Anti-aging sunshine fabric

A sunshine fabric, anti-aging technology, applied in the direction of chemical characteristics of fibers, woven fabrics, textiles, etc., can solve the problems of cracking, yellowing, and mechanical properties of products, and achieve the effect of not aging easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

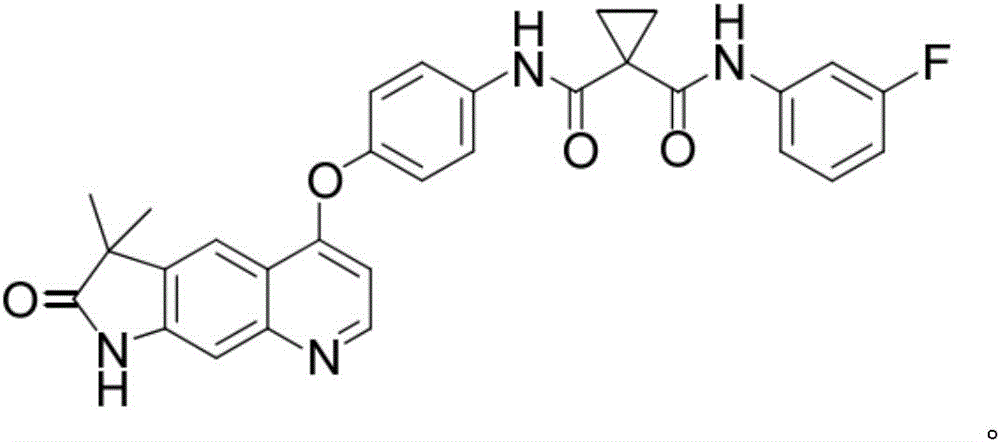

[0016] Take by weighing 120 kilograms of PVC, 5 kilograms of dioctyl phthalate, 25 kilograms of glass fibers, 15 kilograms of antiaging agent, 2 kilograms of zinc peroxide, 805 kilograms of Tween and 20 kilograms of calcium carbonate, and described antiaging agent has following structure:

[0017]

[0018] Mix it into a GB-10 high-speed mixer, heat it to a molten state and stir for 30 minutes, then spin with a spinneret with special-shaped spinneret holes, and use the spinning as warp and weft threads for weaving processing, with a warp density of 80 / cm, the weft thread density is 50 threads / cm, and the fabric 1 is obtained.

Embodiment 2

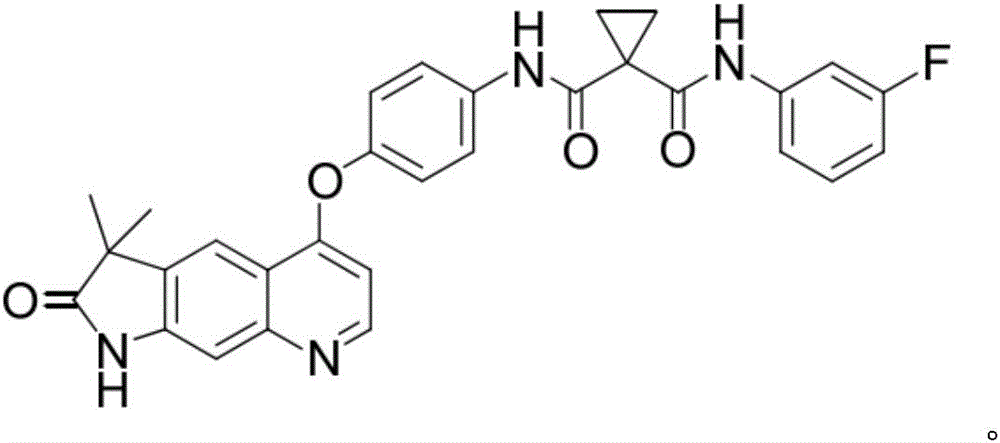

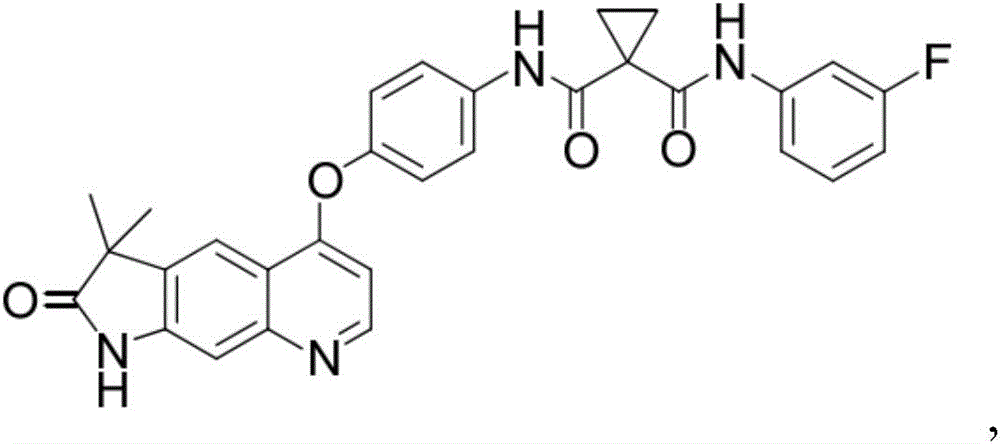

[0020] Prepare anti-aging sunshine fabric in the same manner as Example 1, except that no anti-aging agent is used, and the anti-aging agent has the following structure:

[0021]

experiment example

[0023] Test with reference to the standard of GB / T16422.2-1999, after 3000 hours of testing, the performance retention rate of the fabric in Example 1 is 80%, while the performance retention rate of the fabric in Example 2 is only 30%, which shows that the anti- After the aging agent is added, the anti-aging effect is greatly enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com