Environment-friendly fuel oil and preparation method thereof

A fuel oil and environmental protection technology, applied in the field of environmental protection fuel oil and its preparation, can solve the problems of low flash point, high viscosity, limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

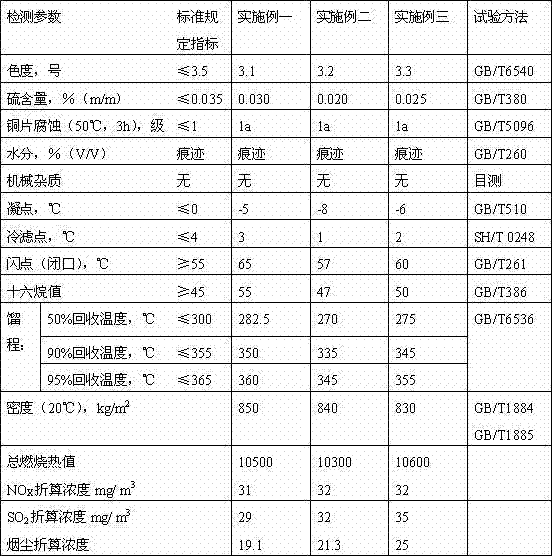

Examples

Embodiment 1

[0021] A kind of environment-friendly fuel oil, its component and the mass parts of each component are as follows:

[0022] Coal oil: 40 parts;

[0023] Vegetable oil: 40 parts;

[0024] Vegetable oleic acid or ethanolamine: 5 parts;

[0025] Methanol: 15 parts.

[0026] The steps of the preparation method of this environment-friendly fuel oil are as follows:

[0027] (1) First put the coal-based oil and vegetable oil together and stir evenly;

[0028] (2) Then add methanol and vegetable oleic acid or methanol and ethanolamine at the same time and stir for a period of time to make environmentally friendly fuel oil products.

Embodiment 2

[0030] A kind of environment-friendly fuel oil, its component and the mass parts of each component are as follows:

[0031] Coal oil: 10 parts;

[0032] Vegetable oil: 20 parts; vegetable oil can adopt waste palm oil.

[0033] Vegetable oleic acid or ethanol: 3 parts;

[0034] Methanol: 10 parts;

[0035] The steps of the preparation method of this environment-friendly fuel oil are as follows:

[0036] (1) First put the coal-based oil and vegetable oil together and stir evenly;

[0037] (2) Then add methanol and vegetable oleic acid or methanol and ethanolamine at the same time and stir for a period of time to make environmentally friendly fuel oil products.

Embodiment 3

[0039] A kind of environment-friendly fuel oil, its component and the mass parts of each component are as follows:

[0040] Coal oil: 30 parts;

[0041] Vegetable oil: 30 parts; vegetable oil can adopt waste palm oil.

[0042] Vegetable oleic acid or ethanolamine: 4 parts;

[0043] Methanol: 25 parts;

[0044] The steps of the preparation method of this environment-friendly fuel oil are as follows:

[0045] (1) First put the coal-based oil and vegetable oil together and stir evenly;

[0046] (2) Then add methanol and vegetable oleic acid or methanol and ethanolamine at the same time and stir for a period of time to make environmentally friendly fuel oil products.

[0047] Coal to oil: The indirect coal liquefaction process is to gasify the raw coal first, and then perform purification treatment to obtain the raw material gas of carbon monoxide and hydrogen. Then synthesize relevant oil products or chemical products at about 270°C ~ 350°C, 2.5MPa and the action of a cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com