Production formula of high-abrasion high-draft high-speed spinning rubber ring

A technology for spinning aprons and production formulas, which is applied to spinning machines, drafting equipment, rubber layered products, etc., and can solve the problems of short service life affecting spinning quality, increased deformation of aprons, and increased use wear, etc. problems, to achieve the effect of reducing labor costs, reducing maintenance cycles, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

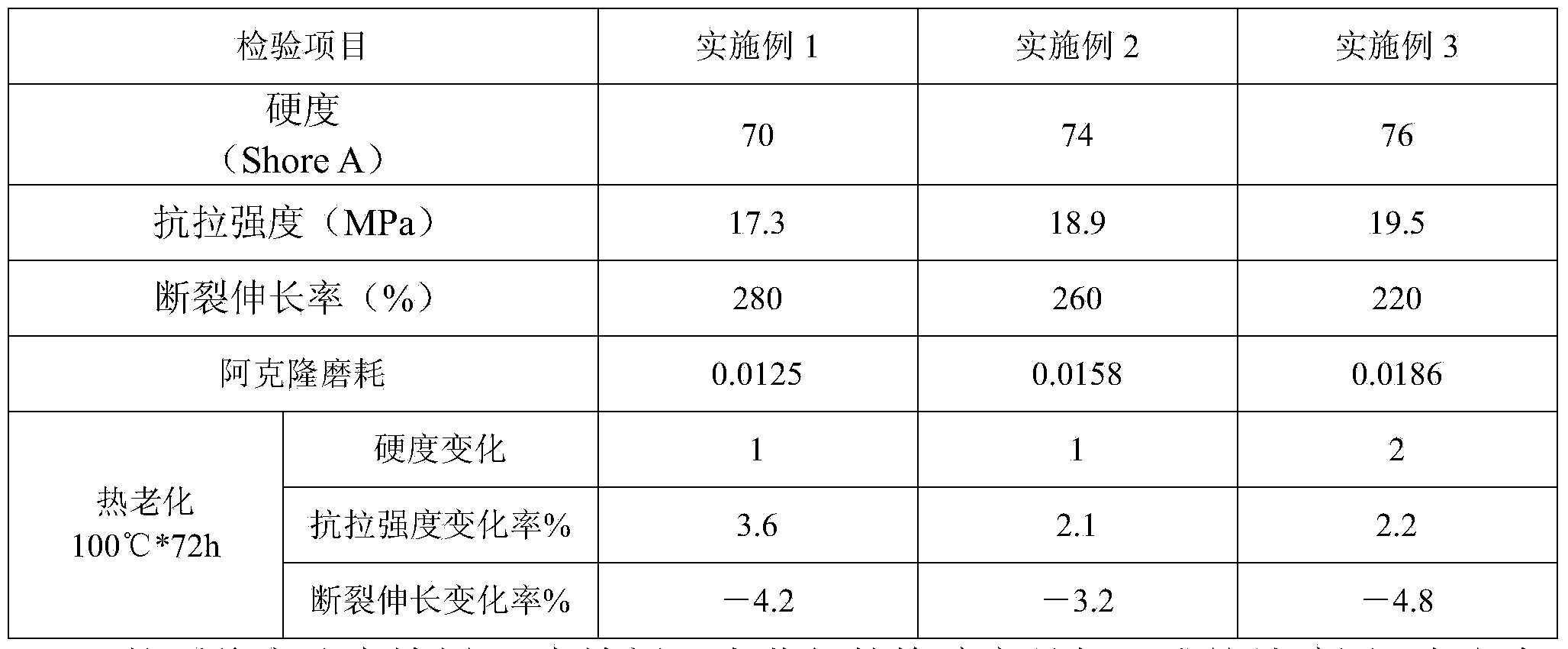

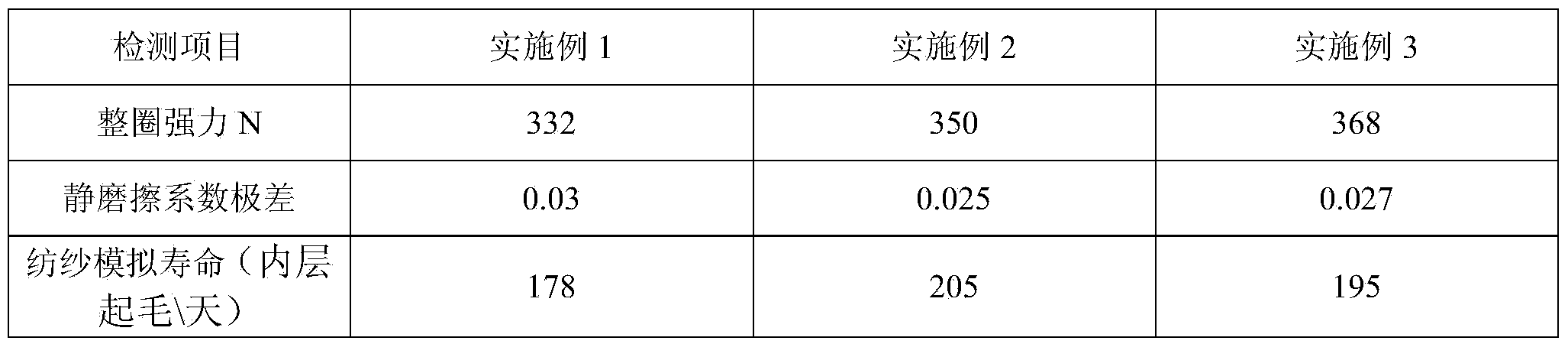

[0016] The present invention will be further described below in conjunction with specific examples.

[0017] Examples 1-3 The raw materials were weighed according to the proportions by weight shown in Table 1, and then thermally masticated and kneaded in a closed rubber mixer to produce rubber products.

[0018] Table 1:

[0019] components

Example 1

Example 2

Example 3

Carboxylated nitrile rubber

50

70

80

Nitrile rubber

50

30

20

PVC 2500

50

40

30

Ethyl acetate rubber

20

30

30

8

8

8

1.5

1.5

1.5

AcceleratorMDB

2.5

2

2

Titanium dioxide

5

5

5

Antiager for BLE

2

2

2

Reinforcing agent Phase silica

10

12

15

Epoxidized soybean oil, TP-90

15

10

10

[0020] sulfur

5

5

5

[0021] The rubber product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com