High efficiency energy-conserving environmental protecting power generating system

A power generation system, high-efficiency and energy-saving technology, applied in the direction of steam generation, feed water heater, preheating, etc., can solve the problems of polluting the environment, underutilized waste heat, affecting people's health, etc., and achieve the effect of clean emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

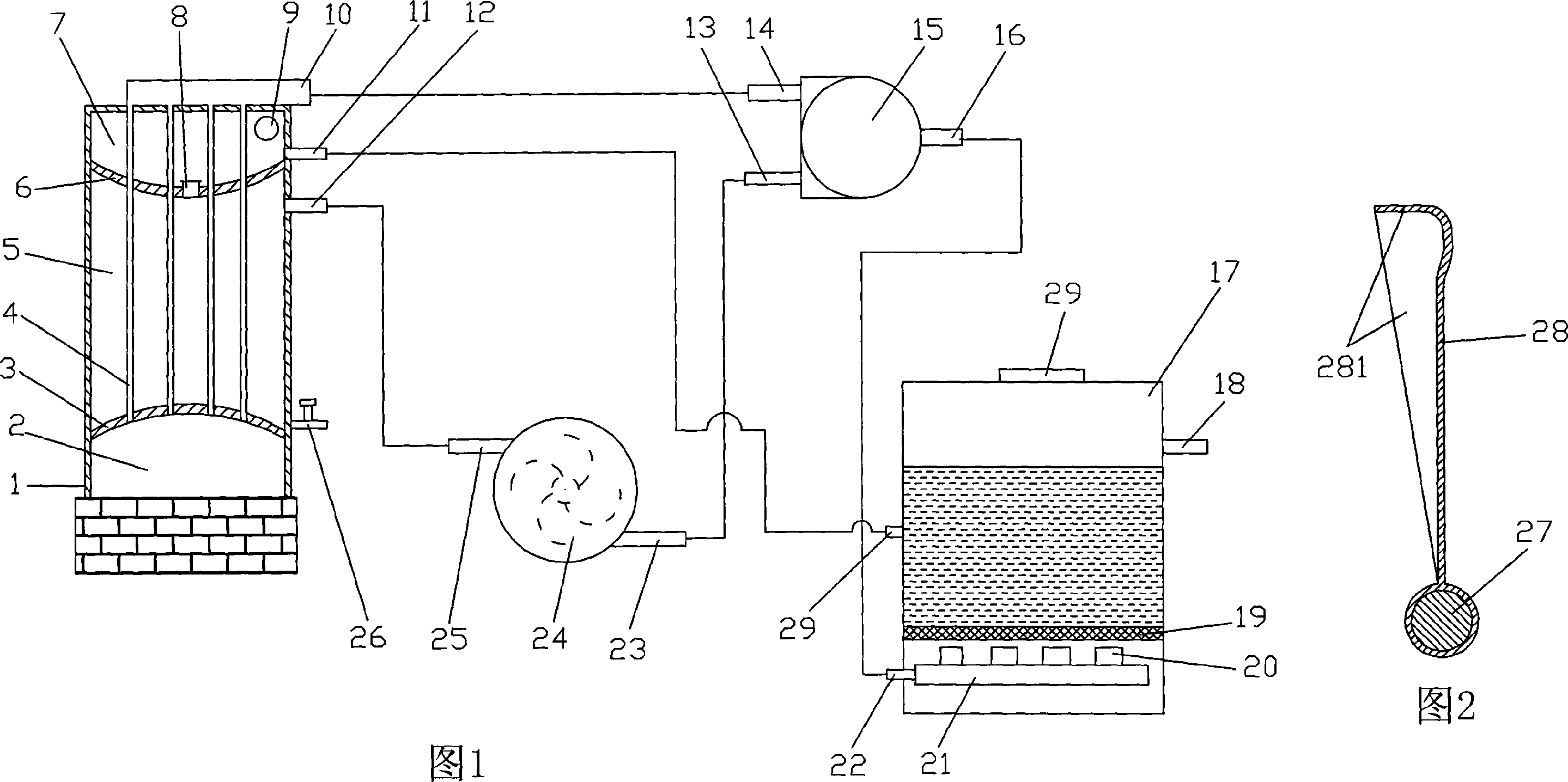

[0014] As shown in Figure 1, the high-efficiency, energy-saving and environment-friendly power generation system of the present invention includes a boiler 1, a turbo-generator 24, an exhaust fan 15 and a hot water tank 17; the bottom wall 3 of the heat exchange tank 5 above the boiler furnace 2 is an upward arch The top wall 6 of the heat exchange tank 5 is a concave arc surface, the side wall of the boiler is provided with a drain valve 26 for the water exchange tank, and the heat exchange pipe 4 in the boiler that communicates with the furnace passes through the heat exchange tank The top wall 6 is connected to the boiler smoke exhaust pipe 10. The top wall 6 of the heat exchange tank and the surrounding boiler shell form a boiler replenishment pre-storage water tank 7. The water ports 29 are connected to each other, and a pre-stored water level cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com