Methanol diesel fuel

A diesel and methanol technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of difficult methanol, poor stability, and low viscosity of methanol, and achieve environmental protection of tail gas emissions, strong resistance to water phase, cetane high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

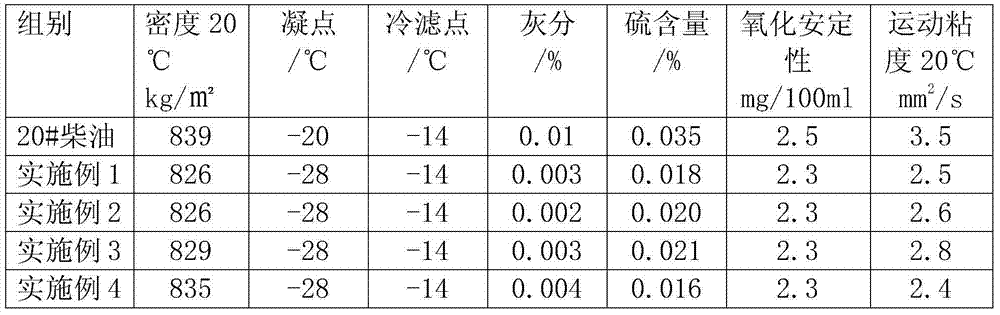

Examples

Embodiment 1

[0018] Formula: methanol 10kg, national standard diesel 40kg, diesel additive 15kg;

[0019] The formula of described diesel oil additive: diethyl phthalate 5kg, zinc peroxide 1kg, cyclopentaferrocene 0.01kg, polyoxymethylene dimethyl ether 5kg, petroleum acid 15kg, ethyl formate 3kg, isooctyl nitrate 5kg , mixed fatty acid glyceride 10kg.

[0020] The preparation method is as follows:

[0021] 1) Mixing methanol and cyclopentaferrocene, and fully dissolving it to obtain denatured methanol;

[0022] 2) mixing denatured methanol with petroleum acid to form a mixture;

[0023] 3) Diesel oil, isooctyl nitrate, ethyl formate, mixed fatty acid glycerides, diethyl phthalate, zinc peroxide and polyoxymethylene dimethyl ether are mixed uniformly to obtain the product.

Embodiment 2

[0025] Formula: methanol 30kg, national standard diesel 70kg, diesel additive 30kg;

[0026] The formula of described diesel oil additive: diethyl phthalate 10kg, zinc peroxide 5kg, cyclopentaferrocene 0.03kg, polyoxymethylene dimethyl ether 15kg, petroleum acid 35kg, ethyl formate 7kg, isooctyl nitrate 5kg ~9kg, mixed fatty acid glycerides 15~25kg.

[0027] The preparation method is the same as in Example 1.

Embodiment 3

[0029] Formula: methanol 10kg, national standard diesel 70kg, diesel additive 15kg;

[0030] The formula of described diesel oil additive: diethyl phthalate 5kg, zinc peroxide 5kg, cyclopentaferrocene 0.01kg, polyoxymethylene dimethyl ether 15kg, petroleum acid 25kg, ethyl formate 7kg, isooctyl nitrate 5kg , mixed fatty acid glyceride 25kg.

[0031] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com