Method for synthesizing self-drying water-soluble alkyd resin from fatty acid methyl ester

A fatty acid methyl ester and alkyd resin technology, applied in polyester coatings, coatings, anti-corrosion coatings, etc., can solve the problems of high production cost, low hardness, poor dryness, etc., and achieve low cost, high hardness, and improved dryness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The method for synthesizing self-drying water-soluble alkyd resin with fatty acid methyl ester of the present invention utilizes fatty acid methyl ester produced from waste oil as a raw material to synthesize self-drying water-soluble alkyd resin, and the raw and auxiliary materials are 30% fatty acid methyl ester and 4% linoleic acid in mass percentage , pentaerythritol 8%, ethylene glycol 6%, terephthalic acid 16.4%, benzoic acid 3%, trimellitic anhydride 8%, organotin 0.8‰, slaked lime 0.15‰, triethylamine 4%, propylene glycol butyl ether 20.505% Preparation; the synthetic operation steps are as follows:

[0054] (1) Add fatty acid methyl esters to the reactor, preheat to 120-160°C, add slaked lime and continue heating;

[0055] (2) Add pentaerythritol when the temperature rises to 180-200°C, and continue to heat up;

[0056] (3) When the temperature reaches 230-240°C, keep it warm for 1-2 hours. After no methanol is evaporated, add linoleic acid, terephthalic acid,...

Embodiment 2

[0060] The method for synthesizing self-drying water-soluble alkyd resin with fatty acid methyl ester of the present invention utilizes fatty acid methyl ester produced from waste oil as a raw material to synthesize self-drying water-soluble alkyd resin, and the raw and auxiliary materials are 21% fatty acid methyl ester and 6% linoleic acid in mass percentage , pentaerythritol 9%, ethylene glycol 7%, terephthalic acid 17%, benzoic acid 4%, trimellitic anhydride 9%, organotin 1.4‰, slaked lime 0.2‰, triethylamine 5%, propylene glycol butyl ether 21.84% Preparation; Synthetic operation steps are the same as in Example 1.

Embodiment 3

[0062] The method for synthesizing self-drying water-soluble alkyd resin with fatty acid methyl ester of the present invention utilizes fatty acid methyl ester produced from waste oil as a raw material to synthesize self-drying water-soluble alkyd resin, and the raw and auxiliary materials are 36% fatty acid methyl ester and 4% linoleic acid in mass percentage , pentaerythritol 7%, ethylene glycol 5%, terephthalic acid 15%, benzoic acid 2%, trimellitic anhydride 7%, organotin 0.7‰, slaked lime 0.12‰, triethylamine 3%, propylene glycol butyl ether 20.918% Preparation; Synthetic operation steps are the same as in Example 1.

