A method for producing lubricating oil base oil

A lubricating oil base oil and deoiling technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of poor product quality and low yield, and achieve the effect of improving product quality and technical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

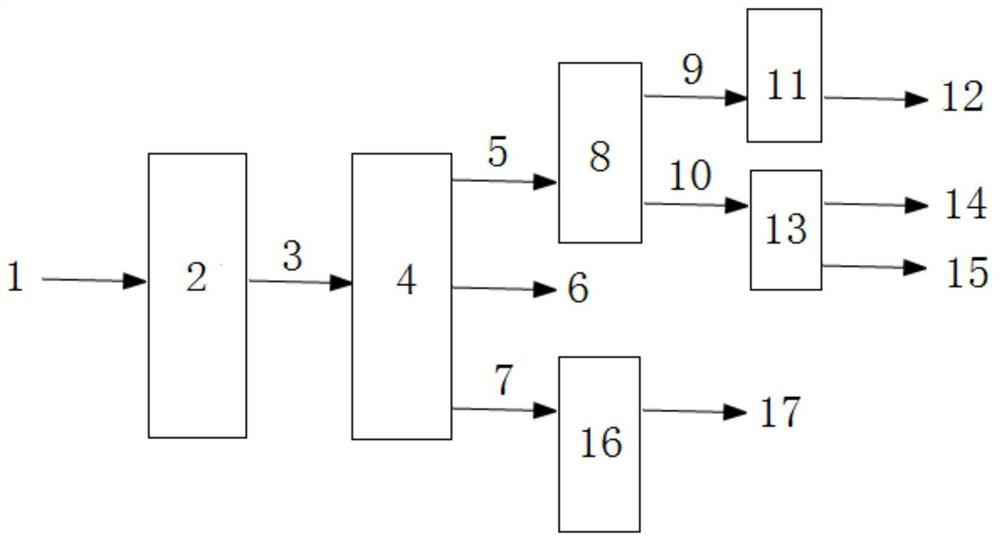

Method used

Image

Examples

Embodiment 1

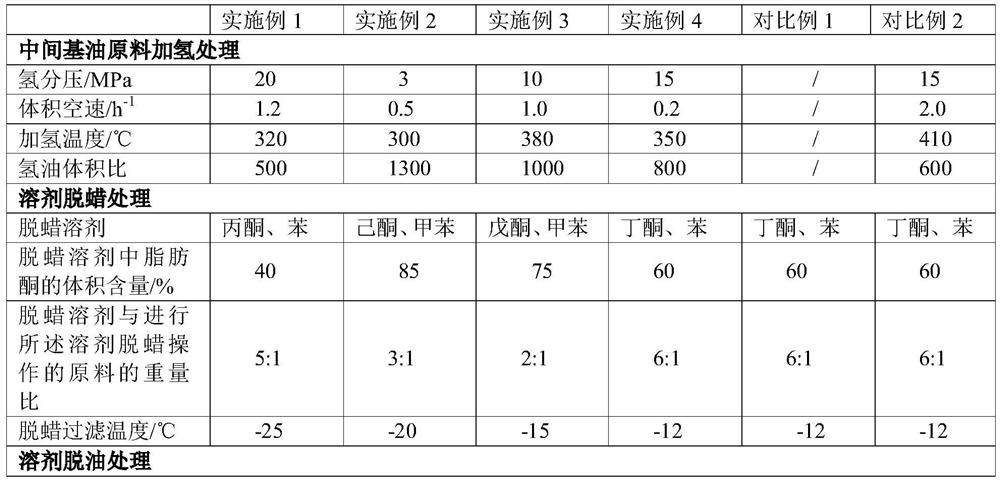

[0081] Using the second-line fraction of Saudi light crude oil as the intermediate base oil raw material, in the presence of the RL-2 catalyst, the intermediate base oil raw material is subjected to hydrogenation treatment to obtain a hydrorefined oil, and the hydrorefined oil is Carry out solvent dewaxing and deoiling treatment to obtain dewaxed oil, waxy oil and deoiled wax respectively; then extract the dewaxed oil with solvent to obtain raffinate oil and extract oil, and the raffinate oil is supplemented and refined I, to obtain lubricating oil base oil, and the extracted oil is subjected to re-extraction treatment to obtain respectively environment-friendly aromatic hydrocarbon rubber extension oil and polycyclic aromatic hydrocarbon oil; then the deoiled wax is subjected to supplementary refining treatment II to obtain petroleum wax.

[0082] The specific process conditions involved in the above examples are shown in Table 2, the yields of products obtained in each proces...

Embodiment 2

[0084] The third-line distillate of Iranian crude oil is used as the intermediate base oil raw material. The specific process conditions are shown in Table 2. The yield of products obtained in each process step is shown in Table 3. The obtained hydrotreated oil, lubricating oil base oil and environment-friendly aromatic hydrocarbon rubber filling The properties of the oil are shown in Table 4.

Embodiment 3

[0086] The fourth line distillate of Saudi medium crude oil is used as the intermediate base oil raw material. The specific process conditions are shown in Table 2. The yield of products obtained in each process step is shown in Table 3. The obtained hydrorefined oil, lubricating oil base oil and environment-friendly The properties of aromatic rubber extender oil are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com