Multi-track rotor type internal combustion engine

A rotor type, internal combustion engine technology, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of internal combustion engine vibration, complex parts structure, poor intake and exhaust, etc., to improve engine speed, stable operation and small vibration , the effect of smooth intake and exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Rotor design parameters: Φ300×1×2×2×1.

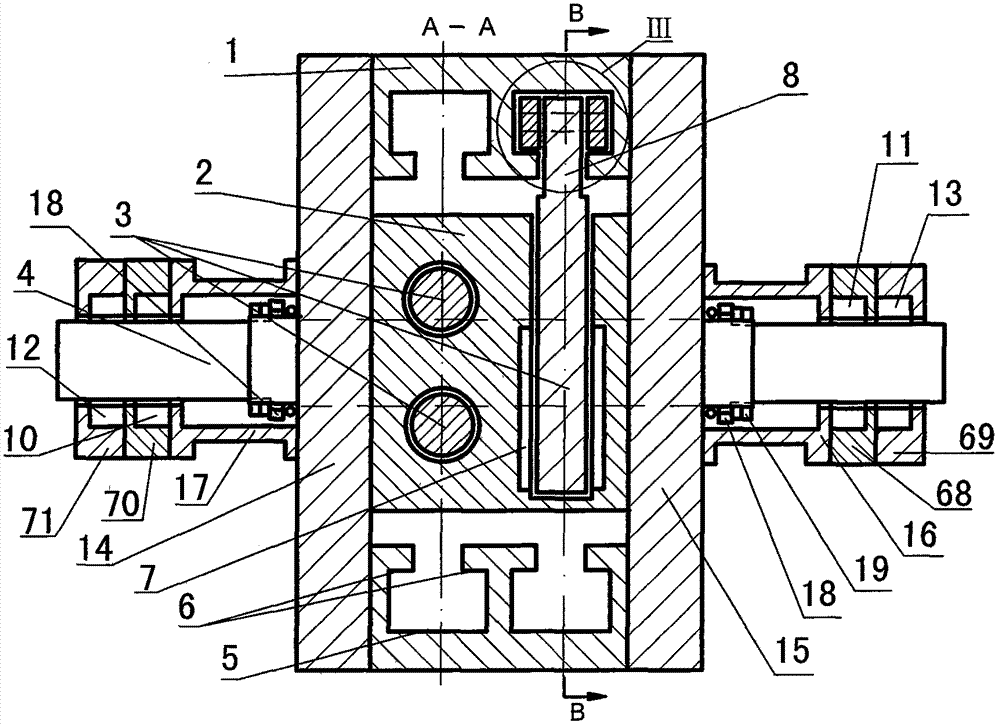

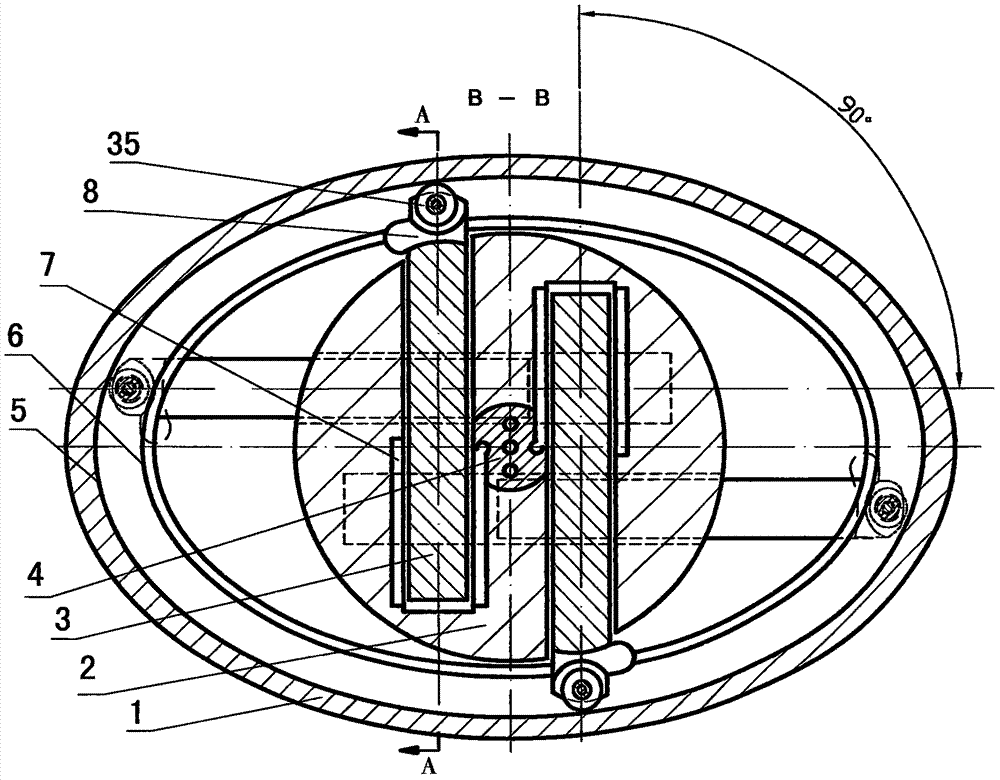

[0062] Such as figure 1 , figure 2 As shown, the multi-track rotor internal combustion engine is composed of a stator 1, a rotor 2, a main shaft 4, a pulley assembly 8, a front end cover 15, a rear end cover 14, and a plurality of front and rear auxiliary end covers.

