Black waterborne automotive chassis paint and preparation method thereof

An automotive chassis, water-based technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems that the anti-corrosion performance cannot meet the demand, is not suitable for dip coating construction, and is not suitable for outdoor construction, and achieves improved adhesion and Anti-corrosion, solve flash rust of weld bead, excellent effect of salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

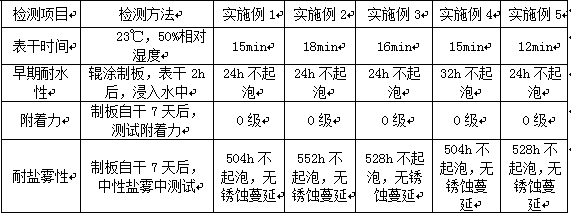

Examples

Embodiment 1

[0034] Black water-based automotive chassis paint comprises the following raw materials in percentage by weight: 20% self-emulsifying acrylic acid modified epoxy ester resin, 20% water-based epoxy ester dispersion, 0.5% water-based drier, 0.5% graphene, 1 % carbon black, 5% complex zinc phosphate, 10% barium sulfate, 1% corrosion inhibitor, 1% propylene glycol butyl ether, 0.1% dimethylethanolamine, 0.2% defoamer, 0.4% Leveling agent (PW-336), 0.3% substrate wetting agent (Tego-245), 39.5% deionized water, 0.5% thickener.

Embodiment 2

[0036] Black water-based automotive chassis paint, including the following raw materials in weight percentage: 25% self-emulsifying acrylic acid modified epoxy ester resin, 25% water-based epoxy ester dispersion, 1% water-based drier, 0.2% graphene, 2 % carbon black, 10% complex zinc phosphate, 15% barium sulfate, 2% corrosion inhibitor, 2% propylene glycol butyl ether, 0.2% dimethylethanolamine, 0.5% defoamer, 0.6% Leveling agent (PW-336), 0.5% substrate wetting agent (Tego-245), 15% deionized water, 1% thickener.

Embodiment 3

[0038] Black water-based automotive chassis paint, including the following raw materials in weight percentage: 22% self-emulsifying acrylic acid modified epoxy ester resin, 23% water-based epoxy ester dispersion, 0.8% water-based drier, 0.05% graphene, 1.5% % carbon black, 8% complex zinc phosphate, 12% barium sulfate, 1.5% corrosion inhibitor, 1.5% propylene glycol butyl ether, 0.2% dimethylethanolamine, 0.3% defoamer, 0.5% Leveling agent (PW-336), 0.4% substrate wetting agent (Tego-245), 27.45% deionized water, 0.8% thickener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com