Method for producing nano zinc peroxide and zinc oxide by using solar

A zinc peroxide, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone oxide, etc., can solve the cost High energy consumption, low purity and other problems, to achieve the effect of low cost, high purity and low cost of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

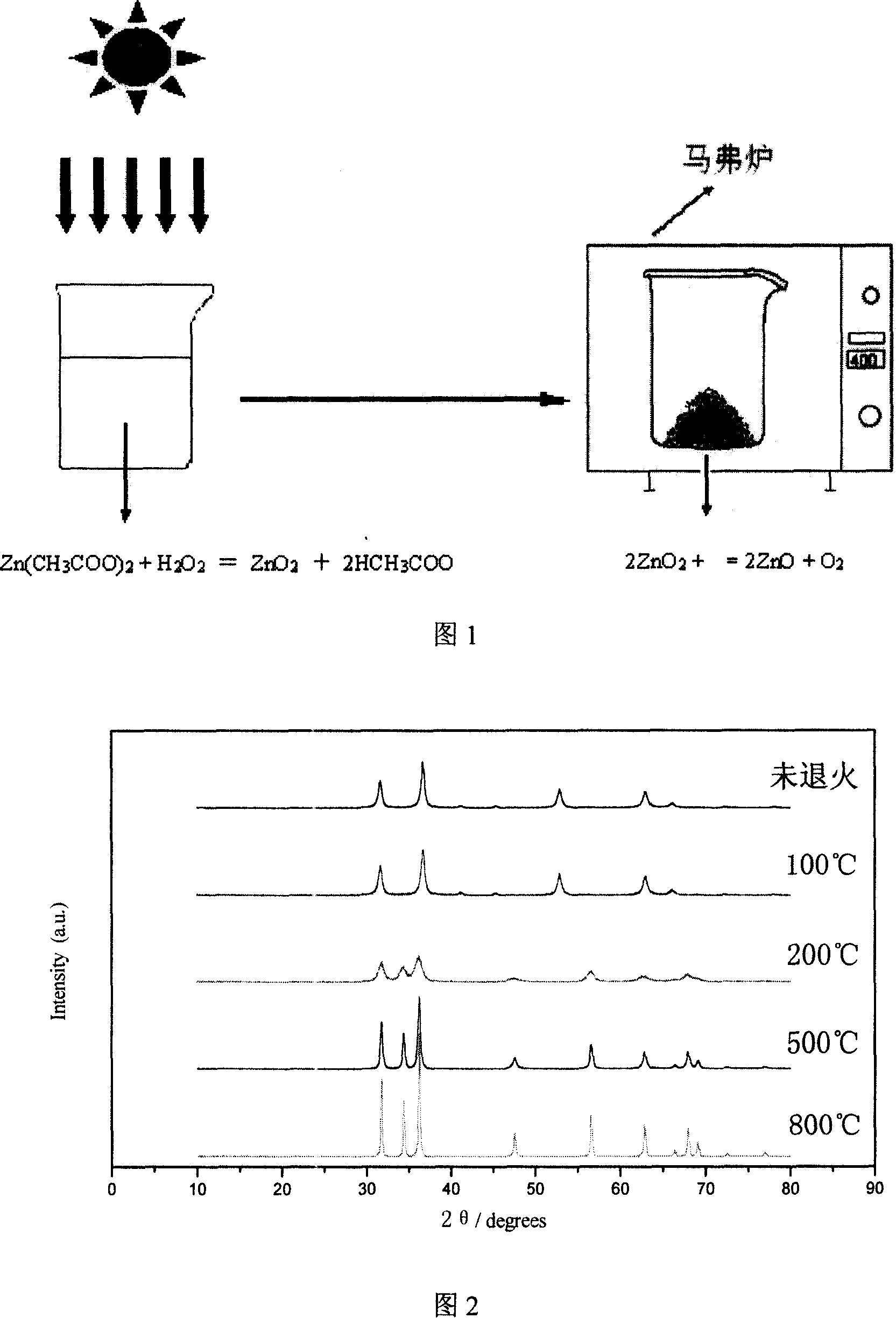

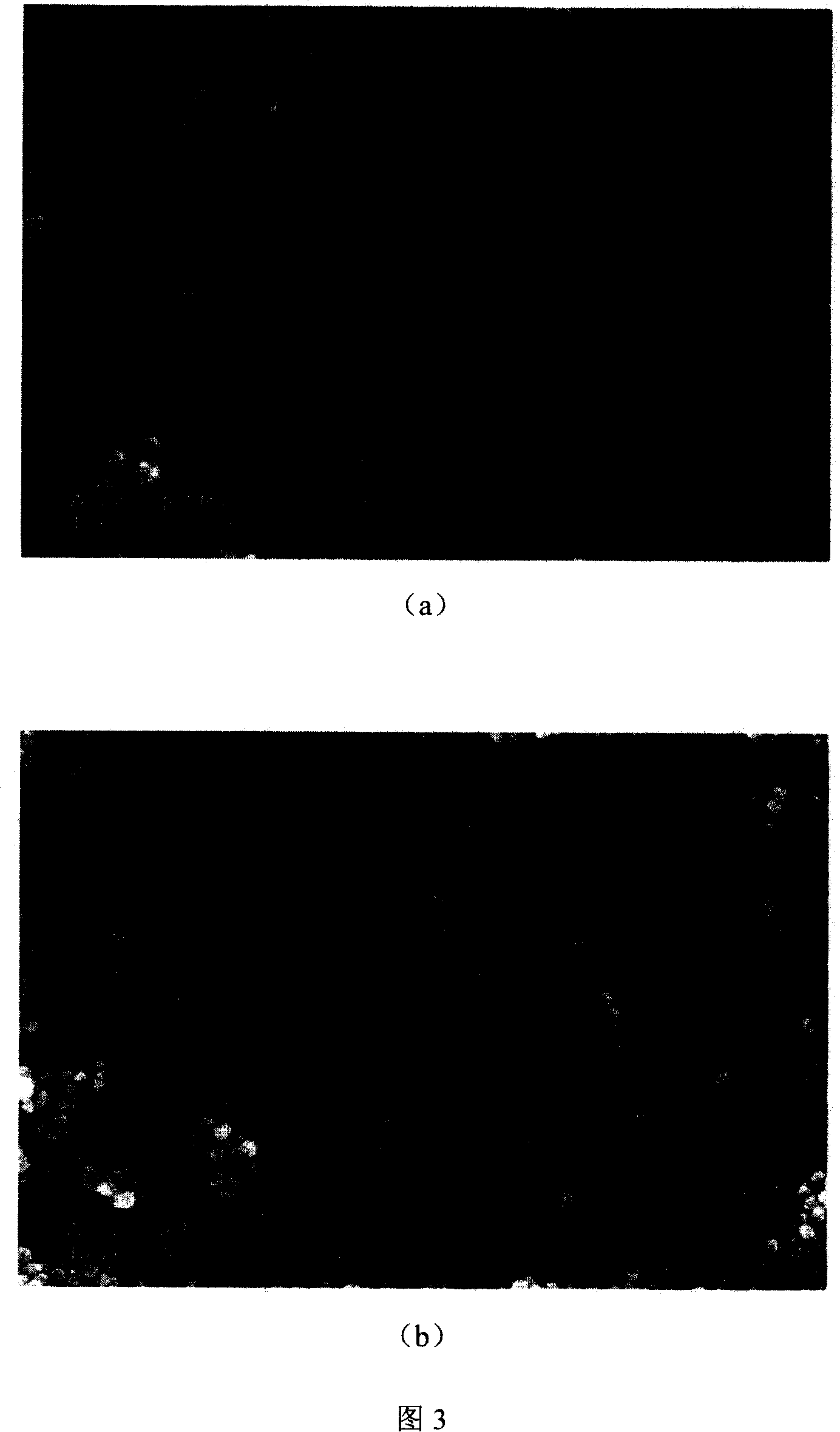

[0021] The present invention is a method for preparing nano-zinc peroxide and zinc oxide by utilizing solar photochemical reaction mode. In the preparation method, hydrogen peroxide and zinc acetate are used as raw materials, hydrogen peroxide is added into deionized water first, and the mixture is evenly stirred. Under the condition of sunlight, dissolve zinc acetate in the above solution to obtain a solution with a concentration between 0.1mol / L-0.5mol / L, and obtain a white color after reacting at room temperature (0℃-40℃) for 8h-20h Sol, drying the sol at a temperature lower than 120° C. to obtain light yellow nano-powders of different sizes, which is zinc peroxide powder. If the powder is annealed at a high temperature of 400℃-800℃, white zinc oxide powder can be obtained.

[0022] The above-mentioned reaction may be carried out in a batch or continuous state.

[0023] In the process of the preparation method, dilute hydrochloric acid, dilute sulfuric acid, dilute nitric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com