Method for recovering multi-component organic gas mixture

A technology of organic gas and recovery method, applied in separation method, chemical instrument and method, vapor condensation, etc., can solve the problem of not being able to recover at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

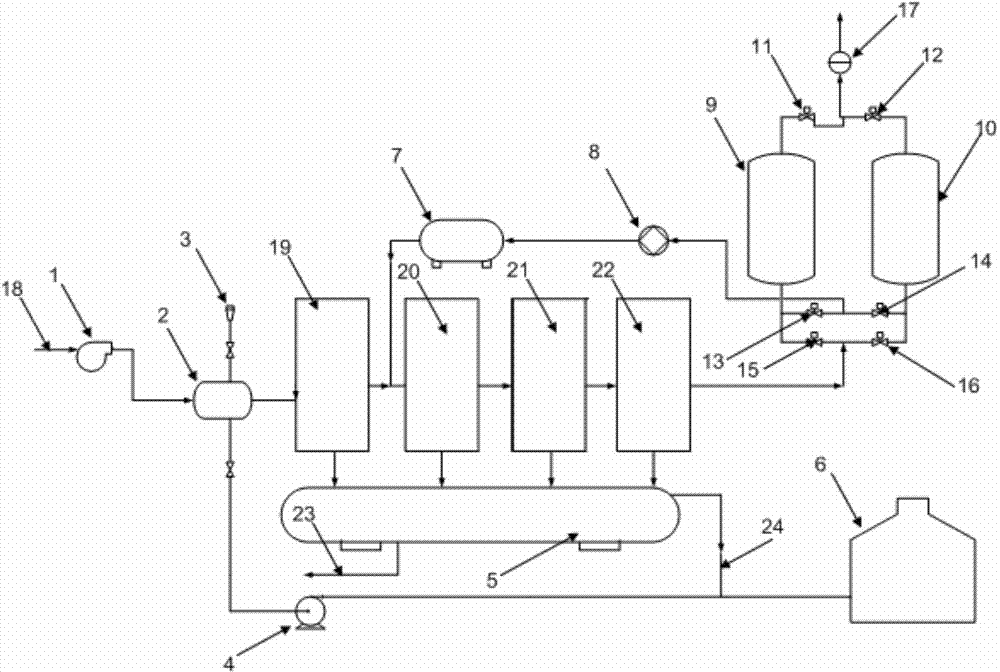

[0025] like figure 1 In the process shown, the volatilized vapors of gasoline, benzene, toluene, xylene and other organic substances are collected in the branch pipeline by fan 1 in the process of loading vehicles, shipping and respiration of storage tanks, and then enter the main pipeline for oil and gas recovery. According to the signal of the micro-pressure sensor, the fan adopts frequency conversion to control the speed, so as to protect the storage tank and tank car and balance the air pressure. The organic gas vapor collected by the fan enters the recovery device for recovery treatment, and the gas that meets the environmental protection requirements is discharged into the atmosphere after treatment.

[0026] Organic gas mass composition: 50% gasoline, 20% benzene, 20% toluene, 10% o-xylene, the steam first enters the condensate tank 2 after being collected by the fan 1, and the condensate tank 2 is located at the lowest point of the device for collecting condensation l...

Embodiment 2

[0031] According to the conditions and steps described in Example 1, the mass composition of organic gas is: gasoline 50%, benzene 20%, o-xylene 30%.

[0032]The gas passing through the condensate tank 2 enters the refrigeration unit for multi-stage continuous cooling. The organic gas first enters the pre-cooler 18 for pre-condensation. The cooling medium used in the pre-condensation is water, which is supplied by the circulating water of the factory. After pre-cooling, the temperature drops to about 8°C, and most of the benzene vapor is condensed and recovered. After that, the vapor enters the two-stage compression refrigeration system, and each stage of the refrigeration system includes equipment and components such as compressors, evaporators, condensers, and expansion valves. After the first stage of condensation, the temperature of the gas steam can be reduced to about -25°C, and the main condensed substance is o-xylene; after the second stage of condensation, the tempera...

Embodiment 3

[0034] According to the conditions and steps described in Example 1, the mass composition of the organic gas is: 50% benzene and 50% o-xylene.

[0035] The gas passing through the condensate tank 2 enters the refrigeration unit for multi-stage continuous cooling. The organic gas first enters the pre-cooler 18 for pre-condensation. The cooling medium used in the pre-condensation is water, which is supplied by the circulating water of the factory. After pre-cooling, the temperature drops to about 8°C, and most of the benzene vapor is condensed and recovered. After that, the vapor enters the first-stage compression refrigeration system, which includes equipment and components such as compressor, evaporator, condenser and expansion valve. The temperature of the gas vapor can be reduced to about -25°C after the first stage of condensation. The main condensed substance is o-xylene, and nearly 95% of the gas vapor can be condensed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com