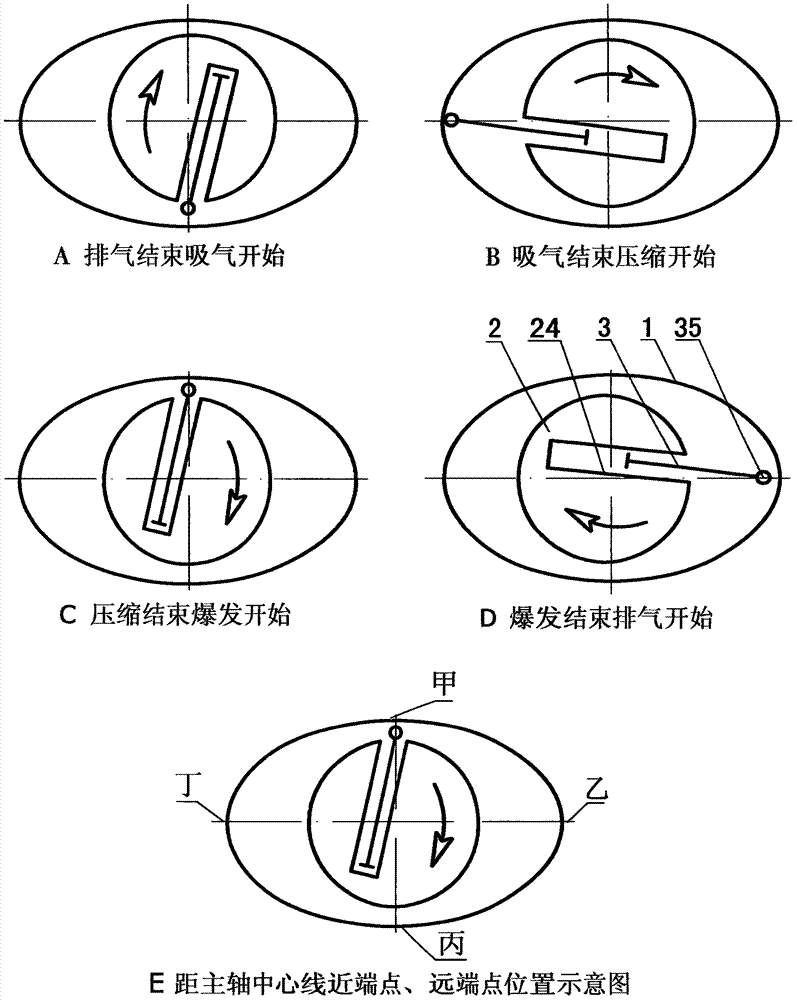

[0063] A slideway around the center of the main shaft 4 is provided on the stator 1, which is composed of an inner slide rail 6 and an outer slide rail 5. The slideway can be set as a concave shape (see figure 2 ) or convex (see Figure 17 ), the present embodiment is concave shape; the distance between the left and right sides of the slideway from the center of the main shaft 4 is greater than the distance between the upper and lower sides from the center of the main shaft 4, and the difference is the size of the piston 3 strokes. The trajectory line connecting the up, down, left, and right slides is a specific curve (see image 3 , Figure 19 , Figure 2...

Embodiment 2

[0076] Rotor design parameters: Φ520+Φ260×1×4×4+2×4+1

[0077] This embodiment is specially designed for large and luxury cars, and adopts a combination of four rows of cylinders arranged with single rotors of different diameters. like Figure 23 , Figure 24 As shown: the main cylinder 66 is installed on the rotor with a large diameter of Φ520 mm 64, and there are 2 rows of 4 cylinders in each row; the auxiliary cylinder 67 is installed on the rotor with a small diameter of Φ260 mm 65, and there are 1 row at the front and rear ends, with 2 cylinders in each row Cylinder; the diameter of the piston in the main cylinder 66 is Φ62 mm, the piston stroke is 100 mm, and the full stroke of each cylinder is 4; the piston diameter in the auxiliary cylinder 67 is Φ50 mm, the piston stroke is 100 mm, and the full stroke of each cylinder for 1 pc. When the multi-track rotor internal combustion engine is running, 2 auxiliary cylinders 67 are used as idle cylinders and 8 main cylinders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com