Latex and synthesis method thereof, and water-based metal anticorrosive paint and synthesis method thereof

A synthesis method and metal anti-corrosion technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of slow drying time, poor water resistance and poor adhesion of the coating film, and achieve excellent self-cleaning, excellent water resistance, and environmental protection performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0024] Embodiment 1-5: Preparation of epoxy resin grafted fluorine-containing acrylate latex (component and mass percentage)

[0025] Table 1 Epoxy resin grafted fluorine-containing acrylate latex formula

[0026] components

Comparative Example 1

Comparative Example 2

Example 3

Example 4

Example 5

Hydroxyethyl Phosphate Methacrylate

0

0.5

0.5

0.8

0.6

1.0

1.0

1.0

0.4

Sodium Nonylphenol Polyoxyethylene Sulfate

0.5

Nonylphenol polyoxyethylene ether

0.5

0.5

0.5

0.25

0.4

0.65

0.65

0.65

0.5

0.6

E-51

10

10

10

15

8

20

20

20

13

15

16

16

15.5

10.9

16.6

...

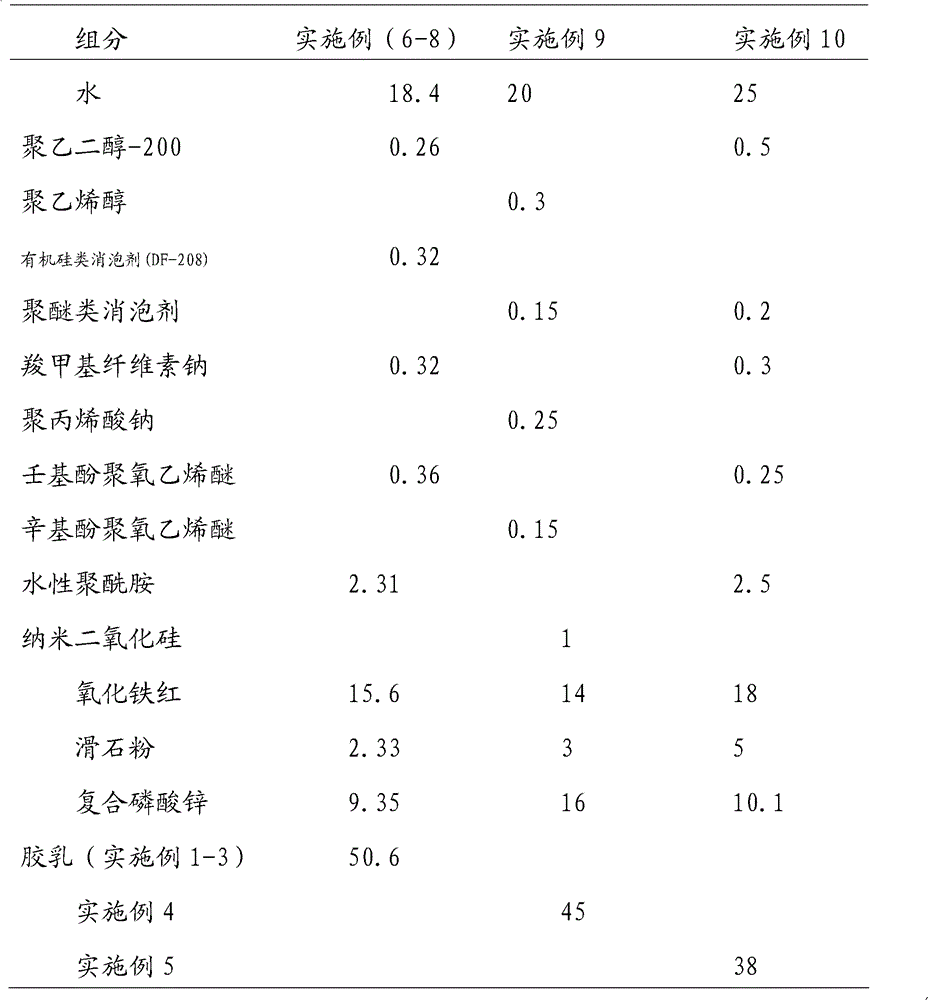

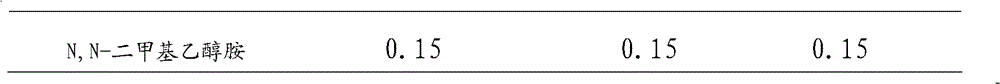

Embodiment 6-10

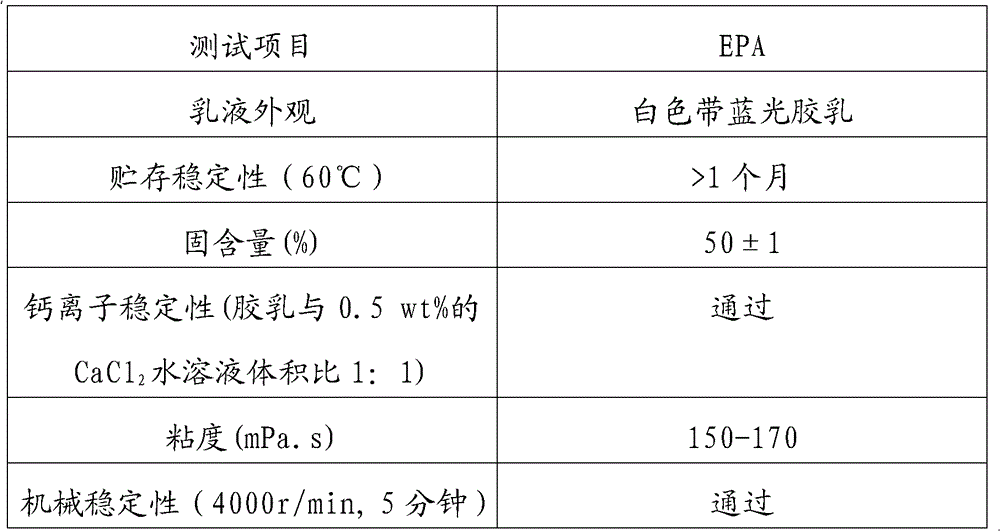

[0029] Embodiment 6-10 Preparation of water-based epoxy resin grafted fluorine-containing acrylate coating

[0030] Table 2 water-based epoxy resin grafted fluorine-containing acrylate coating formula (weight percent %)

[0031]

[0032]

[0033] Coating preparation process:

[0034] (1) Add the wetting agent, dispersant and anti-sedimentation agent used in the formula into the water and stir slowly to disperse, first add 4 / 5 weight of defoamer, stir for 5 minutes, then add iron oxide red, talc powder and compound Stir for 10 minutes with zinc phosphate and other pigments and fillers, then add 2 / 3 weight of thickener, disperse at high speed for 10 minutes, and finally add pH regulator to make the pH of the system 8-9, then disperse for 1 hour to make a slurry, transfer Grind to a fineness of less than 50 μm in a vertical sand mill.

[0035] (2) Add latex to the above color paste, add the remaining defoamer and thickener and stir for 30 minutes to obtain component A of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com