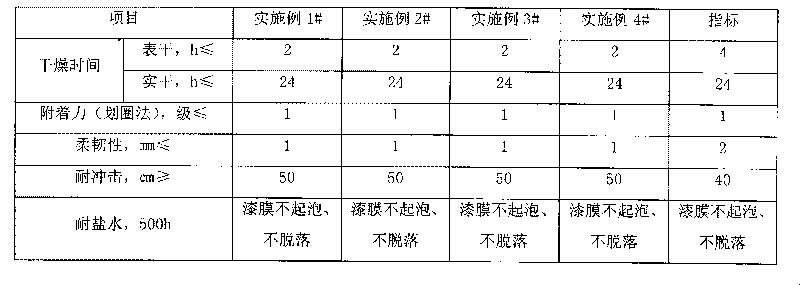

[0013] Table 1 is an example of the present invention, wherein the content of each component is in mass percentage, but the present invention is not limited to the following examples.

[0014] Table 1

[0015]

[0016] The paint preparation process is:

[0017] Component A:

[0018] ① Add water-based epoxy emulsion 3520-WY-55 to the slurry mixing container accurately, add additive 1 and additive 2 respectively (auxiliary 1 is the softened aqueous solution of wetting and dispersing agent byk190, and additive 2 is defoamer byk019 , defoamer byk034 and lauryl alcohol mixture), then add the remaining benzyl alcohol, demineralized water, and stir at low speed for 5 to 10 minutes.

[0019] ② Add filler and stir at low speed for 5-10 minutes.

[0020] ③Use a sand mill, ball mill or three-roll mill to grind to a fineness of less than 50 μm.

[0021] ④ Add water-based bentonite and water-based aluminum silver paste, and stir for 30 minutes.

[0022] ⑤ Filter with 100-mesh coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com