Vortex spinning rubber roll

A technology of vortex spinning and cots, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of decreased oil resistance, increased abrasion, decreased cot hardness, etc., to improve quality and prolong use. Longevity, the effect of reducing the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

[0014] In the present invention, hydrogenated nitrile rubber, carboxylated nitrile rubber and phenolic resin are ternally blended and modified, and liquid nitrile rubber is used for plasticization, so that the existing nitrile rubber formula is not wear-resistant at high temperature and has a large change in hardness. Insufficient, by using hydrogenated nitrile and carboxylated nitrile rubber as the main material, the oil resistance and wear resistance of the rubber roller are improved, and the combination of antistatic plasticizer and antistatic, liquid nitrile rubber is plasticized, and the rubber roller is improved. Antistatic performance under high speed and high temperature operation, and little change in hardness.

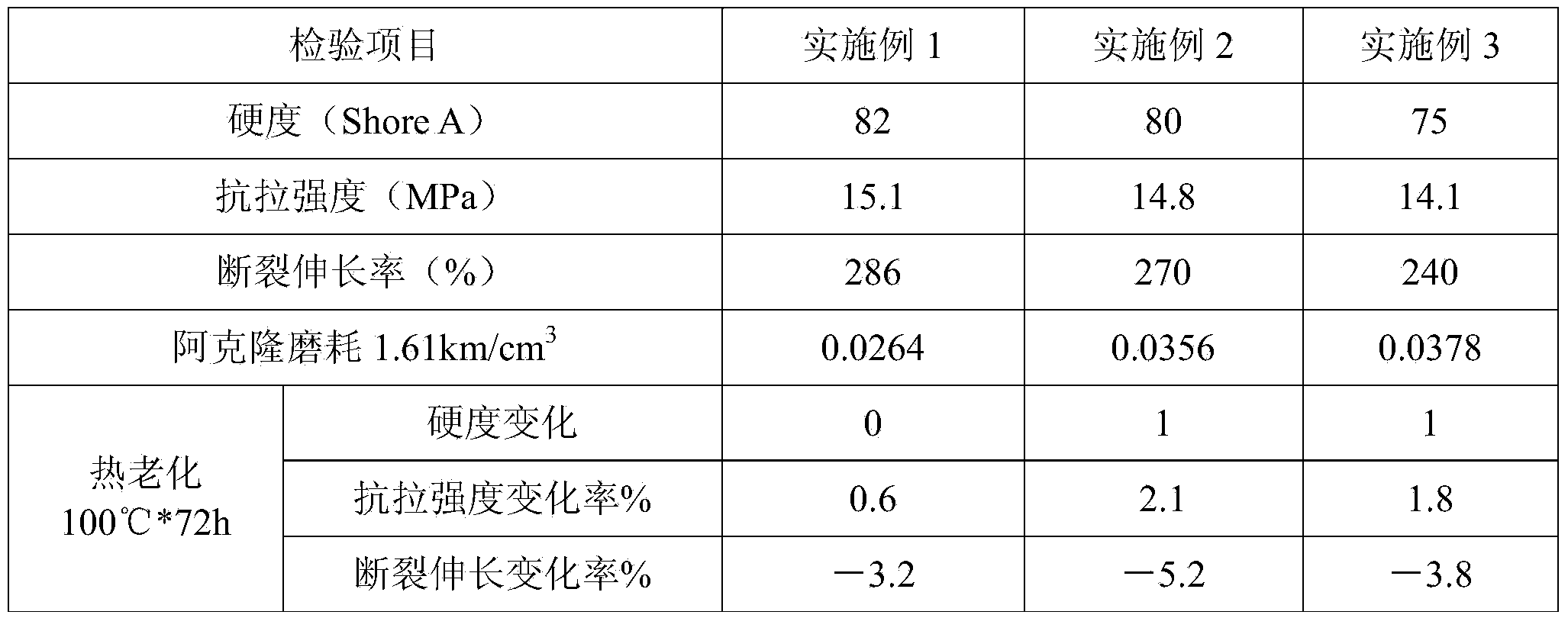

[0015] Examples 1-3 The raw materials were weighed according to the proportions by weight shown in Table 1, and then plasticized and glued with an open mill, and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com