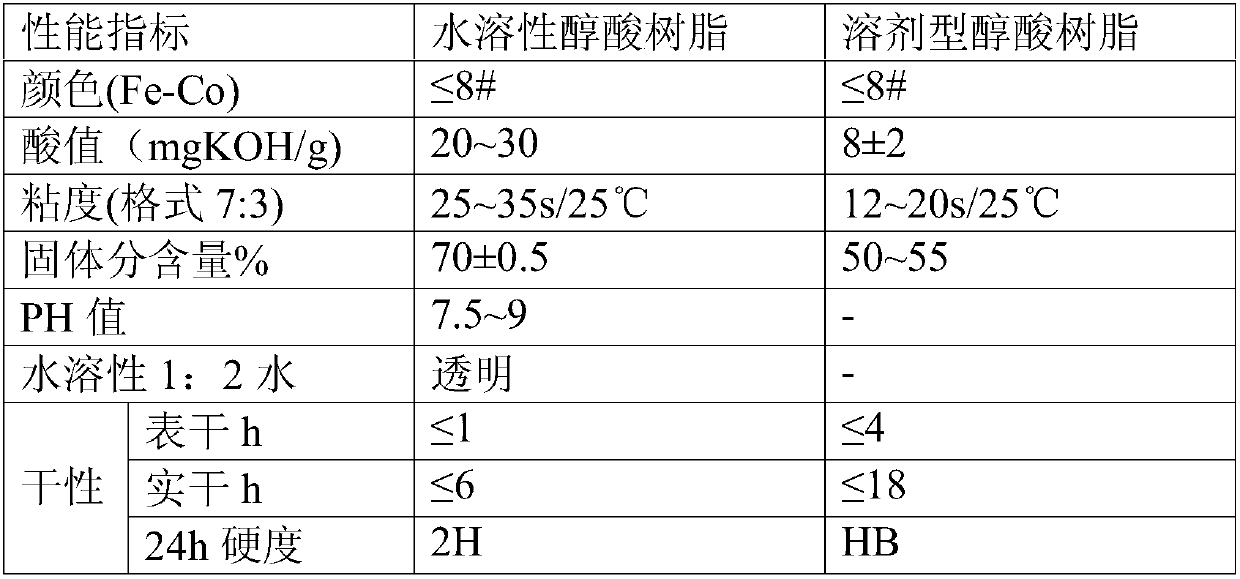

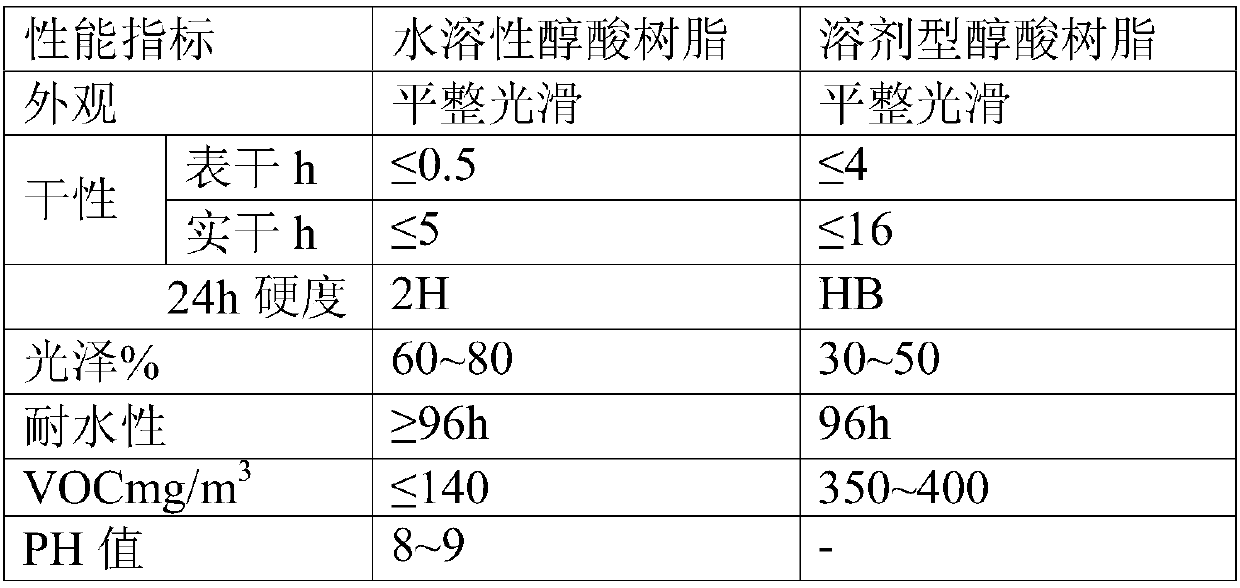

[0063] The above three examples adopt the same operation steps to prepare the self-drying water-soluble alkyd resin, prepare the coating with the same iron red antirust paint formula, and test according to the national standard system. The test results are compared in Table 3.

[0064] The self-drying water-soluble alkyd iron red antirust paint technical in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com