Novel xylidine and acetic acid waste gas recovery device and method

A xylene amine recovery device technology, which is used in the fields of daily chemical additives, electronics industry cleaning agents, metal surface treatment agents, and water treatment agents. It can solve the problems of large adsorption and cooling equipment, incomplete absorption, and high operating costs. , to achieve the effect of wide application range of components, high reuse rate and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

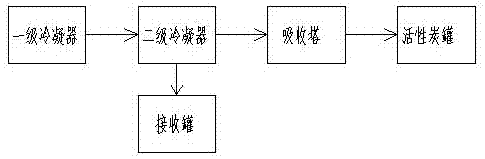

[0030]Turn on the reaction device to prepare polyisopropylene phosphate; when the reaction temperature reaches 140°C, a large amount of xylidine and acetic acid begin to reflux. First, open the valve of the first-stage condenser connected to the reaction kettle, and at the same time turn on the condensed water, control the temperature of the interlayer of the condenser at 20°C, and return a large amount of mixed steam of acetic acid and xyleneamine to the reaction kettle, and at the same time, turn on the first-stage condensation The valve between the condenser and the secondary condenser, open the cooling water of the secondary condenser and the valve of the receiving tank at the lower end of the condenser, keep the interlayer temperature of the condenser at 10°C, and make the mixed gas of xylidine and acetic acid overflow from the primary condenser Condensed again, the condensed liquid enters the condensate recovery tank; the uncondensed mixed gas enters from the middle of th...

Embodiment 2

[0033] Turn on the reaction device to prepare polyisopropylene phosphate; when the reaction temperature reaches 140°C, a large amount of xylidine and acetic acid begin to reflux. First, open the valve of the first-stage condenser connected to the reactor, and at the same time turn on the condensed water, control the temperature of the interlayer of the condenser at 23°C, so that a large amount of mixed steam of acetic acid and xyleneamine is refluxed into the reactor, and at the same time, open the first-stage condensation The valve between the condenser and the secondary condenser, open the cooling water of the secondary condenser and the valve of the receiving tank at the lower end of the condenser, keep the interlayer temperature of the condenser at 13°C, and make the mixed gas of xylidine and acetic acid overflow from the primary condenser Condensed again, the condensed liquid enters the condensate recovery tank; the uncondensed mixed gas enters from the middle of the tail ...

Embodiment 3

[0036] Turn on the reaction device to prepare polyisopropylene phosphate; when the reaction temperature reaches 140°C, a large amount of xylidine and acetic acid begin to reflux. First, open the valve of the first-stage condenser connected to the reaction kettle, and at the same time turn on the condensed water, control the temperature of the interlayer of the condenser at 25°C, and return a large amount of mixed steam of acetic acid and xyleneamine to the reaction kettle, and at the same time, turn on the first-stage condensation The valve between the condenser and the secondary condenser, open the cooling water of the secondary condenser and the valve of the receiving tank at the lower end of the condenser, keep the temperature of the interlayer of the condenser at 15°C, and make the mixed gas of xylidine and acetic acid overflow from the primary condenser Condensed again, the condensed liquid enters the condensate recovery tank; the uncondensed mixed gas enters from the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com