High-cleaning composite gasoline and preparation method thereof

A clean and gasoline technology, applied in the field of high-clean composite gasoline and its preparation, can solve problems affecting the stability of composite gasoline, composite gasoline stratification, air resistance, etc., achieve rich sources of raw materials, clean exhaust emissions, and solve insufficient supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

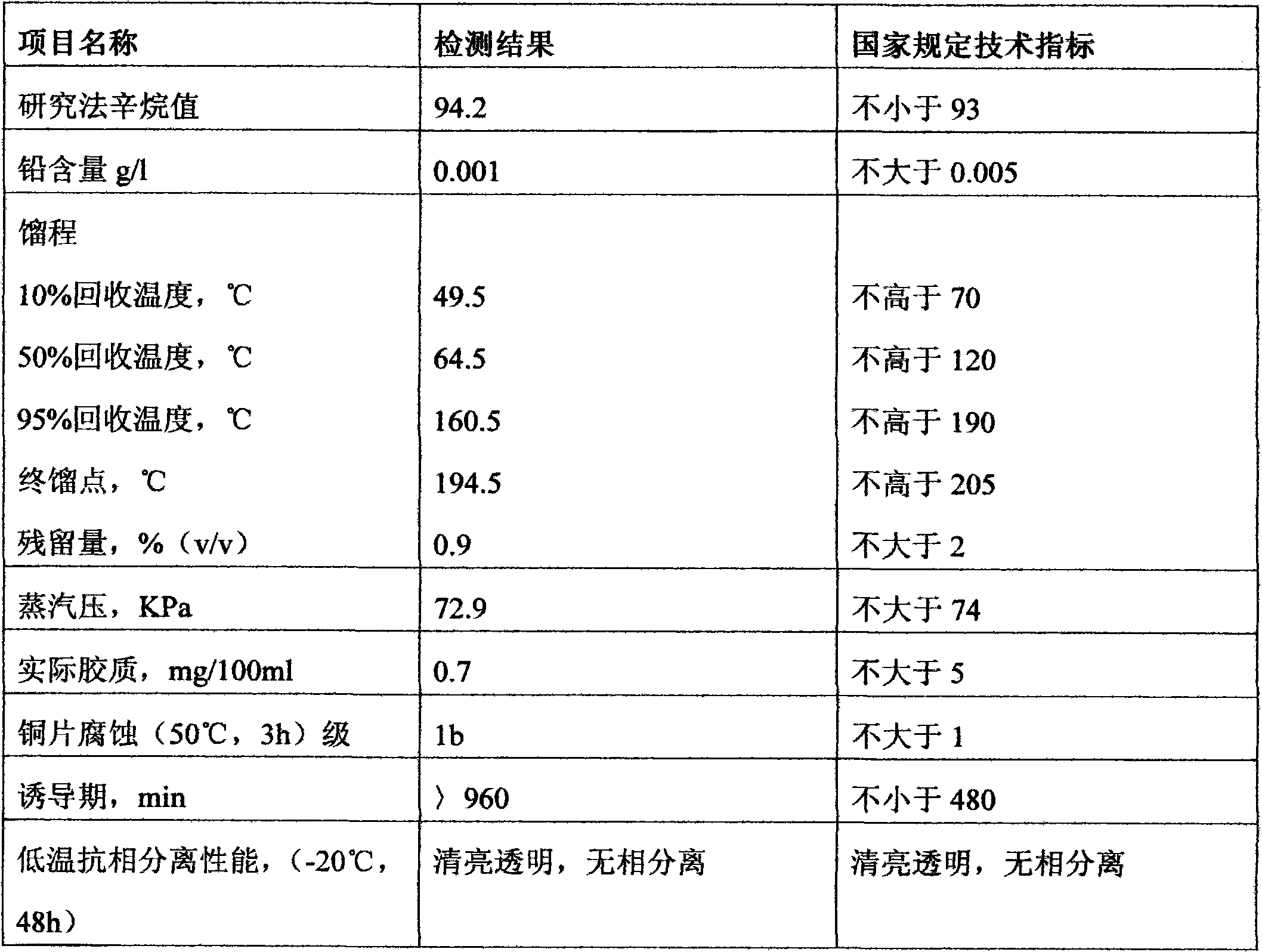

Examples

Embodiment 1

[0021] Tridecanol 10%, sodium cetyl sulfonate 10%, calcium cetyl sulfonate 20%, naphthenic acid 50%, tert-butanol 2.5%, isobutanol 2.5% and isopropanol 5 % is prepared by weight ratio, fully mixed to obtain additives;

[0022] Then 10KG of methanol and 1KG of additives are mixed to obtain denatured methanol;

[0023] Finally, mix 10KG of naphtha, 79KG of solvent gasoline and 11KG of denatured methanol, stir well, let stand for 30 minutes and pack them into tanks.

Embodiment 2

[0025] Tridecanol 10%, sodium cetyl sulfonate 10%, calcium cetyl sulfonate 20%, naphthenic acid 50%, tert-butanol 2.5%, isobutanol 2.5% and isopropanol 5 % is prepared by weight ratio, fully mixed to obtain additives;

[0026] Then 20KG of methanol and 2KG of additives are mixed to obtain denatured methanol;

[0027] Finally, mix 20KG of naphtha, 58KG of solvent gasoline and 22KG of denatured methanol, stir well, let stand for 30 minutes and pack them into tanks.

[0028] During the whole production process, it is necessary to ventilate and avoid the sun, and fireworks are strictly prohibited.

[0029] According to the production process, high-clean composite gasoline is obtained, which is suitable for industrial and civil use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com