Air inlet guide structure for air inlet channels located on bottom face of cylinder cover

A technology of guiding structure and intake port, applied in the direction of cylinder head, cylinder, combustion engine, etc., can solve the problems of difficult gas flow state and difficult gas flow to form large eddy currents, and achieve simple structure, accelerated flame propagation speed, and exhaust gas. Emission cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

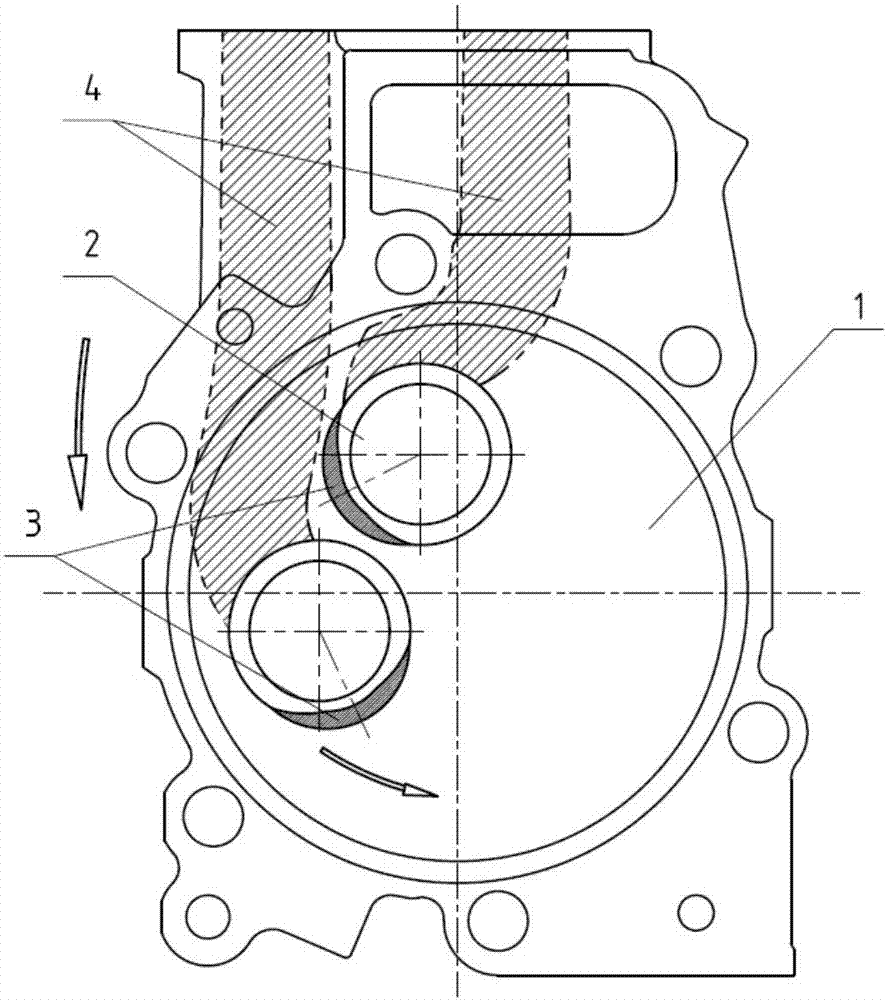

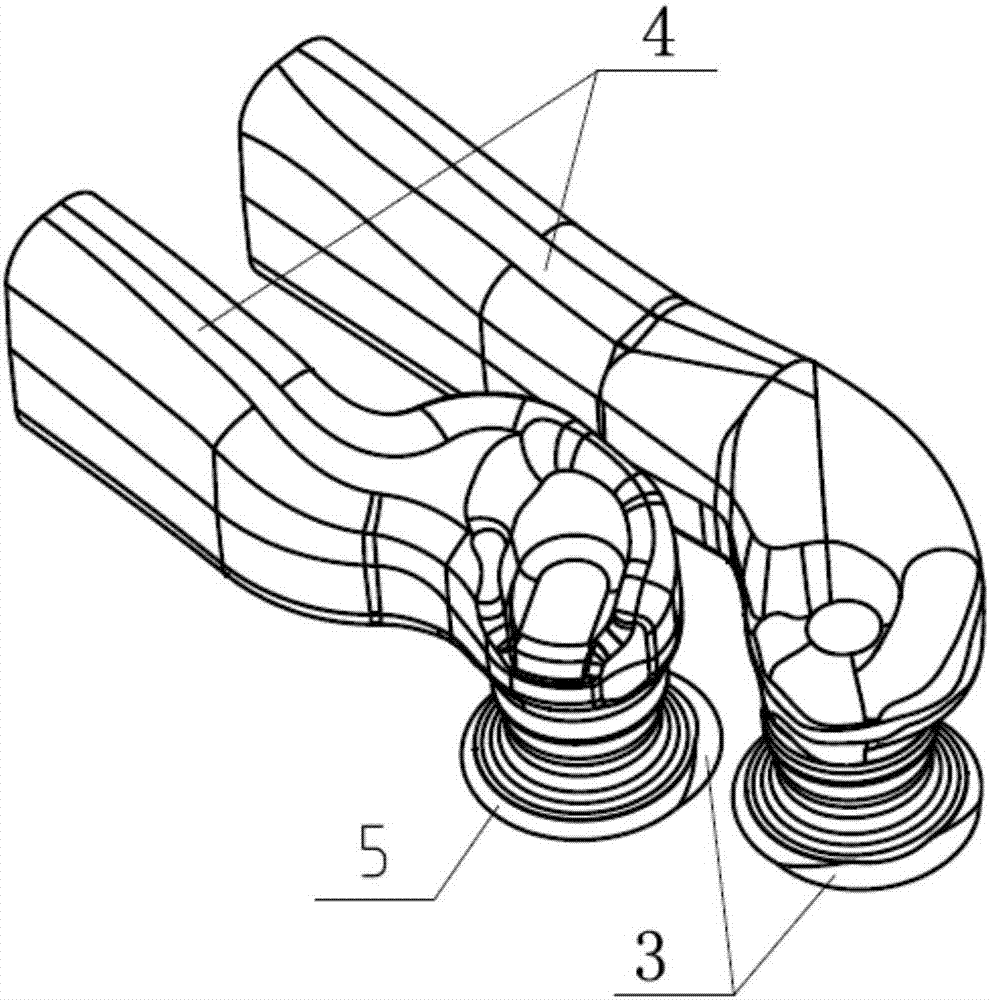

[0013] figure 1 , 2 Among them, including cylinder head 1, intake valve 2, guide groove 3, intake port 4, arc chamfer 5, etc.

[0014] Such as figure 1 , 2 As shown, the present invention is an air intake guide structure with an intake port on the bottom surface of the cylinder head, including a cylinder head 1, the bottom surface of the cylinder head 1 is connected to the intake port 4, and the bottom surface of the cylinder head 1 corresponds to the entrance of the intake port 4 The position is provided with a guide groove 3, and the direction of the guide groove 3 is consistent with the direction of the spiral vortex of the air inlet 4.

[0015] The guide groove 3 is crescent-shaped, and the depth of the middle part of the guide groove 3 gradually decreases toward both sides.

[0016] The junction of the intake passage 4 and the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com